气力式小粒径种子精量排种器吸种效果影响因素研究

廖宜涛,廖庆喜,王 磊,郑 娟,高丽萍

气力式小粒径种子精量排种器吸种效果影响因素研究

廖宜涛1,2,廖庆喜1,2,王 磊1,郑 娟1,高丽萍1

(1. 华中农业大学工学院,武汉 430070; 2. 农业部长江中下游农业装备重点实验室,武汉 430070)

针对油菜、青菜等类球形小粒径种子粒径小、质量轻,通过排种合格指数、漏播指数等指标研究吸种环节影响机制易受后续卸种、导种等串联环节影响的问题,以正负气压组合式小粒径种子精量排种器为研究对象,通过吸种运移状态图像拍摄试验,确定型孔漏吸、单粒吸种及重吸发生概率,开展吸种环节研究。吸种状态分析发现小粒径种子质量轻,−200 Pa时即可被吸附,在负压绝对值较大时会出现4~6粒重吸;型孔单粒吸种发生概率与种子千粒质量、排种盘转速、型孔直径、工作负压等因素相关性极显著(<0.01);排种器存在稳定吸种临界负压,当工作负压在临界负压1~2倍范围内,型孔单粒吸种概率高于0.92,漏吸与重吸发生概率均低于0.04;结合吸种过程受力分析可知排种盘转速变化造成单粒吸种概率变化的主要机制是影响型孔与种子吸附作用时间,进而影响单粒吸种可靠性;当转速增加,实现稳定吸种的临界负压绝对值增大,吸种负压计算的可靠性系数应增大;以漏吸概率0.02及单粒吸种概率0.92的工作负压为参考值,建立了可靠性系数与排种盘工作转速及型孔直径相关的数学模型,利用该模型计算排种器吸种可靠性系数,进而确定吸种负压临界值,可使排种器漏吸发生概率小于0.04,单粒吸种概率大于0.92,排种器稳定工作。研究明确了正负气压组合式小粒径种子精量排种器吸种环节影响机制和用于计算吸种临界负压的可靠性系数模型,为气吸式排种器设计与性能提升提供了参考。

农业机械;农作物;优化;排种器;吸种负压;吸种可靠性;小粒径种子

0 引 言

气吸式精量排种器通过负压气流将种子吸附在排种盘型孔上,运移至卸种区后隔断负压使种子在重力作用下卸种,使种子群转变为单粒等间隔种子流,具有品种适应性强、伤种率低、易实现单粒排种等特点,得到广泛研究与应用[1-4]。油菜、青菜、大白菜等作物种子直径在3 mm以下,粒径小、质量轻,气吸式排种采用的吸种型孔直径小,靠自身质量难以及时卸种,采用强制卸种装置易损伤种子、堵塞型孔,在气吸式排种器卸种区设计与吸种负压气室隔离的正压气室,利用正压气吹适时卸种,有效克服了该难题[5-8]。

吸种负压是影响排种器性能的关键参数[9-10]。型孔处吸附力由工作负压和型孔结构决定;吸附力小,容易发生漏吸,导致排种器漏播指数增大;吸附力过大会使重吸增加,导致重播指数增大[11-14]。排种过程属于多环节串联,吸种效果受充种环节影响。充种室内种子数量过多,会增加吸种时被吸附籽粒与种群的摩擦力,使吸附籽粒脱落,出现漏吸;流动性差的种子充种不充分会降低种群与型孔接触的概率,造成漏吸;排种盘转速增大会导致被吸附种子的离心力增加,种子所需吸附力增大;同时转速增大导致型孔与种子群接触时间变短,会使吸种过程不充分,进而造成漏吸;适当增大工作负压可以提高型孔吸附力,加强型孔从籽粒群中攫取种子的能力,降低漏吸,改善排种性能[15-19]。

由种子吸种环节受力情况分析可建立与型孔直径、排种盘型孔处线速度、种子质量、粒径大小、自然休止角等参数相关的吸种负压计算公式,但需要根据经验选取吸种可靠性系数和外界条件系数等参数[20-21]。通过排种器性能试验,以排种合格指数较高时的吸种负压值为因变量,种子千粒质量、投影面积、球形度等为自变量,采用多元回归分析建立吸种负压预测数学模型可确定不同种子对象的最优工作负压,但建模过程未考虑型孔大小、排种盘转速对吸种性能的影响[22];根据排种器在不同工作负压、工作转速及型孔大小等条件下的合格指数、重播指数及漏播指数,通过优化求解确定最佳参数组合,提升排种性能,但结果仅适应试验种子对象[23-26];而且试验研究以排种性能指数为评价指标,忽略了排种串联过程中卸种与导种环节对排种性能的影响[27-29]。

小粒径种子粒径小、质量轻,吸种效果对排种型孔大小、吸种负压变化敏感,卸种、导种过程更易受扰动,因此需要针对吸种环节进行研究,以明确吸种性能影响机制。本文以正负气压组合式小粒径种子精量排种器为研究对象,试验拍摄排种盘型孔的吸种运移状态图像,通过分析不同试验因素水平下型孔单粒吸种、漏吸和多粒重吸发生概率的变化规律,明确吸种过程影响因素和影响程度,建立类球形小粒径种子吸种可靠性系数数学模型,确定排种器稳定工作负压范围,为类球形小粒径种子气吸式排种器设计与性能优化提供参考。

1 材料与方法

1.1 种子筛分与测量

为获得不同粒径大小和千粒质量的种子对象,试验选用“快绿236”(白菜)、“四月慢”(青菜)、“华油杂62”(油菜)、“中双11”(油菜)等4种作物商品化种子,采用10~14目标准分级筛进行筛选分组。分组的种子利用游标卡尺测定种子长、宽、高三轴尺寸,由全自动数粒仪(浙江托普)和电子感量天平测量千粒质量;其中三轴尺寸每组测量100粒,千粒质量每组重复5次,统计其长宽高三轴尺寸的平均值、颗粒平均粒径、颗粒尺寸范围、千粒质量、球形度等参数。

