织造设备

高效智能 品種适应性强

喷气织机继续向高速、高效、品种适应性强等方向发展,同时在设备的智能化、自动化方面有进一步深化的趋势。相对于其他机型来说,喷气织机降低能耗是一个永恒的话题。进一步创新织机织造关键工艺和设备,加快产品的连续化、自动化、高效化和个性化研究,进一步实现环保生产,正在成为织造设备企业今后的努力重点。

同时,加强织机的模块化、通用化设计,以及实现原有产品和装置之间的互换,满足用户对不同织物品种的工艺要求,降低纺织企业的生产成本正在成为新的发展趋势和方向。

Efficient, smart, adaptable

Air-jet looms continue to develop towards high speed, high efficiency and variety adaptability, while there is a further deepening trend in smart and automatic equipment. Compared to other models, to reduce energy consumption of air-jet looms is an eternal topic. Further innovation of key technology and equipment to speed up the research of continuous, automated, efficient and personalized products for further environmental production is now becoming a focus for the weaving equipment businesses in the future.

Meanwhile, strengthening the modular and universal design of looms, as well as realizing the exchange of existing products and devices to meet the user requirements for technologies of different fabric varieties, and reducing production costs of textile enterprises is becoming a new trend and direction.

牛牌纺机 凸轮开口装置填补国内空白

Niupai Textile Machinery: Cam shedding device fills in the blank in China

江苏牛牌纺织机械有限公司是国家高新技术企业,江苏省织机开口工程技术研究中心,江苏著名商标企业,专业从事各种无梭织机开口装置的研发、生产、销售,并在国内外多地设有4S店,全方位满足客户需求。主要产品有凸轮开口装置、机械多臂开口装置、电子多臂开口装置、电子提花机、综框器材等。先后获得多项国家专利,多项产品被认定为国家重点新产品、高新技术产品等,其中凸轮开口装置在喷水织机上的应用填补了国内空白,被列为国家火炬计划项目。

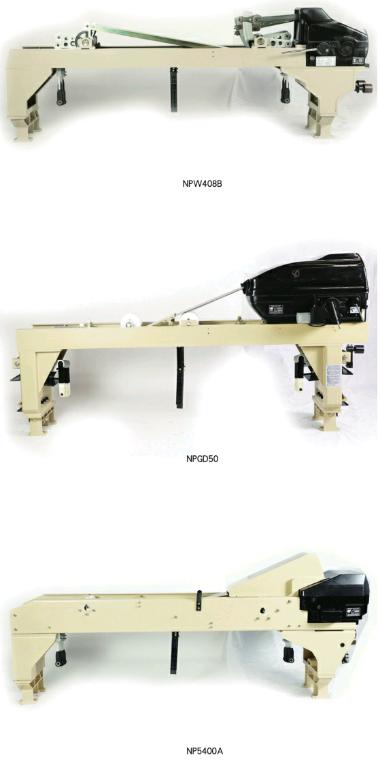

? NPW408B上置积极式高速凸轮开口是津田驹、丰田公司首选配套产品。可织制平纹、斜纹、缎纹等织物组织,已开发147个品种,可根据不同织物的工艺要求设计停顿角。箱体采用整体结构,其刚性强、制造精度高、共轭性能好,能满足重磅高速织物的需求。江苏恒力集团、台湾华隆集团使用均超万台,与多家织机制造商配套替代平开口装置。

? NPGD50多臂开口全套引进日本YAMADA技术,并通过创新获得自主知识产权,可织造1020循环纬数织物,特点是结构简单、操作方便、性价比高。年均销售5000台,国内外市场占有率60%以上。

? NP5400A电子多臂是适用于13000循环纬数的智能化开口,可替代国外同类产品。其特点是结构紧凑,操作简易,特别适用于高速、宽幅等不平衡织物组织,能耗比机械多臂开口低1/3。在时尚织物品种变化快、周期短、技术力量强的企业尤为受欢迎。

