Optimal design of garlic clove’s orientation adjustment system based on parallel robot

ZHU Zhengbo,CAO Xin,ZHANG Ruihong

(School of Mechanical Engineering/Jiangsu Engineering Center for Modern Agricultural Machinery and Agronomy Technology, Yangzhou University, Yangzhou 225127, China)

Abstract: The upward seeding of garlic cloves has the characteristics of emergence early and strong,which is the common planting agronomy of garlic in China.Based on the parallel robot,a control system of garlic clove’s orientation was designed to improve the upward seeding rate,and to promote the garlic planting mechanization in China.This system mainly included four modules:image acquisition,image preprocessing,garlic clove feature extraction and instruction drive.First,when the garlic cloves were transported to the established position,the visual system received the photo trigger signal emitted by the parallel robot and collected the image immediately.Second,the ideal binary image was obtained by median filtering,binarization,and morphological processing of the image to fill holes and filter out background particles,and the area of the connected domain of the binary image was screened according to the size range of garlic species to obtain the garlic binary image of the right size.Third,the center contour of the image and the curvature of the contour were extracted and calculated,and the part with the maximum curvature was regarded as the bud of the garlic clove and this part was used as the clove orientation,while this orientation would be quantified as the angle value and sent to the robot.Finally,according to the position information,velocity vector information and orientation information of the garlic cloves,the parallel robot controlled the grasper to grasp the garlic clove,and the garlic clove was adjusted to a unified direction and put into the established position,so as to adjust the orientation of the garlic clove.The key parameters of the adjusting system were tested and the multiple regression model of the adjusted success rate was established.The results indicated that:(1)the indicators of adjusted success rate were impacted by weight of garlic clove,conveying speed and grasping period significantly.(2)the order of priority of influencing factors is grasping time,weight of garlic cloves,and conveying speed.(3)the combination of the weight of garlic seed(4.54 g),the conveying speed(0.1 m/s),and the grasping time(2.445 s)led to a relatively high adjusted success rate(97.41%).This study provided a technological guidance for the application of the intelligent garlic clove’s orientation control system,which will be helpful for solving the problem of using an embedded industrial computer to adjust garlic clove’s orientation,and promoting the garlic planting mechanization in China.

Keywords: parallel robot;upward seeding;control system;orientation adjustment;visual system

0 Introduction

China is the world’s largest garlic producer,consumer and exporter.The cultivated area of China is about 50% of the world’s total,and its annual output and exports are about 80% of the world’s total[1-3].However,the mechanized seeding rate of garlic in China is less than 5%,and artificial cultivation is the main method at present,which leads to high labor intensity and low operation efficiency.Therefore,it is of great practical significance to realize mechanized planting of garlic in China.

Upward seeding of garlic cloves has the characteristics of emergence,early and strong,which is the common planting agronomy in China[4-6].The degree of mechanization of garlic cultivation in Occident is quite high[7-10],but they does not have the requirement for the clove’s orientation,which is difficult to adapt to the agronomic requirements of China[11-12].In order to realize the upward seeding of the garlic,Japan and South Korea garlic utilize some structural components to extrude the bud of the garlic clove while the buds of the garlic clove of the main varieties in China are not prominent,so that the adaptability and application of the technology is poor in China.The garlic clove’s orientation adjustment technology is the core technical bottleneck to the development of garlic cultivation in China,so it is urgent to be researched and solved[13-15].

In this study,we proposed a kind of garlic clove’s orientation control technology based on the parallel robot and embedded industrial computer.The technology could recognize the identification,positioning and adjustment of garlic cloves by using visual system,four degree of freedom manipulator and pneumatic claw,and we conducted the optimization design for the main factors of the indicators of adjusted success rate,which will be helpful for solving the garlic clove’s orientation adjustment,and breaking through the core technical bottleneck of garlic planter in China.

