Flavor release from traditional dry-cured pork during oral processing

Xing Tin, Zongjun Li*, Ke Li Zhongqin Wu Rui Ren,Hodong Wng, Choqun Zeng

a College of Pharmacy, Hunan University of Chinese Medicine, Changsha 410208, China

b College of Food Science and Technology, Hunan Agricultural University, Changsha 410128, China

c Hunan Engineering Research Center of Drug and Food Homology Functional Food, Changsha 410208, China

Keywords:Dry-cured pork products Food oral processing Taste-active Flavor release Electronic tongue Sensory evaluation

A B S T R A C T The rate of fl avor release in the mouth from traditional dry-cured pork was evaluated in this study. It was hypothesized that a slow steady release of fl avor would occur on chewing and hydration. To test this, high salt dry-cured pork was chewed and held in oral cavity without swallowing for 4 different chewing stages (B,NC30, C30, EC). Saliva and food bolus from 16 healthy subjects were collected during oral processing, and analyzed for saliva fl ow rate, total saliva protein content, saliva pH, conductivity, saliva and sodium, and taste components. Results show that oral processing behavior and salivary release have important effects on fl avor release of dry-cured pork. Sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE) analysis showed that oral processing has a certain effect on the protein composition and concentration in saliva. This study suggests that the interaction between food and saliva that accompanies chewing can lead to signifi cant changes in sensory perception during oral processing.

1. Introduction

Traditional dry-cured pork, with its unique flavor and texture,has been a famous traditional high-salt meat product deeply favored by the Chinese people for over 2 000 years [1]. The most important ingredients used in traditional dry-cured pork are coarse salt and spices, such as star aniseed, ginger, and pepper, which improve both the appearance and the quality of the f inal product [2]. As the most commonly used seasoning, salt reduces the moisture content of meat products, thus inhibiting the growth of pathogenic microorganisms and ensuring the safety of the final product. More importantly, salt also promotes the aroma and taste of the meat products by catalyzing biochemical and enzymatic reactions [3]. However, the salt content of dry-cured pork is relatively high [4] and long-term consumption of high-salt meat products is not conducive to human health, as it increases the burden of such diseases as hypertension, heart disease,and kidney disease [5].

In recent years, consumers have become increasingly concerned about the relationship between diet and health, which has led to an increased demand for healthier meat products [6]. Most studies have focused mainly on the ways to reduce salt content in meat products and, as such, a variety of low-salt meat products have been developed. However, the market recognition of these low-salt meat products is generally low due to their inability to satisfy the taste demands of consumers. In fact, developing low-salt meat products while preserving their f lavor has proven to be very challenging [7].To address this issue, researchers have applied the use of physical instruments for quantitative analysis of various sensory properties [8].Nevertheless, replacing human sensory analysis with instrumentation is still in development. Therefore, human sensory analysis is critical to the study of healthy meat products as it provides information about f lavor perception and hedonic characteristics [9].

Sensory perception is the consumer’s sensory response to a material stimulus. Despite the intimate relationship between an object’s sensory property and its corresponding material property, the two properties are radically different [10]. Taking the flavor research of dry-cured meat as an example, researchers have mainly studied the effects of the changes in the properties, composition, structure,and functions of raw materials, processing, storage and cooking on the flavor quality of dry cured meat for a long time [11]. Although the traditional method of food research has achieved fruitful results,it ignores the basic fact that the traditional study of food flavor not only describes and analyzes food flavor quantitatively by means of materials and techniques, but also qualitatively as it considers the human factors in flavor release and perception. As an edible material,dry-cured pork can only be enjoyed and used for energy and nutrition after entering the body. In fact, the realization of these three basic functions is the result of the interaction between food and the human body, and is especially true for a consumer’s perception of taste. A growing number of researchers have realized that the study of food flavor should be extended from the study of materials science to the study of “food and the human body” [12].

As the very first stage of food consumption, oral processing of food is not only important for food intake, adsorption, and digestion, but also for the appreciation and pleasure of food texture and flavor [13].Although food stays in the mouth for only a few seconds, a large number of physical changes, as well as physiological and psychological responses occur in this short period of time [14]. The process of consumer flavor perception begins from food entering the mouth to flavor disappearing. Flavor perception depends on a lot of variables, such as food composition, chewing behavior,saliva parameters, food-saliva interaction, individual physiological sensitivity, and the kinetics of flavor release [15,16].

As a complex fluid, saliva plays a multifunctional role in the mouth, although the key role of saliva in the oral processing of food and flavor perception has been completely neglected in the traditional sensory evaluation of food. In fact, saliva is an essential component of the eating process as well as sensory perception [17]. Saliva affects the transport of flavor molecules to receptors, adsorption to oral mucosa, enzyme modification metabolism, and friction in the oral cavity [18]. Salivary proteins, or oral mucosa, promote taste by interacting with or metabolizing flavor compounds. Although saliva is thought to play an important role in regulating taste buds and activating ion channels, the basic principle of how saliva affects taste perception during oral processing remains unclear [19].

During oral processing, the oral cavity and saliva lead to mass transfer of flavor substances between the dry-cured pork bolus and saliva, finally fusing to form a cohesive bolus [20]. Previous studies within the Division of Food Science at the Hunan Agricultural University have focused on the release pattern of salt from traditional dry-cured pork during oral processing. When high salt dry-cured pork is consumed, it typically passes through a number of phases: chewing,hydration, bolus formation, and swallowing [21]. Firstly, salt is mixed with the pork loaf and a meat bolus is formed during chewing. Then,salt and other flavor compounds are hydrated and dissolved into the saliva [22,23].

