Effects of Different Bagging Treatments on Fruit Quality of Jinlan Pomelo

TANG Yu-qin, YAN Cheng-pu, WANG Yu-ting, HU Zhong-dong, ZHU Fang-hong

Horticultural Research Institute, Jiangxi Academy of Agricultural Sciences, Nanchang 330200, PRC

Abstract In order to improve the exterior and interior quality of Jinlan pomelo,the suitable paper bag for Jinlan pomelo were screened through different bagging treatments involving single layer yellow paper bag, double layer yellow paper bag,three layer yellow paper bag, single layer red paper bag, double layer red paper bag,three layer red paper bag and no bagging. The results showed that bagging could increase fruit weight and fruit brightness, promote the coloring of fruit and improve fruit appearance quality. The titratable acid content of fruit decreased and the sugaracid ratio and soluble solid-acid ratio of fruit increased after the treatment of yellow paper bags. Double layer yellow paper bag could significantly increase the VC content, which had better effect on improving the exterior quality and interior quality than other treatments. This study provided reference for selecting the paper bag type for Jinlan pomelo.

Key words Jinlan Pomelo; Bagging; Exterior quality; Interior quality

1. Introduction

As one of the three dominant varieties of "Jinggang honey pomelo"[1],Citrus maxima(Burm.) Merr. cv. Jinlan has crisp flesh, sweet and little acid taste, high yield and good storage stability as well as very high economic benefits, which is widely planted in Anfu County, Jiangxi Province[2]. Bagging can effectively reduce fruit surface scars, disease spots, pesticide application, decrease pesticide residues, boost fruit surface smoothness, improve fruit appearance quality, increase fruit commodity rate[3-6]. It also can affect the interior quality of fruit and different material has different bagging effect[5-10]. In Anfu County, the situation of bagging for Jinlan pomelo is disordered, resulting in great differences in quality of Jinlan pomelo, low fruit commodity rate and high quality development of the industry being seriously restricted. At present, there is no research on bagging for Jinlan pomelo. In this study, the effects of different bagging treatment on the exterior and interior quality of Jinlan pomelo were studied to screen out suitable paper bag for Jinlan pomelo, so as to provide reference for the actual production of Jinlan pomelo.

2. Materials and Methods

2.1. Experimental materials

Experimental site was located in Henglong Town, Anfu County, Jiangxi Province (27°367'N,114°542'E). Orchard was flat, red loam, plant spacing was 4 m×5 m and the whole garden management level was consistent. 20 grafted Jinlan pomelo seedling with good tree vigor, consistent fruit quantity and healthy growth were randomly selected as experimental materials. The tested paper bags were all 30 cm×35 cm knife handle bags with air holes underneath,which were produced by Fujian Zhangzhou Shuangyi Bagging Factory and purchased from JD.COM.

2.2. Experimental methods

In the experiment, 7 bagging treatments including no bagging (CK), single layer yellow paper bag (T1), double layer yellow paper bag (T2), three layer yellow paper bag (T3), single layer red paper bag (T4), double layer red paper bag (T5), three layer red paper bag (T6) were designed. 10 Jinlan pomelo in each treatment were taken for experiment and each treatment had three replicates. Bagging was conducted on July 6th, 2021, and harvested on October 23rd,2021. Before bagging, pesticide was applied once in the whole orchard to thoroughly prevent and control various diseases and insect pests.

TASI-TA8121 illuminometer was used to measure the light intensity on September 15th, 2021(sunny, 21~33℃) at 8:00, 10:00, 12:00, 14:00, 16:00 and 18:00 respectively. Vernier caliper was used to measure fruit transverse diameter, vertical diameter and pericarp thickness; electronic balance was used to measure fruit weight; PAL-BX/ACID 1 integrated machine was used to determine soluble solids content; anthrone colorimetry was used to determine soluble sugar content; acid-base titration was used to determine titratable acid content; 2, 6-dichlorophenol method was used to determine VC content; Konica Minolta CR-400 handheld chromaticity tester was used to determine the values of L*, a*and b*of peel and pulp; finally, CCI = 1000×a*/(L*×b*) was used for comprehensive evaluation of fruit color.

2.3. Statistical analysis

Excel was used for data processing and SPSS was used for Duncan multiple comparison.

3. Results and Analysis

3.1. Effects of different bagging treatments on light intensity in bag

As shown in Fig. 1, with the passage of time,the light intensity increased first and then decreased.To be specific, it increased slowly from 8:00 to 12:00,and decreased slowly from 12:00 to 18:00, with the same change trend among all treatments. There were significant differences in light intensity among different bagging treatments. Among them, T1 had the highest light intensity, followed by T4, and T2, T3, T5 and T6 had low light intensity, however, there were no significant differences among these four treatments,all within 10 lux.

