Fatigue behavior of basalt-aramidand basalt-carbon hybrid fiber reinforced polymer sheets

Pan Jianwu Wu Gang Yuan Xigui

(1Civil Engineering Department, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China)

(2School of Civil Engineering, Southeast University, Nanjing 210096, China)

C urrently,some fatigue life models for normal fiber reinforced polymer(FRP)sheets have been presented by Reifsnider et al[1-3].Wu[4]presented a fatigue life model for multilayer hybrid FRP sheets.Some researchers[5-14]also presented fatigue stiffness degradation models for normal FRP sheets.However, there are very few studies on the fatigue behavior of intraply hybrid sheets,especially for the basalt-aramid and basalt-carbon hybrid FRP sheets.In order to research the fatigue behavior of basaltaramid and basalt-carbon hybrid FRP sheets,fatigue experiments with two hybrid types(basalt-aramid,referred to as B-A;basalt-carbon,referred to as B-C)and two hybrid ratios(1∶1 and 2∶1)under different stress levels(from 0.6 to 0.95)are carried out.The hybrid FRP sheets are made by the wet-layup method[15]according to GB/T 3354—1999[16]and GB/T 1447—2005[17].The details of size and preparation of the specimens are the same as Ref.[15].The stress ratios are all 0.1.The experiments are carried out in the Laboratory of Structural Strength in Nanjing University of Aeronautics and Astronautics.The main instrument is an electro-hydraulic servo fatigue experimental machine.

1 Fatigue Experiments

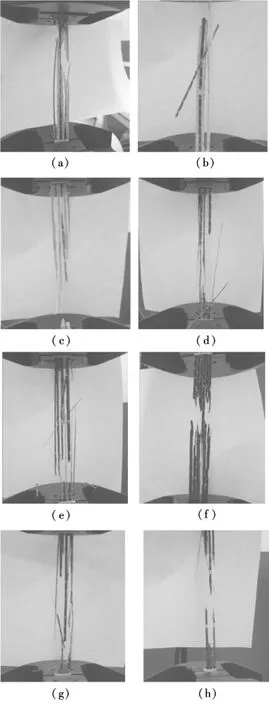

Some typical damage occurred in the specimens during experiments, such as partial fibers failure, edge fractures,central holes, etc., as shown in Fig.1.

Fig.1 Damageofthespecimensduring experiments.(a)B1A1;(b)B1C1;(c)B2A1;(d)B2C1

The final failure modes are all sudden brittle fractures,and all the specimens are incomplete after failure.Fractures occur first in carbon fibers or aramid fibers for the specimens with a hybrid ratio of 1∶1(namely B1A1 and B1C1)(see Fig.2), while fractures occur first in basalt fibers for the specimens with a hybrid ratio of 2∶1(namely B2A1 and B2C1)(see Fig.3).

The fatigue lives under different stress levels are shown in Fig.4.

Fig.2 Failure modes of the specimens with hybrid ratio of 1∶1.(a)B1A1-1;(b)B1A1-2;(c)B1A1-3;(d)B1C1-1;(e)B1C1-2;(f)B1C1-3;(g)B1C1-4;(h)B1C1-5

Fig.3 Failure modes of the specimens with hybrid ratio of 2∶1. (a)B2A1-1;(b)B2A1-2;(c)B2A1-3;(d)B2A1-4;(e)B2A1-5;(f)B2C1-1;(g)B2C1-3

1)The fatigue lives of B-C sheets are higher than those of B-A sheets under the same stress level.

2)The fatigue lives of the hybrid FRP sheets increase with the improvement of the content of carbon fiber or aramid fiber,and the influence of the carbon fiber content improvement to fatigue life is more significant.

3)The fatigue performance of B2A1 is relatively worse,while the fatigue performance of B1C1 and B2C1 is relatively better.B1A1 is at the middle position.

4)When hybrid FRP sheets are used in the strengthening of engineering structures,in order to ensure the fatigue strengthening effect,it is recommended to adopt B1C1,B2C1,B1A1,and the stress levels should be below 70%.

Fig.4 Fatigue lives under different stress levels

2 Fatigue Life Models

Four existing fatigue life models presented by other researchers are used to fit the experimental data,including the models from Refs.[1-4],and the results are shown in Tab.1.Results show that the fitting accuracy and generalization capability of the model in Ref.[2]is relativelybetter on experimental data of four types of intraply hybrid FRP sheets.

Tab.1 Square of correlation coefficient of different models on experimental data

3 Stiffness Degradation Models

Eight existing fatigue stiffness degradation models presented by other researchers are used to fit the experimental data, including the models of Refs.[5-14].The results show that,considering the fitting accuracy and generalization ability, the model of Ref.[14]is the relatively best model.However, the experimental data curve show two inflection points.The first inflection point is caused by damage in the matrix material due to the initial loading,and the second inflection point usually appears near the final failure.But all the existing models have only one inflection point, and thus need to be improved.

Based on the experimental data,a new fatigue stiffness degradation model with dual variables and double inflection points is presented as follows:

wherenis the cycle number;Nis the fatigue life;Eis the stiffness;E(0)is the original stiffness;E(n)is the residual stiffness afterncycles;randCare the experimental constants.According to the experimental data of this paper, it is recommended thatr=0.01 andC=-22.3.

This new model can be used to predict the fatigue stiffness degradation of basalt-aramid and basalt-carbon hybrid FRP sheets.Two sets of experimental data referred to as data(1)and data(2), respectively, from Ref.[14]are also used to verify this new model to see if it is applicable to normal FRP sheets, and the results are shown in Fig.5.

