Liquid Film Characteristics on Surface of Structured Packing*

LUO Shujuan (罗淑娟), LI Huaizhi (李怀志), FEI Weiyang (费维扬),** and WANG Yundong (王运东)

Liquid Film Characteristics on Surface of Structured Packing*

LUO Shujuan (罗淑娟)1, LI Huaizhi (李怀志)2, FEI Weiyang (费维扬)1,** and WANG Yundong (王运东)1

1The State Key Laboratory of Chemical Engineering, Department of Chemical Engineering, Tsinghua University, Beijing 100084, China2Laboratoire des Science du Génie Chimique, Nancy-Université, CNRS, 54001 Nancy, France

Structured packing is a good candidate for CO2capture process because of its higher mass transfer efficiency and lower pressure drop. Now, the challenging problem of CO2capture and storage demands more and more efficiency equipment. The aim of the present study is to investigate the liquid film characteristics under counter current gas phase and throw some insight into the enhancing mechanism of mass transfer performance in structured packing. A high speed digital camera, non-intrusive measurement technique, was used. Water and air were working fluids. Experiments were carried out for different gas/liquid flow rates and different inclination angles. The time-average and instantaneous film widths for each set of flow parameters were calculated. It is shown that the effects of gas phase could be neglected for lower flow rate, and then, become more pronounced at higher flow rate. According to instantaneous film width, three different stages can be distinguished. One is the constant width of liquid film. The second is the slight decrease of film width and the smooth surface. This kind of character will lead to less interfacial area and deteriorate the packing mass transfer performance. For the third stage, the variation of film width shows clearly chaotic behavior. The prediction model was also developed in present work. The predicted and experimental results are in good agreement.

counter current, liquid film, two phases, structured packing

1 INTRODUCTION

CO2capture and storage become more and more important, and urgent problems nowadays. This kind of process has some distinct features. One is that it deals with huge volume of gas, and then, large capacity of equipment is major and necessary. Another is lower pressure drop. Structured packing is good candidate for CO2capture because of its higher mass transfer efficiency and lower pressure drop, and it also has been widely used in many different industrial applications. With the enhancing requirements for energy saving and emission reduction, more and more researchers pay attention to strengthening equipment.

Structured packings are made of regularly arranged corrugated sheets. Liquid phase is supposed to spread over packing surface and flow downward, whereas, mostly, gas phase flow is in opposite direction. Hence, the vapor-liquid hydrodynamics determine the limits of the column and control the mass transfer efficiency. The spreading of liquid film over solid surface has received a substantial attention in the published works owing to its importance in many applications [1, 2]. However, only few studies have examined the film flow on structured packing. Cerro. [3-6] carried out a series of experimental research programs to characterize the mechanics of liquid film over solid surface. They paid more attention to the effects of micro-structure of structured packing, and measured film thickness profiles, streamline patterns, and free-surface velocities for a variety of fluids. Besides, a model based on the viscous long-wave approximation was presented to describe the evolution of film [7]. The influence of liquid properties, solid shapes, and inclination angles on liquid spreading were discussed in detail. Nicolaiewsky. [8] focused on the effect of viscosity and surface tension on liquid width as well as the thickness. They concluded that the liquid film width decreases with liquid viscosity. However, their conclusion is in contradiction with the correlations presented by other researchers [9]. The influence of all relevant parameters on liquid film mass transfer and on the effective interfacial area has not been established unequivocally.

With the development of computational fluid dynamics (CFD), more and more researchers show an interest in using CFD methods to simulate the multiphase flows in column with structured packing. The volume of fluid (VOF) approach, which was developed by Hirt [10] for tracking the interface between two or more non-interpenetrated phases, is mostly chosen to simulate wetting performance. Effects of solid surface microstructure, liquid properties, and gas flow rate on flow pattern were discussed [11-13]. Valluri. [14] presented a model based on the integral balance method. Thin film flow over structured packing at moderate Reynolds numbers was simulated, and the results are in good agreement with those obtained using a CFD approach. However, the main disadvantage of these results in the published works is that the computed geometry is two dimensions. It is hard to explain the real phenomena that happened over the surface of structured packing. Recently, Ataki. [15] investigated the wetting performance of structured packing both experimentally and numerically. Rivulet profile shape was discussed; correlations for liquid hold-up and effective interfacial area were derived. However, they were interested in Rombopak packing. The geometry is a little far from traditional Mellapak packing. Luo. [16] analyzed and calculated the gravity components in different coordinates, so that the liquid flow on structured packing could be simulated by vertical geometry. Because of the limitation of a computer, complex interfacial phenomena, and turbulent flows, it is still a challenging problem to simulate the interaction between gas phase and liquid phase over real packing surface.

