分散染料耐碱性能评定方法的研究

郝芬 荆丽丽 杜金梅 蒋阳 许长海

摘要: 分散染料碱性染色工艺已经获得应用和推广,为了提供一种简单易行的评定分散染料耐碱性能的方法,本文探讨了高温高压染色条件下分散染料的耐碱性能。结果表明,升温速率2 ℃/min,染色温度130 ℃,保温时间30 min,分别采用常规弱酸性条件(pH值约为4.8),2 g/L的CH3COONa、2 g/L的Na2CO3和2 g/L的NaOH的染浴上染涤纶织物,依据碱性条件与常规弱酸性条件染色织物的色差ΔECMC,可有效鉴定出不同分散染料的耐碱性,并根据等级划分将分散染料分为高耐碱性(优)、一般耐碱性(良)、弱耐碱性(中)、不耐碱性(差)四级。

关键词: 分散染料;耐碱性;涤纶织物;染色;评定;高温高压

中图分类号: TS190.9 文献标志码: A 文章编号: 1001-7003(2022)01-0064-05

引用页码: 011110DOI: 10.3969/j.issn.1001-7003.2022.01.010

涤纶织物的前处理通常在碱性浴中完成,而分散染料染色是在酸性浴中进行。前处理后的涤纶织物必须通过洗涤去除碱剂,否则染色过程中染浴pH值会产生波动,导致染色缸差、色光不正或色光变化等疵病,影响织物质量[1-2]。同時,涤纶织物在酸性浴染色时会析出低聚物,引发产品质量下降、染色设备难以清洗等一系列问题[3]。如果涤纶织物的分散染料染色能够在碱性条件下进行,就能够实现前处理、碱减量及分散染料染色一浴一步工艺,可有效避免酸性染色所带来的弊端并能减少废水排放、缩短工艺流程[4-5]。

涤纶染色常用的分散染料在碱性条件下会发生水解,染色无法顺利实施。所以,涤纶碱性染色技术的关键是分散染料的耐碱性[6]。如果不掌握分散染料的耐碱性,而直接进行碱性条件染色,易引起染色质量问题[7-9]。由于染料结构与其耐碱性的关系尚未确定,以及缺乏分散染料的耐碱程度评判方法和碱性染色的分散染料选用标准,从而导致染整工作者选择染料时没有针对性。

根据印染厂涤纶碱性染色出现的实际问题,本文探索了染色工艺条件、碱剂种类及质量浓度对分散染料耐碱性的影响,并且以实验结果为分析依据,确定了快速评估分散染料耐碱性的实验方法,可用于碱性染色的分散染料筛选工作,有助于最大化提高工厂生产效率。

1 实 验

1.1 材料和仪器

材料:涤纶平纹针织布(市售),平方米质量为188 g/m2。

试剂:分散红HA-R、分散红GS、分散黄HE-3R、分散黄BRA、分散蓝H-GLW、分散蓝HGL、耐碱匀染剂均为工业品(蓬莱嘉信染料化工有限公司),氢氧化钠(NaOH)、醋酸钠(CH3COONa)、碳酸钠(Na2CO3)、保险粉(Na2S2O4)均为分析纯(国药集团化学试剂有限公司)。

仪器:Rapid高温高压小样染色机(厦门瑞比精密机械仪器有限公司),UV2600紫外-可见分光光度仪(岛津仪器苏州有限公司),Datacolor-650反射分光光度仪(美国德塔颜色科技有限公司),pH值计STARTER 3100(奥豪斯仪器上海有限公司)。

1.2 染色工艺

采用分散红HA-R、分散红GS、分散黄HE-3R、分散黄BRA、分散蓝H-GLW、分散蓝HGL六种染料,对涤纶针织物进行染色。

1.2.1 染色处方

分散染料质量分数为1%(相对织物质量),染色温度为115、120、125、130、135 ℃,时间为20、30、40、50、60 min,升温速率为0.5、1、1.5、2、2.5 ℃/min,pH 4.8缓冲液为15 mL,匀染剂质量浓度为2 g/L,浴比为1 ︰ 50。