The objective of the present study builds on previous studies and aims to investigate the rate of flavor release from a high-salt meat product into the saliva and to correlate the delivery of flavor components to the saliva and bolus with sensory perceived flavor during oral processing. This will be conducted with a forced chew/without chew protocol to exemplify the release of flavor from the drycured pork products.

2. Materials and methods

2.1 Sample preparation and the measurement of physical and chemical indicators

All the experiments were carried out on 10 fat-free pork loins purchased from a meat supplier (Hunan Weihong Foods Co., Ltd.,Hunan, China). The 10 fat-free pork loins initially weighed (2.5 ± 0.2) kg and came from local cross swine (6 months, (90 ± 5) kg). Each fat-free pork loin ((200 ± 5) g) was sliced and the same amount of flavoring containing 1.5% sugar, 5% salt, 1.5% monosodium glutamate and 2% Chinese liquor was added. Then, the pork loins were air dry-cured at 10 °C with 65% relative humidity for 3 days.After curing, the dry-cured pork strips were air-dried in a blast drying box, with the temperature controlled to 30 °C and the upper and lower layers exchanged every 24 h. After 7 days of air drying, the samples were vacuum packed and stored at –80 °C for freezing.

The pH of the dry-cured pork sample was determined by a digital pH meter (STARTER3100) equipped with a penetration probe in a slurry made by mixing (2.0 ± 0.1) g of the minced sample with 20 mL of distilled water. The concentration of NaCl of the samples was measured using the direct titrimetric methods described by GB/T 5009.42—2016 (China). The moisture content of the samples was analyzed using the dry oven method [24].

2.2 Study participants and saliva and bolus collection protocol

Sixteen study participants (n= 16, 9 females and 7 males, 19−21 years of age) were recruited from the Hunan University of Chinese Medicine’s internal student panel without any exclusion parameters besides being in good health, nonsmoking, and not currently taking medication. All participants volunteered to participate in this work and signed a written consent form and were trained in a standard chewing protocol and saliva swabbing for a period of 4 weeks in 40 min sessions that occurred 3 times a week (8 h in total) prior to evaluation.All participants were asked to brush their teeth and rinse their mouth with 300 mL water, and not to consume any foods, with the exception of water, 90 min prior to the experiment. Each participant chewed and swallowed 10 slices (2 cm × 2 cm/slice) of dry-cured pork samples and recorded their chewing time in the training session. Mastication of each sample lasted less than 1 min, and each training session was conducted at an interval of 30 min.

All meat bolus collections were made between 8 and 11AM. The dry-cured pork samples were maintained at (60 ± 5) °C during testing by immersing the sample jars in a temperature-controlled water bath(DZKW-4, Zhongxing Weiye Instrument Co., Ltd., Beijing, China).Individual intact dry-cured pork samples were inserted in the mouth of a controlled and placed on the rear of the tongue. The sample was then chewed or mouthed for a certain period of time, and with free tongue movement a bolus was formed (where possible). Each participant chewed the dry-cured pork samples to different chewing stages (B, NC30, C30, EC). B represents the original, unchewed dry-cured pork samples that was not inserted in the mouth after cooking. NC30required participants to take the sample orally without chewing for 30 s. C30required participants to chew the dry-cured pork samples for 30 s. EC required participants to chew the drycured pork samples to the swallowing point. Since the swallowing point refers to the point at which the subject is ready to swallow after naturally chewing the dry-cured pork sample, the time to reach the swallowing point varies among different subjects. Bolus samples were not swallowed after mastication, and each participant collected bolus samples (6.0 ± 0.5) g in a 20 mL EP test tube at each chewing stage. Bolus samples from the same chewing stage of all participants were collected in a vacuum bag and stored in a –80 °C freezer for later use. Due to individual differences in chewing behavior and the biochemical composition and content of saliva of the subjects, saliva and bolus samples of the 16 participants at each chewing stage (B,NC30, C30, EC) were collected and mixed to generate mixed samples,which could more accurately reflect the change of various indicators during oral processing. In the study, at least 192 bolus samples were produced to analyze the main taste components of bolus samples during oral processing. Each chewing stage bolus sample (B, NC30,C30, EC) was evaluated in triplicate.

Because a large quantity of saliva is needed forin vitrosaliva component analysis, saliva collection was conducted over at least 40 min in order to collect enough saliva for analysis. Saliva samples were collected in the morning (8:00 and 11:00 AM) at the same time as bolus sample collection following a highly standardized procedure.Each panelist chewed and swallowed 10 slices (2 cm × 2 cm/slices)of dry-cured pork samples to a different chewing stage (B, NC30,C30, EC). In brief, participants were asked to rinse their mouth with 300 mL of bottled water, after which the participants were asked to spit 5 mL original saliva naturally into a salivary collector (Simgen,Zhejiang Xinjing Co., Ltd., Hangzhou, China) to collect B, NC30, C30,EC samples. The 16 participants were simultaneously mixed with saliva samples of the same amount during the same chewing stage (B,NC30, C30, EC). Saliva samples were immediately stored in the –80 °C freezer after collection.

