Experimental investigation on drag reduction in turbulent boundary layer over superhydrophobic surface by TRPIV

Hiping Tin,Jingxin Zhng,Erdn Wng,Zhohui Yo,Nn Jing,c,∗

aDepartment of Mechanics,Tianjin University,Tianjin,30072,China

bDepartment of Engineering Mechanics,School of Aerospace,Tsinghua University,Beijing 100190,China

cTianjin Key Laboratory of Modern Engineering Mechanics,Tianjin 30072,China

Experimental investigation on drag reduction in turbulent boundary layer over superhydrophobic surface by TRPIV

Haiping Tiana,Jingxian Zhangb,Erdan Wanga,Zhaohui Yaob,Nan Jianga,c,∗

aDepartment of Mechanics,Tianjin University,Tianjin,30072,China

bDepartment of Engineering Mechanics,School of Aerospace,Tsinghua University,Beijing 100190,China

cTianjin Key Laboratory of Modern Engineering Mechanics,Tianjin 30072,China

A R T I C L E I N F O

Article history:

Received 30 September 2014

Received in revised form

12 November 2014

Accepted 23 December 2014

Available online 17 February 2015

Superhydrophobic surface

Drag reduction

TBL

TRPIV

Spatial topology

This study aims at the mechanism of drag reduction in turbulent boundary layer(TBL)with superhydrophobic surface.Comparing the time-resolved particle image velocimetry(TRPIV)measurementresults with thatofhydrophilic surface,the drag reduction rate overa superhydrophobic surface isapproximately 10%.To investigate the characteristics of coherent structure in a drag-reduced TBL with superhydrophobic surface,a modified multi-scale spatial locally-averaged structure function is proposed for detecting coherent structure.The conditional sampling and spatial phase-lock average methods are employed to obtain the topology of physical quantities like the velocity fluctuation,spanwise vorticity,and Reynolds stress during eject and sweep process.The results indicate that the suppression of coherent structure burst in the near-wall region is the key mechanism in reducing the skin friction drag for TBL over superhydrophobic surface.

©2015 The Authors.Published by Elsevier Ltd on behalf of The Chinese Society of Theoretical and Applied Mechanics.This is an open access article under the CC BY license(http://creativecommons.org/ licenses/by/4.0/).

The superhydrophobic surface generally refers to special surfaces with hydrophobic chemicals and micro/nanoscale surface roughness,on which the static contact angle of a droplet is usually above 150°and the contact angle hysteresis is less than 10°[1]. Excellent water repellence property and wizardly self-cleaning ability are its main features.Thanks to the rapid development of material science and micro-nano technology,the artificially fabricated superhydrophobic surface has been widely applied to engineering practice.For example,it is used in solar panel surface as antifouling,it is applied to reduce skin friction for saving pumping powerin pipeline,itcan also be applied in underwatervehicle such as torpedoes for speeding up.

The hydrophobic material prevents the water from stepping into the region between the peaks of the roughness,resulting in a shear-free air-water interface.The surprising performance of the superhydrophobic surface has attracted much attention ofscholars and various drag reduction researches were conducted.In laminar flow,most studies were in microtube or micro-channel.Watanabe and Akino[2]got a drag reduction of 14%by measuring the pressure drop.Gruncelletal.[3]performed directnumericalsimulation(DNS)and found that the special surfaces could cause the delay of boundary transition and thus getting a drag reduction efficiency of 50%.Although the results in laminar flows are pretty consistent,there exists discrepancy in turbulent flow.Some studies exhibited drag reduction in TBL,but some indicated no such effect.Min and Kim[4]analyzed several wall boundary conditions by DNS and found the effectofsuperhydrophobic surfaces for turbulentboundary layer(TBL)was actually a combination of two anisotropic mutual influences by the geometry of the surface roughness,that the streamwise slip is conducive to drag reduction but the spanwise slip could cause the anti-drag reduction.

