Effects of CBN content on characteristics of PCBN composites in turning GCr15 hardened steels

, , , , , , , ,

(1.Key Material Physics Laboratory of Education Ministry of China, Physical Engineering College of Zhengzhou University, Zhengzhou 450052, China) (2.SF Diamond Co., Ltd., Zhengzhou 450016, China)

Abstract Well-sintered polycrystalline cubic boron nitride (PCBN) composites with different contents of cubic boron nitride (CBN) were obtained using Al and TiN as additives under pressure of 5.5 GPa and temperature of 1450 ℃. The network structure of CBN grains and bonding materials was observed using scanning electron microscope (SEM). With the help of X-ray diffraction (XRD) analysis, TiB2 and AlN could be determined as main products and Al3Ti also was detected in the Al-rich samples after sintering process. Furthermore, it was shown that Vickers hardness of composites was improved with the increase of CBN contents. However, the lifetime of PCBN composites was in negative correlation with the amount of CBN in turning GCr15 hardened steels, and the surface roughness of workpieces machined by these PCBN composites also showed the same trend. A series of cutting data confirmed that the low CBN content in PCBN composites could enhance the working durability and improve the surface quality in turning hardened steels. The present experiments also indicated that the lowest value of flank wear was not constant for different PCBN composites when they were used to machine several workpieces with different hardness.

Key words CBN contents; hardness; phase composition; microstructure; cutting property

Polycrystalline cubic boron nitride (PCBN) is a promising tool material, which is widely used for hard turning of iron and its alloys. Compared to conventional cutting materials, PCBN has many unique properties, such as good chemical stability, high hardness and high compressive strength[1-6]. In the manufacturing industry, PCBN is usually produced by high pressure and high temperature (HPHT) techniques[2-3], which requires different contents of CBN grains and various additives sintered under static high pressure and high temperature condition.

The content of CBN plays an important role in the characteristics of the PCBN. Generally, PCBN is broadly categorized as higher CBN content material with a metallic-type binder (around 90% CBN, often noted PCBN-H) or lower CBN content having ceramic based binder systems (around 60% CBN, often noted PCBN-L)[4-7]. PCBN-H has high hardness, excellent thermal conductivity and can be used for turning cast iron. PCBN-L has high toughness, good wear resistance and is appropriate for cutting hardened steel. Up to now, some studies have been conducted to investigate the properties of PCBN composites with different CBN contents and diverse additives sintered at various pressures and temperatures. Rong et al[1]compared the performance of 75 vol% CBN-13 vol% TiN-12 vol% Al composite and 86.5 vol% CBN-13.5 vol% Al composite and revealed that abrasion loss of the former composite was smaller than that of the latter composite when cutting die steel after 2 minutes. LIEW et al[7]researched the differences of cutting property between PCBN-H (CBN: 85 vol%) and PCBN-L (CBN: 60 vol%) composites in the ultra-precision machining of stainless steel, results of which showed that the CBN powders were all bonded by TiN and that an increase in CBN content could result in a reduction of cutting performance. LI et al[3]studied the PCBN-H composites (70 wt%-95 wt%) with Al as an additive. It was reported that the well-sintered CBN-Al composites could be obtained with moderate temperatures of 1200 ℃ and the longest tool life appeared in the CBN-15%Al samples for cutting hardened steels. Some literature[5,7]also implied that PCBN-L composites could provide better performance in tool life and surface quality than those of PCBN-H composites. However, there is not enough evidence to decide the role that the amount of CBN plays in the performance of PCBN composites when machining hardened steels. Therefore, a detailed description of the relationship between CBN contents and cutting performance will be investigated in the present experiments.

Furthermore, the additive also has a significant influence on the cutting performance of PCBN composites. Metals, located in the Ⅳb,Ⅴb,Ⅵb groups of the periodic table and their compounds, such as Al, Co, Ni, Ti, Al2O3, TiN, TiC etc, are often used as additives[8]. Among these bonding materials, Al has a lower melting point and can react with CBN at lower temperature[9], while TiN has a better antiwear property and its coefficient of thermal expansion is between CBN and Al[10,11]. Therefore, Al and TiN as the additives of the PCBN composites have received wide attention in recent years.