1.2 吸种试验

试验在JPS-12型排种试验台上进行;所用气力式排种器通过负压吸种、正压气吹卸种,工作时排种链轮带动排种盘转动,种子在充种区被负压吸附到排种盘型孔上,随排种盘一起转动至正压区后,在正压和自身重力作用下脱离型孔进入卸种口,完成排种过程[30]。

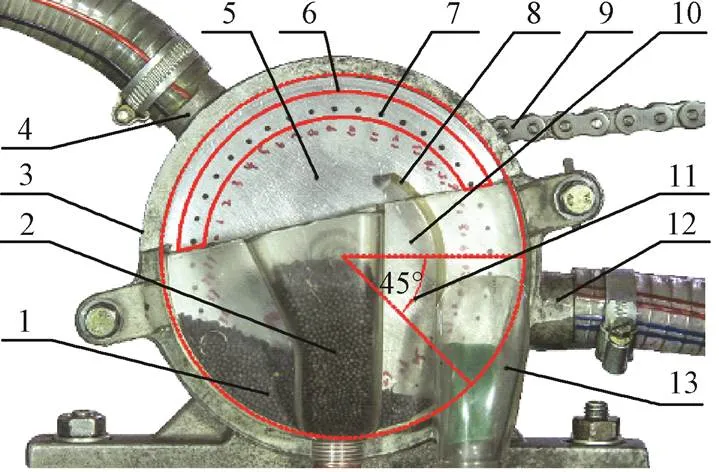

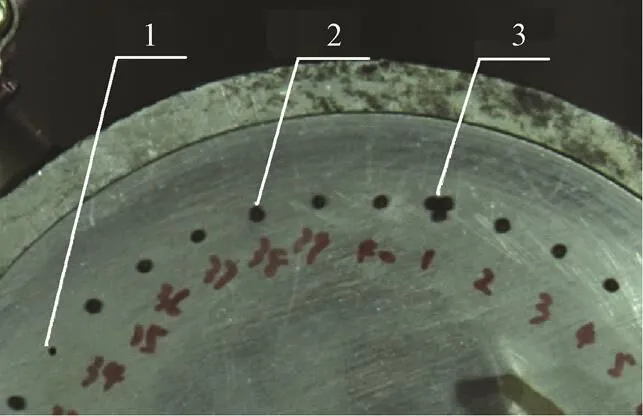

拍摄的排种器吸种运移状态图像如图1所示,为便于吸种运移过程型孔吸种状态判别,去除排种器罩壳上半部分。筛分的种子装入种箱,持续供给充种仓;充种仓种子被负压吸附后随排种盘运移至卸种区;排种盘上半部分圆环形区域为型孔吸种状态观测区域。

1.充种区 2.种箱 3.气室壳体 4.负压出气口 5.排种盘 6.吸种状态观测区 7.被吸附种子 8.充种卸种分隔板 9.传动链条 10.负压气室区域 11.正压气室区域 12.正压进气口 13.卸种口

采用全交互试验,试验因素包括分组种子、排种盘型孔直径、排种盘工作转速及排种器工作负压。其中筛分获得的5组种子,千粒质量分别为5.40、4.67、3.81、2.99和2.65 g;4组排种盘,型孔直径0.9~1.2 mm,试验水平间隔0.1 mm;排种盘转速10~30 r/min,试验水平间隔2 r/min;负压−200~−3 000 Pa,试验水平间隔200 Pa。试验时卸种正压设置为200 Pa。

试验用数码相机为Canon EOS 7D,拍摄参数为:光圈值f/10,曝光时间1/320 s,ISO-400,0曝光补偿,无闪光模式,焦距100 mm,图像分辨率为1 800万像素(5 184×3 456 pixel)。每次图像拍摄后及时观察型孔堵塞情况,如发生堵塞,记录堵塞情况、清理型孔,再重复拍摄。为减少误差影响,每个因素组合重复拍摄10次,获得10幅吸种运移状态图像,统计型孔吸附情况概率用于分析。

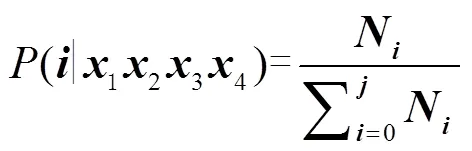

图像由人工观察确定型孔吸附的籽粒数量,计算不同试验条件下型孔漏吸、单粒吸种、多粒重吸的概率,用于吸种过程影响机制分析,概率计算公式为

式中为型孔上吸附籽粒数;为自然数;1为试验用筛分种子千粒质量,g;2为排种盘型孔直径,mm;3为排种盘转速,r/min;4为气室负压,Pa;N为当前试验条件下吸种效果观测区内型孔上吸附籽种子的型孔数,为0即是漏吸,为1即是单粒吸种,大于1是多粒重吸。

第二,企业应建立授权制。财务工作数据化后,数据很容易复制刻录、企业存款转账极易操作,企业人员应建立资金输出文件或报告需授权的制度,确保资金的合理使用。比如,企业经营过程中需要较大额的支出时,除需要企业管理层进行签字审批之外,还需要在财务软件中设立两个以上需要授权登录批准后才可操作的授权制度。与资金相关的重要文件也尽可能地减少输出。

2 结果与分析

2.1 种子物理特性分析

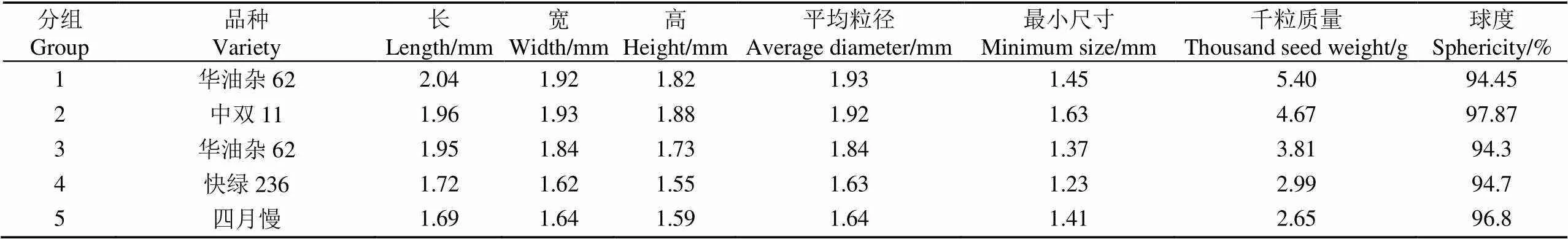

筛分获得5组种子,按千粒质量大小排序,进行球度、几何尺寸等测量统计,用于吸种运移状态拍摄试验。第1、2组分别为“华油杂62”、“中双11”2种种子由10目标准筛筛下、12目标准筛筛上获得;第3、4、5组种子为“华油杂62”、“快绿236”、“四月慢”等3种种子由12目标准筛筛下、14目标准筛筛上获得。