The mechanism of drag reduction in turbulent flow over superhydrophobic surfaces still remains an open problem with its great potentialapplications.At present,few experimentalresearch in centimetre-scale were reported.In this paper,a time-resolved particle image velocimetry(TRPIV)system was employed to investigate the mechanism and the influence caused by a large-scale superhydrophobic test surfaces.The emphases are focused on the changed characteristic of coherent structure in drag-reduced TBL by the presence of superhydrophobic surface.

Experimental setup and apparatus The contrast experiments between hydrophilic plate and superhydrophobic plate have been conducted in an open circulating water channel in Tianjin University,while the two replaceable plates are equal in size of 200 mm ×200 mm×15 mm.The testsection ofchannelis 5.4 mlong,0.3 m high,and 0.25 m wide.The flat plate with superhydrophobic surface,which has micro-nano dual-scale structures[5],was fabricated by Tsinghua University.Based on the result of contact angle measuring device(JC2000CD1),static contact angle was 161°and contact angle hysteresis was 0.9°.

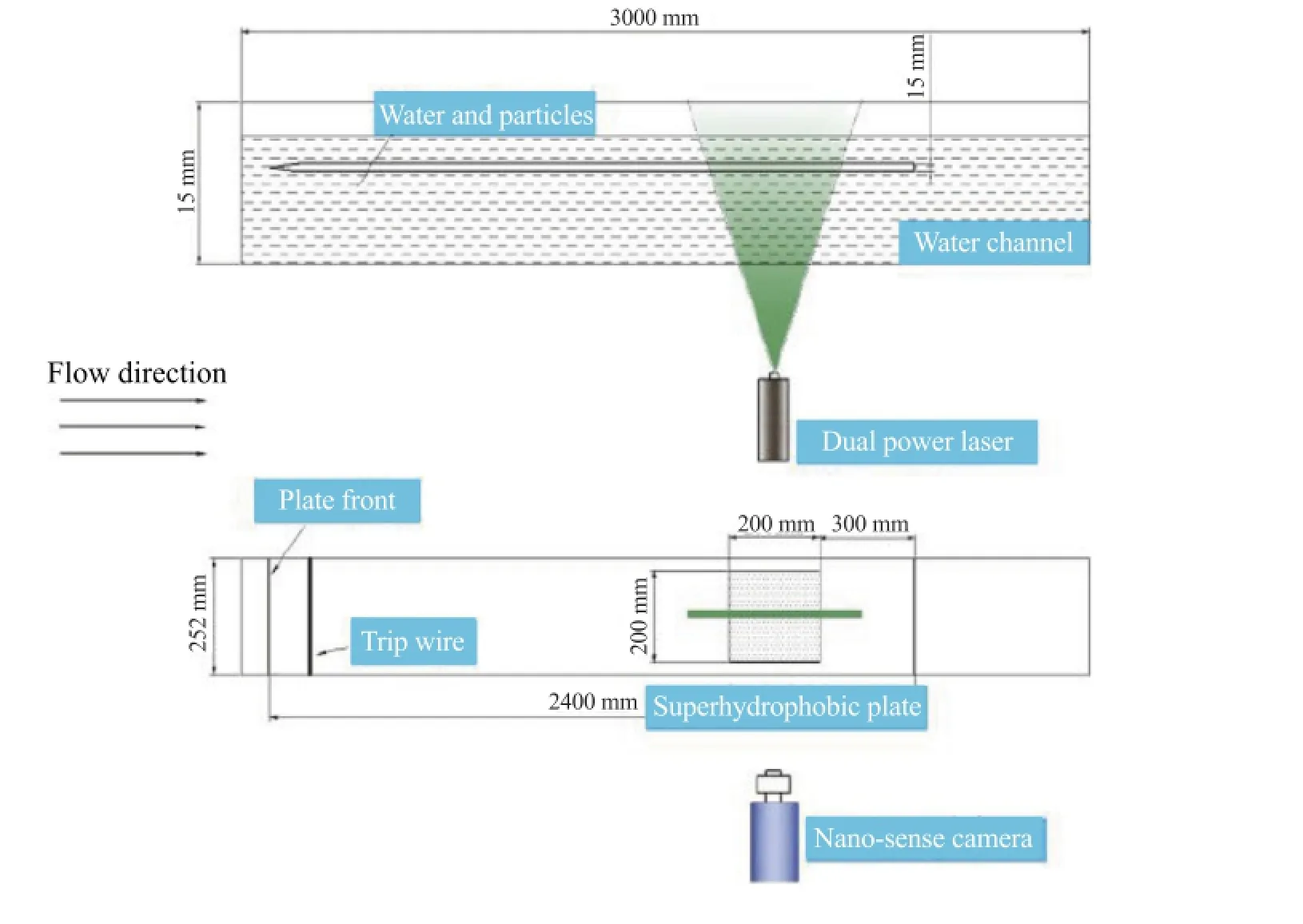

Figure 1 shows the schematic of experimental setup.The TBL was generated by a trip wire which was attached to the leadingedge of the plate.The free-coming stream velocity was 0.17 m/s.A CMOS camera(1280 pixels×1024 pixels)recorded 6001 images for hydrophilic plate