In this paper, it is reported that Al and TiN were chosen as additives to research the sintering process between Al-TiN and CBN. The hardness, phase composition, microstructure and wear mechanisms of PCBN system with different CBN contents (ranging from 50 vol% to 75 vol%) are investigated. Moreover, the lifetime of PCBN and the surface roughness of workpieces of GCr15 hardened steels are studied.

1 Experiment

1.1 Sample preparation

The CBN powder (99.9% purity, average size 10-20 microns, SF Diamond Co., Ltd., Zhengzhou, Henan), TiN powder and Al powder (99.9% purity, commercially available) were used as starting materials in the present experiment. The volume fractions of CBN in the starting materials ranged from 50% to 75%. Meanwhile, the weight ratio of Al and TiN was kept for 2∶1 in all the samples. The mixture powders were manually mixed using an agate mortar and pestle for 2 h. Subsequently, the mixture powders were degassed in vacuum of 1×10-2Pa at temperature of 800-1000 ℃ for 1 h. Then the dried admixtures and WC substrates were put in a molybdenum capsule for sintering experiment.

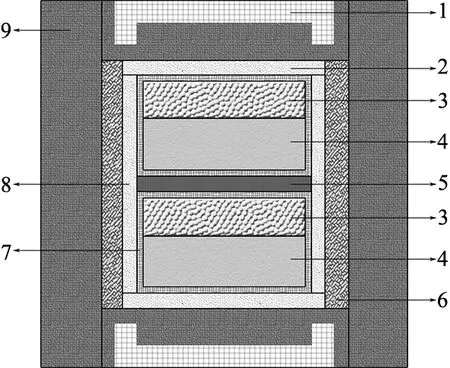

The sintering experiments were carried out in cubic hinge presses (Guilin Metallurgical Machinery General Factory, CS-IVD460, China) and the schematic diagram of sintering cell was assembled as shown in Fig.1.

1-stell ring, 2-flake of salt, 3-mixed powders of CBN-Al-TiN,4-tungsten carbide, 5-pressure spacer, 6-graphite pipe,7-molybdenum capsule, 8-NaCl tube, 9- pyrophyllite.

The process of the sintering experiment was as follows: the sample was first heated to 1450 ℃ with the heating rate of 200 ℃/min and then pressurized to 4.5 GPa and held for a short time; subsequently, the pressure was increased to 5.5 GPa and maintained for 13 min. After that, the sample was cooled and depressurized to normal values within 5 min. During the process of sintering, the cell temperature was measured by Pt6%Rh-Pt30%Rh thermocouple and the pressure was calibrated by the silver melting point method.

1.2 Sample polishing and characterization

The sintered samples were named as PCBN50, PCBN60, PCBN70 and PCBN75.The numbers stood for the volume percent of CBN in the samples. The four samples were machined to a thin cylinder (about 13 mm in diameter and 4.9 mm in thickness) and then manually polished to smooth mirror surface with diamond paste. The average Vickers hardness of the samples was measured by microhardness tester (HVS-1000) with 4.9 N of applied load and 10 s indented time. X-ray diffraction (XRD, PHILIP X′Pert, Holland) using CuΚαradiation and scanning electron microscope (JEOL JSM-6390A, Japan) equipped with an energy dispersive spectrometry analyzer (EDS, OxFord, INCAX-sight) were used to study the phase composition and the microstructures of the PCBN composites.

1.3 Tool preparation and cutting experiment

The polished samples were cut into the desired size and welded on the tool body with the model of WNMA080404 (ISO03364-1985). The tool holder was MWGNR2525M08E (ISO5608-1989).