? NP6016电子提花开口装置采用16列纵向组件排列,结构紧凑、轻巧、坚固,能满足高速需求,与剑杆、喷水、喷气织机等配套,油浴式共轭凸轮驱动,同心轴传动,可根据织物织造需求选择不同停顿角的清晰开口,承载能力强,组件寿命长,操作便捷、耗能低、维护成本小。具有电器自检功能,可织制领带、商标、毛巾、服装面料、里料。

Jiangsu Niupai Textile Machinery Co., Ltd. is a national new high-tech enterprise, Jiangsu provincial research center of loom shedding engineering technology, Jiangsu famous trademark enterprise. The company specializes in R&D, production and sales of all sorts of shuttleless loom shedding devices. Sales-and-service shops are set up in many places at home and abroad to comprehensively meet customers needs. The core products are cam shedding device, mechanical dobby, electronic dobby, electronic jacquard, heald frame and etc. The company has earned many national patents. Many products are identified as the states key new products, new high-tech products. Among them, the application of cam shedding device on water-jet loom has filled a domestic gap in this field, and is listed in China Torch Program.endprint

? NPW408B, whose frame box adopts integral structure, is top-mounted high-speed positive cam shedding device. Its the first choice of Tsudakoma and Toyota as complementary product of their looms. They are capable of weaving plain, twist, satin as well as other fabric weaves within 12 weft picks; 147 patterns have been developed for them; stoppage angle can be designed based on respective process requirements of different fabrics. With the property of strong rigidity, high manufacturing precision, excellent conjugacy, it can meet the needs of high speed and heavy duty loom. More than 10 thousand sets are used by Jiangsu Hengli Group and Taiwan Hualong Group respectively.

? NPGD50 Mechanical Dobby is designed based on in- troduced full set Japanese YAMADA technologies and earns independent intellectual property right through innovation. Its widely applied to water-jet looms. With advantages of more weft picks, simple structure, easy operation and high cost-effectiveness, the device has occupied over 60% of market share.

? NP5400A Electronic Dobby is top-mounted intelligent positive shedding device. The lubrication oil is forced to circulate via oil pump, and oil level sensor is adopted to avoid lacking oil. Its characterized by compact structure and easy operation. Thus, it is especially suitable for fast speed and wide unbalanced fabrics. Its energy consumption is 1/3 less than mechanical dobbys. The device is particularly popular among enterprises with fast changeover of fashion fabrics, short lifecycle and advanced technologies.

? NP6016 Electronic Jacquard Shedding Device features longitudinal arrangement of 16 lines of components. With the advantages of compact structure, light weight and robustness, the device can meet the needs of high speed running. it is applied to rapier, water-jet and air-jet looms. Its driven by oilbath conjugated cam and concentric shaft. Different stoppage angles can be selected to create clear opening for meeting various weaving needs of multifarious fabrics. The Jacquard machines features strong bearing capacity, components of long service life, easy and convenient operation, low consumption and less maintenance cost. NP6016 is equipped with electrical self-check function. Its capable of weaving tie, trademarks, towels, clothing fabric and lining.

郑纺机GA313型宽幅高效浆纱机

Zhengzhou Textile Machinery: GA313 wide high-efficient sizing machine

GA313型寬幅高效浆纱机是郑纺机研制的新一代高端宽幅浆纱机。该机车身工作幅宽2400mm,车头最大工作幅宽4000cm,适用于各种短纤纤维上浆工艺,特别是高支高密宽幅家纺,满足各类宽幅单织轴、双织轴喷气织机、高速剑杆织机等,先进的工艺流程,有效的降低纱线的覆盖系数,减少经轴数量,效率大幅提高,解决了多头份,大张力工艺方面的问题。endprint

GA313型寬幅高效浆纱机具有多项技术创新:高支、高密、宽幅织物的高效上浆技术,解决了双织轴织造过程中纱线张力差异大,布幅不平整,产品优等率不高的问题,大幅提高浆纱机生产效率和织造质量;宽幅高压均匀轧辊的成对设计和制造技术,满足宽幅高压上浆工艺需求,为宽幅单轴上浆代替双轴分别上浆提供技术保障,并减轻烘燥负担,有效提高车速,增产、节能效果显著;宽幅、大卷装、大张力卷绕车头的设计和制造技术,满足超宽幅经纱大张力均匀卷绕需求,实现恒张力、变张力等方式卷绕,满足不同的卷绕工艺要求,提高浆纱机织轴卷绕质量;浆纱机干、湿区张力控制技术,解决了浆纱过程中高、低速状态,总经根数不同,品种不同,张力变化大的控制问题,提高浆纱机的控制精度。