5组种子长宽高平均值、平均粒径等物理特性如表1所示。其中“华油杂62”商品化种子由不同规格标准筛筛分出的2组种子千粒质量差距接近15%;不同品种种子以相同标准筛筛分,各组种子千粒质量、平均粒径等指标出现10%以上差异;同一组内种子粒径最小尺寸与平均尺寸相差20%以上。

对比第1~2组种子的长、宽、高三轴尺寸概率分布可知:“华油杂62”种子的长度分布为1.62~2.42 mm,宽度分布为1.50~2.23 mm,高度分布为1.45~2.09 mm;中双11种子长度分布为1.75~2.16 mm,宽度分布为1.71~2.14 mm,高度分布为1.63~2.14 mm。两种类球形种子虽处在同一筛分规格内,但因为“中双11”种子球形度更高,筛分后的种子尺寸分布更加集中,更接近于标准正态分布;“华油杂62”种子球形度低,筛分后的种子尺寸分布跨度更大;第3~5组种子尺寸分布也符合该规律。

表1 分组种子物理特性统计

注:长为100粒种子3个方位测量最大尺寸值的平均值;宽为100粒种子3个方位测量居中尺寸值的平均值;高为100粒种子3个方位测量最小尺寸值的平均值。

Note: Length is the mean of the maximum values of the measured 100 seeds on the orientation of orthogonal three axis; width is the mean of the mediate values of the measured 100 seeds on the orientation of orthogonal three axis; Height is the mean of the minimum values of the measured 100 seeds on the orientation of orthogonal three axis.

种子物理特性分析表明小粒径类球形种子虽然粒径小、质量轻,但个体之间球度、三轴尺寸、质量等均存在差异;种子球形度越高,筛分分级的种子尺寸分布更集中,千粒质量更小,尺寸分布更近似于标准正态分布。

2.2 型孔吸种情况分析

试验观察到型孔的吸种状态包括漏吸、单粒吸种、多粒重吸等3种,如图2所示。

1.漏吸 2.单粒吸种 3.多粒重吸

因种子质量轻,在−200 Pa时即能观察到种子被吸附在型孔上,在−800 Pa时观察到有重吸现象。吸种过程是型孔与充种仓种子群的随机作用过程,因此在−2 800 Pa也能观察到型孔漏吸现象,而观测区的型孔可能会出现漏吸、单粒吸种、多粒重吸同时存在的现象。与文献[20]所述大粒径种子气吸式排种情况不同,类球形小粒径种子因所需吸附负压值较低,在工作负压值较高情况下会出现型孔吸附4~6粒种子的现象。在排种试验台上测试排种性能,吸种阶段型孔漏吸会导致排种器漏播指数相应增加,2粒重吸会导致重播指数相应增加,而型孔3粒以上重吸会导致排种器重播指数急剧增加。因此为避免后续串联过程中卸种与导种环节的影响,需要针对吸种运移环节分析排排种盘工作转速、型孔直径、气室负压等因素对排种性能的影响机制。

试验中未发现种子破损情况,但在第4组种子采用1.2 mm型孔直径排种盘时现了型孔堵塞情况。堵塞主要原因是型孔吸附到粒径偏小的种子,部分嵌入型孔中不能吹落,转过卸种区后在充种卸种分隔板的挤压下将型孔完全堵塞。因此在使用气吸式排种器播种小粒径种子时,必须对种子进行筛分处理,去除粒径较小的籽粒,为降低型孔堵塞风险,建议使用的排种盘型孔直径与播种种子最小粒径之比小于0.9。

