Research and Application of the Molt Salt Energy Storage Heating System with Single Tank

YAO+Junbin+ZHAO+Zhengzheng

Abstract:Purpose To find a molten salt system in heat supply and to research the its situation of application in practical heating project. To resolve the problem of pollution like haze in north of China. Method Designing a molten salt energy storage heating system with single tank which is used in the project. To record the inlet and outlet temperature of the heating water, inside and outside temperature of the environment according to the running situation. Results the average temperature of the supply water is 79.9℃,and the back water is 63.6℃,the temperature range of the room is from 16.3℃ to 20.7℃,the average temperature of the room is 18.4℃ after using the energy storage heating system with single tank. Conclusion The energy storage heating system can not only meet the users need in heating project, but also can eliminate emissions of pollutants completely which provide a new idea for heating project in winter in north of China.

Key words:molten salt;off-peak electricity;heating;energy storage with single tank

In recent years, with the development of economy and the living standard of residents, the governments and residents have paid more and more attention to the quality of environment [1]. In recent years, the haze problem has become a national environmental problem. In China, coal using is an important factor affecting the quality of the environment, especially in northern China. The more pollutants are discharged, the greater the harm to the environment. In addition to generating a large amount of solid particles (including PM2.5), coal will produce harmful gases such as CO2, CO, SO2, NOx, etc., and these harmful gases will react in the atmosphere to produce secondary PM2. 5, Causing significant pollution to the environment and great harm to the human body [2-8].

Currently, common winter "coal to electricity" heating methods are: air source heat pump system, electric boilers, water storage systems and solid thermal storage systems. Among them, the air source heat pump could not be used when the outdoor temperature was extremely low. Electric boiler in the cold season was using the electricity all the day and Annual operating costs are high. Water storage and solid thermal storage system were using only low-power, the costs of annual operating are low, water storage temperature difference is small, although the specific heat capacity, but the storage volume is large, it was not suitable for small room area. In order to raise the upper limit of water temperature, water storage system increased the pressure on the equipment, the entire system are pressure vessels, it is prone to danger. Solid storage system have thermal storage temperature difference, up to 800 ℃ or more, but the heat transfer coefficient is low, and high temperature alternating heat storage magnesia, it is easy to produce chalking phenomenon.

Molten salt as a cooling medium has long been used in the nuclear industry, its physical and stability has been tested. In recent years, to achieve a stable thermal power plant power generation, solar thermal power generation usually used molten salt as a heat transfer and storage medium. It can be concluded that, the molten salt is a very reliable and stable heat storage medium.

1 Introduction of the molten salt energy storage system

Fig.1 Single tank of molten salt thermal storage heating system

Figure 1 is a system diagram of single tank of molten salt thermal storage heating. The molten salts in the tank are heated to high temperature in the off-peak, and its temperature is 430℃ in this case. The air from the fan outlet come into storage tank, and is heated by high temperature molten salt, then come into wind-water exchanger. The molten salts transfer heat to circulating water, and out flow, then re-enter into the fan, completing the circulation. The heat supply return water from heat user enter into wind-water exchanger, and outflow after transferring heat. Then it re-enter into heat user to supply heat, completing the water circulation. The stored heat of molten salts in the storage tank is transferred to heat user by circulation water, which temperature gradually decreased , until to the setting temperature, and in this case, the temperature is 160 ℃.

2 The design selection of main components

2.1 the calculation of the dosage of the molten salt

In the single pot and molten salt regenerative heating system,molten salt is used as a storage medium. Molten salt has high specific heat capacity, wide temperature range of use, and physical properties is very stable, so it is the ideal energy storage medium. In this example, low melting salt as a heat transfer heat storage medium, whitch temperature range 160 ℃ to 430 ℃. Low price of electricity power at night is used to add hot melt salt for energy storage. Molten salt dosage computation formula is as follows:

(1)

M is molten salt dosage on the system, kg;

Q is the amount of energy storage system, kJ;

Cp is the specific heat at constant pressure of the molten salt ,kJ/kg ·℃;

△t is the temperature difference value of the molten salt, ℃;

In this example, the total weight of molten salt is 22 t.

2.2 The fan type selection design

In the single pot and molten salt regenerative heating system, molten salt in the salt storage tank does not flow. The circulating air fan is used to take heat from the hot salt. So the operation of the fan selection for the system is very important.