GA313 wide high-efficient sizing machine is a new generation developed and manufactured by Zhengzhou Textile Machinery. The working breadth of the machine is 2,400mm and the biggest working breadth of the head is 4,000 cm. It is suitable for the sizing technologies of various short fibers, especially the home textiles in high count and high density. It can satisfy various wide width single driving shaft, double driving shaft air jet loom, high-speed rapier loom and so on. Its advanced technological process can reduce the covering coefficient of the yarns effectively, decrease the quantity of the beam and increase the efficiency dramatically, solving the technological problems of multithread division and big tension

GA313 wide high-efficient sizing machine has several technological innovations: the high-efficient sizing technology on the high-count, high-density and wide-breadth textiles can solve the problems of great tension variations of the yarns, uneven cloth width, low efficiency of good quality products and so on in the double driving shaft weaving process, thus improving the manufacturing efficiency and weaving quality dramatically. The pairing design and manufacturing technology of the even roller in wide breadth and high pressure can satisfy the technological demand of sizing in wide breadth and high pressure, so as to provide technological guarantee to use the single shaft sizing in wide breadth to replace the separated sizing of two shafts, relieve the drying burden, accelerate the speed effectively, have significant production increasing and energy conservation effects. The design and manufacturing technology of the winding head in wide breadth, large package and high tension can satisfy the even winding demand of the warp in super wide breadth in high tension, realize the winding in constant and changeable tensions, reach requirements of different winding technologies, improve the shaft winding quality of the sizing machine. The technology of controlling the tensions in dry and wet areas of the sizing machine can solve the control problems of great tension variations caused by the different speeds, different warp quantities and different varieties in the sizing process, thus improving the control accuracy of the sizing machine.endprint

常熟紡机

Changshu Textile Machinery: A brief introduction to the exhibited products

今年,参加上海国际纺织工业展览会的展品,均是2016-2017年开发的新品,展品涵盖公司三大系列产品。其中D2861是今年新研发的高速电子多臂,就是为了适应高档、高速剑杆织机配国产电子多臂的需求,一旦批量投入市场,将填补这一领域高速开口的国内空白,市场前景可期盼。

D2861型电子多臂主要适用于工艺转速在550~600rpm的国内外各类高档剑杆织机,用于织造棉、毛、丝、麻等原料的平纹、斜纹和小花纹织物。它的特点是高效能生产,织物质量高,对环境影响小,用途广泛。

D2869型电子多臂是本公司2016年开发的一款为高速喷水织机配套的电子多臂。用于高效织造棉、毛、丝、麻等为原料的平纹、斜纹和小花纹织物。最高转速是650rpm,适用于JW系列、HJ系列、ZW系列等各类国产、进口高档喷水织机,采用全自动电子控制、存储方式和高可靠性机械结构,适应织机翻改品种范围较广,新型封闭式回综机构更加美观。经过近一年市场推广,已得到许多用户的认可和欢迎。

JL2410电子提花机:24列,适用于喷气、剑杆、片梭等各类无梭织机,用于织造大提花织物,目前针数从5376~9216针。

S1353积极式凸轮开口装置是一款高速踏盘,采用积极式共轭凸轮。适用下置式、10片装,齿轮泵主动顺滑,顺滑效果好,操作放便,适应织造平纹、斜纹造物。

经过这几年来的开发,公司的产品已基本上能为国内外各类织机配套,满足不同转速、不同档次,逐步进入了高端市场,实现了高速化、电子化、个性化和系列化。

The products exhibited in ShanghaiTex 2017 are all new products developed in 2016 - 2017, covering the three big series of the company, in which, D2861 is the newly-developed high-speed electronic dobby. It is designed to satisfy the requirement that the high-end and high-speed rapier loom is equipped with the domestic electronic dobby. Once it is put into the market, it will fill in the domestic blank in China in this area with promising market prospect.