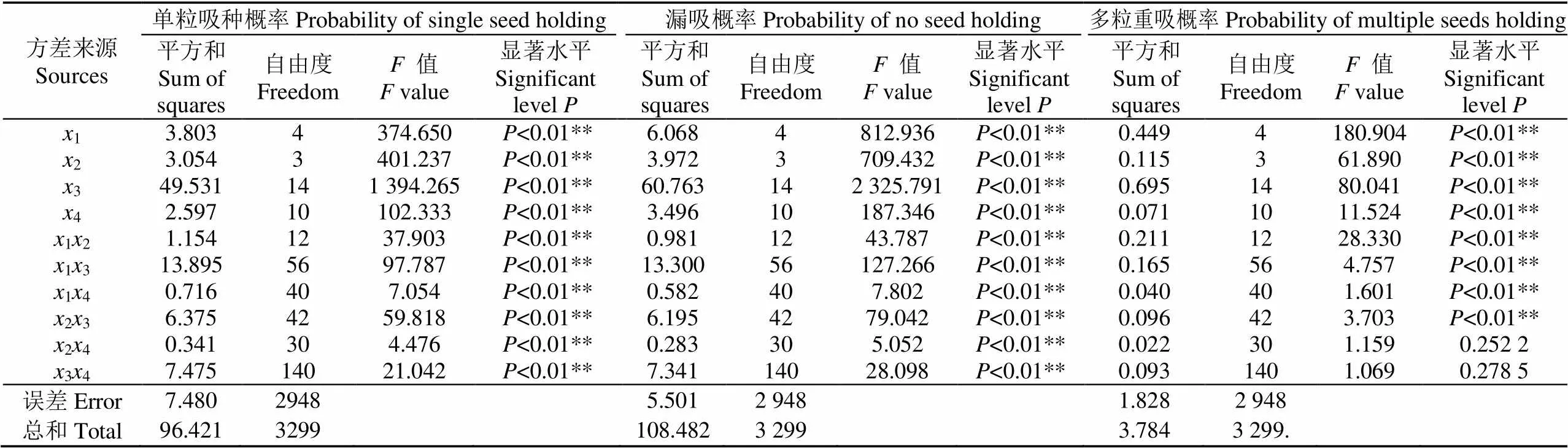

2.3 吸种效果影响因素分析

统计不同排种盘转速、不同型孔直径、不同工作负压下排种盘型孔吸附各组种子时型孔发生漏吸、单粒吸种、多粒重吸的概率,以吸孔吸附状态发生概率为因变量,种子千粒质量1;型孔直径2;为排种盘转速3;气室负压4等因素为自变量,开展多因数方差分析和多重比较。方差分析结果如表2所示:单粒吸种、漏吸及多粒重吸发生概率受籽粒千粒质量1、排种盘型孔大小2、工作转速3及吸种负压4影响极显著;但排种盘型孔大小2和吸种负压4的交互作用对多粒重吸发生概率影响不显著、排种盘转速3和吸种负压4的交互作用对多粒重吸发生概率影响不显著。

表2 吸种效果影响多因素方差分析

注:1为种子千粒质量,g;2为排种盘型孔直径,mm;3为排种盘转速,r·min-1;4为气室负压,Pa。**<0.01,极显著。

Note:1is thousand seeds weight, g;2is hole diameter of seeding disc, mm;3is rotate speed of seeding plate, r·min-1;4is negative pressure of air chamber, Pa. **<0.01, extreme significant.

多重比较得单因素多个水平之间的排种器吸种状态概率平均值差异如图3所示。单粒吸种的发生概率与种子千粒质量大小呈线性递减关系,与排种盘型孔大小呈非线性递增关系,与排种盘转速大小呈线性递减关系;漏吸发生概率与种子千粒质量大小呈线性递增关系,与排种盘型孔大小呈非线性递减关系,与排种盘转速大小呈线性递增关系。从整体趋势看,千粒质量大时多粒重吸发生概率小,排种盘型孔小时多粒重吸发生概率小,排种盘转速高时重吸概率小;但千粒质量、排种盘型孔、转速等因素与重吸发生概率均值为非单调函数关系,表明重吸发生概率存在随机性波动。由多个负压水平之间的吸种效果发生概率均值差异可知当负压值在−200~−1 400 Pa范围内,随着负压绝对值增加,单粒吸种概率单调递增,漏吸概率单调递减;在−1 600~−3 000 Pa范围内,随着负压绝对值增加,漏吸发生概率均值差异不明显;在−1 600~−2 800 Pa范围内,随着负压绝对值增加,单粒吸种与重吸发生概率均值差异不明显;达到−3 000 Pa时单粒吸种概率下降,重吸发生概率增大。

图3 影响排种器吸种状态概率的各因素多重比较结果

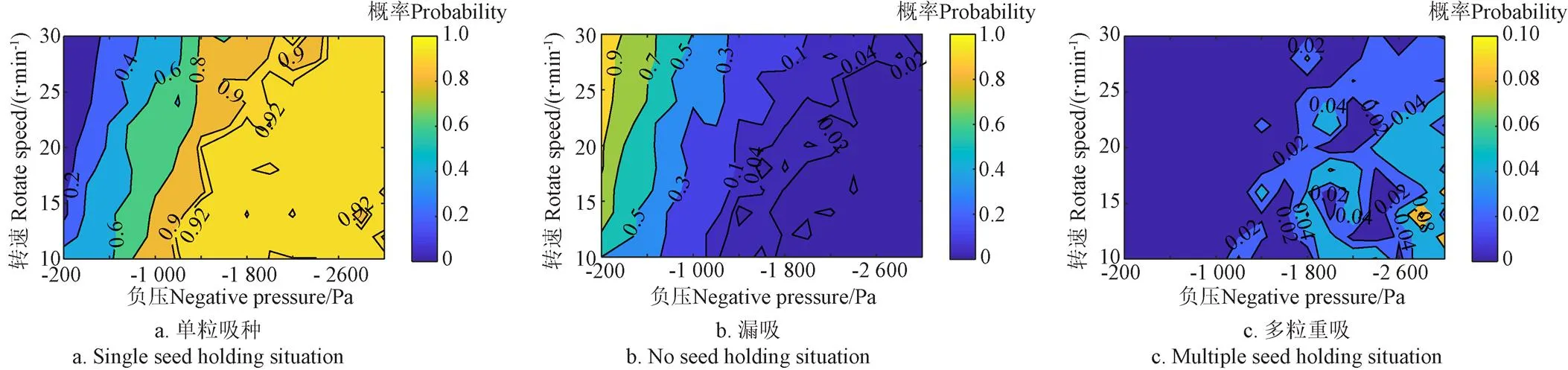

排种盘型孔单粒吸种,漏吸及多粒重吸发生概率随工作负压(4−200~−3 000 Pa)和转速(310~30 r/min)变化而变化的等高线图如图4所示(第1组种子,千粒质量1=5.40 g;排种盘型孔直径2=0.9 mm)。由图4可知类球形小粒径种子气吸式排种存在稳定吸种临界气压0;且排种器工作转速越大,实现稳定吸种的临界气压0绝对值越大。当工作负压|4|<|0|,由排种器单粒吸种及漏吸的发生概率受排种盘工作转速的影响明显,重吸发生概率小于0.02,属于小概率偶然事件;当|4|≥|0|时,单粒吸种概率稳定在0.92以上,漏吸概率稳定在0.04以下,重吸发生概率在0.04以下,吸种状态发生概率受转速影响不明显,重吸与漏吸具有一定随机性;而|4|继续增加,重吸发生概率有增加趋势。