Besides, there are some interesting phenomena coming from experiments at large scale and these phenomena could not be explained yet now. For example, the mass transfer efficiency deteriorates at a certain degree in the loading region with the distillation experimental results [17]. The knowledge of the film characteristics under counter current gas phase is of utmost importance for the pressure drop, mass transfer estimations, as well as the experimental phenomena explanation.

As for the liquid flow on surface of structured packings, there are similarities to flow over inclined plate. Luo. [18] focused on the inclined surface and have discussed the effect of gas phase on liquid film, which is very sketchy. The objective of the present work is to develop a prediction model of film width and to investigate the film characteristics under counter current gas phase in more detail.

2 EXPERIMENTAL

Figure 1 shows the schematic description of the experimental facility. All the experiments were carried out in an inclined duct. The dimension of the duct is 120 mm×16 mm×215 mm, and the bottom surface of the inclined duct was glass.

Water and air were used as liquid phase and gas phase. The water was supplied from a huge tank and made to flow downward from top of the duct. The flow rate was controlled by a centrifugal pump and measured by liquid flow meter. Air coming from a compressor passed through a surge pump, and then, entered the inclined duct from the bottom. The volumetric flow rates of air were determined by gas flow meter.

A high speed digital camera was used to capture the details of the flow in the present work. Pictures were taken at a speed of 1000 frames per second and a shutter rate of 1/2000. The resolution of pictures was 640×480 pixels. The light and the camera were located on the different sides of the inclined duct.

All tests in present work were performed at room temperature (20°C). The volumetric flow rates of liquid phase varied from 2×10-7m3·s-1to 1.4×10-6m3·s-1. The values of gas flow rate ranged from 0 m3·s-1to 3.25×10-3m3·s-1. The inclination angle from horizontal was chosen as 30°, 45°, and 60°, respectively.

The sequence of images for different situations was recorded. The analysis of images was performed by MATLAB. Because of the meandering rivulet phenomenon on a plane [19], the average width of different places at fixed time was calculated and used to evaluate the liquid film characteristics. Besides, the instantaneous width was another interesting point in the present work.

3 MODEL

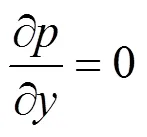

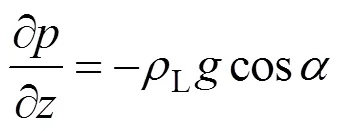

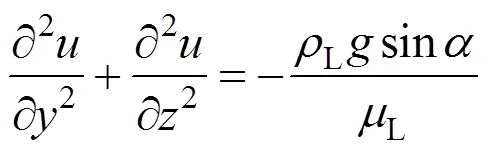

The flow down along an inclined plane without gas phase is assumed to be steady and uniform. The liquid properties, such as density, viscosity, contact angle, surface tension, and so on, are supposed to be constant. Cartesian coordinates, namely, Oxyz are illustrated in Fig. 2. With a further assumption that the Newtonian liquid is incompressible and flow is laminar, the Navier-Stokes equations reduces to

Figure 1 Experimental set up

Figure 2 Liquid flow parameters

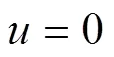

The boundary condition is the following:

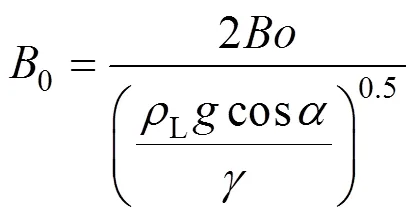

whereais the atmospheric pressure,is the gas-liquid interface,is the coefficient of surface tension,is the contact angle, and0is the width of liquid film in the absence of gas phase.

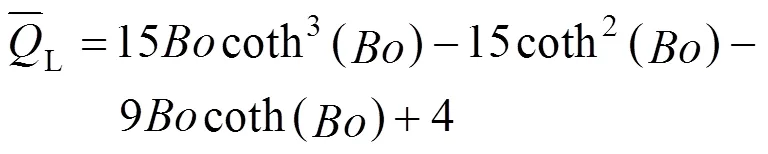

Several authors [20-22] have discussed this kind of problem and proposed different solutions. Because Duffy’s results are in a more useful form, their correlation is used directly in the present work.0is expressed explicitly by Eq. (4).