D2861 electronic dobby is mainly suitable for various high-end rapier looms at home and abroad with the technological revolving speed within 550 - 600 rpm to weave the plain, twill and faconne made of such raw materials as cotton, fur, silk, and linen. Its characteristics include high-efficient manufacturing, high fabric quality, little influence to the environment and wide application.

D2869 electronic dobby is developed by the company in 2016 for the high-speed hydraulic loom. It is used to the plain, twill and faconne made of such raw materials as cotton, fur, silk and linen. Its maximum speed is 650 rpm. It is suitable for various domestic and imported high-end hydraulic looms of JW series, HJ series and ZW series. It adopts full-automatic electronic control, storage mode and highly reliable mechanical structure. It has a wide scope to get adapt to the loom renovation varieties. The new enclosed down-pull element is more beautiful. After being promoted in the market for almost one year, it is recognized and welcome by many users.

JL 2410 electronic jacquard machine: 24 rows, suitable for various shuttleless looms such as air-jet looms, rapier and projectile shuttle. It is used to weave big jacquard. At present, the gauge is 5,376 - 9,216 needles.endprint

S1353 positive cam opening equipment: it is a kind of high-speed shedding cam. It adopts the positive conjugate cam. It is suitable for the underneath type, with 10 pieces. The gear pump is active and smooth. It has a good smooth effect and easy operation. It is suitable for knitting the plain and twill fabrics.

After the development of these years, the products of the company can be assorted to almost various domestic and overseas textile machines and satisfy the requirements of different revolving speeds and levels. At present, it is gradually entering into the high-end market, with high speed, electronization, individuation and serialization being realized.

薩维奥 为中国客户提供高效、节能和用工少的络筒机

Savio: Exhibiting the Polar Evolution

意大利萨维奥机械设备公司自1911年即开始专注于纺纱后纺机械设备的研发,至今已发展成为在络筒机、倍捻机和气流纺机领域技术领先的供应厂商,其生产制造工厂分布于意大利、中国、印度和捷克共和国。

做为一家纺织机械的制造商,萨维奥公司生产的络筒机已成为满足各种不同生产需求的理想选择,更可以协助用户开发新的应用方式来应对纺织行业日趋激烈的市场挑战。

本届展会,萨维展出最新开发的Polar Evolution(博纳优+)型络筒机,它在工艺、效益、质量和维护各个方面汇集了所有的技术革新方案。在实现纺织现代化的过程中,尤其在中国,投资将主要集中于采用全自动的络筒机去取代使用圆形纱库型的喂入方式。而现实情况往往是,很多的纺纱厂仍然使用旧一代的细纱机,大部份不带自动落纱装置。

SAVIO此次展出的络筒机是独立式全自动,设备提供新的附加功能特征,用以加工“不太友好“的管纱 。

萨维奥提供一个崭新设计的喂纱斗─“阶梯式整理喂入装置(PSF)”去处理那些有缠结、纠缠牵连和纱尾错乱位置等成型不良而在喂入过程中容易造成堵塞的管纱,从而优化其喂入的速度和顺畅性。

博纳 EVOLUTION 亦提供专用的解决方案,设计用于全自动型络筒机的自动装置(如预备管纱装置,管纱输送等)来控制和加工弹力纱。在加工单芯或双芯纱时,可提供一套用在找头器上的特殊“氨纶纱套件”,使管纱准备的效率达到最高。

为了应付纺织纤维的发展趋势和各种纱线的结构,博纳EVOLUTION呈献:崭新的EVO槽筒,以改善筒纱退绕时的表现;在下游工序中,改善筒纱的退绕状态和速度有利于提高生产效率,从而获得更好的利润;一整套的槽筒系列可以覆盖所有纱线种类和纱支的生产要求,从而满足下游工序不同的要求。