1 Garlic clove’s orientation adjustment system

1.1 Structure and working principle

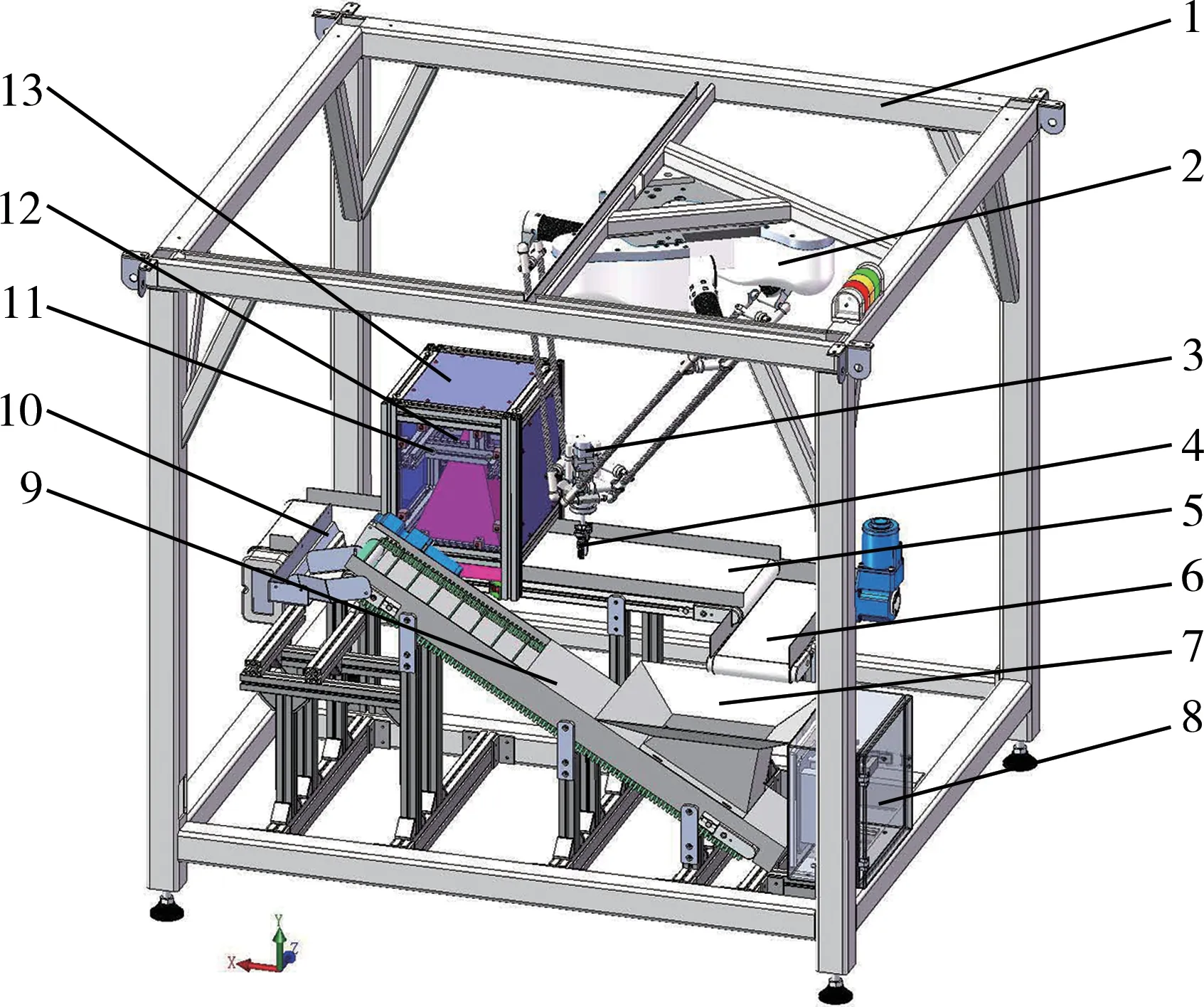

The structure diagram is shown in Figure 1.The parallel robot mainly made up of control cabinet,body,speed control motor and flexible touch grasper,and the model was D3PM-600-P0.The working diameter of the parallel robot was 600 mm,and the maximum load was 3 kg.The visual system was mainly composed of an industrial computer(P15RF),LED light belts,industrial camera(MV-CE020-10GC)and black boxes.And the model of camera lens was Computar MP2-8.