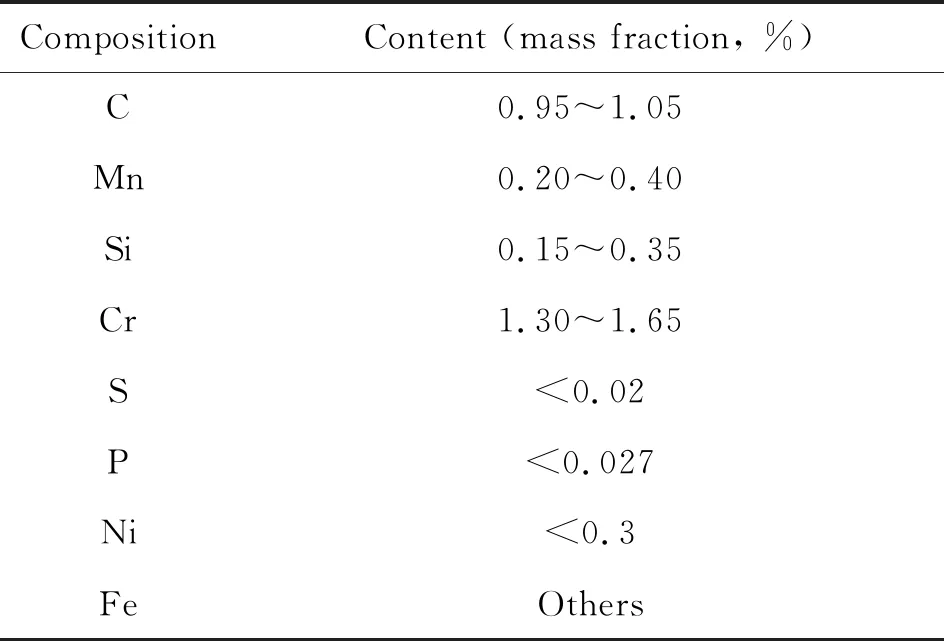

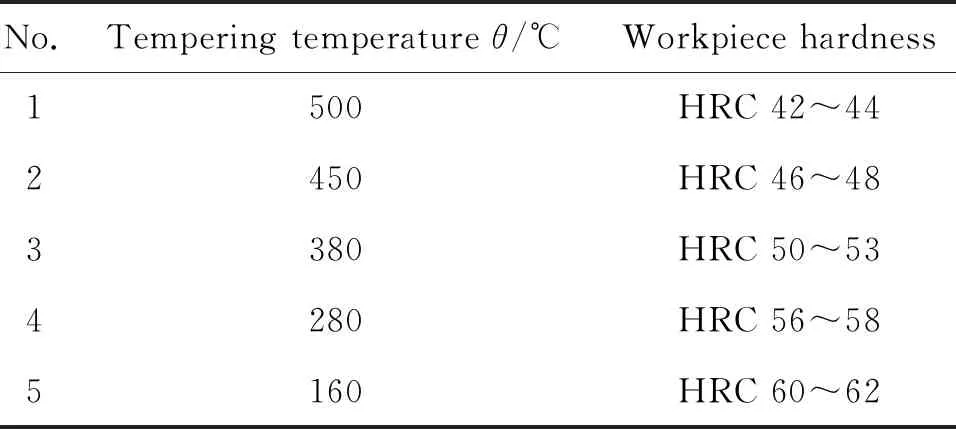

The cutting experiment was carried out on a CNC lathe (SMTCL CAK6185di, China) and the parameters were 100m/min of cutting speed, 0.25 mm of cutting depth and 0.09 mm/r of feed. GCr15 steel with hardness of 42~62 HRC was used as work material. The heat treatment conditions are shown in Table 1 and Table 2.

The tool wear was observed through SEM (JEOL JSM-6390A, Japan)and the surface roughness was measured by profilometer (Beijing Time High Technology Ltd. TR200,China). No lubricant or coolant were used in turning process. The GCr15 steel was heated to 850 ℃ and then oil quenched and tempered at different temperatures for 4 h.

Table 1 Composition of GCr15 steel

Table 2 Hardness of GCr15 steel after different heat-treatments

2 Results and discussion

2.1 Vickers hardness, phase composition and microstructure analysis

The measurement of the Vickers hardness followed the procedures of GB/T4340.1—1999 using a rectangular pyramid diamond indenter. The average Vickers hardness of the samples with different CBN contents is presented in Fig. 2.

From Fig. 2, it is clear that the average Vickers hardness is found to be maximum (3778 HV) for PCBN75 and minimum (2485 HV) for PCBN50. The hardness of the samples is improved with increase of CBN contents. For the CBN-TiN-Al system, CBN has the highest hardness of about 8000 HV compared to TiN (2500 HV) and Al (20 HV). Because of high hardness of CBN and TiN, it is inferred that the hardness of PCBN composite is mainly attributed to the content of CBN and TiN, while Al mainly serves as adhesive in sintering process.