From Figs.5(a)and(b), we can see that the experimental data curve has two inflection points and the fitting curve of the new model also has two inflection points,while the fitting curve of the model of Ref.[14]only has one inflection point,so the new model has relatively better curve fitting result when the experimental data curve has two inflection points.From Figs.5(c)and(d), we can see that the new model has also a relatively better curve fitting result when the experimental data curve has only one inflection point.Therefore, the new model is also applicable to predict the fatigue stiffness degradation of normal FRP sheets.

4 Conclusions

Fatigue experiments on hybrid fiber reinforced polymer sheets with two hybrid types and two hybrid ratios(1∶1 and 2∶1)under different stress levels(from 0.6 to 0.95)are carried out.Conclusions are as follows:

1)The fatigue lives of B-C hybrid FRP sheets are higher than those of B-A hybrid FRP sheets.The fatigue lives of the hybrid FRP sheets increase with the improvement of the content of carbon fibers or aramid fibers,and the influence of the carbon fibers content improvement to fatigue life is more significant.

Fig.5 New model vs.model of Ref.[14].(a)The new model fitting the data(1)of Ref.[14];(b)The model of Ref.[14]fitting the data(1)of Ref.[14];(c)New model fitting the data(2)of Ref.[14];(d)The model of Ref.[14]fitting the data(2)of Ref.[14]

2)The fatigue performance of B2A1 is relatively worse,while the fatigue performance of B1C1 and B2C1 is relatively better.B1A1 is at the middle position.When hybrid FRP sheets are used in the strengthening of engineering structures,in order to ensure the fatigue strengthening effect, it is recommended to adopt B1C1, B2C1,and the stress levels should be below 70%.

3)In the four existing fatigue life prediction models,according to the fitting accuracy to the experimental data of hybrid FRP sheets, the model of Ref.[2]is the relatively best one.In the eight existing fatigue stiffness degradation models,according to the fitting accuracy and generalization capability to the experimental data of hybrid FRP sheets, the model of Ref.[14]is relatively the best one.However, the experimental data curves often show two inflection points,but all the existing models have only one inflection point,and thus need to be improved.

4)A new fatigue stiffness degradation model with dual variables and double inflection points is presented,which is not only applicable to hybrid FRP sheets,but also applicable to normal FRP sheets,so it has a wider range of application.

[1]Reifsnider K L.Fatigue of composite materials[M ].New York:Elsevier Science Publishers, 1991:431-468.

[2]Hwang W,Han K S.Fatigue of composite,fatigue modulus concept and life prediction [J].Journal of Composite Materials,1986,20(2):155-165.

[3]Wu Fuqiang,Yao Weixing.S-N curve model of composite laminate [J].Journal of Mechanical Strength,2004, 26(S1):127-129.(In Chinese)

[4]Wu Zhishen, Wang Xin, Kentaro Iwashita.Tensile fatigue behaviour of FRP and hybrid FRP sheets [J].Composites:Part B,2010,41(5):396-402.

[5]Yang J N, Lee L J, Shen D Y.Modulus reduction and fatigue damage of matrix dominated composite laminates[J].Composite Structures,1992, 21(2):91-100.

[6]Yang J N, Jones D L,Yang S H,et al.A stiffness degradation model for graphite/epoxy laminates [J].Journal of Composite Materials,1990, 24(7):753-769.

[7]Wu W F, Lee L J, Choi S T.A study of fatigue damage and fatigue life of composite laminates [J].Journal of Composite Materials,1996, 30(1):123-137.

[8]Echtermeyer A T, Engh B, Buene L.Lifetime and Young's modulus changes of glass/phenolic and glass/polyester composites under fatigue [J].Composites,1995, 26(1):10-16.

[9]Guo Weiguo, Zhang Kaida.Fatigue residual stiffness for composite laminates [C]//Proceedings of the Fifth National Fatigue Conference.Beijing:China Aviation Society Press, 1991:26-29.(in Chinese)

[10]Li Haitao,Du Shanyi,Feng Peifeng.Fatigue life predicting model for stitched composite laminates[C]//Proceedings of the Fifth National Fatigue Conference.Beijing:China Aviation Society Press, 1991:22-25.(in Chinese)

[11]Whitworth H A.Modeling stiffness reduction of graphite/epoxy composite laminates [J].Journal of Composite Materials,1987, 21(4):362-372.

[12]Zhang D Q, Sandor B I.Damage evaluation in composite materials using thermo graphic stress analysis [C]//Advances in Fatigue Lifetime Predictive Techniques.Philadelphia:ASTM Special Tech Publication, 1992:341-353.

[13]Philippidis T P, Vassilopoulos A P.Fatigue of composite laminates under off-axis loading [J].International Journal of Fatigue,1999, 22(3):253-262.

[14]Yang Zhongqing.Fatigue behavior of glass fiber reinforced polymer composites[D].Nanjing:Nanjing University of Aeronautics and Astronautics, 2008.

[15]Pan Jianwu,Yuan Xigui.Experimental study on mechanical properties of basalt hybrid fiber reinforced polymer sheets [C]//Advanced Materials Research.Kunming,China, 2012:238-241.

[16]China Standards Bureau.GB/T 3354—1999 Test method for tensile properties of oriented fiber reinforced plastics[S].Beijing:China Standards Press, 1999.(in Chinese)

[17]China Standards Bureau.GB/T 1447—2005 Fiber-reinforced plastics composites-determination of tensile properties [S].Beijing:China Standards Press, 2005.(in Chinese)

Journal of Southeast University(English Edition)2013年1期

Journal of Southeast University(English Edition)2013年1期

- Journal of Southeast University(English Edition)的其它文章

- A personalized trustworthy service selection method

- L1-norm minimization for quaternion signals

- Feature combination via importance-inhibition analysis

- W-band sharp-rejection bandpass filter with notch cavities

- Factors affecting headway regularity on bus routes

- Optimization of RDF link traversal based query execution