1.2.2 还原清洗处方

保险粉质量浓度为2 g/L,NaOH质量浓度为2 g/L,温度为85 ℃,时间为20 min,浴比为1 ︰ 30。

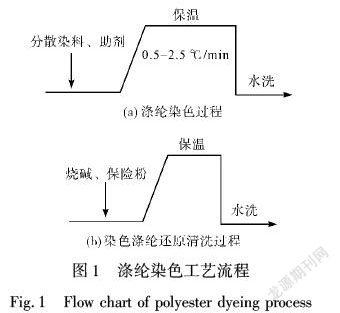

1.2.3 工艺流程

工艺流程如图1所示。

1.3 染色性能

使用Datacolor-650反射分光光度仪(D65光源,10°视角下)测定试样K/S值及色差(ΔECMC)。以碱性条件染色与常规弱酸性条件(pH 4.8)染色织物的色差ΔECMC变化判断其色变等级,分析碱性条件下分散染料的染色性能。

2 结果与分析

2.1 染色工艺优化

2.1.1 染色温度的影响

涤纶需要在高温下才能上染,因此以织物的颜色深度K/S值为衡量标准,探究温度对织物染色效果的影响。按1.2染色工艺进行涤纶染色,其中染色升温速率2 ℃/min,保温40 min。染色织物的K/S值如图2所示。

由图2可以看出,采用常规弱酸性条件染色时(pH 4.8),随着染色温度的升高,各支染料染色织物的K/S值会不同程度提高,而温度达到130 ℃后,织物K/S值不再变化。这是因为涤纶无定形区分子链段随着染色温度的提高热运动增强,形成更多可容纳染料的孔隙,吸附在纤维表面的染料扩散进入孔隙完成染色,所以织物K/S值增大。但是通过分子链运动形成的孔隙的数量及体积受到涤纶高分子聚集态结构的限制,不会无限增大,故织物K/S值不随染色温度升高而无限增大,基本在130 ℃会有较好的染色效果。

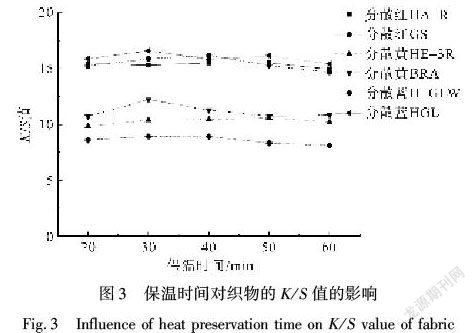

2.1.2 保温时间的影响

按1.2染色工艺,以2 ℃/min的升温速率,130 ℃的染色保温温度探究保温时间对涤纶染色性能的影响,处理后染色织物的K/S值如图3所示。由图3可知,随着保温时间的延长,分散红HA-R、分散红GS、分散黄HE-3R、分散黄BRA、分散蓝H-GLW和分散蓝HGL所得染色织物的K/S值基本不变,且保温染色30 min后织物色深几乎保持稳定,说明染料在该染色时间内基本完成染色。

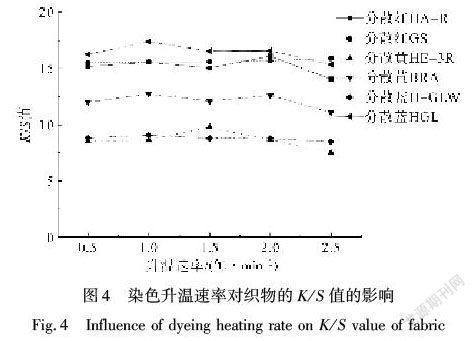

2.1.3 升温速率的影响

其他染色条件不变,探究升温速率对染色所得织物K/S值的影响,结果如图4所示。由图4可知,升温速率对织物K/S值的影响规律同保温时间对织物的影响,即升温速率对织物K/S值的影响不大。对比六种染料在不同升温速率下所得织物K/S值可知,大部分染料以较高的升温速率染色仍可以获得较稳定的得色量,考虑到升温速率与能源节省及匀染性之间的关系,升温速率宜选择2 ℃/min。