This project fan selection is as follows:

Table1 The parameters of fan

2.3Type selection design of electric heater

In the single tank molten salt heat storage heating system, the energy of molten salt is stored by the trough power at night。Molten salt electric heater is the key equipment of low temperature electric heating molten salt energy storage system。In the trough period,the molten salt in the tank is heated from 160℃ to 430℃. The relationship between the power of the electric heater , the heat storage and the trough time is as follows:

(2)

Q:Daily consumption,kWh;P :Electric heater power,kW;T:Trough power time,h;η:Magnification factor,0.8.

The parameters of molten salt electric heater in our engineering:

Table2 The parameters of molten salt electric heater

2.4Salt/air heat exchanger

The salt-air heat exchanger is used to exchange the energy from the molten salt into the hot air to realize the energy transfer process. In the single tank molten salt heat storage heating system,the designed inlet air temperature is 110 ℃, and the outlet air temperature is 150 ℃ to 210℃

The volume flow of air is calculated as follows:

(3)

Vair:Volume flow of air,m3/h;Q:User heat load,kW;C:molten salt heat capacity,kJ/kg·℃;ΔT:Air outlet temperature difference,℃;ρ:molten salt density,kg/m3;σ2:Efficiency of air- water heat exchanger;σ3:Efficiency of salt-air heat exchanger

The parameters of molten salt electric heater in our engineering:

The parameters of the air side of the salt-air heat exchanger

Table3 The parameters of salt/air heat exchanger fin side

2.5 The design of type selection of air/water heat exchanger

In the project of transforming a process ,generally does not consider the end of heating in order to reduce the modification cost . In this project ,still use water as the heating medium to supply heat for the user . The wind/water heat exchanger is an equipment that transfer the energy from hot wind to water .

In this project ,the parameters of water side of the wind/water heat exchanger can be shown in the table below.

Table4 The parameters of wind/water heat exchanger fin side

3 The acquisition of experimental data

The single tank heating system of molten salt is composed of molten salt tank, air-molten salt heat exchanger, water-air heat exchanger and molten salt electric heater etc.. In this project, we take ground measurement to the an office building in Fuxin which is using the single tank molten salt heat storage heating system. The office building is 6000 square meters with 24 hours heating. The vally electricity time begin from 22:00 to 6:00 the next day. The data of the control cabinet to half hour intervals from November 4, 2016 18 to November 30th 18 measurement, a total of 1248 data sets. The measured data includes the?temperature of the molten salt tank, the entrance temperature and the outlet temperature of the air in molten salt-air heat exchanger, the entrance temperature and the outlet temperature of the water in water-air heat exchanger, the indoor and outdoor temperature.