EVO槽筒通过变化的槽筒圈数及卷绕角可优化筒纱的退绕速度和筒纱成形。而优化的筒纱成形可获得在下游工序中更好的退绕比率,同时获得均匀的筒纱密度并降低退绕时的断头率。

接头解决方案的升级,博纳EVOLUTION的卷绕系统配备技术创新的捻接装置以确保获取理想的接头。

空捻和水雾捻 采用双重空气喂入系统,分别用于预备纱尾和捻接。这个独立分隔的空气系统可以个别设定最合适的气压值,用来轻松地捻接不同的纤维和其混纺组合。

关于萨维奥(Savio)纺织机械公司

由企业家马尔切洛 萨维奥(Marcello Savio)于1911年在意大利东北的波代诺内市(Pordenone)创立。成立当初是一个小工厂,替本地工业生产纺织零部件。今天萨维奥已经是生产后纺领域机械的领导者,在世界各地生产和营销自动络筒机、热定型络筒机、倍捻机和气流纺机,生产设施遍布于意大利、捷克共和国、中国和印度。扎根于一个世纪之前的,成就于马尔切洛 萨维奥的天赋和技能,经历不断的进化,通过这些年间以研发为基准点的创进,达至最高的生产灵活性和高质量标准。

Since 1911, Savio has been specialized in the yarnfinishing segment, being the leading supplier of winding, twisting and rotor spinning machines, with manufacturing plants spanning over Italy, China, India and Czech Republic. As a manufacturer of textile machinery, Savio offers winding systems that are ideal for many different needs.

The Polar Evolution winding machine: A high performance, energy saving and less labor-intensive product for the Chinese customersendprint

The Polar winders have been recently developed to the Evolution series, gathering all the innovative solutions in terms of technology, efficiency, quality output and maintenance. The winder on display, is a freestanding fully automated one, provided with new special features to process“unfriendly” bobbins. Savio proposes a newly designed hopper “Pace Sorter Feeder” to optimize a fast and smooth flow feeding of yarn bobbins whose formation and shape, show entanglements, misplaced yarn tails, often tied together, creating bobbin jams.

Polar Evolution is also provided with dedicated solutions, engineered for automatic devices (bobbin preparation, transport, etc.) present in the fully automatic winder models, to control and process springy elastic yarns. A special “Lycra kit” is available for yarn end finder station, in case of fully automatic winding machines, to grant the highest efficiency for the bobbin preparation in presence of single or dual core yarns.

Polar Evolution presents:

New Evo drums for improving package-unwinding performance

A complete range of grooved drums cover all yarn types, counts for different downstream processes. The EVO drums offer new capabilities to optimize both the packages unwinding speed and their yarn content, through variable number of turns with different winding angles. The package shape is optimized in order to obtain advantages for a better unwinding ratio in the downstream process, as well as for homogeneous package density and for lower rewinding breaks.

Upgraded splicing solutions

The Polar Evolution winding unit is now equipped with innovative splicing devices for ensuring perfect joints. Air and Moistair? splicers boasts a Duo Air Feeding system, for yarn tail preparation and splicing. This air separation system, allows the individual setting of the most appropriate value of air pressure, and makes these splicers able to easily process any different fibers and blends combination.

To catch the world of I.T. connectivity: Savio Winder 4.0 – Smart Industry Solutions for Textile Mills

Following the worldwide trend of the digital evolution, Savio presents its integrated proposal for the Textile Mills, thanks to the winding process which is today, completely monitored by electronic technologies.

Savio Evo winders can be equipped upon request with Smart Industry Solutions for connectivity, data management, remote machine set up and operator real-time interactivity. Savio Winder 4.0 represents an important step towards a wide digitalization process, being a solution for intelligent networking of machines in the spinning/winding room. This data system represents a very modern and important management tool, relieving mill staff of time-consuming routine work. The mill manager, directly from his/her desk, has access to the winding room live monitoring. Thanks to data analytics, a wealth of data are available, allowing to manage the different production phases in the best possible way and to monitor all significant parameters anytime and anywhere, making use of mobile devices. All these features enable Savio customers to control overall equipment effectiveness, increase workforce efficiency, and maximize quality and working time.endprint