2.2 分散染料耐碱性能评价

2.2.1 分散染料对CH3COONa碱调节剂溶液的耐受性

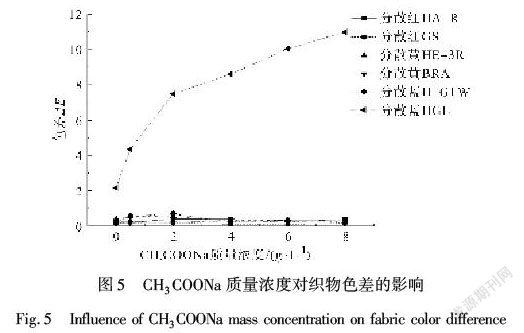

分别将分散红HA-R、分散红GS、分散黄HE-3R、分散黄BRA、分散蓝H-GLW、分散蓝HGL按1.2染色工艺对涤纶织物进行染色,其中升温速率为2 ℃/min,染色温度为130 ℃,保温时间为30 min,仅改变CH3COONa质量浓度。通过与常规弱酸性条件(pH 4.8)染色织物对比,以色差ΔECMC为衡量指标,获取以上染料染色时对含不同质量浓度的CH3COONa碱调节剂溶液的耐受性,实验结果如图5所示。

当两个染色涤纶织物样品的色差小于1.0时,可认为两个颜色几乎无差别。对于同一支染料,仅改变染色酸碱性,其他参数不变,如果织物色差小于或尽可能接近1.0,则说明染料在该条件下稳定[10]。由图5可知,以pH值为4.8的染色涤纶织物做对照样,除分散藍HGL外,其他染料在不同CH3COONa质量浓度下均具有小于1的色差。分散蓝HGL染色时,无论CH3COONa质量浓度为多大,色差都明显大于1,说明染料色光发生了改变,即该染料在非酸性条件下不稳定。随着CH3COONa质量浓度的增大,溶液pH值增大,在CH3COONa达到2 g/L时不再改变(pH 8),属于弱碱性。可以以此质量浓度为染料是否耐受CH3COONa碱调节剂溶液的临界点,作为评判染料是否属于耐碱性的标准。据此,可认为分散蓝HGL为不耐碱性染料,而分散红HA-R、分散红GS、分散黄HE-3R、分散黄BRA、分散蓝H-GLW耐受弱碱可进一步增加染色溶液碱性以明确其耐碱程度。

2.2.2 分散染料对Na2CO3碱调节剂溶液的耐受性

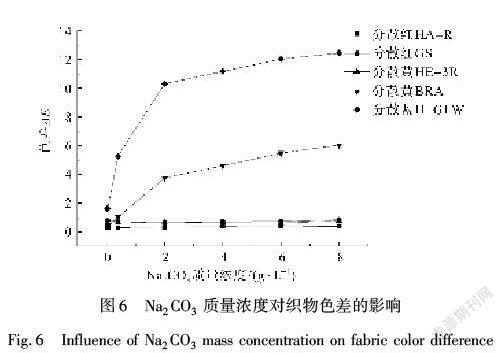

将分散红HA-R、分散红GS、分散黄HE-3R、分散黄BRA、分散蓝H-GLW按1.2染色工艺对涤纶织物进行染色,其中升温速率为2 ℃/min,染色温度为130 ℃,保温时间为30 min,仅改变Na2CO3质量浓度,通过与常规弱酸性条件(pH 4.8)染色织物对比,以色差ΔECMC为衡量指标,获取以上染料染色时对含不同质量浓度的Na2CO3碱调节剂溶液的耐受性,实验结果如图6所示。