and another 6001 images for superhydrophobic plate with the sampling frequency was 500 Hz.The size of flow image is 56.6 mm×45.1 mm(streamwise length×normalheight). The interrogate window for correlation is 32 pixels×32 pixels,and the overlap rate is 75%.157×125 velocity vectors with the spacing of 0.3585 mm are reconstructed for each image.Although the velocity information ofnear wallpoints has a kind ofinaccuracy for wall surface effect by the PIV technique.After subtracting wallnormal distance of wall position,the closest point is obtained,which is 0.3181 mm above the wall and corresponds to y+≈3.

Fig.1.The schematic of experimental setup.

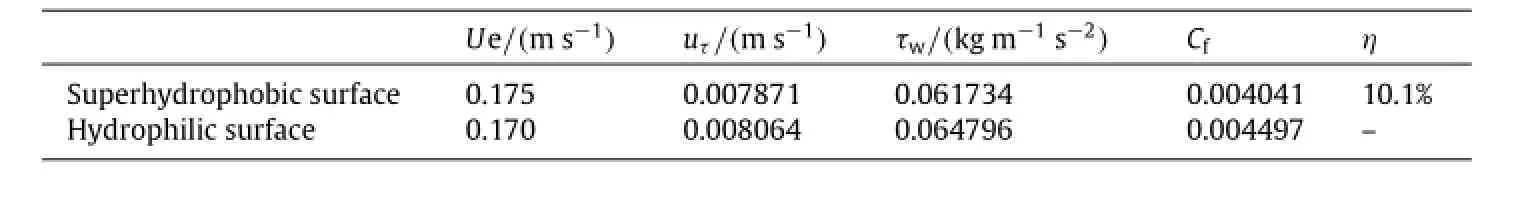

Table 1Flow parameters of the TBL over superhydrophobic and hydrophilic surfaces.

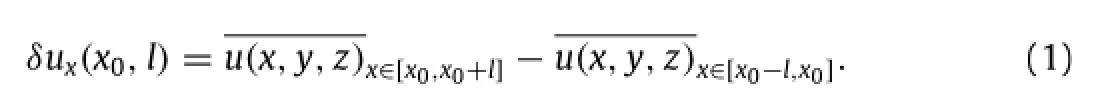

The flow image processing method The idea of multi-scales and local averaged velocity structure function proposed by Liu and Jiang[6]was gradually adopted for detecting coherent structure in TBL.Tian et al.[7]extended this concept into the research of spatial topological mode of coherent structure with three velocity component.Based on the spatial local-averaged velocity structure function,a new detection criterion was introduced to educe the spatial topological mode of coherent structures in TBL.The spatial local-averaged structure function for streamwise velocity component in streamwise direction is defined as