Fig. 2 Microhardness of raw materials and PCBN composites

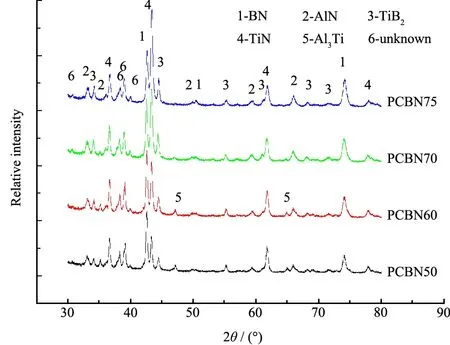

Fig. 3 shows the XRD patterns of the PCBN50, PCBN60, PCBN70 and PCBN75. The major phases in the four samples are BN (cubic phase), AlN (hexagonal phase), TiB2(hexagonal phase) and TiN (cubic phase). No metallic Al is detected in the XRD spectrum of these samples, which testifies that the starting Al is consumed completely. TiB2and AlN are main reaction products. The reaction mechanism in the CBN-Al-TiN composites had been reported by RONG et al[1], which could be summarized as follows:

2BN(s) + TiN(s) +3A1(1) → TiB2(s) + 3A1N(s)

(1)

Fig. 3 XRD patterns of PCBN50, PCBN60, PCBN70 and PCBN75

However, the diffraction peaks of Al3Ti (tetragonal phase) are simultaneously observed in the PCBN50 and PCBN60. It can be speculated that not all of Al has been used up after the reaction (1) as a result of relatively high content of Al in PCBN50 and PCBN60. The residual metallic Al is expected to react with TiN and the following reaction may occur:

6Al(l) + 2TiN(s) → 2Al3Ti(l) + N2(g)

(2)

Al3Ti as one of intermetallic compound in trialuminide alloys has some prominent advantages, such as good mechanical properties at high temperature, excellent inoxidizability and high specific tenacity[12]. Hence, it is predicted that Al3Ti may be served as a particular bonding material for the sintering of PCBN composites.