Figure 1 Structural representation of garlic clove’s orientation adjustment system

The garlic cloves were put into the hopper,and they were dropped into the vibration conveyor through the hoist.After the vibration,the cloves were dropped into the first conveyor in an independent state.A visual system was installed above the first conveyor.When cloves were passing through it,the visual system determined the position and orientation images by photography of camera,and sent the images to the parallel robot controller.Under the assistance of the speed sensor and the orientation information received,the controller adjusted the clamping direction of the grasper through the speed regulating motor,and the garlic clove was grasped through the robot body and the manipulator.Finally,the clove orientation was adjusted to a unified direction and put into the established position.The unfinished garlic cloves were returned to the hopper through the second conveyor.

The four operation steps were as follows:(1)setting the angle,position and grasping time of the grasper;(2)performing the grasp action;(3)adjusting the angle of the grasper;(4)putting garlic clove in the set position.

1.2 Visual system and garlic clove’s orientation adjustments

The visual program mainly consisted of four modules:image acquisition,image preprocessing,clove feature extraction and instruction drive.The four modules were executed sequentially in the while process to accomplish the function of image acquisition,preprocessing,garlic feature judgment and issuing instructions to the controller[16-20].Figure 2 shows the three main working steps after the program starts.First,the visual system received the photo trigger signal emitted by the parallel robot and collects the image.Second,the ideal binary image was obtained by median filtering,binarization,and morphological processing of the image to fill holes and filter out background particles,and the area of the connected domain of the binary image was screened according to the size range of garlic species to obtain the garlic binary image of the right size.Third,the center contour of the image and the curvature of the contour were extracted and calculated,and the part with the maximum curvature was regarded as the bud of the clove and this part was used as the clove orientation,while this orientation would be quantified as the angle value and sent to the robot.

Figure 2 Three main working steps of visual program

2 Optimal experiment

2.1 Experimental design

In order to conduct the algorithm verification test,we chose more than 10 kg garlic cloves and classified them by weight.All the garlic cloves were selected randomly for image acquisition without reuse.Two hundred images of single garlic clove and 200 images of multiple garlic cloves were collected,respectively,with BMP format.The whole test process was completed on the parallel robot machine.