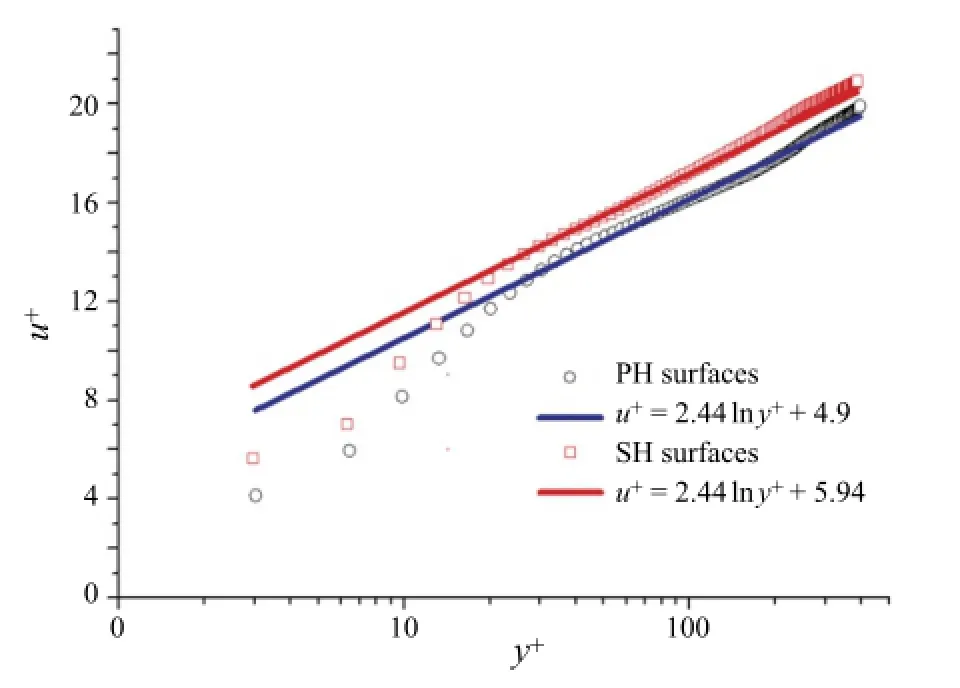

Fig.2.Mean velocity profile in TBL over superhydrophobic and hydrophilic surfaces.

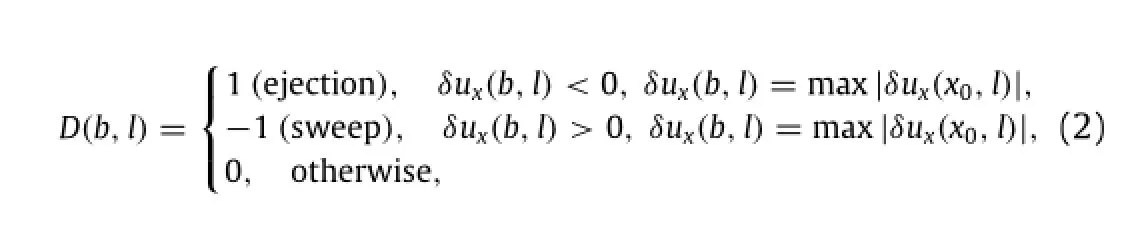

δux(x0,l)is the local-averaged streamwise velocity of an eddy in scale 2l with center located at x0in streamwise direction.Thus the local-averaged streamwise velocity strain reveals the tensile and compressive deformation of eddy structure located at x0within scale 2l.Aconditionaleduction and segmentation algorithm was developed.The conditional sampling criterion based on thestreamwise-streamwise spatial local-averaged velocity structure function can be defined as

Fig.3.Contours offluctuating velocity during ejection.(a)Streamwise for hydrophilic surface.(b)Streamwise for superhydrophobic surface.(c)Normal-wallfor hydrophilic surface.(d)Normal-wall for superhydrophobic surface.(For interpretation of the references to colour in this figure legend,the reader is referred to the web version of this article.)

where D(b,l)is the detection function with l the spatial scale in streamwise direction and b is the spatial location in streamwise direction.

It detectsδux(x0,l)along streamwise direction at each wallnormal layer for which satisfies the detection condition.Then a square area with 32×32(x×y)grid sizes,which corresponding to 11.5 mm×11.5 mm≈108 WU(wall units)×108 WU in two cases,centered at the detected point with a physical quantity was cut out from the instantaneous flow field.