由图6可知,分散黄BRA、分散蓝H-GLW染料所染织物的色差明显大于1,分散红HA-R、分散红GS、分散黄HE-3R均小于1。可认为分散黄BRA、分散蓝H-GLW不耐受Na2CO3作为碱调节剂的染色,而分散红HA-R、分散红GS、分散黄HE-3R可耐受Na2CO3溶液的染色。由图6还可见,不耐受Na2CO3碱调节剂溶液的染料随Na2CO3质量浓度的增大,所得织物色差持续增大,但当Na2CO3质量浓度大于2 g/L后,色差增大幅度减小。由于2 g/L的Na2CO3溶液的pH值约为11.30,继续增大Na2CO3质量浓度,染浴pH值基本不变,因此可以将2 g/L的Na2CO3作为染料是否耐受Na2CO3碱调节剂溶液染色的临界点,以此作为鉴定染料是否属于一般耐碱性。据此,可认为分散黄BRA、分散蓝H-GLW属于耐弱碱性染料,而分散红HA-R、分散红GS、分散黄HE-3R属于一般耐碱性染料,可进一步增加染色溶液碱性以明确其耐碱程度。

2.2.3 分散染料对NaOH碱调节剂溶液的耐受性

将分散红HA-R、分散红GS、分散黄HE-3R按1.2染色工艺对涤纶织物进行染色,其中升温速率为2 ℃/min,染色温度为130 ℃,保温时间为30 min,仅改变NaOH质量浓度,通过与常规弱酸性条件(pH 4.8)染色织物对比,以色差ΔECMC为衡量指标,获取以上染料染色时对含不同质量浓度的NaOH碱调节剂溶液的耐受性,实验结果如图7所示。

由图7可知,随着NaOH质量浓度的增大,分散红GS和分散黄HE-3R所得染色织物的色差显著增大,且在NaOH质量浓度达到2 g/L时色差都超过了1;分散红HA-R在NaOH质量浓度小于2 g/L时,织物色差均小于1,超过2 g/L时,织物色差ΔECMC趋向于1,但变化不明显。因此可选2 g/L的NaOH溶液作为染料是否属于高耐碱性的临界点。据此,可认为分散红GS、分散黄HE-3R属于一般耐碱性,而分散红HA-R为高耐碱性染料。

2.2.4 评价等级的确定

通过改变染色体系碱性,确定了评定染料耐碱性应选用的碱剂种类及质量浓度,分别为2 g/L CH3COONa、2 g/L Na2CO3、2 g/L NaOH。以染料在不同碱性条件下染色所得织物与常规弱酸性条件(pH 4.8)染色织物的色差ΔECMC为衡量指标,满足ΔECMC≤1.0所对应的最高碱性条件为该染料的耐碱程度。分散染料按耐碱性强弱可分为优、良、中、差四级,其中优为高耐碱性(2 g/L NaOH条件下ΔECMC≤1.0),良为一般耐碱性(2 g/L Na2CO3条件下ΔECMC≤1.0,但2 g/L NaOH条件下ΔECMC>1.0),中为弱耐碱性(2 g/L CH3COONa条件下ΔECMC≤1.0,但2 g/L Na2CO3条件下ΔECMC>1.0),差为不耐碱性(2 g/L CH3COONa条件下ΔECMC>1.0)。分散红HA-R、分散红GS、分散黄HE-3R、分散黄BRA、分散蓝H-GLW、分散蓝HGL评价等级见表1。分散蓝HGL在高温及2 g/L CH3COONa条件下染色的涤纶织物色差ΔECMC>1,耐碱性评为差;分散黄BRA、分散蓝H-GLW在2 g/L的CH3COONa条件下染色的织物色差ΔECMC<1,而在2g/L的Na2CO3条件下染色织物色差ΔECMC>1,耐碱性评为中;分散红GS、分散黄HE-3R在2 g/L的CH3COONa、Na2CO3条件下染色的织物色差ΔECMC<1,而在2 g/L的NaOH条件下染色织物色差ΔECMC>1,耐碱性评为良;分散红HA-R在2 g/L的CH3COONa、Na2CO3、NaOH条件下染色织物色差ΔECMC<1,耐碱性则评为优。

3 结 论

本文探讨了分散染料在不同碱性条件下对涤纶织物进行高温高压染色的性能,根据染色涤纶织物的色差分析了分散染料的耐碱性,得出如下结论:

1) 不同分散染料的耐碱性能差异较大。

2) 判定分散染料耐碱性能的合适实验条件为:染色温度130 ℃,升温速率2 ℃/min,保温时间30 min。

3) 分别选用2 g/L CH3COONa、2 g/L Na2CO3、2 g/L NaOH碱性条件染色,依据与常规弱酸性条件(pH 4.8)染色织物的色差ΔECMC,评价染料耐碱程度。满足ΔECMC≤1.0所对应的最高碱性条件为该染料的耐碱程度。耐碱性强弱可分为优、良、中、差四级,其中优为高耐碱性,良为一般耐碱性,中为弱耐碱性,差为不耐碱性。

《丝绸》官网下载

中国知网下载

参考文献:

[1]孙海建. 耐NaOH介质的分散染料短流程碱性染色技术研究[D]. 苏州: 苏州大学, 2012.

