Design Method of Equipment Optimization Development Based on Standardization Theory

Lv-bo MAI

Design Method of Equipment Optimization Development Based on Standardization Theory

Lv-bo MAI

China North Standardization Research Center,Beijing 100089,China

The matters of equipment optimization development are usually discrete,fuzzy and non-quantitative.It is diff i cult directly to optimize the equipment development with a mathematical model.A set of methods for designing the equipment optimization development with six dimensions and eight main elements is established based on the theory and method of standardization.The top-tier design space of systematic development of equipment is built up by the relations of basic models,series and model spectrums.The relations of time and space for equipment optimization development are established.The design processes of a six dimension systematic space are expounded.The connotation of each plan in the main system space is analyzed.A design method for an entire equipment is established with standardization theory.The coordinating design methods of equipment technical system and the optimization design methods of equipment integration are discussed.The design methods for universalization and serialization of components and parts are established.The design methods of equipment optimization development highlight the relations of the basic model of platform,the serialization of platform basic models,the modularization of equipment functions,the model spectrum of variant equipment,and the universalization and serialization of components and parts.

CopyrightⒸ2013,China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

Equipment;Optimization development;Standardization;Design method

1.Introduction

The design methods of equipment optimization development include three design levels.The fi rst level design is the top-tier optimization design of equipment systematic development,the second is the optimization design of equipment ensemble,and the third is the optimization design of equipment components and parts.The three level designs shouldn’t be alone conducted.The optimization relations of product performances are usually of mathematical functions and continuous.The optimum solution can be got using the mathematical extremum solution and the iterative approximation methods.The optimization of system design,system integration,variety of components and parts is diff i cult to be mathematically solved because their relations are discrete, fuzzy and non-quantitative.The standardization theory has a special role to the optimization.The standardization theory includes the theories of commonality,serialization,modularization and interchangeability,and provides an effect way for the solution of discrete,fuzzy and non-quantitative matters.

2.Equipment top-tier design method

2.1.System space of top-tier design

The conception of Top-tier design is to consider and plan the equipment development in the most possible scope of equipment usages.The purpose of this method is to establish the reasonable relations for taking full advantage of existing product resources to use the least varieties of equipment to cover themost scopes of equipment applications.The top-tier design method is based on standardization theory.It depends on using the conceptions of basic model,commonality,serialization, modularization,model spectrum,product family and systematism.A top-tier design system space(TDSS)is established with six dimensions and eight elements.The equipment development relations in TDSS are based on the integration considering design of objects from the demands,the rational utilization of resource and the scienti fi c calculation of relations.That makes the weapons in TDSS not only be independent of each other but also be connected each other.The relation of unity of opposites of‘single’and‘more’,‘same’and‘difference’should be fully considered for equipment.It means that a platform can be installed with many different payloads and one payload can be used in many platforms.The different functions in the same basic model product can be constructed to make the ultilization of technology resource be maximized.The thinking of top-tier design is systematically relative design.The designs are conducted with the top-tier design relation of six dimensions and eight elements.The general relations of top-tier design are shown in Fig.1[1].In Fig.1,the coordinate system(x,y,z) makes up a three-dimension design space which is called as the fi rst three-dimension design space,and the coordinate system (α,β,γ)makes up another three-dimension design space which is called as the second three-dimension design space,which is related to the coordinate system(x,y,z).Space(α,β,γ)can accept the mapping of any point in space(x,y,z).The design objects in Fig.1 are the examples of armored vehicles.In Fig.1, the vocabularies of tracked vehicles and their abbreviations are Tank(TK),infantry fi ghting vehicle(IFV),amphibious vehicle (AMV),airborne vehicle(AV),support vehicle(SV),reconnaissance vehicle(RV),command vehicle(CV),self-propelled artillery(SPV),the vocabularies of wheeled vehicles and their abbreviations are wheeled assault vehicle(WASV),wheeled infantry fi ghting vehicle(WIFV),wheeled armored carrier (WAC),wheeled reconnaissance vehicle(WRV),wheeled command vehicle(WCV),wheeled support vehicle(WSV), wheeledself-propelledartillery(WSPA),wheeledselfpropelled mortar(WSPM),and the vocabularies of developing phases and their abbreviations are item proof(IP),itemapproval(IA),advance development(AD),engineering development(ED),design fi nalization(DF),produce examination fi nalization(PEF)and troop use(TU).

