915 nm/974 nm单发射区半导体激光器光纤耦合模块设计

刘翠翠, 井红旗, 倪羽茜, 王 鑫, 吴 霞, 马骁宇*

( 1. 中国科学院半导体研究所 光电子器件国家工程研究中心, 北京 100083; 2. 中国科学院大学, 北京 100049)

1 Introduction

The development of industrial applications and fiber laser pumping has demonstrated an increased requirement of semiconductor laser diode(LD for short below) fiber-coupled module[1]. Compared with other two types of high-power semiconductor LDs, laser bars and stacks, with a problem of “smile”, single-emitter LDs are excellent because of their relatively low cost, small size, high repetition rate, high efficiency and compatibility with optical fibers[2-4]. Additionally, all facts mean that single-emitter LDs are a better choice to assemble fiber-coupled modules in the commercial market. At the same time, wavelength multiplexing is a good technology to design fiber-coupled modules with high power and high optical power density[5]. Hence many research institutes have studied fiber-coupled modules based on wavelength multiplexing. In 2013, Germany Direct Photonics Company designed 939 nm/943 nm/947 nm/951 nm single-emitter semiconductor fiber-coupled module based TFF wavelength multiplexing through wavelength-lock by VBG. This module can produce 450 W output power, but its optical elements are so expensive that it is not cost-effective for industrial manufacture[6]. In 2014, two different wavelengths beams from two single-emitter LDs are coupled into a standard fiber with a 100 μm/NA 0.2. In the working current of 2.5 A, 808 nm LD and 980 nm LD can output 4.05 W continuous power in total. Finally, optical fiber produces 3.25 W output power, the coupling efficiency is above 80%[7]. As the output power of single-emitter semiconductor LD has been greatly increased from 1 W to 15 W at present, the output power of the LD fiber-coupled modules from 30 W up to above 200 W between 800 nm and 980 nm of the wavelength are available[8]. Though the researches of wavelength multiplexing based on single-emitter LDs are much less than laser bars and stacks, a wider market about single-emitter LD fiber-coupled modules is for-seen.

In the present work, 6 single-emitter LDs are chosen to compose a fiber-coupled moduleviawavelength multiplexing as well as fiber coupling techniques. And a 105 μm/NA 0.22 fiber-coupled module at 915 nm/974 nm LDs is demonstrated both by ZEMAX software simulation and real experiment. Finally, the module can output 46 W with a coupling efficiency of 83%.

2 Optical Design and Stimulations

2.1 Optical Design

Wavelength multiplexing is an effective method and generally be utilized in LD fiber-coupled module to meet the demand of high power and higher optical power density from optical fiber without decreasing the quality of beam[9]. As far as we know, single-emitter LD is more reliable than laser bar or stack on account of its smaller volume, lower density of emitters and no “smile”, so it is a better choice for fiber-coupled module.

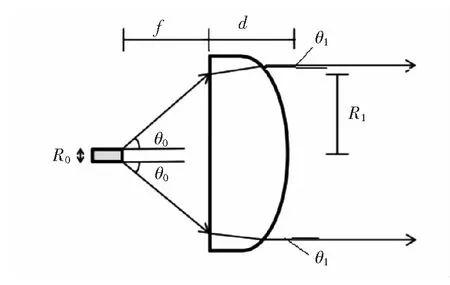

The simulation of optical structure and ray simulation is designedviaZEMAX software. Single-emitter LDs collimated by the fast collimators (FAC) and the slow fast collimator (SAC) are stepwise arranged with the height gradient of 0.4 mm on a heat sink, then the beams are reflected by mirrors respectively. The optical coupling-efficiency of three wavelengths single-emitter fiber-coupled module is optimized to 92.6% from a multi-mode optical fiber of core diameter 105 μm and NA 0.22. The optical design and the whole structure of the fiber-coupled module are shown in Fig.1.

Fig.1 Optical entire structure of the fiber-coupled module(a) and the half of the module including one wavelength(b) designed by ZEMAX

2.2 Beam Reshaping

Great flexibility and radial symmetry can be obtained at fiber-coupled module of single-emitter LDs. To improve the coupling efficiency, beam reshaping is necessary before assembling the whole module[10]. At this stage, two kind of aspheric cylindrical lens, FAC and SAC, are used to reduce divergence angle in the fast axis and the slow axis for a reshaping beam with an extremely small divergence angle after reshaping. The schematic diagram of reshaping is shown in Fig.2.