Fig. 1 Effects of different bagging treatments on light intensity in bag

3.2. Effects of different bagging treatments on appearance quality of Jinlan pomelo fruit

Fig. 2 Effects of different bagging treatments on peel color of Jinlan pomelo

As shown in Fig. 2, the peel colors in the T2, T3,T5 and T6 were golden yellow and evenly colored;that in the T4 was bright yellow, not golden but evenly colored; in the T1 and CK were yellow green. Sample in the T1 colored better than that in the CK. In terms of appearance color, the bagging effect was in the order: T3≥T6≥T2=T5>T4>T1>CK

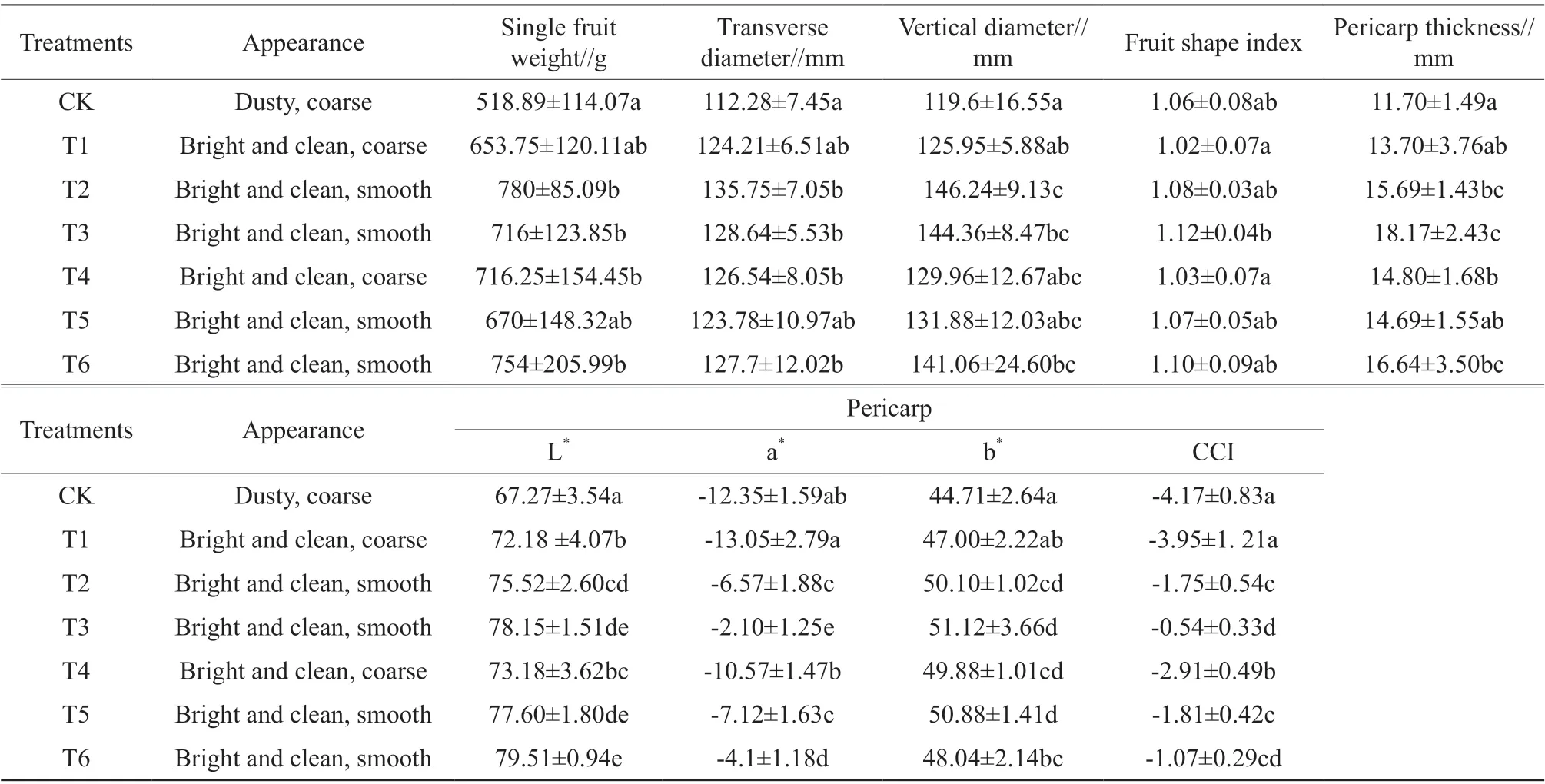

Different bagging treatments had different effects on the appearance quality of Jinlan pomelo fruit (Table 1). Bagging could increase fruit weight,the heaviest fruit was produced by using T2, followed by T3, T4 and T6, the lightest fruit was produced by no bagging. After bagging, the fruit transverse and vertical diameter increased, whereas fruit shape index had little change. Bagging could also significantly increase pericarp thickness, the thicker the paper bag,the thicker the pericarp. Compared with red paper bag, yellow paper bag had better effects on pericarp thickness.