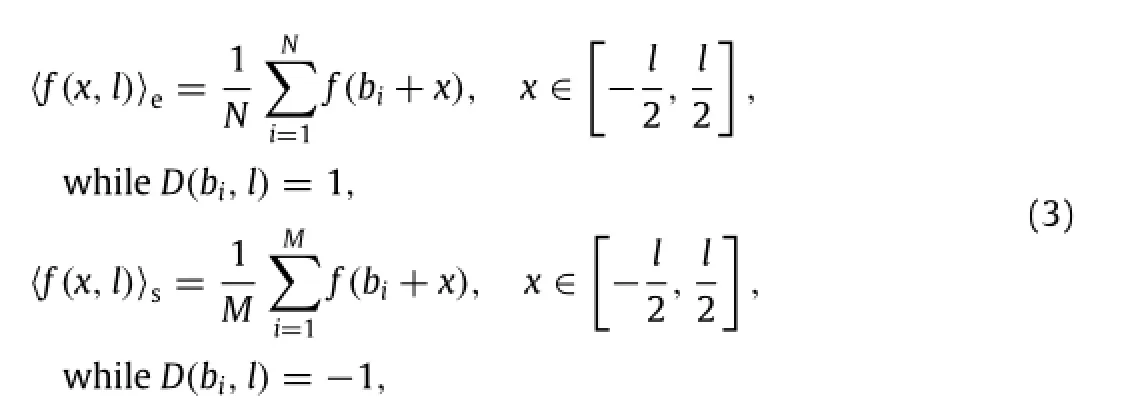

Spatial topology modes of physical quantities of coherent structure,such as fluctuating velocity,velocity gradient,velocity strain rate and vorticity,are obtained by 2D spatial phase-locked average method across these sampled squares.

〈〉represents the samples ensemble average,and f(x,l)is the wondering physical quantities which respectively stands for fluctuating velocity,velocity strain rate or fluctuating vorticity.N is the number of ejection events and M is the number of sweep events.

Results and discussion

The statistic parameters of the TBL over superhydrophobic and hydrophilic surface plates are listed in Table 1.It should be noted that the running status of water channel in the experiment was stable.Through the comparison,the free-stream velocity Ueover superhydrophobic surface is a little higher than that of thehydrophilic one for the same power.This shows that the existence of superhydrophobic surface reduces the skin friction drag in turbulent boundary layer flow and increases mainstream velocity. τwstands for wall shear stress and cfis the skin friction coefficient. Finally,the drag reduction rateηis approximately 10.1%.