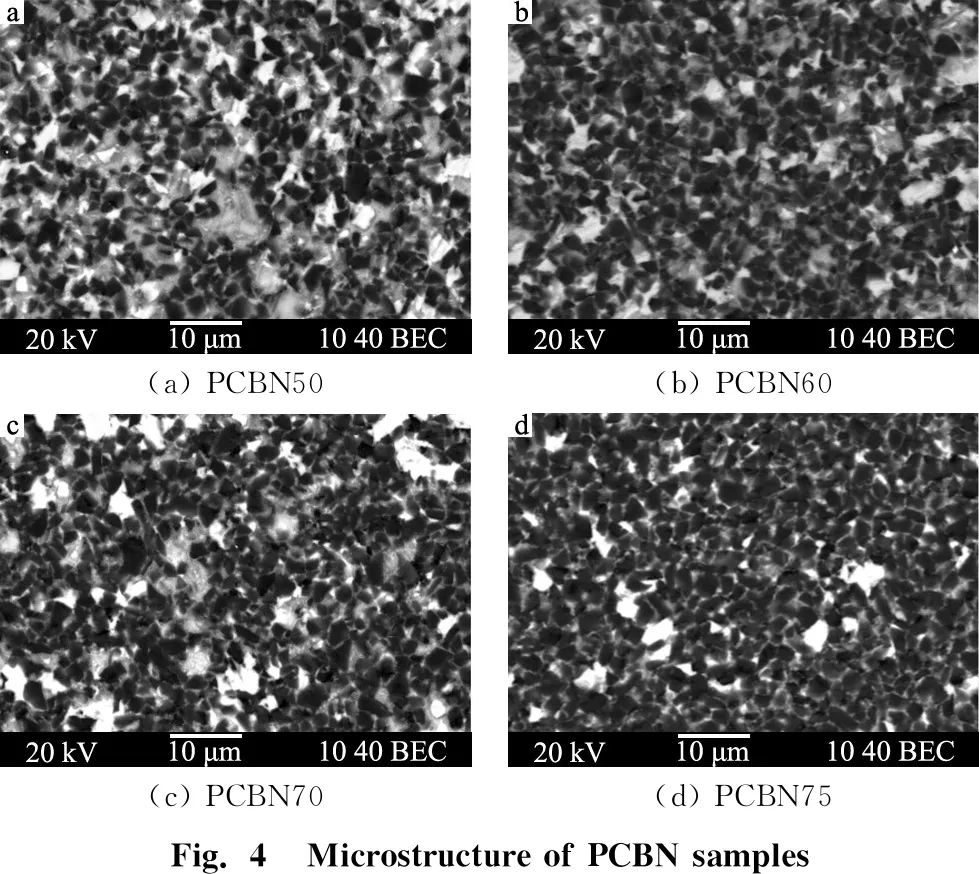

Fig. 4 shows the microstructures of the four PCBN samples. The back scatter electron microscopy (BSEM) images prove that the well-sintered PCBN composites can be synthesized using Al and TiN as additives.All of the samples are dense, integrated and have similar microstructure. With the help of energy dispersive spectrometer (EDS) and X-ray diffraction (XRD) analyses, the dark portion is found to be BN, and the gray portion to be AlN, while TiN and TiB2are determined to comprise the bright portion.

(a) PCBN50(b) PCBN60(c) PCBN70(d) PCBN75Fig. 4 Microstructure of PCBN samples

Moreover, the CBN grains are well-distributed and surrounded by the bonding materials, which forms a network structure. The additives and products act as binders that tightly bond the CBN grains together in the network structure. The shape of CBN grains becomes smoother due to the reaction between CBN and additives. In addition, the direct bonding of CBN grains can be detected in some regions of PCBN70 and PCBN75. The agglomeration of binder is observed in our experiment as well[2], but the agglomerate zones lessen gradually in the samples with higher CBN contents.

2.2 Wear mechanisms and surface roughness analysis

The purpose of the cutting test was to determine the correlation between the percentage of CBN and the cutting performance. The lifetime was represented by the average width of flank wear (wb) and the surface quality of machined parts was characterized by the average arithmatic roughness (Ra).