4 The analysis of experimental data

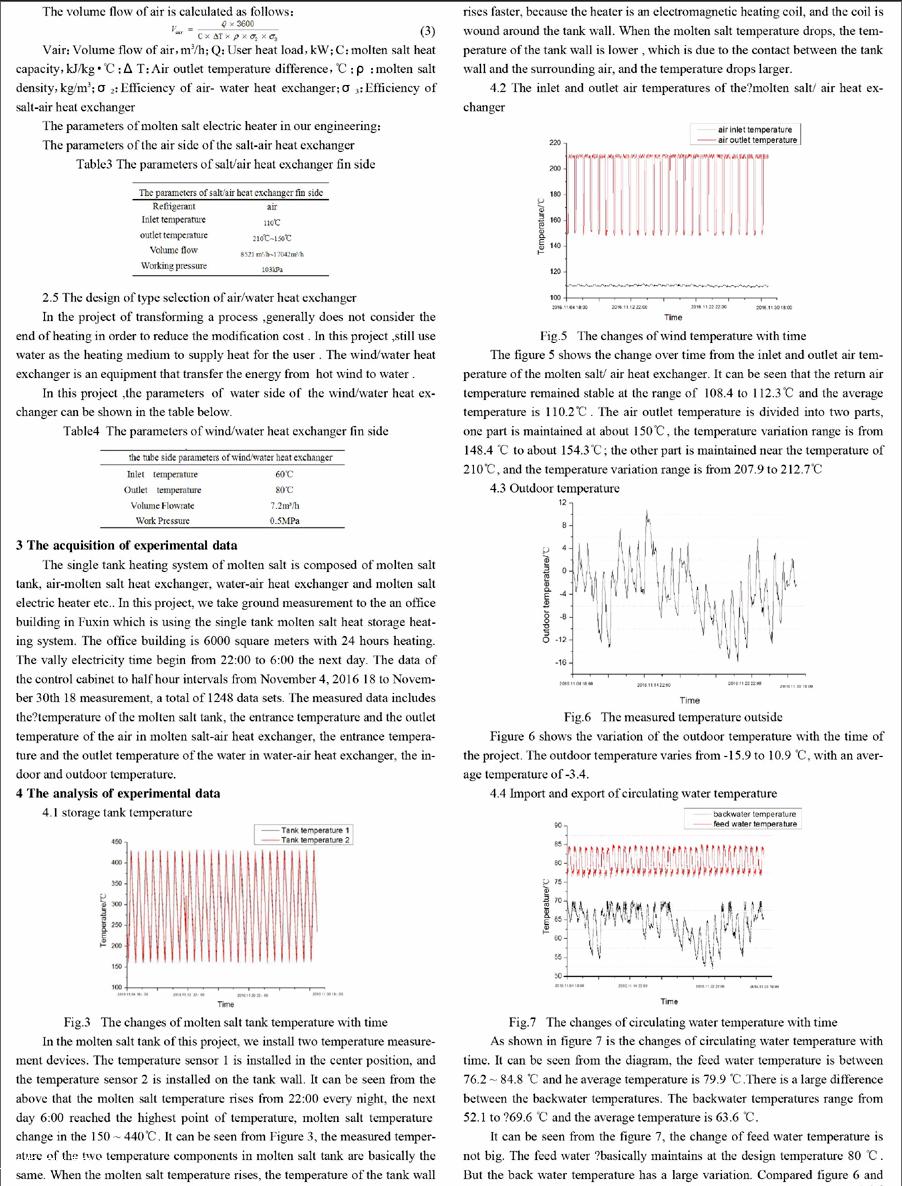

4.1 storage tank temperature

In the molten salt tank of this project, we install two temperature measurement devices. The temperature sensor 1 is installed in the center position, and the temperature sensor 2 is installed on the tank wall. It can be seen from the above that the molten salt temperature rises from 22:00 every night, the next day 6:00 reached the highest point of temperature, molten salt temperature change in the 150 ~ 440℃. It can be seen from Figure 3, the measured temperature of the two temperature components in molten salt tank are basically the same. When the molten salt temperature rises, the temperature of the tank wall rises faster, because the heater is an electromagnetic heating coil, and the coil is wound around the tank wall. When the molten salt temperature drops, the temperature of the tank wall is lower , which is due to the contact between the tank wall and the surrounding air, and the temperature drops larger.

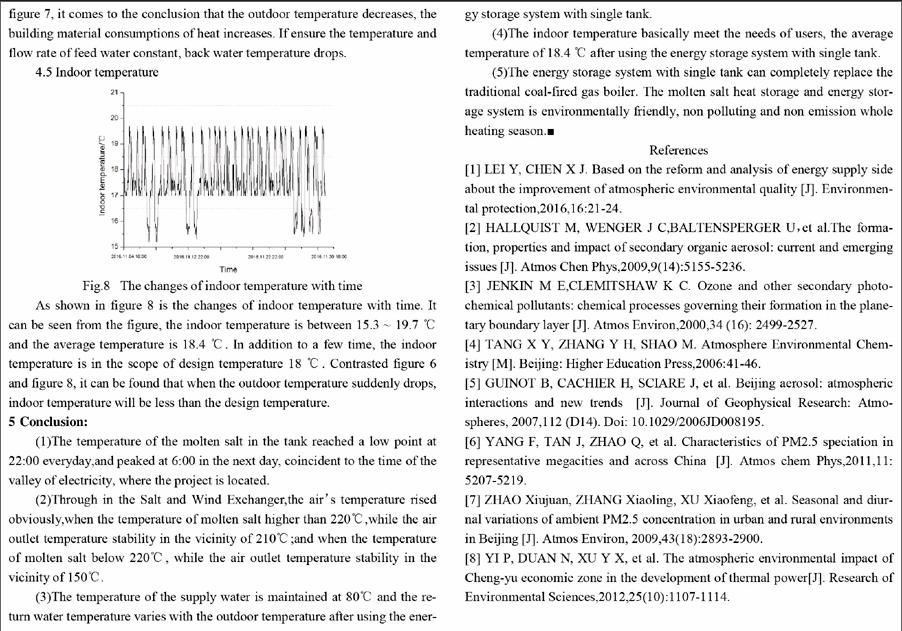

4.2 The inlet and outlet air temperatures of the?molten salt/ air heat exchanger

The figure 5 shows the change over time from the inlet and outlet air temperature of the molten salt/ air heat exchanger. It can be seen that the return air temperature remained stable at the range of 108.4 to 112.3℃ and the average temperature is 110.2℃. The air outlet temperature is divided into two parts, one part is maintained at about 150℃, the temperature variation range is from 148.4 ℃ to about 154.3℃; the other part is maintained near the temperature of 210℃, and the temperature variation range is from 207.9 to 212.7℃

4.3 Outdoor temperature

Figure 6 shows the variation of the outdoor temperature with the time of the project. The outdoor temperature varies from -15.9 to 10.9 ℃, with an average temperature of -3.4.