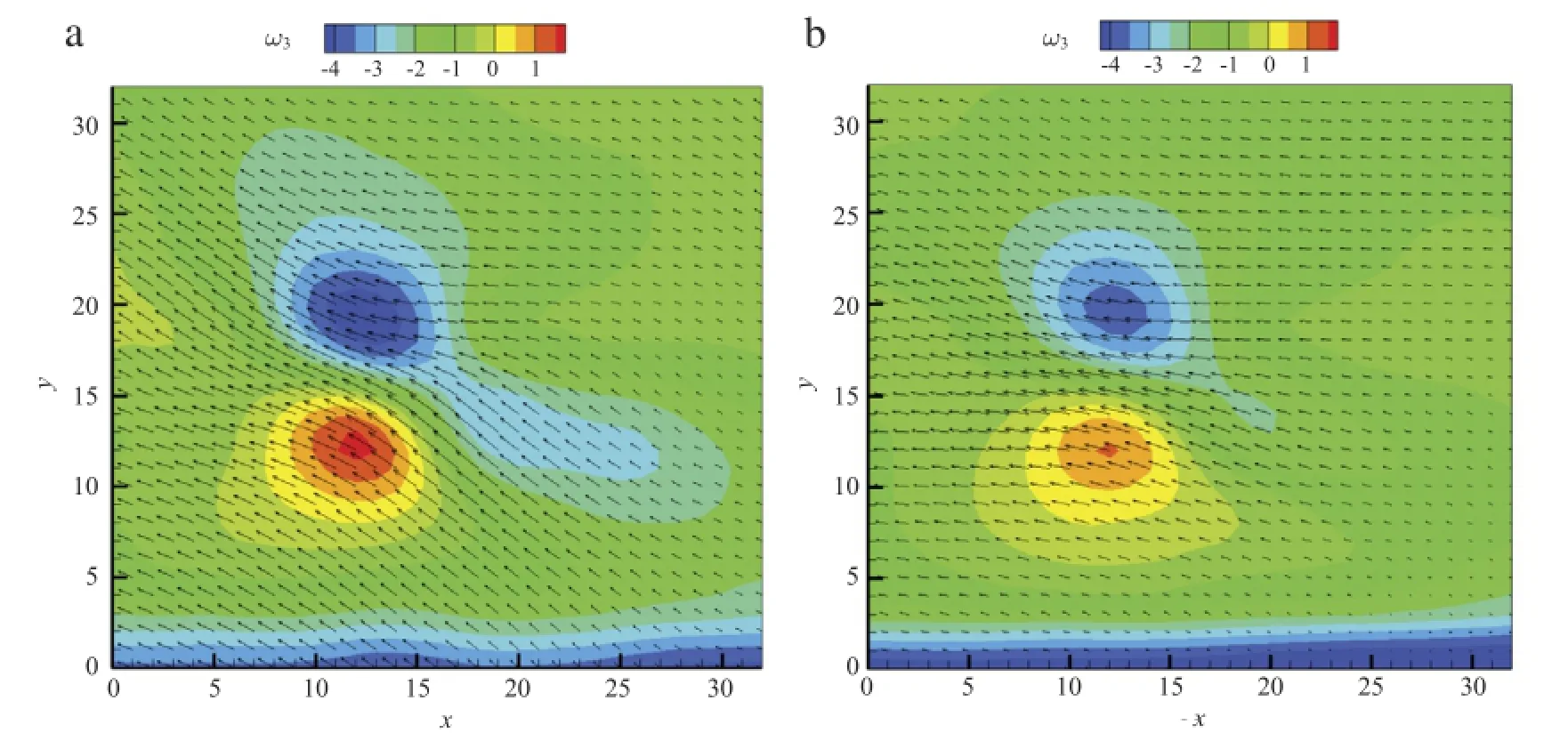

The local averaged velocity structure function was employed to decompose the velocity vector into multi-scales.After conditional sampling detection by Eq.(2)and spatial phase-lock averaging by Eq.(3),the spatial topological coherent structure of physicalquantities including the fluctuation velocity,vorticity,and Reynolds shear stress during the ejection and sweep process are obtained with the spatial scale corresponds to 5.74 mm in streamwise and normal-wall direction.Contours of streamwise fluctuating velocity,normal-wall fluctuating velocity,spanwise vorticity,and Reynolds shear stress during eject events in both cases are shown in Figs.3-5,respectively.

Fig.4.Contours of spanwise vorticity during ejection.(a)Hydrophilic surface.(b)Superhydrophobic surface.