图4中,排种器转速10 r/min时,图4a显示单粒吸种概率大于0.92、图4b与4c显示漏吸重吸概率小于0.04,对应0约为−1 200 Pa;14 r/min时,对应0约为−1 400 Pa;30 r/min时,对应0约为−2 400 Pa。以排种器工作负压为4=−1 400 Pa为例,当排种器转速10 r/min时,|4|>|0|,此时图4a中单粒吸种概率大于0.92,图4b中漏吸概率小于0.04,图4c中多粒重吸概率小于0.04;当排种器转速14 r/min时,|4|=|0|,此时图4a中单粒吸种概率等于0.92,图4b中漏吸概率等于0.04,图4c中多粒重吸概率小于0.04;当排种器转速30 r/min时,|4|<|0|,此时图4a中单粒吸种概率小于0.90,图4b中漏吸概率大于0.10,图4c中多粒重吸出现概率小于0.02。当排种器转速14 r/min时,排种器工作负压4达到−2 800 Pa,|4|≈2|0|,此时图4c显示排种器重吸发生概率增大到0.08;结合型孔吸种情况方差分析多重比较结果可知排种器合理的工作负压范围为|0|≤|4|≤2|0|。

注:试验对象是第1组种子,千粒质量x1=5.40 g;排种盘型孔直径x2=0.9 mm。

2.4 稳定吸种临界负压分析

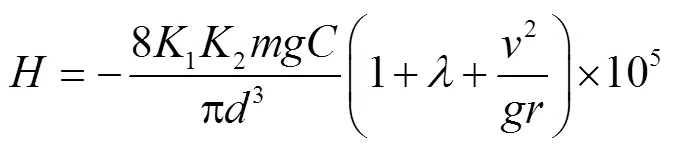

根据种子在排种盘上的受力情况分析,气吸室所需负压计算公式为[20]

式中为气吸室负压,Pa;为种子重心与排种盘间距,cm;为一粒种子的质量,kg;为排种盘吸孔中心处的线速度,m/s;为型孔直径,m;为排种盘吸孔处的转动半径,m;为重力加速度,m/s2;为种子的摩擦阻力综合系数,=(6~10)tan,为种子自然休止角;1为吸种可靠性系数;2为工作稳定可靠性系数。

由式(2)可知气吸室所需负压与种子千粒质量、排种盘型孔大小、排种盘转速等相关,转速越低、排种盘型孔越大、种子千粒质量越小,稳定吸种所需要的|0|越小。

在理想条件下,即=0、1=1、2=1时,试验用种子吸种负压在−20~−160 Pa,因此试验观察到负压−200 Pa时有种子被吸附,但因种子间摩擦阻力影响,且吸种可靠性和工作稳定可靠性较低,漏吸现象发生概率大。油菜、青菜等类球形小粒径种子自然休止角=26.7[31],种子流动性好,充种区种子量较少,摩擦阻力综合系数=6tan;试验中外界振动及冲击影响较小,取2=1.6;排种器的排种盘吸种处转动半径=0.057 5 m。

排种盘转速去试验最高转速30 r/min时,式(2)中种子运动离心力系数2/=0.058,远小于种子重力和种子之间内摩擦阻力影响系数(1+),说明类球形小粒径种子采用的排种盘直径小,转速变化引起的离心力变化较小,对所需负压吸附力变化影响较小。而排种器在临界负压以下,漏吸概率和单粒吸种概率均受排种盘转速影响明显,表明吸种负压低于临界负压时,排种器转速影响型孔与充种区种子的接触时间,进而影响吸种可靠性。转速越高,型孔与种子吸附作用的时间越短,相同吸种负压条件下型孔吸附种子的可靠性就越差,种子被型孔吸附的概率越低,漏吸概率越大;转速越高,实现稳定吸种的临界负压绝对值就越大。因此吸种可靠性系数1与排种器工作转速密切相关。

根据排种器稳定吸种状态下单粒稳定吸种与漏吸概率变化情况,取排种盘吸种状态概率等高线图中单粒吸种概率0.92及漏吸概率0.02的等高线坐标值为对应转速下稳定吸种压临界负参考值ref,以种子平均粒径、千粒质量、排种盘型孔与转速为因变量,对应临界负压参考值为自变量,根据式(2)通过非线性拟合计算确定吸种可靠性系数1。其中第1、3、5组种子为校正集,第2、4组种子为验证集。

设吸种可靠系数1与排种盘工作转速3线性相关(方案I),即

K

1

=

a

x

3

+

b

(3)

计算得:1=0.0643+0.638。

设1与排种盘工作转速3及排种盘型孔直径2线性相关(方案II),即

K

1

=

a

1

x

3

+

b

1

x

2

+

c

1

(4)

计算得:1=0.0643+1.7072−1.032。

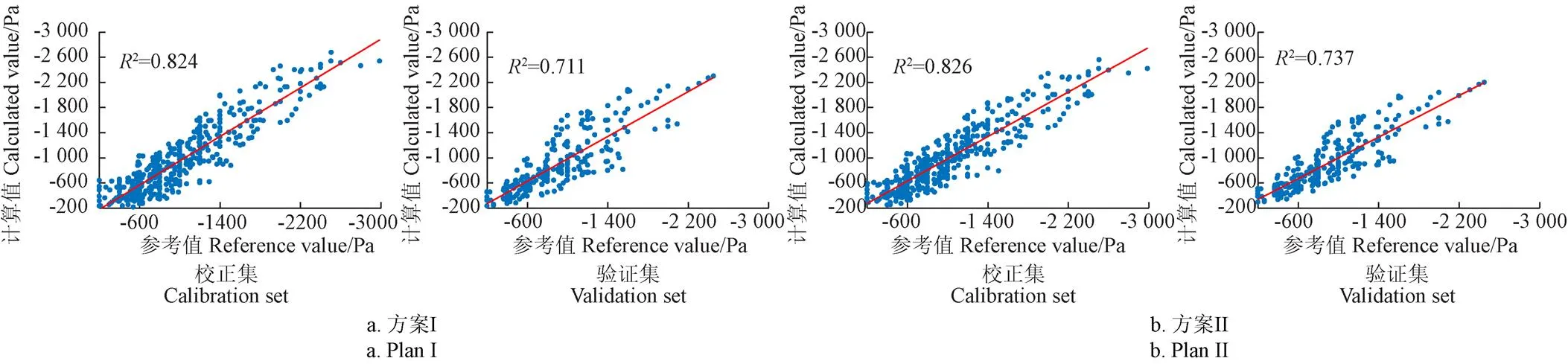

根据2种方案确定1,由式(2)计算校正集和验证集各组种子在不同型孔、不同转速下的单粒稳定吸种临界负压值与参考值相关性如图5中所示。由图5可知虽然方案I与方案II的校正集决定系数接近,均大于0.82,但因未考虑型孔直径变化对吸种可靠性系数1影响,其验证集决定系数低于方案II。