Table 1 Effects of different bagging treatments on appearance quality of Jinlan pomelo fruit

Bagging could significantly improve the peel brightness value (L*), the thicker the paper bag, the higher the L*value. Moreover, red paper bag had better effects on peel brightness value compared to yellow paper bag. a*value (red saturability) can reflect the difference between red and green of fruit,the greater the negative value, the greener the fruit,conversely, the greater the positive value, the redder the fruit. In this study, CK and T1 gave the lowest a*value, which increased with the increase of paper bag thickness. b*value (yellow saturability) can reflect the difference between yellow and blue, the greater the negative value, the bluer it is; on the contrary, the greater the positive value, the yellower it is. After bagging, the b*value was higher than that of CK,yellow paper bag and red paper bag had the similar effects on b*value. CCI is a comprehensive index for color evaluation. Positive value is red, negative value is blue-green, and 0 is a mixture of red, yellow and blue-green. The results showed that CCI values of different treatments were different, among which,samples in T3 and T6 had the better peel color, T2, T4 and T5 had the same effect on peel color, and T1 had the worst effect.

3.3. Effects of different bagging treatments on inner quality of Jinlan pomelo fruit

Compared with peel, bagging had less effects on the color difference of pulp. Except for T1, the a*value in the other treatments was higher than that in the CK. After bagging, the CCI value of pulp was high compared to no bagging (Table 2). In this study,bagging had little effects on soluble solids content and soluble sugar content, but it had significant effects on titratable acid content of fruit. Yellow paper bag could reduce titratable acid content of fruit, which in the T1 was the lowest, only 0.27 mg/g, far lower than that in the other treatments. While, red paper bag could significantly increase titratable acid content of fruit,which in the T5 was the highest, up to 0.47 mg/g.Total solube solid to total acid (TSS/TA ratio) and sugar acid ratio can be used to evaluate fruit flavor comprehensively. The TSS/TA ratio and sugar acid ratio of fruit in the T1 was much higher than that in the other treatments. Nonetheless, the TSS/TA ratio and sugar acid ratio of fruit bagged with red paper bag was low, even lower than those with no bagging. The thickness of yellow paper bag had a great effect on VC content in fruit. The VC content in the T1 was only 41.13 mg/g, while that in the T2 reached 48.18 mg/g.Red paper bag and no bagging had a similar effect on VC content in Jinlan pomelo.

Table 2 Effects of different bagging treatments on inner quality of Jinlan pomelo fruit

4. Conclusion and Discussion

Light is an essential part of plant growth and development, directly or indirectly involved in plant life activities[11]. After bagging, the light reduced,prochlorophyll-ester could not be converted into chlorophyll-ester, resulting in chlorophyll degradation,so as to increase the proportion of carotenoids,accelerate the peel to show the ripe color[12-13]. In this study, bagging could significantly improve the peel brightness, increase the saturation of red and yellow,increase the color difference value of peel, making peel more yellow. Some studies showed that bagging did not affect single fruit weight and transverse and vertical diameter of fruit[6,14], but other studies showed that fruit single weight after bagging was larger than that with no bagging[15-16]. In this study, the results showed that bagging could significantly increase single fruit weight, and transverse and vertical diameter of fruit, which was consistent with the latter.Previous studies showed that bagging could reduce pericarp thickness[6,9]. However, this study showed that bagging could increase pericarp thickness, which was correlated with paper bag thickness. The results of this study were consistent with those of WANG L Xet al.[16], which may be related to variety. Double layer yellow paper bag, three layer yellow paper bag and three layer red paper bag could obviously increase fruit weight and promote fruit surface colouring, and had better appearance quality.

Changes in light quality and intensity under bagging microenvironment affect the accumulation of fruit nutrients[17-18]. Generally speaking, bagging will reduce light intensity, thus decreasing the accumulation and transportation of assimilation substances, and reducing soluble solid content,VC and titratable acid content of fruits. The results showed that bagging had no significant influence on soluble solid content and total sugar content, which was consistent with the research results of SU M Let al.[10]. Yellow paper bag can reduce the titratable acid content, while the red paper bag can increase the titratable acid content, which may be related to different paper bags passing through different light quality. Red paper bags had no significant effect on VC content, whereas double yellow paper bags could significantly increase VC content in fruits. This study showed that bagging could improve fruit appearance and inner quality. Considering fruit quality and paper bag cost, double yellow paper bag was highly recommended for Jinlan pomelo.

Agricultural Science & Technology2022年1期

Agricultural Science & Technology2022年1期

- Agricultural Science & Technology的其它文章

- Effects of Different Intercropping Patterns on Population Yield and Benefit of Fresh Maize and Mung Bean

- Analysis on Interaction Effects Between Variety and Site of Silage Maize Regional Test in Guizhou Province

- Mechanism of Solid State Fermentation in Reducing Free Gossypol in Cottonseed Meal and the Effects on the Growth of Broiler Chickens

- Control Effects of Mixture of Metamifop and Cyhalofopbutyl on Annual Weeds Barnyard Grass in Directseeding Paddy Field

- Study on Weed Control and Safety of Tembotrione-Atrazine Tank Mixture in Spring Maize Fields

- TIB for Micropropagation and the Relationship between Anthocyanins and Chlorophyll of Strawberry Seedlings