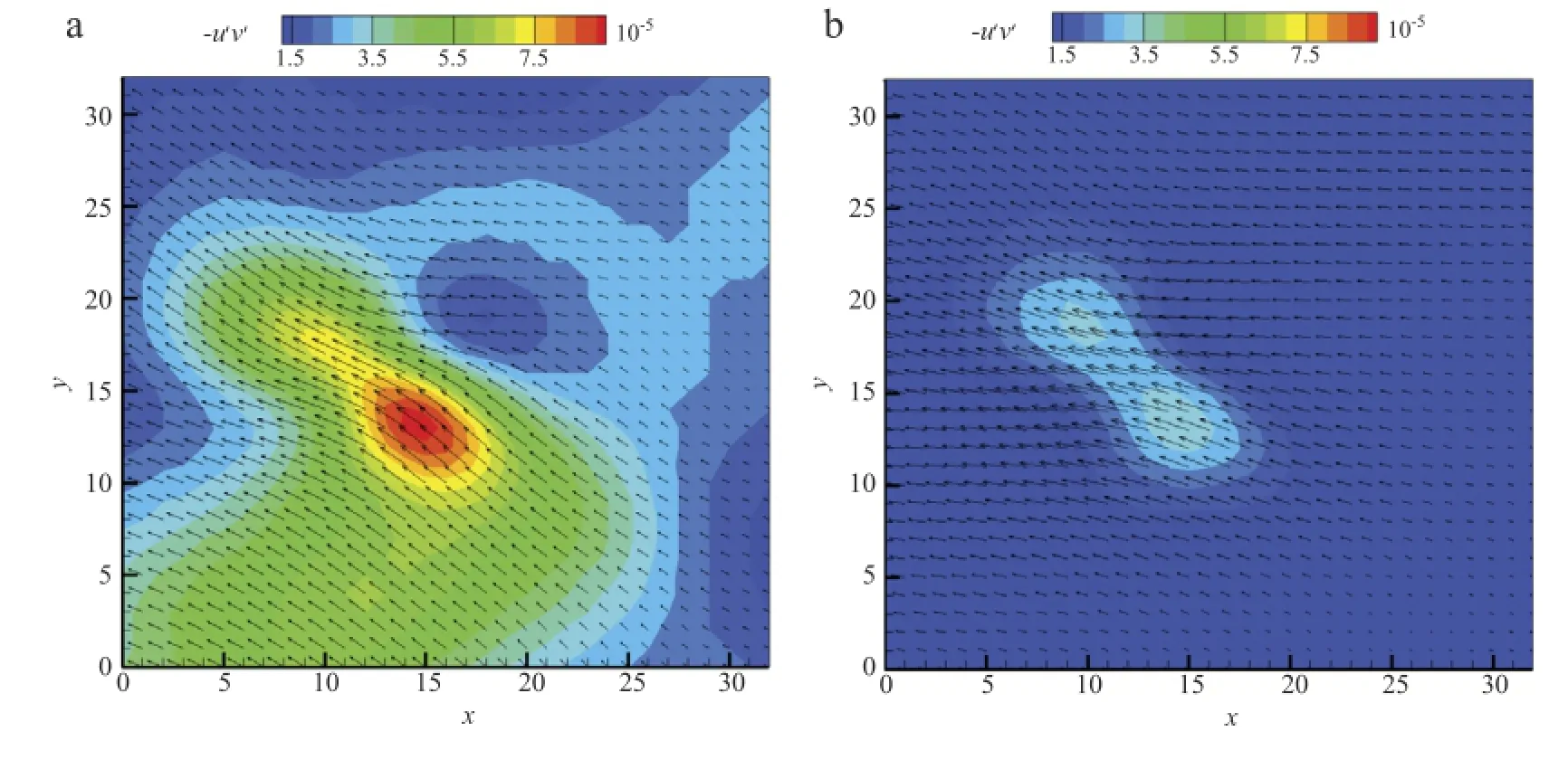

Fig.5.Contours of Reynolds shear stress during ejection.(a)Hydrophilic surface.(b)Superhydrophobic surface.

Compared with the blue regions for the low-speed fluids of both cases in Fig.3,the superhydrophobic surface reduces the magnitude of the streamwise fluctuation velocity u′<0 and the normal-wall fluctuation velocity v′>0 during the low-speed fluids eject.The angle of fluctuating velocity vectors down from the x axis over hydrophilic surface is larger than the situation of superhydrophobic surface.It indicates that the superhydrophobic surface weakened the strength of eject events.In Fig.4,the strength of spanwise vorticityω3is also decreased by the superhydrophobic surface.Moreover,the contour map of Reynolds shear stress,which is thought to be a vital source of the turbulence production,was also shown in Fig.5.Apparently,the strength of Reynolds shear stress over superhydrophobic surface is about one order smaller than that of the hydrophilic case.These results indicate that the existence of superhydrophobic surface greatly depresses the burst events of coherent structures.