2.3 Saliva analysis

The saliva samples of each subject were collected with different chewing stage(B, NC30, C30, EC)by use salivary collector. All subject’s saliva samples in some chewing stage were mixed together and immediately frozen centrifuged at 10 000 r/min for 5 min after collection. Saliva sample with validated sodium contents were also evaluated for conductivity with a DDS-11A digital conductivity meter(INESA Scientific Instrument Co., Ltd., Shanghai, China) which showed repeatability (R2> 0.99) and linearity up to 10 mg/L. Saliva sodium were determined with an ABL 500 gas analyzer (model iCE 3500, Thermo Scientific, Germany) using 400 µL of saliva by the direct ion-selective electrode technique, calibration curves demonstrated repeatability (R2> 0.99), and linearity up to 10 mg/L.Total protein content of saliva sample was measured in triplicate by following a modified bicinchoninic acid (BCA) assay protocol with an Enzyme standard instrument [25] (model FC, Thermo Scientific Multiskan, US). Saliva pH was measured in a slurry made by mixing 1mL of the saliva sample into 20 mL of distilled water by using a digital pH meter (STARTER3100) equipped with a penetration probe in triplicate.

2.4 Sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE) analysis of saliva protein

Saliva samples from all were mixed together (mix-B, mix-NC30,mix-C30, mix-EC) and subjected to SDS-PAGE. 5 mL of saliva samples were first frozen centrifuged at 4 °C and 10 000 r/min for 5 min using a TGL16M model centrifuge (Xiangyi Scientific Instrument Co. Ltd., Hunan, China). A total of 10 µL saliva protein from 4 different sampling points (mix-B, mix-NC30, mix-C30, mix-EC)were run each lane, in a 12% polyacrylamide separation gel (Protean xi, Bio-Rad) using a Laemmli buffer system [26]. The electrophoresis was run at 120 V for 30 min and run at a constant voltage of 150 V until the dye front reached the end of the gel. Gels were stained with Coomassie bright blue R250 for 1 h and detained until the background was colorless. Gel images were acquired using a scanning molecular dynamics densitometer with internal calibration and LabScan software(GE Healthcare).

2.5 Electronic tongue measurement

A TS-sa402b electronic tongue (INSENT Inc., Japan) equipped with wide area selection specific artificial lipid membrane sensors analyzed bolus samples from the different chewing stages (B, NC30,C30, EC) based on their response to sensors for nonvolatile compounds(saltiness, sourness, sweetness, umami, bitterness, and astringent). The taste sensory index data in the samples to be tested were calculated according to the absolute value of the lipid membrane potential of each artificial sensor on the basis of the potential of the solution, in which the output value of the reference solution (ultrapure water)is called the tasteless point. In this study, as shown by the tasteless blank sample, the tasteless points for different taste components were 0,and values bigger than these tasteless points were considered meaningful.Bolus samples (50.0 ± 1.0) g from different chewing stages (B, NC30,C30, EC) were homogenized (10 000 r/min) for 60 s with 200 mL distilled water (40 °C) then centrifuged at 3 000 r/min for 10 min at 4 °C.The supernatant was removed and filtered with 3 layers of gauze.Mixed saliva samples ((10.0 ± 1.0) mL) from different chewing stages(B, NC30, C30, EC) were homogenized (10 000 r/min) for 60 s with 50 mL distilled water (40 °C) and then centrifuged at 3 000 r/min for 10 min at 4 °C. The supernatant was then removed by centrifugation.The analysis was conducted as previously described [27]. Data collected by the electronic tongue were calculated according to the formula as described. The mean values of the last three cycles were used for the statistical analysis and analyzed using TS-sa402b Library search software (INSENT, Japan).

2.6 Sensory analysis

Quantitative descriptive sensory analysis was performed with the same participants (n= 16, 9 females and 7 males) with an average age of (20 ± 2) years. 16 participants trained in sensory assessment and rating, chewed the high-salt dry-cured pork in 40 min sessions that occurred 3 times a week (6 h in total) for a period of 3 weeks.Details on the exact training procedure are given in Tian et al. [27].The sensory evaluation included 4 types of flavor characteristics(umami, saltiness, richness, and aroma), and was performed following the method of Qi et al. [28], with some modifications. For sensory evaluation, the participants consumed the dry-cured pork samples(2 cm × 2 cm/slices, (4.0 ± 0.2) g) to different chewing stages(B, NC30, C30, EC) in triplicate. The dry-cured pork samples were maintained at (60 ± 5) °C during testing and then randomly distributed to the 16 trained participants. The participants were asked to score the dominant attribute once the dry-cured pork sample was taken into the oral cavity. Evaluations were measured using semantic differential scales and were based on flavor strength, expressed as a score from 0 to 5, where 0 represented none at all and 5 represented extremely high intensity.

2.7 Statistical analysis

Statistical analysis was performed by using IBM SPSS Statistics 25.0 software (IBM, Chicago, IL, USA) and Prism 6.0 software(GraphPad, San Diego, CA, USA). Mean and standard deviation (SD)were calculated. Duncan’s test was used for multiple comparison. AP< 0.05 was considered statistically significant.