Fig.1.Top-tier design system space.

2.2.Basic model design

The technology relations of the f i rst dimension(x)include two main design elements.The f i rst design element is to determine the basic model maim body of design objects.This is the basic point of top-tier design.The product platforms or main functions are usually selected as basic model main body objects.For example,the basic model main body objects of armored vehicles are their chassis,and the basic model main body objects of artilleries are their tubes and so on.The second design element is the series relation design of basic model main body object.The f i rst step of the series design is to choose the main parameters of basic model main body objects. The main parameters usually are some important parameters that determine the main performances of equipment or the parameters of main construction.For example,the main parameter of basic model main bodies of armored vehicles is the tonnage relation of carrying capacity of chassis,and the main parameter of basic model main bodies of artilleries is the size relation of artillery caliber.The main parameter of basic model main body should be designed into series relations.The meaning lies in scientif i cally dispersing the parameter values of basic model main body objects,avoiding the multi-variety problems due to the continuous use or unreasonable tight dispersing of main parameters.The scientif i c dispersing laws of mathematics should be used for the reasonable dispersing relations of main parameters.Equal ratio number series,not equal difference series,are usually adopted for equipmentproducts,such as R5 or R10 series.Using R5 series,the tonnage series values of armored vehicles are 10t,15t,25t,40t and 60t.Using R10 series,they are 10t,12t,15t,20t,25t,30t, 40t,50t,60t and 80t[2].The common ratios of two series are R5→510and R10→1010,respectively.The carrying capabilities of basic model main bodies are usually designed into‘covering a small parameter with a large one’and‘supporting a large parameter with a small one’.‘Covering a small parameter with a large one’,which is an economic problem, means that a basic model parameter covers its half down interval ability.‘Supporting a large parameter with a small one’, which is a carrying capability problem,means that the basic model parameters can cover its half up interval ability.The scope suitable for use of chassis is from half up interval ton weight+basic model tonnage to half down interval tonnage+basic model tonnage.The carrying capacity of basic model chassis should be designed as half up interval tonnage+basic model tonnage.The third design element is to consider that the one series or two series is used for the basic model series.The series of armored vehicles can be divided into two series,i.e.wheel vehicle series and track vehicle series,in moving modes.

2.3.Function model spectrum design

The second dimension(y)design relation is of function and use.It is the design of object function spectrum.The design is comprehensively planned according to an object function or use.This is the fourth-design main element.Taking armored vehicle as an example,the armored vehicles include tank,infantry f i ghting vehicle,assault vehicle,airborne vehicle,amphibious vehicle,command vehicle,reconnaissancevehicle,electroniccountermeasurevehicle,selfpropelled antiaircraft gun,self-propelled gun-howitzer,selfpropelledmortar,anti-tankmissilelaunchingvehicle, armored carrier,technology support vehicle,engineering support vehicle,logistics support vehicle and so on.Wheeled vehicles and tracked vehicles may be separately listed,seeing axis y and axis y'in Fig.1.

2.4.Relation design of equipment upgrade

The third dimension(z)design relation is the development relation design of equipment upgrade.This relation is formed when some important characteristic technologies are developed,such as the new generation armored vehicles with smart, whole electricity or new concept technologies.The equipment upgrade must be characterized by the signi fi cant improvements in equipment technology and performance.It is the fi fth-design element.