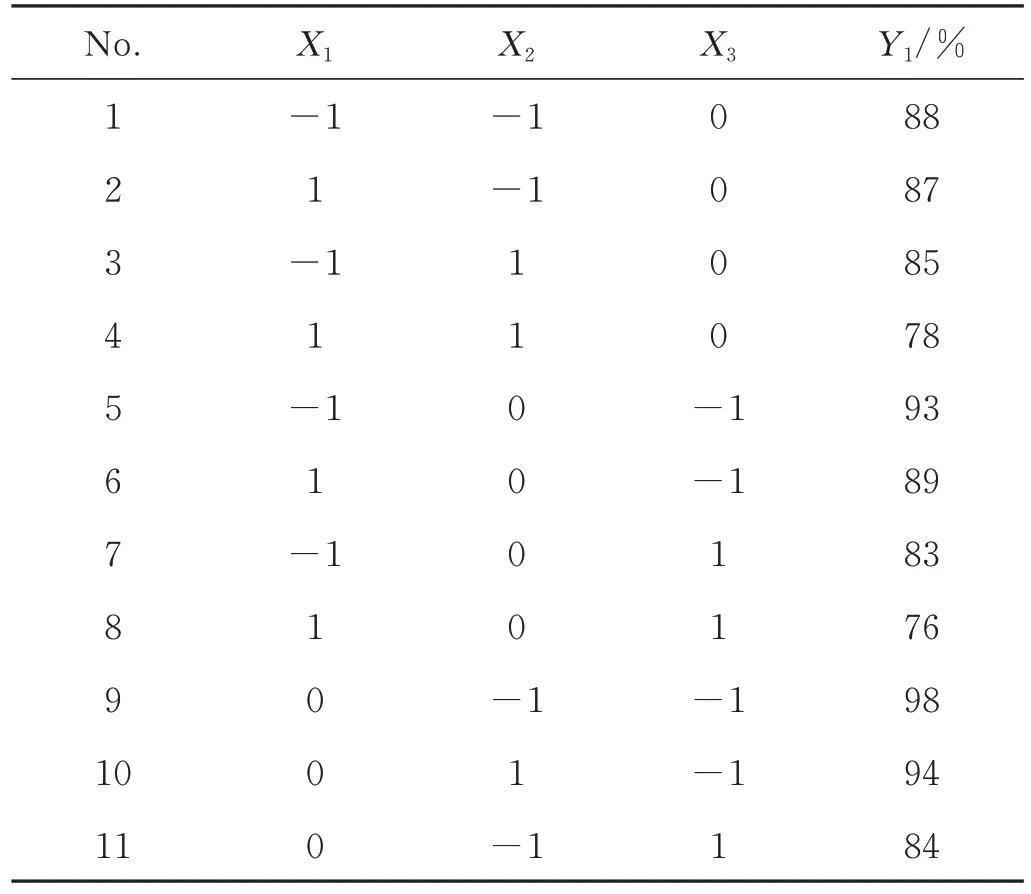

The previous tests showed that the weight of garlic clove,conveying speed and grasping time had the significant influence on the adjusted success rate.Therefore,these three factors were taken as the experimental factors,and the adjusted success rate was taken as the experimental response index.The experimental design was based on Box-Benhnken central composite design theory,and the experimental factors,their levels,and their coded values are listed in Table 1.

Table 1 Parameters and coded results of X1,X2,and X3

The formula for calculating the adjusted success rate is shown in Formula 1.

where,Y1is the adjusted success rate,% ;N1is the weight of garlic cloves which were successfully adjusted,g;N0is the total weight of garlic cloves,g.

2.2 Results and analysis

The adjustment experiments of garlic clove orientation are shown in Figure 3.

Figure 3 Adjustment experiments of garlic clove orientation

The experiment design and results were shown in Table 2.

Table 2 Experiment design and results

According to the multiple regression fitting analysis,the regression equation ofY1can be written as:

The significant variables from the results of the statistical analysis of the adjusted success rate based on the optimization numerical module of Design-Expert software are listed in Table 3.

Table 3 Variance analysis of regression models

The optimal parameter combination ofY1was weight of garlic clove(4.54 g),the conveying speed(0.1 m/s),and grasping time(2.445 s).At this stage,the adjusted success ratepredicted by the model was 97.41%.Under the same experimental conditions,three batches were tested,and 1 000 cloves were grabbed in each batch.The average success rate of adjustment was 96.67%.The regression model of the adjusted success rate was consistent with the experimental results.

3 Conclusions and discussions

3.1 Conclusions

First,based on machine vision,we designed a garlic clove’s orientation adjustment device.The industrial camera was used to collect the image of garlic seeds,while the clove orientation was identified by image analysis.According to the recognition results,the clove orientation was adjusted to appropriate direction.

Second,an algorithm for garlic clove orientation recognition was proposed.The garlic binary image was obtained by image preprocessing,and the parallel robot found the garlic connected region which was calculated and analyzed to acquire the characteristic parameters of the bud of the garlic clove,and the characteristic parameters was used to recognize the garlic clove orientation.

Third,three-factors and three-levels regression orthogonal test was carried out by Box-Behnken central composite method to establish a multiple regression model for the adjusted success rate.The combination of the weight of garlic seed(4.54 g),the conveying speed(0.1 m/s),and the grasping time(2.445 s)led to a relatively high adjusted success rate(97.41%),and the result of the tests was 96.67%.

3.2 Discussions

Some garlic cloves happened to have an outwardly protruding slender bulge which was similar to the buds,and led to the error of algorithm identification,which indicated that identification algorithms need to be improved in the later research.

The recognition algorithm had poor filtering effect on accidental interference factors(eg.garlic peel),and could not recognized the garlic cloves without peel well,which reduced the adjusted success rate.

The probability of abnormal factors occurring at the same time was low,so the adjusted success rate was high for garlic clove’s orientation by using the proposed algorithm.