3. Results and discussion

3.1 Physical and chemical analysis of dry-cured pork samples

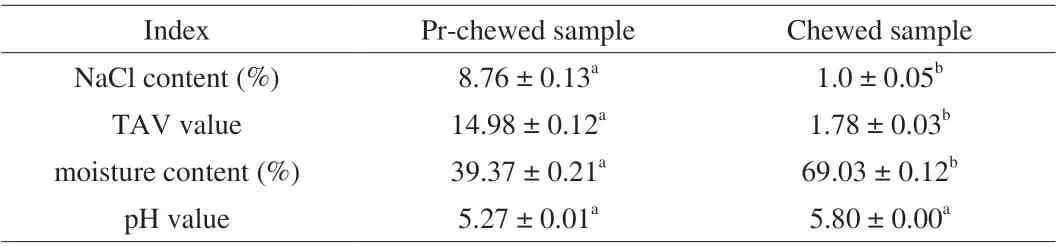

The pH, moisture, salt content, and the taste activity value(TAV) of the dry-cured pork samples, before and after chewing,were measured and are presented in Table 1. Because of the weakly acidic environment of the mouth, the pH level of the dry-cured pork before and after chewing was between 5.3 and 5.8, respectively.The moisture content of the dry-cured pork bolus increased(P< 0.05) after chewing. Due to the increase in salivary secretion during oral processing, the dry-cured pork bolus mixed with saliva more evenly, thereby increasing the moisture content of the food bolus. The concentration of salt and the TAV in the dry-cured pork significantly decreased after chewing (P< 0.05). The TAV of the chewed samples decreased nearly nine-fold compared to the pre-chewed samples. In general, when the TAV is greater than 1,the substance has an important effect on the sample [29]. Therefore,food oral processing plays an important role in the perception of the saltiness of dry-cured pork products.

Table 1 Physical and chemical indexes of dry-cured pork before and after chewing.

3.2 Analysis of human saliva

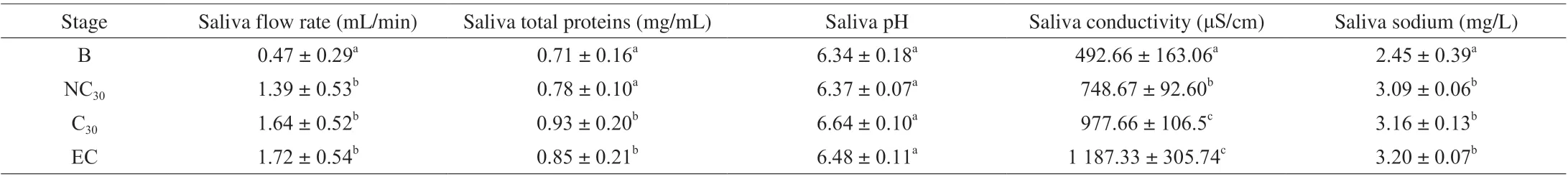

Differences in salivary flow rate, salivary pH, and salivary sodium levels have been shown to affect taste perception [30]. As such, the salivary flow rate, active acidity (pH), sodium concentration, and total protein concentration were analyzed at different chewing stages(B, NC30, C30, EC) of dry-cured pork samples collected from the 16 participants (Table 2). Saliva cleanses the mouth, allowing the taste buds to more accurately identify taste, and its secretion may be closely related to food flavor release during oral processing [31].It can be seen that the secretion rate of the blank saliva sample (B)was significantly lower than that of saliva sample collected during chewing (NC30, C30, EC) (P< 0.05) (Table 2), and is consistent with the literature [32]. However, the saliva secretion of the three different chewing sampling points (NC30, C30, EC) did not differ significantly as a result of the chewing process (P> 0.05). This may be due to the fact that the frequency of post-mastication is basically stable,and saliva secretion tends to be stable. At the end point of chewing,saliva secretion increases and finally reaches its maximum value.The pH of saliva samples (P> 0.05) was slightly acidic and there was no significant difference in pH among the chewing stages. The concentration of saliva sodium and saliva conductivity increased during chewing. When dry-cured pork was consumed, there was a slightly greater increase with the presence of meat bolus, which is presumed to be due to the release of soluble conductive materials form meat bolus. However, the saliva sodium concentration of the three different sampling points (NC30,C30, EC) during the chewing process were similar (P> 0.05). Our findings agree with previously reported observations [33].

The total protein concentration of the saliva samples from the different chewing stages (B, NC30, C30, EC) was between 0.71 mg/mL and 0.93 mg/mL. Although no significant differences were observed,if we focus separately on the chew/without-chew protocol, it is evident that the saliva sample from the without-chew protocol(B, NC30) exhibits lower salivary protein concentration than the saliva sample from the with-chew protocol (C30, EC). Nevertheless,because of large inter-participant variability, these findings were notsignificant and remain indicative only. Therefore, further analysis to evaluate salivary proteins were performed.

Table 2 Parameters obtained from participant saliva with different chewing stage.