In summary,current research implies that the superhydrophobic surface can achieve drag reduction for macroscopic-scale TBL. Despite the process ofgetting the streamwise velocity profiles normalized by the wall friction velocity has the applicability of uncertainty in superhydrophobic case,the superhydrophobic surface produces a result that the log-law layer is lifted up and buffer layer is thicken which was accompanied by a little increase of mainstream velocity.The most important features of turbulent coherent structure associated with the burst events were well captured by conditional sampling and spatial phase-lock average methods. The conditionally averaged fluctuating velocity,spanwise vorticity,and Reynolds shear stress for coherent structure burst are decreased by the superhydrophobic surface,indicating that the suppression of coherent structure burst in the near-wall region is the key mechanism in reducing the skin friction drag for TBL over superhydrophobic surface.

Acknowledgments

This work was supported by the National Natural Science Foundation of China(11272233,11272176,11411130150, and 11332006(key project)),National Basic Research Program(973Program)(2012CB720101 and 2012CB720103).

[1]B.Bhushan,Y.C.Jung,Wetting,adhesion and friction of superhydrophobic and hydrophilic leaves and fabricated micro/nanopatterned surfaces,J. Phys.Condens.Matter 20(2008)225010,http://dx.doi.org/10.1088/0953-8984/20/22/225010.

[2]K.Watanabe,T.Akino,Drag reduction in laminar flow between two vertical coaxial cylinders,J.Fluids Eng.121(1999)541-547.http://dx.doi.org/10.1115/ 1.2823502.

[3]R.K.Gruncell,D.Sandham,G.Mchale,Simulation of laminar flow past a superhydrophobic sphere with drag reduction and separation delay,Phys. Fluids 25(2013)043601,http://dx.doi.org/10.1063/1.4801450.

[4]T.Min,J.Kim,Effects of hydrophobic surface on skin-friction drag,Phys.Fluids 16(2004)55-58,http://dx.doi.org/10.1063/1.1755723.

[5]S.Lu,Z.H.Yao,P.F.Hao,C.S.Fu,Drag reduction in turbulent flows over superhydrophobic surfaces with micro-nano textures,Mech.Eng.35(2013)20-24,http://dx.doi.org/10.6052/1000-0879-13-098.(in Chinese).

[6]W.Liu,N.Jiang,There kinds of velocity structure function in turbulent flows,Chin.Phys.Lett.21(2004)1989-1992,http://iopscience.iop.org/0256-307X/21/10/035.(in Chinese).

[7]H.P.Tian,S.Q.Yang,L.Cheng,Y.Wang,N.Jiang,Antisymmetric quadrupole mode of coherent structures in wall-bounded turbulence,Theoret.Appl.Mech. Lett.3(2013)052002,http://dx.doi.org/10.1063/2.1305202.

[8]X.Fan,N.Jiang,Skin friction measurement in turbulent boundary layer by mean velocity profile method,Mech.Eng.27(2005)28-30,http://dx.doi.org/10.6052/1000-0992-2004-213.(in Chinese).

[9]K.Fukagate,N.Kasagi,A theoretical prediction of friction drag reduction in turbulent flow by superhydrophobic surfaces,Phys.Fluids 18(2006)051703,http://dx.doi.org/10.1063/1.2205307.

∗Corresponding author at:Department of Mechanics,Tianjin University,Tianjin 30072,China.

E-mail address:nanj@tju.edu.cn(N.Jiang).

*This article belongs to the Fluid Mechanics

Theoretical & Applied Mechanics Letters2015年1期

Theoretical & Applied Mechanics Letters2015年1期

- Theoretical & Applied Mechanics Letters的其它文章

- Adjoint-based optimization of flapping plates hinged with a trailing-edge flap

- Numerical simulation of unsteady flows over a slow-flying bat

- Propulsive performance of two-and three-dimensional flapping flexible plates

- Learning from bat:Aerodynamics of actively morphing wing

- A coupled immersed boundary-lattice Boltzmann method and its simulation for biomimetic problems

- A modified criterion for wave-induced momentary liquefaction of sandy seabed