2.5.Main element design of the second three-dimension space

根管弯曲,特别是根管入口处弯曲可增加根管治疗的难度。上颌第二磨牙髓室及根管系统的变异率更高[1],狭窄的髓室底视野较差,易导致MB2根管的遗漏,同时也增加了预备MB2的难度。1-2 型MB2是根管上段为1个根管口,中下端分为两个根管,其发生率约3.7%[2-4]。我们接诊了1例上颌第二磨牙根管入口急弯伴近颊根1-2型的患者,现报道如下。

The fourth dimension(α)design relation is the design of model spectrum relations which is to modify the equipment functions.The model spectrum improvements of equipment are the improvements or technology innovations of which the prototype equipment structures are not obviously changed and the changes will not arouse the obvious changes of military equipment performances.The design of improved series is the sixth design main element.The f i fth dimension design relation is the developing time planning of equipment in the system space,which is expressed with year relations.It is the seventh design main element.The sixth dimension design relation is the working phrase design of equipment development,including item proof,item approval,advanced development,product development,design f i nalization,produce examination f i nalization,troop use.It is the eighth design main element.The six dimension table expression is shown in Fig.1.

2.6.Expression of six dimension data relation

The system space of top-tier design has the visual effect of designexpression,butitisdiff i culttolabelallthesixdimension data for each kind of equipment in a limited space.The six dimension data is expressed with a table.In order to match the six dimension elements in the top-tier design,the six dimension elements are expressed witha table.The elements in Table 1 are only the example elements and not necessary.In theory,each element of each dimension can match each element of other dimension in Table 1.The matching relation among dimension elements is theoretically the combination relation of six dimension elements,i.e.the multiplying among dimension vector matrixes:X·Y·Z·A·B·Γ.In fact,not all the elements in each dimension can match the elements in other dimensions one by one.

Table 1Six dimension relation table of top-tier design system space.

For example,each functional vehicle has various tonnage basic model chassis,and various vehicle models must be developed in every year.The matching among those elements is selective.The element matching is conducted by drawing a dimension element vector table.Table 1 is a dimensionelement vector matrix table.The detailed element matching relations of military vehicles can be matched according to Table 1.

2.7.Comprehensive analysis of system space

The plane(y,z)which passes through each basic model point on the axis x gives the vehicle families with the same functions,the different functions and the vehicle father,son and grandson generation relations based on the same basic model in the top-tier design space.The plane(x,y)which passes through each developing generation on the axis z gives the series relation and function model spectrum of the contemporaries.The plane(x,z)which passes through each functional equipment node on y axis gives the series relation and upgrade relation of the same functional vehicle.The space (α,β,γ)gives the developmental phrases,opportunities and model-modif i ed relations for each vehicle of the prototype basic models and modif i ed basic models in the space(x,y,z). In nature,the space(x,y,z)is the technology design space of equipment,and the space(α,β,γ)is the developing route space of equipment.After matching each variant,various basic model family pictures should be established in accordance with the basic model main body relations to clearly express the results of top-tier design.The top-tier design based on standardization theory is an all-purpose relation layout with the conceptions of basic model,serialization,extended function, upgrade,model-modif i ed development.The design can connect the individuals with the entirety to avoid the waste of technological resources due to repetitive development and the uninterchangeability of supporting resources.

3.Optimization design of monomer equipment

The optimization design method for monomer equipment based on standardization theory is mainly to coordinate the monomer equipment according to the equipment technical system and the united technical parameters,and optimize the integration of monomer equipment.

Thetechnicalsystemsandtheunitedtechnicalparametersof monomer equipment are usually specif i ed by military standards.The design is a design which coordinates with the united technical parameters.The equipment technical systems and the united technical parameters are the interactive technical relations of specif i c input and output of equipment which are specif i ed by top-level documents and standards.The kind of interactive relations have two types which are external and internal.The interactive relations are usually the inputs and outputs of physical and chemical quantities of equipment.The technical system is a technology relation of which the acrossservice equipment needs to be unif i ed.The monomer equipment technical systems of armored vehicle include artillery caliber,vehicle tonnage,and communication protocol and so on.The united technical parameters of armored vehicle mainly includetotalweightandoveralldimensionsofequipment,order format,wavelength and coding of light communication,electrical power interface,supply interface,testing and maintaining interface,interface of external stores,dragging and pulling interface,stealth mode against detecting,quantity and unit,and interchangeability and so on[3].The coordinating design of unitedtechnical parametersisbased on the standards.When the designers cannot f i nd the relative standards,they can design a prototype according to the approved policies or plans.The coordinating design contents of equipment technical systems and united technical parameters are shown in Fig.2.The coordinatingdesignsofequipmenttechnicalsystemsandunited technical parameters are mainly the designs of existing military technical systems and united technicalparameters.On the other hand,in order to meet the demands of equipment optimization, improvement and upgrade,the new supplement and perfect programs for equipment technical systems and setups can be researched and provided.The specif i cations of technical systems and united technical parameters in monomer equipment design can be executed to establish the systematic connecting relations among monomer equipment.