In order to identify the contributions of salivary proteins during chewing dry-cured pork samples, SDS-PAGE was performed to analyze the presence of proteins. The electrophoresis results of the saliva sample is shown in Fig. 1, in which lane 1 is a lane of protein markers, lane 2 represents blank saliva sample (mix-B), lane 3 is for saliva proteins of the mix-NC30saliva sample (to take the sample orally without chewing dry cured pork samples for 30 s and to mix all subject saliva sample together), lane 4 represents mix-C30saliva sample (to chew dry cured pork sample for 30 s and to collect mix saliva samples), lane 5 is for saliva proteins of the swallowing point (mix-EC). It can be seen in Fig. 1 that human saliva contains numerous proteins of varying molecular weights, consistent with those reported by Esser et al. [34]. Compared to the blank saliva sample(mix-B), the saliva protein bands of the three different sampling points (mix-NC30, mix-C30, mic-EC) (lanes 3, 4 and 5) exhibit some major differences with that of blank saliva sample (lane 2). The saliva protein bands of group mix-B, mix-NC30, mix-C30and EC bands differ in intensity, indicating that oral processing has a certain effect on the protein composition and concentration of salivary proteins. This is an indication that saliva interacts with food components to form a boluslike degradation structure, while proteins in saliva combine with proteins in food bolus, resulting in changes in the protein composition and concentration of saliva. After the food is ingested, it is broken down into tiny particles or food bolus, which interact with the taste bud cells to produce a taste sensation under the action of saliva during the process of oral processing [35]. Certain compounds in saliva can continue to stimulate taste receptors, creating an adaptation that affects taste sensitivity. Saliva and a number of salivary proteins, such as mucin, glycosylated proline proteins, or salivary proteins present in the mucosal membranes, play an important role in oral lubrication and thus affect the perception of food flavor during oral processing [36].The changes of salivary protein composition and concentration may lead to changes in taste perception of dry-cured pork during oral processing. Human saliva interacts with food and plays a dominant role in influencing the eating and sensory experience [37]. In addition,saliva can be used as an effective emulsifier and oral emulsification may be an important mechanism of oral processing [38]. During oral processing, saliva interacts with the meat bolus, which results in the change of the protein composition of the saliva and bolus, which may also be an important factor affecting the flavor perception. There is growing evidence to suggest that saliva composition is related to the way in which food is perceived in the oral cavity [39]. Therefore,further taste attribute analysis of the saliva and meat bolus samples at different chewing stages were carried out.

Fig. 1 SDS-PAGE lanes.