All the single-emitter semiconductor LDs are produced from our laboratory, the divergence angles in the fast and slow axis are shown in Tab.1. The process of reshaping is calculated following formula (1) to (3). According to ZEMAX software, the focal length of the FAC lens and the SAC lens is 200 μm and 12.5 mm with materials of S-TIH53 and K9, respectively[11].

Fig.2 Principle of beam shaping in the fast axis and slow axis by D-type micro lens

(1)

(2)

wherefdonates the focal length of reshaping cylindrical lens,R0andR1donate the half size of the beam waist before and after the reshaping lens,θ0andθ1donate the half-divergence angle before and after the reshaping lens.

Tab.1 Beam parameters of single emitter semiconductor LD before reshaping

The beam parameter product (BPP for short below) is usually used to characterize the beam quality of LDs. And BPP can be calculated by Eq.(3):

KBPP=Rθ,

(3)

an efficient coupling can be received if Eq.(4) and (5) are satisfied:

(5)

the result according to Eq.(1) and (2) is thatR1fast=0.093,θ1fast=1.340.21°/3.665 mrad,R1slow=1.34 mm,θ1slow=0.23°/4.014 mrad.Tab.2 shows the main properties of LDs after reshaping calculating by Eq.(1)-(3).

Tab.2 Beam parameters of single emitter semiconductor LD after reshaping

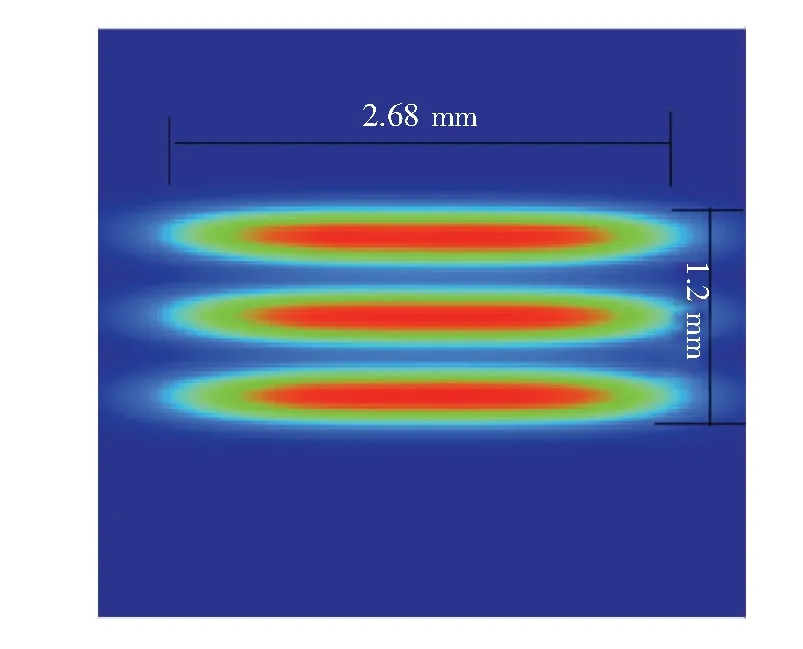

The beams collimated by reshaping lens are rotated by corresponding reflectors to 90° with the original direction, which makes three beams become a beam. The spot after wavelength multiplexing is shown in Fig.3, and the spot size in fast axis and slow axis is 1.2 mm and 2.6 mm, respectively.

Fig 3 Optical spot after beam reshaping and wavelength multiplexing

The size of optical spot after coupling can be calculated following Eq.(6) and (7):

(6)

(7)

wherewfastandwslowdonate the length of the original optical spot output from fiber in the fast axis and slow axis, respectively,fFACandfSACdonate the focal length of the FAC lens and the SAC lens,respectively. The size of spot after focusing is 40 μm× 64 μm according to Eq.(6) and (7), and the BPPs of spot in fast axis and slow axis after reshaping both meet the requirement of the Eq.(4) and (5) in this module.