图5 临界负压计算值与参考值比较

排种器工作在临界负压计算值cal条件下单粒吸种、漏吸概率如图6所示(第1、2组种子,千粒质量1=5.40、4.67 g;排种盘型孔直径2=0.9、1.0、1.1、1.2 mm)。由图6可知,排种所需的单粒稳定吸种临界负压cal绝对值随种子千粒质量1增大而增大,随型孔直径2增大而减小,随工作转速增大3而增大。型孔直径0.9 mm时,方案I确定的cal绝对值高于方案II;型孔直径1.0 mm,方案I与方案II的cal绝对值接近;型孔直径1.1、1.2 mm时,方案I确定的cal绝对值低于方案II。结合单粒吸种概率和漏播概率等高线分布可知,方案I确定型孔直径0.9 mm的cal绝对值偏大,型孔直径1.1、1.2 mm的cal绝对值偏小;型孔直径1.2 mm时,排种器工作在cal条件下单粒吸种概率小于0.90、漏吸概率大于0.04,工作负压偏低,处于非稳定吸种状态。方案II考虑型孔影响,排种器工作在cal条件下,排种器的漏吸发生概率小于0.04,单粒吸种概率大于0.92,处于稳定工作状态。由计算结果对比可知,方案II优于方案I,即排种器吸种可靠系数1与排种器工作转速及型孔大小相关。

3 结论与讨论

1)油菜、白菜、青菜等类球形小粒径种子,球度在90%以上,种子个体之间球度、三轴尺寸、质量等均存在差异;为避免型孔堵塞,小粒径种子气吸式排种的型孔直径与种子群最小颗粒粒径之比应小于0.9;种子在工作负压值较高时会出现型孔吸附4~6粒种子的现象,通过型孔漏吸、单粒吸种及重吸发生概率开展吸种环节研究可有效避免后续卸种、导种等串联环节的影响。

2)型孔吸种状态发生概率分析表明排种器存在稳定吸种临界气压0,当排种器工作负压范围为0~20时,排种器处于稳定工作状态;稳定吸种临界气压与种子千粒质量、型孔直径、排种盘转速、吸种可靠性系数、工作稳定可靠性系数等参数密切相关;结合吸种过程受力分析明确排种盘工作转速对型孔吸种状态的主要影响机制是影响型孔与充种区种子的接触时间,进而影响吸种可靠性;排种器工作转速越高,达到稳定吸种的临界气压绝对值|0|就越高,要求临界负压计算选取的可靠性系数越大。

3)以排种盘型孔吸种状态概率等高线图中漏吸概率0.02以及单粒吸种概率0.92的等高线坐标值为对应转速下稳定吸种压临界负参考值,通过非线性拟合建立了吸种可靠性系数与型孔直径、排种盘转速的函数关系,研究结果为气吸式排种器设计与性能提升提供了参考。

本文通过台架试验研究了排种器吸种过程的影响机制,确定了小粒径种子气吸式排种器吸种负压计算的可靠性系数计算公式。播种机田间作业条件下排种器的吸种状态影响及吸种负压计算的工作稳定可靠性系数确定有待进一步研究。

[1] 廖庆喜,雷小龙,廖宜涛,等. 菜精量播种技术研究进展[J]. 农业机械学报,2017,48(9):1-16.

Liao Qingxi, Lei Xiaolong, Liao Yitao, et al. Research progress of precision seeding for rapeseed[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(9): 1-16. (in Chinese with English abstract)

[2] Li Y, Bingxin Y, Tao C, et al. Global overview of research progress and development of precision maize planters[J]. International Journal of Agricultural and Biological Engineering, 2016, 9(1): 9-26.

[3] St Jack D, Hesterman D C, Guzzomi A L. Precision metering of(Australian Sandalwood) seeds[J]. Biosystems Engineering, 2013, 115(2): 171-183.

[4] Kachman S D, Smith J A. Alternative measures of accuracy in plant spacing for planters using single seed metering[J]. Transactions of the ASAE, 1995, 38(2): 379-387.

[5] 田波平,廖庆喜,黄海东,等. 2BFQ-6型油菜精量联合直播机的设计[J]. 农业机械学报,2008,39(10):211-213.

Tian Boping, Liao Qingxi, Huang Haidong, et al. Design of 2BFQ-6 combined precision seeder for rapeseed[J]. Transactions of the Chinese Society for Agricultural Machinery, 2008, 39(10): 211-213. (in Chinese with English abstract)

[6] 李明,刘晓辉,廖宜涛,等. 气力滚筒式油菜精量集排器[J]. 农业机械学报,2013,44(12):68-73.

Li Ming, Liu Xiaohui, Liao Yitao, et al.Pneumatic cylinder-type centralized precision metering device for rapeseed[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(12): 68-73. (in Chinese with English abstract)

[7] Li Yitao, Wei Lei, Li Qingxi. Design and test of an inside-filling pneumatic precision centralized seed-metering device for rapeseed[J]. International Journal of Agricultural and Biological Engineering, 2017, 10(2): 56-62.

[8] 颜秋艳,廖宜涛,廖庆喜. 油麦气力式一器双行兼用型排种器的设计与功能分析[J]. 华中农业大学学报,2014,33(3):109-114.

Yan Qiuyan, Liao Yitao, Liao Qingxi. Design and function analysis of dual-purpose rape-wheat pneumatic double-row metering device[J]. Journal of Huazhong Agricultural University, 2014, 33(3): 109-114. (in Chinese with English abstract)

[9] 廖宜涛,舒彩霞,廖庆喜,等. 油菜精量直播机气力式排种系统稳压控制方法与试验[J]. 农业工程学报,2017,33(15):49-56.