3.3 Changes in taste attributes by electronic tongue

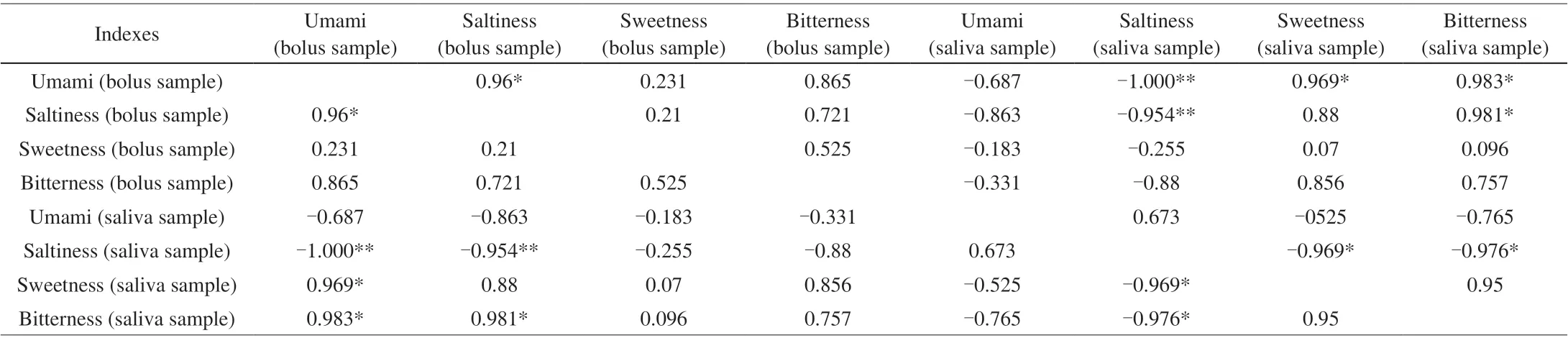

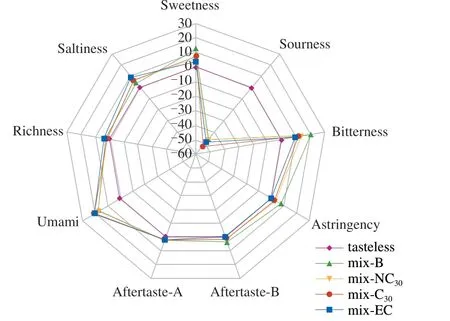

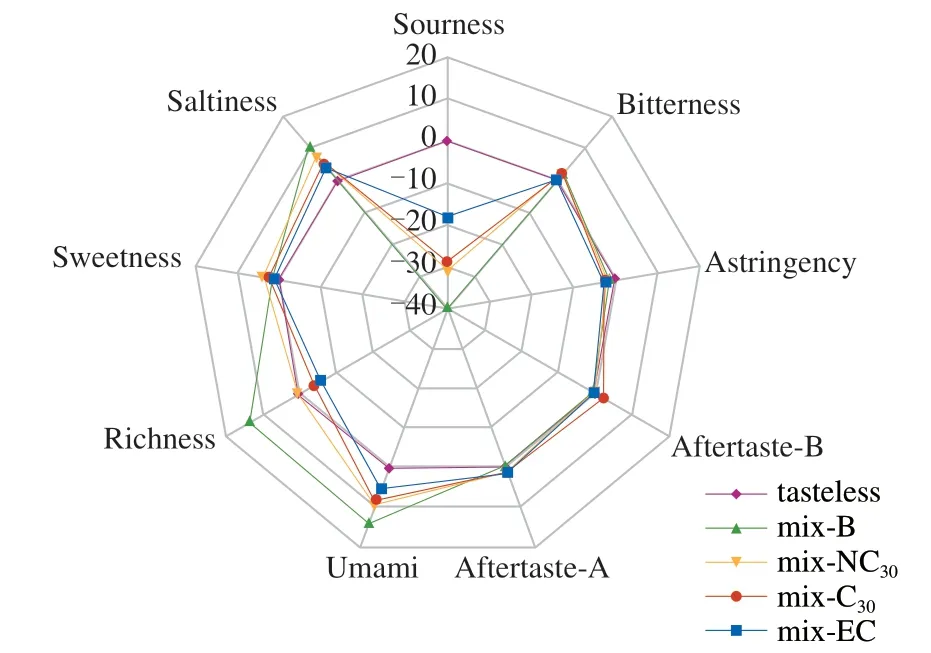

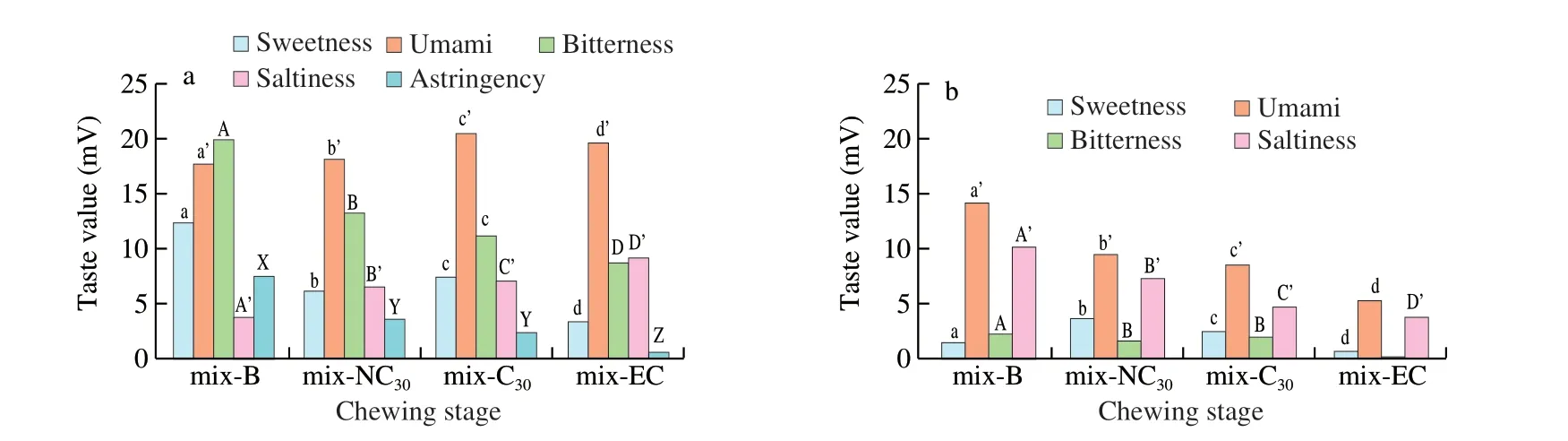

Electronic taste sensing is an alternative for human sensory evaluation that is useful for the quality control and monitoring of various samples in the food industry, and especially for meat products. The taste attributes of saliva and meat bolus samples from the four different chewing stages of dry-cured pork samples (B, NC30,C30, EC) were detected by an electronic tongue. The TS-sa402b series intelligent taste system is based on the changes in the membrane potential of the lipid membrane of each artificial sensor to determine the basic taste sensory index. The taste indices of the saliva and meat bolus samples from the 4 different chewing stages of dry-cured pork sample (mix-B, mix-NC30, mix-C30, EC) were made into spider plots and are presented in Fig. 2 and Fig. 3. The change of effective taste indices (i.e., saltiness, sweetness, astringency, umami, and bitterness)of the saliva and meat bolus samples are presented in Figs. 4a and 4b,and were significantly higher than the tasteless point. The correlation coefficients between the electronic tongue taste attributes (saltiness,sweetness, umami, and bitterness) of the saliva sample and the meat bolus sample with four different chewing stage of dry-cured pork sample (B, NC30, C30, EC) are presented in Table 3.

Table 3 Pearson correlation coefficients between saliva sample taste attributes and meat bolus sample taste attributes.

Fig. 2 Spider plot for the electronic tongue evaluation saliva samples sensory score with 4 different chewing stage of dry-cured pork samples (mix-B, mix-NC30,mix-C30, mix-EC). The data was analyzed using TS-sa402b electronic tongue(INSENT, Japan) with wide area selection specific artificial lipid membrane sensor. (Richness was umami aftertaste; Aftertaste-A was astringency aftertaste;Aftertaste-B was bitter aftertaste; mix-B represents the blank saliva sample; mix-NC30 represents the mix-C30 saliva sample; mix-C30 represents the mix-C30 saliva sample; mix-EC represents the end of chewing saliva sample.)

Fig. 3 Spider plot for the electronic tongue evaluation meat bolus samples sensory score with 4 different chewing stage of dry-cured pork samples(mix-B, mix-NC30, mix-C30, mix-EC). The data was analyzed using TS-sa402b electronic tongue (INSENT, Japan) with wide area selection specific artificial lipid membrane sensor. (Richness was umami aftertaste; Aftertaste-A was astringency aftertaste; Aftertaste-B was bitter aftertaste; mix-B represents the blank dry-curd pork sample; mix-NC30 represents the mix-NC30 meat bolus sample; mix-C30 represents the mix-C30 meat bolus sample; mix-EC represents the end of chewing meat bolus sample.)