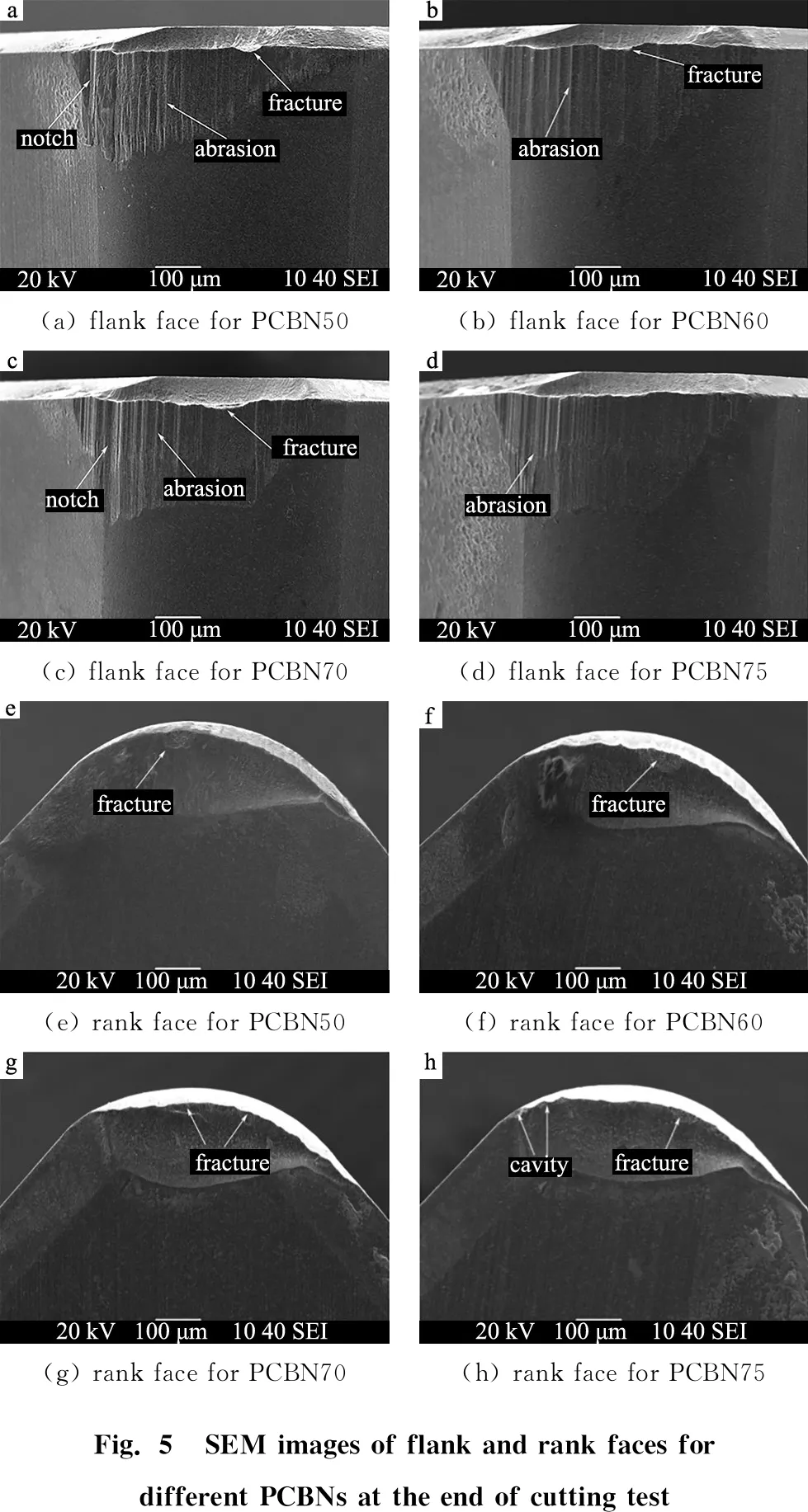

The wear behavior of PCBN composites is discussed in terms of flank wear and crater wear which are presented in Fig. 5.

It should be noticed that no chipping or breakage is visible on any of the PCBN composites at the end of cutting test. This fact shows that all composites are sufficiently tough and have good chemical stability to withstand the impacts and high temperatures caused by cutting process. It is well known that the flank and crater wear are attributed to abrading on the flank side with workpieces and movement of the chips on the rake face respectively. Therefore, as can be seen from Fig. 5a to Fig. 5d, the thin scratches on the flank face indicate that the main wear mechanism is abrasion and the scar gradually increases from PCBN50 to PCBN75. Similarly, from Fig. 5e to Fig. 5h, the same tendency is found for crater wear. The wear region on rake face gradually expands with increase of CBN contents. Moreover, some slight fractures appear and fracture zones become larger in higher CBN composites. According to EDS analysis, the elements of Fe, Cr, Mn and S are detected in the rake face, which come from the workpieces. Thus, it is concluded that diffusion simultaneously acts on the rake face.