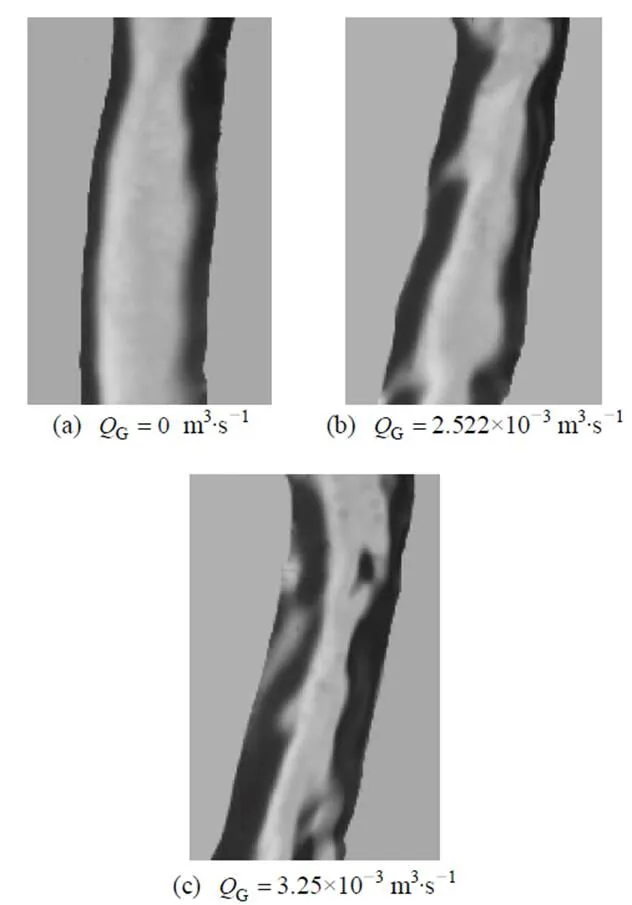

The shape of the flow is not uniform any more under counter current gas phase (Fig. 3). Besides, the pressure around liquid phase and contact angle is unstable either. It is still a challenging problem to get an approximate solution from Navier-Stokes equation for this situation. Here, half-empirical Eq. (7) is used to predict the width of liquid film with gas phase.