The aspheric cylindrical lens with 8 mm focal length and 9 mm CA is used to focus, whose NA is 5. The coupling efficiency is 92.6% based on the simulation by ZEMAX.

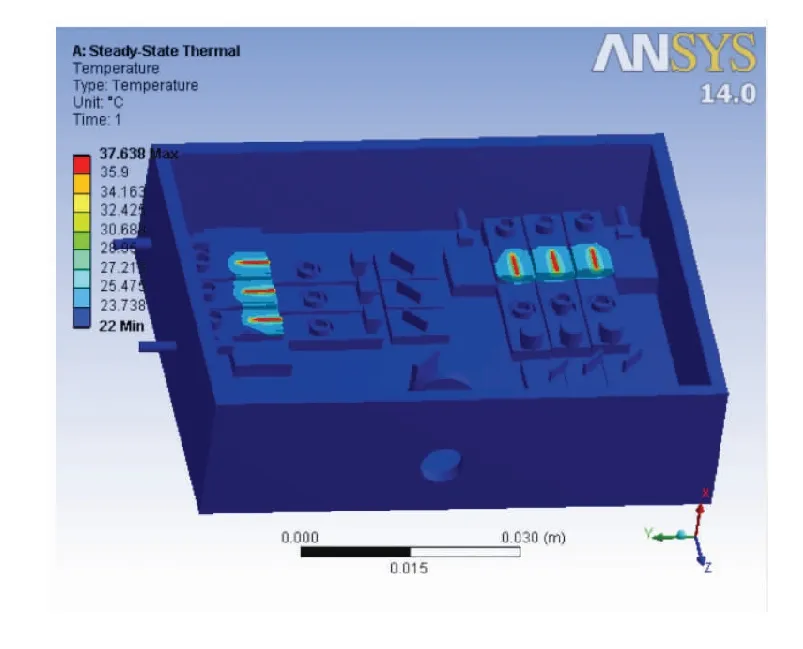

3 Thermal Simulation Analysis

The life and the reliability of fiber-coupled module depend on its thermal performance, which affects its output power and optical power density. The package of the module is made up of Chip-on-Submount(CoS), optical elements, multiple secondary modular submounts and integrated heat-sink[12]. Generally, the whole assemble of the module is fixed on a cooling heat-sink to take the heat of the module away by the cooling water to maintain its working temperature. The thermal stimulation of the module is evaluated by ANSYS softwore. 915 nm and 974 nm single-emitter LDs are operated at 12 A for 11 W, the temperature of the cooling water is 22 ℃, the result of the thermal simulation is as the Fig.4.

Fig.4 Thermal performance about the stimulation result of the package by ANSYS

The thermal performance of the module is excellent owing to the design of the ladder heat sink, which provides an efficient thermal path for each LD. By analyzing the result of ANSYS, the module can still maintain normal operating temperature at below 37 ℃ after 1 minute’s work normally. Therefore, the well thermal performance of the package can be believed.