As an important taste indicator, the saltiness of the saliva sample and meat bolus were both significantly changed during the chewing of dry-cured pork. As seen from Figs. 4a and 4b, the saltiness of saliva samples and meat bolus showed opposite trends with chewing stage (B,NC30, C30, EC). The saltiness characteristic value of the meat bolus sample was positively correlated with umami (r= 0.96,P< 0.05)and negatively correlated with the saltiness characteristic value of the saliva sample (r= –0.954,P< 0.05) (Table 3). With the extension of chewing time, the sodium ions from the meat bolus sample were continuously dissolved into the saliva, and the saltiness in saliva showed an upward trend until the peak. However, the saltiness characteristic value measured by the electronic tongue reflected the remaining NaCl content in the meat bolus sample, so the saltiness characteristic value of meat bolus sample showed a downward trend.Salt perception is driven by the local sodium concentration at the saliva-receptor interface relative to the normal baseline concentration and the rate of change of concentration within the salivary protein [40].Due to the low surface tension of saliva, food particles are promptly moistened and flavor substances are quickly diffused [41]. Salt must be transferred from the protein matrix of dry-cured pork to the saliva,and then migrate to the saliva-receptor interface, where it has the opportunity to interact with ion channel receptors and subsequently leads to the sensation of saltiness [42]. The concentration of salt dissolved in saliva has been shown to affect taste more than the initial concentration of sodium ions in food substances [43]. Therefore, the taste detection threshold of NaCl is slightly higher than the sodium concentration of saliva to prevent the continuous stimulation of taste receptors [36].

Sweet taste plays a critical role in determining food preference and choice [44]. With the increase of chewing time, saltiness in saliva gradually increases, while sweetness decreases during oral processing. The sweetness characteristic value of the saliva sample was negatively correlated with saltiness in the saliva sample (r=–0.969,P< 0.05). The non-chewing saliva sample (NC30) tasted slightly less sweet than the chewing saliva sample (C30), while the non-chewing meat bolus sample (NC30) tasted slightly sweeter than the chewing meat bolus sample (C30). A similar trend was observed with the saltiness characteristic value of the saliva sample. There may be a connection between saltiness perception and sweetness perception during oral processing of dry-cured pork. Sweetness and saltiness signal that a food is edible, and so it makes sense that when our bodies need energy, people would be more sensitive to these tastes. Oral processing mechanisms and salivary protein content play an important role in the sensory perception of sweetness in meat products. Salivary protein has a direct effect on the levels of sweet molecules present in the mouth. The relationship between salivary proteins and sweetness sensitivity may be explained by more than just the specific function of each single protein [45]. Saliva pH most strongly affects the sweetness sensitivity. In our analysis, the pH of saliva samples was slightly more acidic than neutral (Table 2). It should be noted that salivary proteins with charge near neutrality, at the pH of saliva, might precipitate, making its access to taste receptors difficult, and agrees with those reported in literature [46].

Fig. 4 Changes of effective flavor indexes in meat bolus sample (a) and saliva sample (b) with different chewing stage (mix-B, mix-NC30, mix-C30, EC). The data was analyzed using TS-sa402b electronic tongue (INSENT, Japan) with wide area selection specific artificial lipid membrane sensor. Letters a-d denote significant difference (P < 0.05) for saliva and meat bolus samples sweetness with different chewing stage, letters a’-d’ denote significant difference (P < 0.05) for saliva and meat bolus samples umami with different chewing stage. Letters A-D denote significant difference (P < 0.05) for saliva and meat bolus samples bitterness with different chewing stage. Letters A’-D’denote significant difference (P < 0.05) for saliva and meat bolus samples saltiness with different chewing stage. Letters X-Y denote significant difference (P < 0.05) for saliva samples astringency with different chewing stage. For samples in the same processing point with different salt content. Each treatment is repeated three times (n = 3) (Richness was umami aftertaste).

Umami, which stems from a Japanese term meaning ‘‘delicious”,plays an important role in the flavor of traditional Chinese meat products, and is often used to describe the flavor of meat [47]. As shown in Figs. 4a and 4b, it was possible to observe that the umami characteristic value in the saliva sample with chew protocol (B, NC30)was significantly higher than the saliva sample without chew protocol(C30, EC) (P< 0.05). The umami characteristic value of meat bolus decreased gradually with chewing stage during oral processing. The change in umami of the meat bolus sample was similar to saltiness during oral processing. This suggests that the subjects may have reached the optimal point of the human perception of saltiness and umami when they chewed dry-cured pork samples to the swallowing point. In fact, there is still a certain amount of salty and umami substances in the meat bolus that human taste receptors do not recognize and sense at the swallowing point. The umami characteristic value of the meat bolus sample was positively correlated with saltiness(r= 0.96,P< 0.05) and the sweetness characteristic value of saliva sample (r= 0.969,P< 0.05), while negatively correlated with saltiness in the saliva sample (r= – 1.000,P< 0.05) (Table 3). Umami can modulate sweet taste, enhance salty taste, and suppress bitterness [49].The increase of sodium chloride enhanced the umami-like taste (MSG)and the feel in the mouth to some extent [48]. With the extension of chewing time, the umami substances of the meat bolus are fully released. After chewing until the swallowing point (EC), the umami characteristic value of the meat bolus sample decreased significantly,which may be related to salivary dilution and water loss.