Fig.2.Design content of technical systems and united technical parameters.

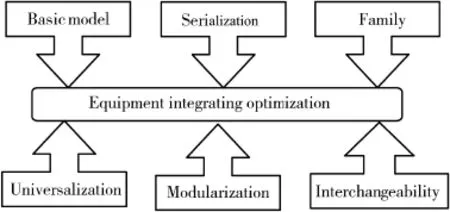

3.2.Optimization design of monomer equipment integration relation

The integration relation optimization of products is different from the performance optimization of products.It is necessary to consider comprehensively the optimization of product design,manufacture and use costs which are bought by product composition relations in whole application scope.The performance optimization of products is mainly to consider the reasonable distribution of product performances and the optimization of target performances of a single product.The integration optimization design of monomer equipment is mainly to design the monomer equipment with the standardization elements of universalization,serialization,combination, modularization,interchangeability and interface universalization.From this the standardized technology states of monomer equipment can be established.The system combinationrelations with standardization states can cover the most wide application scope with the least varieties and meet the most use requirements with the lowest costs.The characteristic relations of equipment integration optimization are shown in Fig.3.The design idea of equipment integration optimization can be divided into four aspects:modularization of system structure, universalization of core modules,serialization of special modules,and universalization and interchangeability of interfaces.Modularization of system structure is to decompose a system into functional modules in accordance with independent functions,and then integrate the functional modules into a modular system according to the application requirements.It is convenient to disperse the design and manufacture of system and conduct inheriting use and transforming development. Universalization of core modules is to enlarge the use scope of high value and high technology core modules to make the full use of the design and manufacture values.Serialization of special modules is to change the main parameters of highly individualized modules scientif i cally and regularly,and control the production of unnecessary varieties.Universalization and interchangeability of interfaces is to support the transforming developments and maintenance support of equipment[4].The optimization design of standardization theory for the integration relations is mainly to inject the standardization technology state elements of universalization,serialization,modularization,interchangeability into monomer equipment,promote the extent ofinheritance,reusability and interchangeability of parts and components in integrated equipment and compress the varieties and specif i cations of integrating equipment parts and components.The varieties and specif i cations of equipment are compressed using merging method or extending method.The design of monomer equipment should f i t with the top-tier design relations and the united technical parameters of equipment.

Fig.3.Standardization characteristic relations of integrating optimization.

4.Universalization and series design methods of components and parts

4.1.Universalization design method of components and parts

The universalization design of components and parts are to fi nd out their common physical characteristics and typical structures through merging,specially choosing and simplifying according to their common and similar characteristics.It is an optimal design that can enlarge the use scope of the same units to the most extent[5].The universalization is based on the interchangeability.The interchangeability means that an unit can arbitrarily be substituted with another unit without any change or modif i cation,and the substituted unit can meet the same use requirements or performances.The interchangeability includes function and interface interchangeabilities. The embodiment forms of universalization are productborrowing universalization,product main body universalization(basic model),technology universalization,interface universalization and software universalization.The productborrowing universalization is to borrow the units with common property in the developed products to the developing products.The product main body universalization is to develop the product main body into a basic model in the development of a new product,make the main body have the wider applicability,extensibility and ease of transforming development, and derive new function with a little change.Universalization is relative.Commonality is valid only in a certain scope.In a whole optimization space,the universalization ensemble of the similar products with various specif i cations will constitute a series of products.