4 Experimental Results

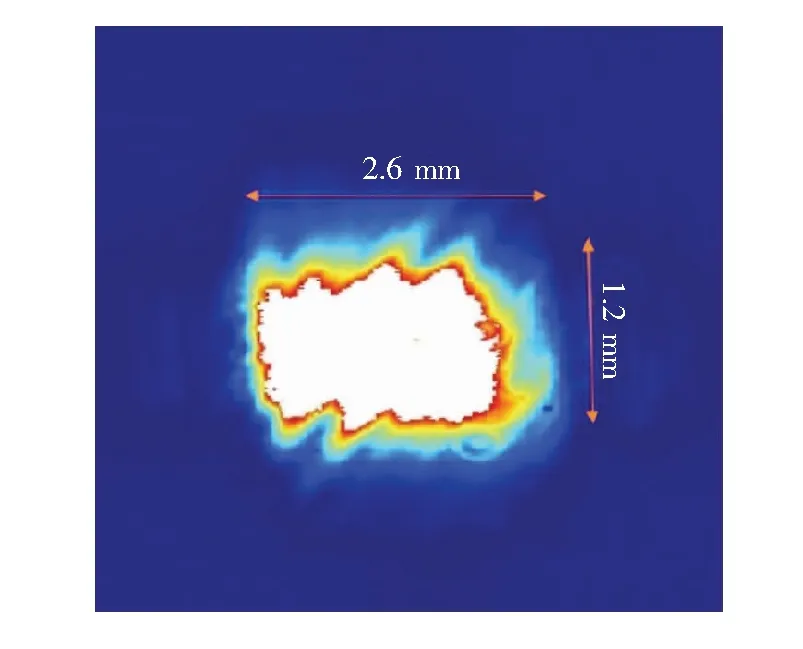

The light spot of the module is measured by charge-coupled device(CCD for short below) before and after focusing, which is shown in the Fig.5. Because of the size of the focusing spot is less than 80 μm, a 105 μm and NA 0.22 optical fiber is appropriate for coupling technology.

After focusing by the aspheric cylindrical lens, the beam is coupled into the optical fiber, we can get the spot outputted from the optical fiber as Fig.6(a). Through the analysis of the beam outputted from the fiber, two wavelengths, 915 nm and 974 nm, can be tasted by spectrograph as Fig.6(b), which proves that the beam of the two wavelengths are coupled into the optical fiber.

Fig.5 Real spot after wavelength multiplexing tested by CCD

Fig.6 Light spot(a) output from fiber and the analysis(b) of beam by spectrograph

Finally, we obtain a module which can produce above 46 W from a standard optical fiber with 105 μm and NA 0.22, and the coupling efficiency is 83%.Additionally, we can calculate the optical power density output from this module is 3.5 mW/cm2-stras according to Eq.(8):

(8)

whereBdonates the optical power density,Pdonates the output power from the fiber,θdonates the NA of the optical fiber.

Compared with the result of simulation by ZEMAX, the lower output power and coupling efficiency are mainly due to that the reflectivity and transmittance of dichroic mirrors are less 95% and 90%, respectively, not 100% as well as in simulation. Meanwhile, the center wavelengths of these LDs are shorter than 974 nm and 915 nm exactly at lower currents, respectively, which reduces the efficiency of dichroic mirror.

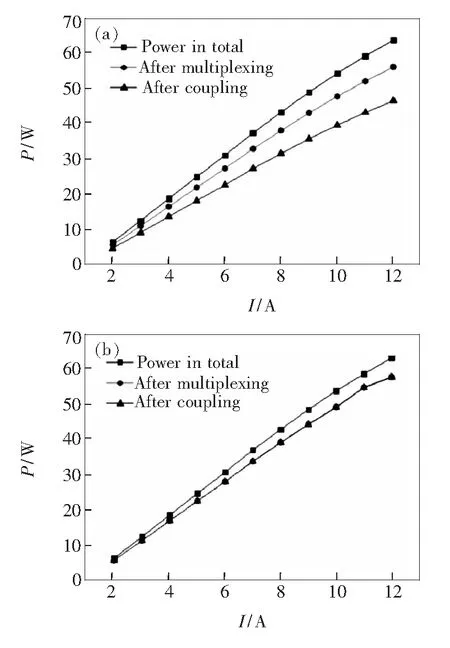

The relationship between the output power and the current of the module in fact is shown in Fig.7(a). And the result of simulation by ZEMAX is shown in Fig.7(b) when the reflectivity and transmittance of dichroic mirrors are 95% and 90% for 912 nm and 968 nm, respectively. The reason for the lower coupling efficiency in fact is that the beam quality, the divergence angle for example, will be worse at higher currents because of the accumulation of large amount of heat, which affects the real coupling efficiency.

Fig.7 Output power and the current of the semiconductor laser diode fiber coupling module in fact(a) and by ZEMAX(b)

5 Conclusion

According to the excellent results recommended by ZEMAX and ANSYS software, a wavelength multiplexing fiber-coupling module is designed and verified by experiment. Due to the wavelength multiplexing and fiber coupling technologies, six single-emitter semiconductor LDs are efficiently coupled into a multimode optical fiber, whose output power and optical power density is 46 W and 3.5 MW/cm2-stras, respectively. And the coupling efficiency is 83%. Additionally, we believe these results are beneficial of the development of fiber lasers and materials processing industries. The next stage about this fiber-coupled module is to realize the superposition of more lasers in the fast axis direction, which can produce much higher output power.

——李振声