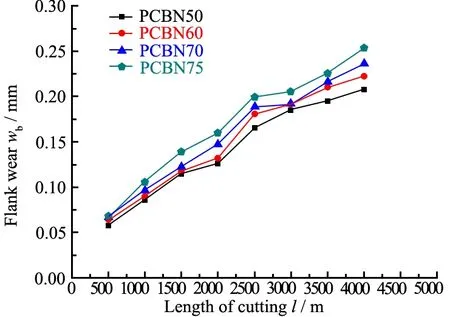

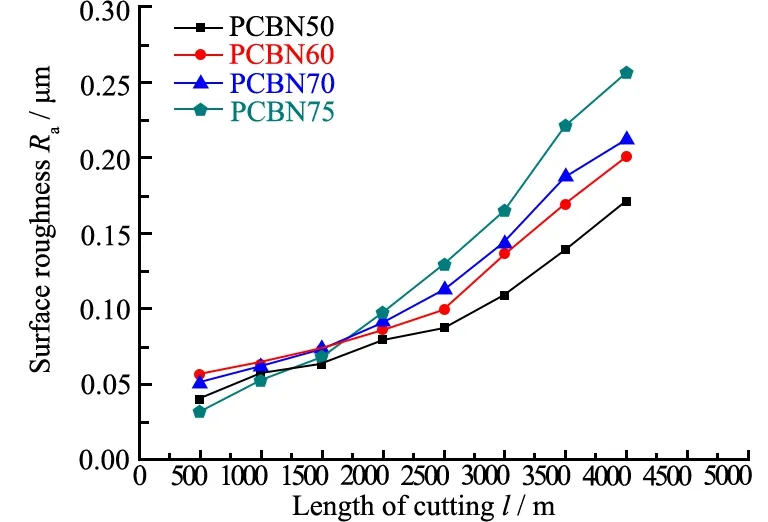

The wear curves of each tool used to machine GCr15 hardened steel are shown in Fig. 6a. It can be seen that the flank wear of PCBN composites is accelerated with the increase in CBN content. PCBN50 has best cutting performance during turning hardened steel and it can survive for about 6000 m when the flank wear reaches 0.3 mm. Alternatively, PCBN75 has the poorest result and it survives 1500 m, which is much less than that of PCBN50. So it can be deduced that the relationship between the lifetime and CBN content is inverse in our experiment. On the one hand, the tool binder is rubbed by hard carbide particles in the workpiece material, and CBN grains are detached from the surface of PCBN with the bond material consumption[8], which leads to crater growth as the test progresses. On the other hand, increasing the content of the binder and decreasing the content of CBN in PCBN composites can reduce the porosity and increase their ductility, which helps to restrain fracture propagation in the composites[7]. Consequently, the improvement of bonding strength and the decline of fracture zones reduce wear and tear when the volume of additives materials increases. Therefore, it is deduced that the lower content of CBN in PCBN-L composites can enhance their lifetime when machining these hardened steels.

(a) flank face for PCBN50(b) flank face for PCBN60(c) flank face for PCBN70(d) flank face for PCBN75(e) rank face for PCBN50(f) rank face for PCBN60(g) rank face for PCBN70(h) rank face for PCBN75Fig. 5 SEM images of flank and rank faces for different PCBNs at the end of cutting test

(a) Wear curves of each tool when machining GCr15

(b) Relation between CBN content and Ra of machined partsFig. 6 Cutting performance of different PCBN tools

Fig. 6b illustrates the relation between the CBN contents of the PCBN composites and surface roughnessRaof the machined parts. At the beginning of turning, theRavalue of parts machined by PCBN75 is 0.464 4 μm, the minimum and that of parts machined by PCBN60 is 0.511 8 μm, the maximum. As the program goes on, the surface roughness changes evidently when using PCBN75 to machine after 1500 m. TheRagoes up to more than 0.9 μm at the end of 4000 m. Conversely, theRavalue obtained by PCBN50 is generally better, which is 0.741 8 μm when the cutting length reaches 4000 m. This phenomenon can be attributed to the excellent abrasion resistance of PCBN50, which creates a relative stable machining condition that improves the surface finish of workpieces. When PCBN75 is used to machine, a better surface quality may be achieved due to its high hardness and low plasticity at the starting stage. However, the sharp increase in wear scars causes chattering in the turning process after 1500 m, which has clear implications on the worse surface accuracy of machined parts. Consequently, the experiment results imply that the surface roughness of workpiece is strongly associated with wear of composites. In conclusion, the lower volume fraction of CBN in PCBN composites can provide a smoother cutting environment, which improves surface quality on the machined parts.