Bitterness is generally perceived unpleasantly, and suppressing bitterness in food has been a huge challenge for the food industry.Saliva plays a role in the perception of bitter and salty flavors [49].When dry-cured products were consumed (Fig. 4a), the characteristic values of bitter taste in saliva samples began to decrease gradually (P< 0.05). This may be due to the combination of saliva and meat bolus during chewing, which increases people’s adaptive capacity and reduces the negative perception of bitter compounds. In addition, the bitterness characteristic values of meat bolus at four different chewing stages (B, NC30,C30, EC) were all less than 3 mV during oral processing, and the characteristic value of bitter taste at the swallowing point (EC)approached 0 mV. The bitterness characteristic value of the saliva sample was negatively correlated with the saltiness characteristic value of the saliva sample (r= –0.976,P< 0.05) (Table 3).The addition of salt into food protein hydrolysates suppresses bitterness [50], which may also be one of the important reasons for the reduced bitterness of high-salt dry-cured meat products during oral processing. Therefore, understanding the mechanism of action of salt in suppressing bitterness will encourage future research in identifying other compounds with similar properties that will not increase the level of salt intake.

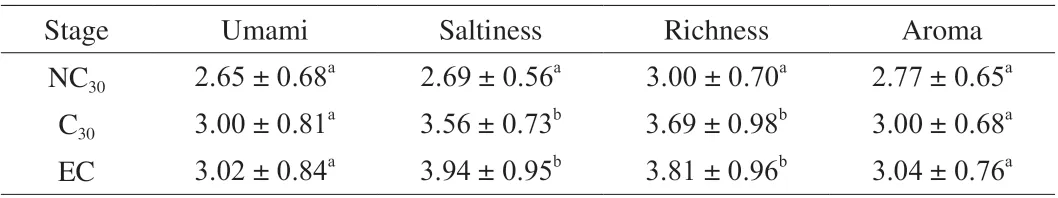

3.4 Sensory evaluation

The comparative results of the quantitative descriptive analysis(QDA) among the different chewing stages of dry-cured pork sample(NC30, C30, EC) are summarized in Table 4. The changes in the saltiness ratings of the meat bolus samples were attributed to the effect of oral behavior (P< 0.05). The saltiness and richness ratings of meat bolus sample without chew protocol (NC30) were significantly lower than the ratings of the sample with chew protocol (C30, EC)(P< 0.05), whereas the umami and aroma ratings were not significantly different (P> 0.05). In summary, sensory perception for meat bolus samples during oral processing as shown in Table 4 indicated highly comparable shaped curves to the electronic tongue data. During oral processing, the salty substances in the meat bolus were released in the saliva, which reduced the salty substances in the meat bolus, while the salty characteristic value of saliva sample increased, and the saltiness perception of meat bolus also significantly increased. Sensory perception is dynamic and occurs during all stages of oral processing. From the start of consumption, people are exposed to the different structures and flavors present in food. In terms of consumption of dry-cured pork, the delayed peak of saltiness perception will not be perceived as the sodium load will be delivered after swallowing and temporal dominance of sensations was used to reveal which foods dominate sensory perception at which stages of consumption [51]. However, the relationship between food oral processing and sensory perception are not yet fully understood [52].

Table 4 Sensory evaluation of meat bolus sample with different chewing stage.

Sensory perception is a human’s perception or response to a material stimulus [8]. In fact, food flavor perception is not only a sensory perception, but also a complex relationship based on a variety of senses, including psychological, physical and chemical senses.Traditional food flavor research describes and analyzes food flavor substances quantitatively and qualitatively by means of materials and techniques, ignoring the factors of human perception in food flavor release and perception. However, based on the interaction between food and the human body, food oral processing analyzes the changes in food structure and the interaction between food and the human body, and reveals the physiological reaction mechanism and sensory response from the oral cavity.

4. Conclusion

In this study, holding a chewed high-salt dry-cured pork in the mouth for an extended period of time allows the continued delivery of taste components over time. Surprisingly there were some correlations between the taste attributes of saliva and meat bolus samples. There may be a connection between saltiness perception and sweetness perception during oral processing of dry-cured pork.The oral processing behavior has a great influence on sensory perception. Foods are rarely consumed alone, and the accompanying interaction between food and saliva causes significant changes in sensory perception. SDS-PAGE analysis showed that oral processing has a certain effect on the protein composition and concentration of saliva and salivary protein. Although the preliminary study had some limitations in experimental design, it provided data to support the theoretical basis for the in-depth study of salivary proteomics in the oral processing of dry-cured pork. Further studies of salivary proteomics can provide additional information about an individual’s salivary characteristics by identifying the metabolites present in saliva. Salivary proteomics studies are ongoing in the author’s lab,and we hope to report more about these advancements in the future.

Ethical statement

All human experiments in the current study were authorized by the Animal Care & Welfare Committee of Hunan Agricultural University.The ethics approval number is SYXK (XIANG) 2014-0026.

Conflicts of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of,the manuscript entitled.

Acknowledgments

This study was supported by “Hunan Natural Science Foundation Program of China” (Project No. 2019JJ50450),” and “Project support of Hunan Province Agricultural Industry Technology system(2019-105)” funded by the Hunan Provincial Science &Technology Department, China.

- 食品科学与人类健康(英文)的其它文章

- Wine, beer and Chinese Baijiu in relation to cardiovascular health:the impact of moderate drinking

- Comparative analysis of physicochemical properties, ginsenosides content and α-amylase inhibitory effects in white ginseng and red ginsen

- Monitoring and identif ication of spoilage-related microorganisms in braised chicken with modif ied atmosphere packaging during refrigerated storage

- Effect of cooking processes on tilapia aroma and potential umami perception

- Formation mechanisms of ethyl acetate and organic acids in Kluyveromyces marxianus L1-1 in Chinese acid rice soup

- Volatile prof ile and multivariant analysis of Sanhuang chicken breast in combination with Chinese 5-spice blend and garam masala