4.4 Import and export of circulating water temperature

As shown in figure 7 is the changes of circulating water temperature with time. It can be seen from the diagram, the feed water temperature is between 76.2 ~ 84.8 ℃ and he average temperature is 79.9 ℃.There is a large difference between the backwater temperatures. The backwater temperatures range from 52.1 to ?69.6 ℃ and the average temperature is 63.6 ℃.

It can be seen from the figure 7, the change of feed water temperature is not big. The feed water ?basically maintains at the design temperature 80 ℃. But the back water temperature has a large variation. Compared figure 6 and figure 7, it comes to the conclusion that the outdoor temperature decreases, the building material consumptions of heat increases. If ensure the temperature and flow rate of feed water constant, back water temperature drops.

4.5 Indoor temperature

As shown in figure 8 is the changes of indoor temperature with time. It can be seen from the figure, the indoor temperature is between 15.3 ~ 19.7 ℃and the average temperature is 18.4 ℃. In addition to a few time, the indoor temperature is in the scope of design temperature 18 ℃. Contrasted figure 6 and figure 8, it can be found that when the outdoor temperature suddenly drops, indoor temperature will be less than the design temperature.

5 Conclusion:

(1)The temperature of the molten salt in the tank reached a low point at 22:00 everyday,and peaked at 6:00 in the next day, coincident to the time of the valley of electricity, where the project is located.

(2)Through in the Salt and Wind Exchanger,the airs temperature rised obviously,when the temperature of molten salt higher than 220℃,while the air outlet temperature stability in the vicinity of 210℃;and when the temperature of molten salt below 220℃, while the air outlet temperature stability in the vicinity of 150℃.

(3)The temperature of the supply water is maintained at 80℃ and the return water temperature varies with the outdoor temperature after using the energy storage system with single tank.

(4)The indoor temperature basically meet the needs of users, the average temperature of 18.4 ℃ after using the energy storage system with single tank.

(5)The energy storage system with single tank can completely replace the traditional coal-fired gas boiler. The molten salt heat storage and energy storage system is environmentally friendly, non polluting and non emission whole heating season.

References

[1] LEI Y, CHEN X J. Based on the reform and analysis of energy supply side about the improvement of atmospheric environmental quality [J]. Environmental protection,2016,16:21-24.

[2] HALLQUIST M, WENGER J C,BALTENSPERGER U,et al.The formation, properties and impact of secondary organic aerosol: current and emerging issues [J]. Atmos Chen Phys,2009,9(14):5155-5236.

[3] JENKIN M E,CLEMITSHAW K C. Ozone and other secondary photochemical pollutants: chemical processes governing their formation in the planetary boundary layer [J]. Atmos Environ,2000,34 (16): 2499-2527.

[4] TANG X Y, ZHANG Y H, SHAO M. Atmosphere Environmental Chemistry [M]. Beijing: Higher Education Press,2006:41-46.

[5] GUINOT B, CACHIER H, SCIARE J, et al. Beijing aerosol: atmospheric interactions and new trends [J]. Journal of Geophysical Research: Atmospheres, 2007,112 (D14). Doi: 10.1029/2006JD008195.

[6] YANG F, TAN J, ZHAO Q, et al. Characteristics of PM2.5 speciation in representative megacities and across China[J]. Atmos chem Phys,2011,11: 5207-5219.

[7] ZHAO Xiujuan, ZHANG Xiaoling, XU Xiaofeng, et al. Seasonal and diurnal variations of ambient PM2.5 concentration in urban and rural environments in Beijing [J]. Atmos Environ, 2009,43(18):2893-2900.

[8] YI P, DUAN N, XU Y X, et al. The atmospheric environmental impact of Cheng-yu economic zone in the development of thermal power[J]. Research of Environmental Sciences,2012,25(10):1107-1114.