Liao Yitao, Shu Caixia, Liao Qingxi, et al. Air pressure stabilizing method and experiment of pneumatic seed-metering system of precision rapeseed planter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(15): 49-56. (in Chinese with English abstract)

[10] 舒彩霞,韦跃培,廖宜涛,等. 油菜气力式排种系统参数对其负压特性的影响及风机选型[J]. 农业工程学报,2016,32(10):26-33.

Shu Caixia, Wei Yuepei, Liao Yitao, et al. Influence of air blower parameters of pneumatic seed-metering system for rapeseed on negative pressure characteristics and air blower selection[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(10): 26-33. (in Chinese with English abstract)

[11] 杨明金,邱兵,杨玲,等. 振动气吸式精密穴播机的排种性能[J]. 农业工程学报,2010,26(9):139-143.

Yang Mingjin, Qiu Bing, Yang Ling, et al. Metering performance of the vibrational vacuum precision tray seeder[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(9): 139-143. (in Chinese with English abstract)

[12] 陈海涛,李桐辉,王洪飞,等. 气吸滚筒式垄上三行大豆密植排种器设计与参数优化[J]. 农业工程学报,2018,34(17):16-24.

Chen Haitao, Li Tonghui, Wang Hongfei, et al. Design and parameter optimization of pneumatic cylinder ridge three-row close-planting seed-metering device for soybean[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(17): 16-24. (in Chinese with English abstract)

[13] 杨松,廖宜涛,廖庆喜. 2BFQ-6型油菜精量联合直播机气力式排种系统试验研究[J]. 农业工程学报,2012,28(17):57-62.

Yang Song, Liao Yitao, Liao Qingxi. Experimental study on pneumatic seed-metering system of 2BFQ-6 precision planter for rapeseed[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(17): 57-62. (in Chinese with English abstract)

[14] 廖宜涛,黄海东,李旭,等. 浸种预处理对油菜籽气力精量排种性能的影响[J]. 农业机械学报,2013,44(增刊1):72-76.

Liao Yitao, Huang Haidong, Li Xu, et al. Effects of seed pre-soaking on sowing performance by pneumatic precision metering device for rapeseed[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(Supp.1): 72-76. (in Chinese with English abstract)

[15] 张静,李志伟,刘皞春,等. 气力滚筒式排种器种子吸附边界模型及验证[J]. 农业工程学报,2016,32(23):12-20.

Zhang Jing, Li Zhiwei, Liu Haochun, et al. Mathematical modeling and validation of seeder’s suction-boundary on pneumatic-roller type metering[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(23): 12-20. (in Chinese with English abstract)

[16] 赖庆辉,马文鹏,刘素,等. 气吸圆盘式微型薯排种器充种性能模拟与试验[J]. 农业机械学报,2017,48(5):44-53.

Lai Qinghui, Ma Wenpeng, Liu Su, et al. Simulation and experiment on seed-filling performance of pneumatic disc seed-metering device for mini-tuber[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(5): 44-53. (in Chinese with English abstract)

[17] 史嵩,张东兴,杨丽,等. 基于EDEM软件的气压组合孔式排种器充种性能模拟与验证[J]. 农业工程学报,2015,31(3):62-69.

Shi Song, Zhang Dongxing, Yang Li, et al. Simulation and verification of seed-filling performance of pneumatic-combined holes maize precision [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(3): 62-69. (in Chinese with English abstract)

[18] 颜丙新,张东兴,崔涛,等. 排种盘和负压腔室同步旋转气吸式玉米精量排种器设计[J]. 农业工程学报,2017,33(23):15-23.

Yan Bingxin, Zhang Dongxing, Cui Tao, et al. Design of pneumatic maize precision seed-metering device with synchronous rotating seed plate and vacuum chamber[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(23): 15-23. (in Chinese with English abstract)

[19] 贾洪雷,陈玉龙,赵佳乐,等. 气吸机械复合式大豆精密排种器设计与试验[J]. 农业机械学报,2018,49(4):75-86,139.

Jia Honglei, Chen Yulong, Zhao Jiale, et al. Design and experiment of pneumatic-mechanical combined precision metering device for soybean[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(4): 75-86, 139. (in Chinese with English abstract)

[20] 李林. 气吸式排种器理论及试验的初步研究[J]. 农业机械学报,1979,10(3):56-63.

Li Lin. A preliminary study on the theory and experimentation of the suction-type metering device for precision drill[J]. Transactions of the Chinese Society for Agricultural Machinery, 1979, 10(3): 56-63. (in Chinese with English abstract)

[21] 刘文忠,赵满全,王文明,等. 气吸式排种装置排种性能理论分析与试验[J]. 农业工程学报,2010,26(9):133-138.

Liu Wenzhong, Zhao Manquan, Wang Wenming, et al. Theoretical analysis and experiments of metering performance of the pheumatic seed metering device[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(9): 133-138. (in Chinese with English abstract)

[22] Karayel D, Barut Z B, Özmerzi A. Mathematical modelling of vacuum pressure on a precision seeder[J]. Biosystems Engineering, 2004, 87(4): 437-444.

[23] Arzu Yazgi, Adnan Degirmencioglu. Optimisation of the seed spacing uniformity performance of a vacuum-type precision seeder using response surface methodology[J]. Biosystems Engineering, 2007, 97(3): 347-356.

[24] 高筱钧,周金华,赖庆辉. 中草药三七气吸滚筒式精密排种器的设计与试验[J]. 农业工程学报,2016,32(2):20-28.

Gao Xiaojun, Zhou Jinhua, Lai Qinghui. Design and experiment of pneumatic cylinder precision seed-metering device for panax notoginseng[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(2): 20-28. (in Chinese with English abstract)

[25] 赵佳乐,贾洪雷,姜鑫铭,等. 大豆播种机偏置双圆盘气吸式排种器[J]. 农业机械学报,2013,44(8):78-83.

Zhao Jiale, Jia Honglei, Jiang Xinming, et al. Suction type offset double disc seed metering device of soybean seeder[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(8): 78-83. (in Chinese with English abstract)

[26] 丛锦玲,余佳佳,曹秀英,等. 油菜小麦兼用型气力式精量排种器[J]. 农业机械学报,2014,45(1):46-52.