2.3 Effect of workpiece hardness on wear property of composites and machined surface quality

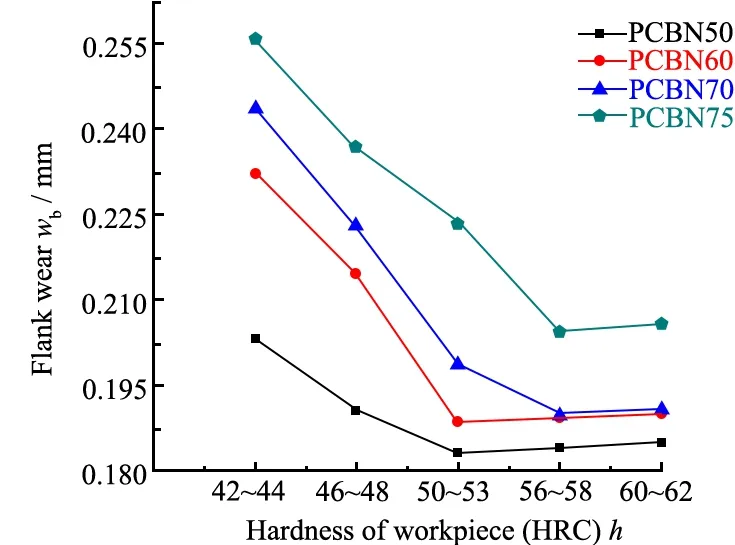

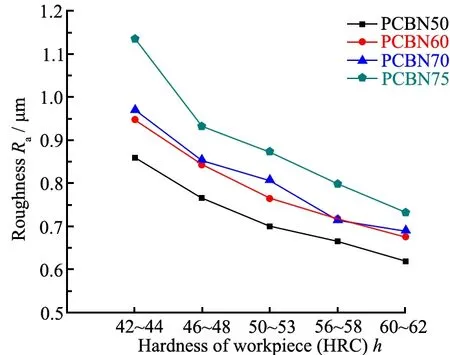

To investigate the effect of the workpiece hardness on the wear property of the composites and the machined surface quality, GCr15 steels with hardness from 42 HRC to 62 HRC are machined by PCBN composites. The flank wear of PCBN composites and the surface roughness of workpiece after cutting for 3000 m at a speed of 100 m/min, a depth of 0.25 mm and a feed of 0.09 mm/rev are shown in Fig. 7.

In Fig. 7a, it is observed that the wear curves of the flank face decreases rapidly with the increase of hardness when the hardness of workpiece is less than 50-53 HRC for PCBN50, PCBN60 or 56-58 HRC for PCBN70, PCBN75. However, the wear data rebound when the hardness of the workpiece exceeds the above values respectively. This phenomenon can be explained by a traditional metal cutting theory known as the metal softening effect. For the PCBN, it has been well known that cutting temperature increases with workpiece hardness. When the workpiece reaches a critical hardness value, the cutting temperature rises and the hardness of machined zone decreases, which makes turning easier and reduces composites wear[13]. Additionally, at this value, the above phenomenon is enhanced with the formation of a protective layer on the PCBN composites. Whereas, when the hardness exceeds this value, the higher cutting temperatures will activate diffusion and chemical wear and thus the wear of PCBN becomes serious. Some literature[13]showed that 50 HRC was the critical hardness for the metal softening effect. However, it is found that this critical hardness is not stationary for different PCBN composites in the present tests. The critical hardness is about 50-53 HRC for PCBN50, PCBN60 and about 56-58HRC for PCBN70, PCBN75. PCBN50 and PCBN60 have lower thermal conductivity and therefore more heat would retain in machined zone. PCBN70 and PCBN75 have higher thermal conductivity[5]and hence dissipate heat more easily.

(a) flank wear for PCBN composites

(b) machined surface roughnessFig. 7 Tool performance of different PCBN tools as workpiece hardness changing from 42 HRC to 62 HRC

Consequently, a lower cutting temperature is generated when high CBN contents composites are used to machine the hardness materials than that of composites with low CBN content. For the composites PCBN-H, turning a workpiece with higher hardness is required to reach the critical temperature value for which the metal softening effect exists. This is the reason why the critical hardness varies for composites with different CBN composites in turning workpieces with different hardness.

From Fig. 7b, it is also observed that the machined surface roughness value decreases with the increase in hardness. The best surface quality is obtained when workpiece hardness is around 60 HRC. This may result from the change of plasticity in the workpiece. The small plastic deformation may bring excellent surface quality. Hence, higher workpiece hardness is beneficial for obtaining better surface quality of the workpiece in the present work. Furthermore, this series of cutting data also confirm the conclusion that the best cutting performance can be achieved by PCBN composites with low CBN content when turning hardened steels.

3 Conclusion

Based on experimental results, the following conclusions can be drawn:

(1) Well-compacted PCBN samples can be obtained with Al and TiN as additives sintered at 1450 ℃ and 5.5 GPa. There forms a network structure in the samples and the bonding materials symmetrically coat the CBN grains. After the sintering process, TiB2and AlN are discovered as main products in all composites, and Al3Ti is also detected in the Al-rich composites (PCBN50 and PCBN60).

(2) The relationship between Vickers hardness of the samples and the content of CBN is proportional. The cutting investigation demonstrates that PCBN50 has the outstanding performance both in lifetime and in machined surface finish. Increases of CBN content in PCBN composites usually results in the degeneration of cutting performance.

(3) The flank wear of each PCBN composite has minimum value when workpiece hardness reaches a critical hardness. However, this critical hardness varies for different PCBN composite. The composites having high CBN content usually have higher critical machining hardness.

Acknowledgement:

This work is funded by SF Diamond Co., Ltd., China.