Figure 3 Shape of liquid film under different gas flow rates

4 RESULTS AND DISCUSSION

4.1 Average width of the liquid film

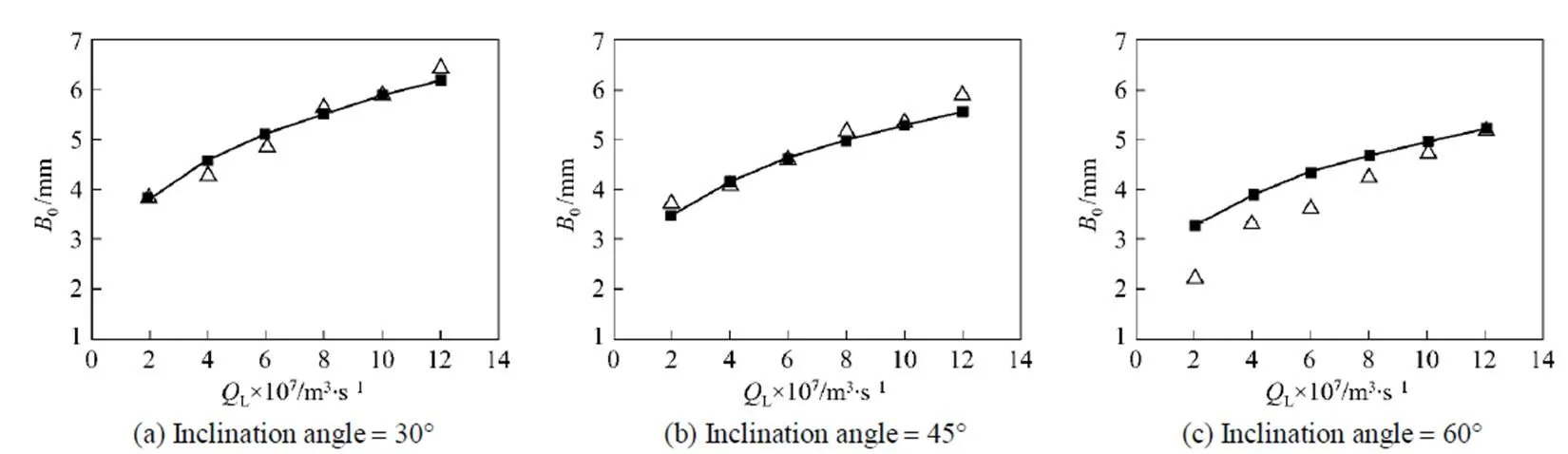

Figure 4 illustrates the measured and predicted time average width of liquid film. It is a function of the liquid flow rate. The effect of counter current gas phase is ignored. Fig. 5 takes the influence of gas phase into consideration. It shows the film width under different liquid and gas flow rates. Obviously, the prediction with/without gas phase agrees fairly well with the experiment in the range of experimental flow rates.

Figure 4 Width of the liquid film without gas phase

△ experimental data; ■ Eq. (4)

Figure 5 Effect of counter current air on the film width

As shown in Fig. 4 and Fig. 5, both liquid phase and gas phase have significant effect on the film width. The time average width of the liquid film increases notably with increasing the liquid flow rate. The effect of gas phase is a little more complex, and the width remains insensitive to the counter current gas phase for lower gas flow rate. However, the film width decreases pronouncedly for higher values of gas flow rate.

The inclination angle is also a key parameter that affects the film characteristics. The film width decreases no matter what the gas phase is. Comparing the a, b, and c in Fig. 4 and Fig. 5, the film width decreases by 30% when the inclination angle increases from 30° to 60°. The width of rivulet is proportional to the wetted surface area [9] and has a strong effect on the mass transfer efficiency. Decreasing width means reducing wetted surface area and deteriorating the mass transfer performance. It corroborates the experimental results in the published works [17]. The mass transfer performance of structured packing with 60° inclination angle is much lower than the packing with 45°.

4.2 Instantaneous width of the liquid film

It is worth pointing out that the instantaneous place-average film width has some special characters. The width at specific place is stable without air but the place-average width changes a little. The fluctuation could come from experimental error, such as the camera or lighting. According to Fig. 7 (a), the mean value of the width is 6.4425 mm, and the maximum fluctuation is approximately 0.007 mm. The experimental error is then less than 1%. With the increase in the gas flow rate, the oscillations of place-average width changes from regular to chaotic [Figs. 7 (b) and 7 (c)]. They are similar to those at a fixed place.

Figure 6 Instantaneous film width at a fixed place

5 CONCLUSIONS

The present experiments were carried out on inclined plate. Based on the sequence of recorded images at different liquid/gas flow rates, the characteristics of the liquid film on inclined plate under counter current gas phase were studied. Water and air were used as working fluids. The width of the liquid film is the key parameter investigated in the present work.

Figure 7 Instantaneous place-average film width

The prediction model for film width under counter current gas phase was developed. The main parameters were0andG. The predictive results are in good agreement with the experimental data. Liquid/ gas flow rates have significant effect on the film width. It increases with the increase in liquid flow rate. However, it decreases under heavy gas phase. Besides, inclination angle is also an important influencing factor. The film width decreases by 30% when the inclination angle increases from 30° to 60°.

Three different stages can be observed with the instantaneous width. The first is constant width with smooth film shape. The second is thinner rivulet with smooth film shape. This kind of characteristic might bring about less interfacial area and deteriorate mass transfer performance. For the third stage, the variation of film width illustrates chaotic behavior.

ACKNOWLEDGEMENTS

,,.

NOMENCLATURE

width of liquid film under gas phase, mm

0width of liquid film without gas phase, mm

Bond number

eqequivalent diameter, m

gas-liquid interface

fluid pressure, Pa

aatmospheric pressure, Pa

volumetric flow rate, m3·s-1

Reynolds number

velocity, m·s-1

inclination angle to the horizontal, (°)

contact angle, (°)

coefficient of surface tension, N·m-1

density, kg·m-3

dynamical viscosity, Pa·s

Subscripts

L liquid phase

G gas phase

1 Chang, H.C., “Wave evolution on a falling film”,..., 26 (1), 103-136 (1994).

2 Oron, A., Davis, S.H., Bankoff, S.G., “Long-scale evolution of thin liquid films”,..., 69 (3), 931-980 (1997).

3 Zhao, L., Cerro, R.L., “experimental characterization of viscous flows over complex surfaces”,.., 18 (4), 495-516 (1992).