Cong Jinling, Yu Jiajia, Cao Xiuying. Design of dual-purpose pneumatic precision metering device for rape and wheat[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(1): 46-52. (in Chinese with English abstract)

[27] 陈学庚,钟陆明. 气吸式排种器带式导种装置的设计与试验[J]. 农业工程学报,2012,28(22):8-15.

Chen Xuegeng, Zhong Luming. Design and test on belt-type seed delivery of air-suction metering device[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(22): 8-15. (in Chinese with English abstract)

[28] 邢赫,臧英,曹晓曼,等. 水稻气力式排种器投种轨迹试验与分析[J]. 农业工程学报,2015,31(12):23-30.

Xing He, Zang Ying, Cao Xiaoman, et al. Experiment and analysis of dropping trajectory on rice pneumatic metering device[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(12): 23-30. (in Chinese with English abstract)

[29] Yazgi A. Effect of seed tubes on corn planter performance[J]. Applied Engineering in Agriculture, 2016, 32(6): 783-790.

[30] 廖庆喜,李继波,覃国良. 气力式油菜精量排种器试验[J]. 农业机械学报,2009,40(8):44-48.

Liao Qingxi, Li Jibo, Qin Guoliang. Experiment of pneumatic precision metering device for rapeseed[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(8): 44-48. (in Chinese with English abstract)

[31] 丛锦玲,廖庆喜,曹秀英,等. 油菜小麦兼用排种盘的排种器充种性能[J]. 农业工程学报,2014,30(8):30-39.

Cong Jinling, Liao Qingxi, Cao Xiuying, et al. Seed filling performance of dual-purpose seed plate in metering device for both rapeseed & wheat seed[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(8): 30-39. (in Chinese with English abstract)

Investigation on vacuum singulating effect influencing factors of pneumatic precision seed metering device for small particle size of seeds

Liao Yitao1,2, Liao Qingxi1,2, Wang Lei1, Zheng Juan1, Gao Liping1

(1.430070,; 2.430070,)

Accurately separating a single seed from the seed population by vacuum suction precision is the core advantage for a precision pneumatic seed metering device. For spherical small particle size seeds such as rapeseed, vegetable seed, investigating on the influence mechanism of vacuum singulation process of pneumatic seed metering device through the qualified index and missing index is susceptible to subsequent seed discharging and seed guiding processes. The purpose of this research was to explore the vacuum singulation process of a precision pneumatic seed metering device which was innovated specifically for spherical small particle size seeds by employing negative vacuum and positive pressure to singulate and discharge the seed respectively. With different parameter combinations of grouped seeds, hole diameter, seeding disc rotate speed and negative pressure, the photos of seed suction and migration state on seed metering device were photographed. It were statistics and analysis that the probabilities of the holes no seed holding, single seed holding and multiple seeds holding in the seeding disc. 5 sets of seeds with different thousand seeds weight were obtained by seed screening pretreatment. The analysis of seed physical properties showed that there were large relative differences although these small-sized seeds had small particle size and light weight. The experiment revealed that small particle size seeds could be held by the hole at -200 Pa because they were light in weight, 4-6 multi-seeds holding would occur when the absolute value of negative pressure was too large. The analysis showed that the probability of single-seed holding was a highly significant correlation with factors such as thousand seeds weight, the hole diameter of seeding disc, the rotate speed of the seeding disc and negative pressure. There was an applicable negative pressure range as 1-2 times of the critical negative pressure to ensure the seed metering device to separate a single seed accurately, by which the single seed holding probability of the device was higher than 0.92, and the probabilities of no seed holding and multiple seeds holding were less than 0.04. Force analysis of the suction process showed that the critical negative pressure was related to mechanical and physical properties of seeds, hole diameter, rotate speed of seeding disc and suction reliability. The main mechanism of the variation of seeding disk rotate speed affecting the seed holding was that the fast rotation speed reduced the effective time of the hole and the seed, thereby degraded the single seed holding reliability. When the rotate speed was faster, the absolute value of the critical negative pressure to accurately separate a single seed should increase. Therefore, the reliability coefficient to calculate the negative pressure should be increased. In order to quantify the reliability coefficient of seed holding by vacuum, a nonlinear fitting calculation method was applied. The 1st, 3rd, and 5th set seeds were divided into the correction set for the fitting calculation and the 2nd and 4th set seeds were divided into the verification set. The working negative pressure with no seed holding probability 0.02 and single seed holding probability 0.92 were selected as the reference value. A mathematical model of the reliability coefficient was established with rotate speed of seeding disc and hole diameter as dependent variables. The determination coefficient of the calibration set and the verification set of the mode were both greater than 0.82, which proved the reliability coefficient could be determined by using this model. Then the critical value of negative pressure could be worked out, by which the no seed holding probability kept less than 0.04, the single seed holding probability kept more than 0.92 and the seed metering device worked at optimal status. The research clarifies the influence mechanism of positive and negative pressure combined precision metering device for small particle seed accurately separating process and provides a reference for design and performance improvement of pneumatic seed metering device.

agricultural machinery; crops; optimization; seed metering device; negative pressure of seed holding; seed holding reliability; small particle size seed

廖宜涛,廖庆喜,王 磊,郑 娟,高丽萍. 气力式小粒径种子精量排种器吸种效果影响因素研究[J]. 农业工程学报,2018,34(24):10-17.doi: 10.11975/j.issn.1002-6819.2018.24.002 http://www.tcsae.org

Liao Yitao, Liao Qingxi, Wang Lei, Zheng Juan, Gao Liping. Investigation on vacuum singulating effect influencing factors of pneumatic precision seed metering device for small particle size of seeds[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(24): 10-17. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.24.002 http://www.tcsae.org

2018-08-19

2018-12-10

国家自然科学基金资助项目(51405180,51875229);国家重点研发计划资助项目(2017YFD0700702);国家油菜产业体系专项资助项目(CARS-12)

廖宜涛,博士,副教授,主要从事现代农业装备设计与测控研究。Email:liaoetao@mail.hzau.edu.cn

10.11975/j.issn.1002-6819.2018.24.002

S223.2

A

1002-6819(2018)-24-0010-08