SUN Haijian. The Technology Research of Disperse Dyes Shortened Dyeing Process in NaOH Solution[D]. Suzhou: Soochow University, 2012.

[2]樊如梅. 涤纶纤维碱性染色工艺[J]. 印染, 2006(3): 22-24.

FAN Rumei. Alkaline dyeing of polyester fiber[J]. Dyeing and Finishing, 2006(3): 22-24.

[3]何永锋. 分散染料碱性染色与印花及糊料流变性研究[D]. 上海: 东华大学, 2016.

HE Yongfeng. Studies on Alkaline Dyeing and Printing of Disperse Dyes and Rheological Properties of Paste[D]. Shanghai: Donghua University, 2016.

[4]曹机良, 孟春丽, 陈云博, 等. 涤纶碱减量和染色一浴处理工艺研究[J]. 丝绸, 2016, 53(2): 19-25.

CAO Jiliang, MENG Chunli, CHEN Yunbo, et al. One bath dyeing and alkali deweighting process of polyester fabric[J]. Journal of Silk, 2016, 53(2): 19-25.

[5]夏建明, 陳晓玉, 吴爱莲. 涤棉混纺针织物免还原清洗染整工艺[J]. 针织工业, 2009, 37(9): 35-37.

XIA Jianming, CHEN Xiaoyu, WU Ailian. Study of the reduction clearing free dyeing and finishing technology for the polyester/cotton blended knitted fabric[J]. Knitting Industries, 2009, 37(9): 35-37.

[6]张巍峰. 涤纶织物的碱性染色工艺探究[J]. 智慧中国, 2018(12): 92-94.

ZHANG Weifeng. Study on alkaline dyeing process of polyester fabric[J]. Smart China, 2018(12): 92-94.

[7]辛云川. 涤纶/人棉织物碱性色烂花印花的研究[D]. 苏州: 苏州大学, 2010.

XIN Yunchuan. Study of Alkaline Colored Burnt-Out Printing in Polyester/Rayon Fabric[D]. Suzhou: Soochow University, 2010.

[8]刘杰. 超细涤纶织物碱性浴染色工艺研究[J]. 染料与染色, 2005, 42(4): 45-48.

LIU Jie. The technology and properties of superfine polyester fabric dyed in alkaline bath[J]. Journal of Dyes and Dyeing, 2005, 42(4): 45-48.

[9]杨栋樑. 超细旦涤纶织物的染色问题[J]. 印染, 2004(5): 42-49.

YANG Dongliang. Certain problems arising in supermicro polyester fabric dyeing[J]. Dyeing and Finishing, 2004(5): 42-49.

[10]HUSEYIN A E, PERVIN A. Dye selections for alkaline one-step disperse/reactive dyeing of polyester/cotton blends[J]. AATCC Review, 2004, 4(7): 23-27.

Abstract: Conventionally, the pretreatment process of polyester fabric is completed in alkaline condition, but polyester fabric dyeing process is usually carried out in acidic condition. Therefore, multiple washing and acid pickling before dyeing are required to remove the residual alkali agent on the fabric, otherwise it would easily cause pH fluctuation of dyeing bath and affect the dyeing quality of fabric. In addition, due to the low solubility of the oligomer precipitated in acid bath, the dyeing fabric and dyeing equipment will be affected.