4 Shetty, S.A., Cerro, R.L., “Flow of a thin film over a periodic surface”,.., 19 (6), 1013-1027(1993).

5 Shetty, S.A., Cerro, R.L., “Spreading of liquid point sources over inclined solid surfaces”,...., 34 (11), 4078-4086 (1995).

6 Shetty, S.A., Cerro, R.L., “Spreading of a liquid point source over a complex surface”,...., 37 (2), 626-635 (1998).

7 Shetty, S.A., Cerro, R.L., “Fundamental liquid flow correlations for the computation of design parameters for ordered packings”,...., 36 (3), 771-783 (1997).

8 Nicolaiewsky, E.M.A., Tavares, F.W., Rajagopal, K., Fair, J.R., “Liquid film flow and area generation in structured packed columns”,., 104 (1), 84-94 (1999).

9 Shi, M.G., Mersmann, A., “Effective interfacial area in packed columns”,..., 8 (2), 87-96 (1985).

10 Hirt, C.W., Nichols, B.D., “Volume of fluid (VOF) method for the dynamics of free boundaries”,..., 39 (1/2), 201-225 (1981).

11 Gu, F., Liu, C.J., Yuan, X.G., Yu, G.C., “CFD simulation of liquid film flow on inclined plates”,..., 27 (10), 1099-1104 (2004).

12 Ataki, A., Bart, H.J., “The use of the VOF-model to study the wetting of solid surfaces”,..., 27 (10), 1109-1114 (2004).

13 Szulczewska, B., Zbicinski, I., Gorak, A., “Liquid flow on structured packing: CFD simulation and experimental study”,..., 26 (5), 580-584 (2003).

14 Valluri, P., Matar, O.K., Hewitt, G.F., Mendes, M.A., “Thin film flow over structured packings at moderate Reynolds numbers”,..., 60 (7), 1965-1975 (2005).

15 Ataki, A., Bart, H.J., “Experimental and CFD simulation study for the wetting of a structured packing element with liquids”,..., 29 (3), 336-347 (2006).

16 Luo, S.J., Fei, W.Y., Song, X.Y., Li, H.Z., “Effect of channel opening angle on the performance of structured packings”,..., 144 (2), 227-234 (2008)

17 Olujic, Z., Seibert, A.F., Fair, J.R., “Influence of corrugation geometry on the performance of structured packings: An experimental study”,..., 39 (4), 335-342 (2000).

18 Luo, S.J., Li, H.Z., Fei, W.Y., Wang, Y.D., “Effect of counter current gas phase on liquid film”,..., doi 10.1007/s11705- 009-0129-1.

19 Nolwenn, G.P., Daerr, A., Limat, L., “Meandering rivulets on a plane: A simple balance between inertia and capillarity”,..., 96 (25), 254-503 (2006).

20 Towell, G.D., Rothfeld, L.B., “Hydrodynamics of rivulet flow”,., 12 (5), 972-980 (1966).

21 Allen, R.F., Biggin, C.M., “Longitudinal flow of a lenticular liquid filament down an inclined plane”,.., 17 (2), 287-291 (1974).

22 Duffy, B.R., Moffatt, H.K., “Flow of a viscous trickle on a slowly varying incline”,..., 60 (1-3), 141-146 (1995).

2008-07-04,

2008-10-21.

the National Natural Science Foundation of China (20070003154), the National High Technology Research and Development Program of China (2006AA05Z316, 2006AA030202), the Specialized Research Fund for Doctoral Program of Higher Education of China (20070003154), and the Key Program for International Cooperation of Science and Technology, China (2001CB711203).

** To whom correspondence should be addressed. E-mail: fwy-dce@tsinghua.edu.cn

Chinese Journal of Chemical Engineering2009年1期

Chinese Journal of Chemical Engineering2009年1期

- Chinese Journal of Chemical Engineering的其它文章

- Modeling and Optimization for Scheduling of Chemical Batch Processes*

- Simulation of Droplet-gas Flow in the Effervescent Atomization Spray with an Impinging Plate*

- Numerical Investigation of Constructal Distributors with Different Configurations*

- The Kinetics of the Esterification of Free Fatty Acids in Waste Cooking Oil Using Fe2(SO4)3/C Catalyst

- Multiple Model Soft Sensor Based on Affinity Propagation, Gaussian Process and Bayesian Committee Machine*

- Measurement and Correlation of Solid-Liquid Equilibria of Phenyl Salicylate with C4 Alcohols