4.2.Series design method of components and parts

The series designs of components and parts are to classify and merge the main parameters and specif i cations of similar units in accordance with scientif i c mathematical laws in order to establish product serialization system,and establish a numeral series relation of meeting most needs with less varieties [5].The serialization is to unify the construction forms and performances of product varieties by subsections,thereby purposefully dispersing the varieties and specif i cations of products and building up the optimal developing relations of product varieties.On the one hand,the serialization is to compress and simplify the existing varieties.On the other hand,it is to guide the development of new varieties and specif i cations,thus building up a product system of complete product varieties,def i ned amount and optimized structures and functions.The relation of serialization formation is shown in Fig.4.A product variety is arbitrarily developed according to any demand before it is serialized,as shown in Fig.4.For the tanglesome and much specif i cations,a series method should be applied scientif i cally to clear up the main parameters of product and reduce the unnecessary specif i cations,and a scientif i c development relation of variety is established.The scientif i c numerical law of series application has several kinds of schemes,such as equal differential number series,equal ratio number series,mold number series and other series.The Equal differential number series is usually used for the optimized objects of which the relation of parameter changes is absolute.The equal ratio number series is usually used for the optimized objects of which the relation of parameter changes is relative,such as product ability and power parameter classif i cation.The equal ratio number series is preferred numberseries.The preferred number series is a kind of scientif i c number value system and a kind of no unit classif i cation number series.It is suitable for the classif i cation of various quantity values and a kind of ten time amplif i cation geometrical series.The preferred number series has the scientif i c classif i cation advantages and has been made into an international standard[2].The preferred number series can play the role of simplifying and coordinating the varieties of optimized objects.

5.Conclusions

The system space of top-tier design is the space in which professional knowledge,standardization knowledge and scientif i c knowledge are integrated.Standardization theory is used to establish a united space of optimization relations for equipment development.The standardization mode of equipment optimization development can be summarized as basic model of platform,serialization of basic model,function modularization,model spectrum of variant,universalization and serialization of components and parts.That makes the equipment development be series and relative and of family. Standardization plays prominent advantage role in optimizing the discrete,fuzzy and non-quantitative relations.The optimization relations are benef i cial to achieve the goals of the better inheritance,short development period,low development cost,high supportability and high reliability.

The standardization theory described in the paper is of universal applicability.It is applied to the top-tier design, monomer equipment design,and component and part design of armored vehicles and other equipment.

Fig.4.Series forming relation of products.

[1]Mai LB.Standardization theory and method for product top-tier design. Chin Stand 2013;(3):46-50[in Chinese].

[2]ISO 3-1973(E).Preferred numbers-series of preferred numbers.Printed in Switzerland;1973.

[3]Mai LB.Standardization system engineering mode for complicated product optimum developing.Chin Stand 2011;(3):46-50[in Chinese].

[4]MaiLB,JinWQ.Optimunprinciplesanditsmodelingofintegratedrelation for FPA thermal imagers.In:Proceeding SPIE 6621,international symposium on photoelectronic detection and imaging,vol.6621;2007.266.

[5]Mai LB.Generalization,series,unitization(modularization).Mil Stand 1996;(1):2-4.

19 May 2013;revised 20 June 2013;accepted 24 July 2013 Available online 4 October 2013

E-mail address:mailb7@163.com.

Peer review under responsibility of China Ordnance Society

Production and hosting by Elsevier

2214-9147/$-see front matter CopyrightⒸ2013,China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

http://dx.doi.org/10.1016/j.dt.2013.09.012

- Defence Technology的其它文章

- The Research on Compressive Properties of Polytetraf l uoroethylene at High Strain Rate

- Numerical Research on The Nozzle Damping Effect by A Wave Attenuation Method

- First-principles Study of Electronic Structures,Elastic Properties and Thermodynamics of the Binary Intermetallics in Mg-Zn-Re-Zr Alloy

- The Spatial Color Mixing Model of Digital Camouf l age Pattern

- Research on Optical Properties and Micro-processing Characteristics of Collodion Thin Film

- Application of Space-time Conservation Element and Solution Element Method in Intake and Exhaust Flows of High Power Density Diesel Engine