The above problems can be solved to a certain extent by using alkaline dyeing, which essentially depends on the alkali resistance of disperse dyes. However, it is difficult for dyeing and finishing workers to choose targeted dyes for alkaline dyeing because of the undetermined relationship between the dye structure and its alkali resistance, as well as the lack of alkali resistance evaluation methods for disperse dyes. To address the practical problems of alkaline dyeing of polyester fabric, we explored the impact of dyeing process conditions, types and dosages of alkali agents on the alkali resistance performance of disperse dyes and determined a simple and rapid evaluation method of the alkali resistance performance of disperse dyes with the experimental results as the analysis basis.

Firstly, we investigated the factors affecting the alkali resistance of disperse dyes under high-temperature and high-pressure conditions and chose the optimal process conditions for evaluating the alkali resistance performance of disperse dyes. K/S value was used as a measurement standard to explore the impact of temperature, heat preservation time and heating rate on the dyeing effect of polyester fabric. It was found that the K/S values of polyester fabrics were stable after dyeing at 130 ℃ for 30 minutes with a heating rate of 2 ℃/min with a dye concentration of 1% (o.w.f) and this process conditions met the requirements of alkali resistance performance test.

Secondly, we discussed the stability of disperse dyes in different alkaline solutions, and analyzed the feasibility of evaluation indexes. Disperse dyes, Red HA-R, Red GS, Yellow HE-3R, Yellow BRA, Blue H-GLW and Blue HGL were used to dye polyester fabrics under different concentrations of CH3COONa, Na2CO3 and NaOH according to above optimum dyeing process. Color difference ΔECMC between the dyed fabrics under different concentrations of different alkali agents and the dyed fabrics under conventional weak acid condition (pH 4.8) was used as a measurement index to obtain the alkali resistance of the above dyes. The results show that color differences of the 6 disperse dyes have significant differences under alkaline conditions of 2 g/L CH3COONa, 2 g/L Na2CO3, 2 g/L NaOH, respectively. ΔECMC of polyester fabrics dyed with Blue HGL disperse dye is higher than 1.00 under 2 g/L CH3COONa (pH 8.00), and ΔECMC of polyester fabrics dyed with the other five disperse dyes is all lower than 0.50 under this condition. ΔECMC of polyester fabrics dyed with Yellow BRA and Blue H-GLW disperse dyes is higher than 1.00 under 2 g/L Na2CO3 (pH 11.30), while that of Red GS Yellow HE-3R disperse dyes is higher than 1.00 only under 2 g/L NaOH (pH 12.62). ΔECMC of polyester fabrics dyed with Red HA-R disperse dye is still lower than 1.00 under 2 g/L NaOH. Therefore, alkali resistance performance of disperse dyes can be evaluated according to the color difference ΔECMC and alkaline conditions of 2 g/L CH3COONa, 2 g/L Na2CO3, 2 g/L NaOH, respectively.

Finally, the test method for evaluating the alkali resistance performance of disperse dyes was established and verified. Through dyeing under alkaline conditions of 2 g/L CH3COONa, 2 g/L Na2CO3 and 2 g/L NaOH, respectively, according to the color difference ΔECMC between the dyed fabrics and the conventional weak acid condition (pH 4.8), the alkali resistance degree of the dyes was evaluated. The highest alkaline condition meeting ΔECMC≤1.0 was determined as the alkali resistance of the dye, which can be classified in four levels: high alkali resistant (excellent), medium alkali resistant (good), weak alkali resistant (medium) and non-alkali resistant (poor). According to the established evaluation method, the alkali resistance performance of 6 disperse dyes was evaluated. The results show that Red HA-R disperse dye is evaluated as high alkali-resistant type, which can withstand dyeing with at least 2 g/L NaOH alkali regulator concentration; Red GS and Yellow HE-3R disperse dyes are medium alkali resistant; Yellow BRA and Blue H-GLW disperse dyes are weak alkali-resistant and Blue HGL is not alkali-resistant and cannot be dyed under alkaline conditions.

This evaluation method is expected to be used for evaluating the alkali resistance performance of disperse dyes with unknown evaluation structure and for the screening of disperse dyes for alkaline dyeing, and it can help maximize the production efficiency of related factories.

Key words: disperse dyes; evaluation method of alkali resistance performance; alkaline dyeing; dyeing process; polyester; alkali resistant disperse dyes