Effects of different thermal processing methods on bioactive components, phenolic compounds, and antioxidant activities of Qingke (highland hull-less barley)

Qingyue Hong, Guangjing Chen, Zhirong Wang, Xuhui Chen, Jianquan Kan,*

a College of Food Science, Southwest University, Chongqing 400715, China

b Laboratory of Quality and Safety Risk Assessment for Agro-products on Storage and Preservation (Chongqing), Ministry of Agriculture, Chongqing 400715, China

c Chinese-Hungarian Cooperative Research Centre for Food Science, Chongqing 400715, China

d Food and Pharmaceutical Engineering Institute, Guiyang University, Guiyang 550005, China

Keywords:Qingke (highland hull-less barley)Thermal processing Antioxidant activity Phenolic compounds Bioactive components

A B S T R A C T Qingke (highland hull-less barley) is a grain replete with substantial nutrients and bioactive ingredients. In this study, we evaluated the effects of boiling (BO), steaming (ST), microwave baking (MB), far-infrared baking (FB), steam explosion (SE), and deep frying (DF) on bioactive components, phenolic compounds,and antioxidant activities of Qingke compared with the effects of traditional roast (TR). Results showed that the soluble dietary fiber, beta-glucan and water-extractable pentosans of Qingke in dry heat processes of TR,SE, MB and FB had a higher content compared with other thermal methods and had a better antioxidant activity of hydroxyl radical scavenging and a better reduction capacity, while those in wet heat processes of BO and ST had a better antioxidant activity of ABTS radical scavenging and a better Fe2+ chelating ability. DF- and SE-Qingke had a higher content of tocopherol, phenolic, and flavonoid. Overall, 6 free phenolic compounds and 12 bound phenolic compounds of Qingke were identified, and free phenolic compounds suffered more damage during thermal processing. Principal component analysis showed that SE had more advantages in retaining and improving the main biological active ingredients of Qingke, and it may be the best method for treating Qingke.* Corresponding author at: College of Food Science, Southwest University, Chongqing 400715, China

1. Introduction

Whole grains have seen increasing attention and use in many countries because their consumption is negatively correlated with risk for a variety of diseases and can prevent many common diseases caused by oxidative stress [1,2]. Qingke (Hordeum vulgareL. var.nudum Hook. f), also known as highland hull-less barley, is a special type of barley without a hull that is mainly produced on the Qinghai-Tibet plateau in China [2]. Qingke is planted on more than 270 000 hectares of land, producing more than 1 million tons annually in China [3]. Qingke is widely used in many types of food, brewing,and beverages, and is also the traditional staple food of the Tibetan people [4]. The nutrient composition of Qingke conforms to the needs of modern human’s “ three high and two low” diet structure(high protein, high fiber, high vitamin, low fat and low sugar) [5]. To cope with extreme environmental stresses including low temperature,hypoxia, and strong light, Qingke has developed strong stress resistance mechanisms and is rich in secondary metabolites such asβ-glucan, pentosan, and phenolic compounds [6]. These bioactive ingredients endow Qingke with antioxidant properties, making it useful for the prevention of cardiovascular diseases, diabetes, and cancer, and for lowering blood pressure and blood fat, and improving intestinal flora [5,7].

Grains can be digested and absorbed by the body after they are cooked [8]. Steaming, boiling, baking, and other hot processing technologies have been widely used to process grains and improve their palatability, stability and safety [8]. Boiling (BO) and steaming(ST) are common wet heat methods for processing grain that make use of circulating steam, which can cause the loss of water-soluble nutrients [9,10]. Roasting (TR) and deep frying (DF) are traditional Chinese methods for processing grain which transfer heat using sand or oil [10]. Microwave baking (MB) and far-infrared baking (FB)are more modern thermal processing technologies with great energy efficiency and high heat transfer rate [11,12]. Steam explosion (SE)is a novel grain processing technology in which high temperature,saturated steam under high pressure quickly penetrates into the grain tissue; heat energy is released instantaneously into mechanical energy,thereby destroying the grain cell tissue [13].

The quality and active ingredients of grains are often affected to different degrees during thermal processing [14]. The degree of nutrient loss by processing varies with food type, processing type,and nutrient properties [8]. Different thermal processing methods can lead to changes in cell wall structure, affect the structure, content,and properties of dietary fiber components, and affect the content of polyphenols and other active substances in grains [15,16]. Further,bound phenolic compounds are released during thermal processing,affecting the antioxidant capacity of grains [17]. Traditional roast is the most commonly used way to prepare Qingke [10]. Stir-fried Qingke is ground into powder to produce “zanba”, which is the staple food of the Tibetan people, but this processing method produces a coarse texture and the product quality cannot be guaranteed [10,18].Other processing methods of Qingke, such as SE and TR, have not yet been industrialized [7,19]. According to Gong et al. [10],different thermal processing methods have different effects on the nutrients and bioactive ingredients of Qingke. Therefore, it is important to identify a thermal processing method that ensures better product quality while also having a lower operating cost and reduced environmental impact.

This study examined 7 kinds of thermal processing methods including TR, BO, ST, MB, FB, SE and DF, and compared their effects on Qingke. Specifically, we explored their effects on dietary fiber, beta-glucan, pentosan, vitamin E, and phenolic compounds.Additionally, the effects of heat treatment on the antioxidant activity of Qingke were studied to determine which processing method(s)could better preserve the nutritional value and active ingredients.This work has important implications for industrial production of highland barley.

2. Materials and method

2.1 Materials and chemicals

Whole grain Qingke (Himara 22) was donated by Xigaze Agricultural Science Research Institute in Tibet, China, in April 2019,and stored at 4 °C.

L-ascorbic acid, gallic acid,D-xylose,α,β,γandδ-tocopherol were purchased from Sigma-Aldrich (Shanghai, China); Folinephenol and ABTS were purchased from Sangon bioengineering Co.,Ltd. (Shanghai, China). Rutin was purchased from Nanjing Jiancheng Biological Engineering Co., Ltd. (Nanjing, China). Coumaric acid,p-hydroxybenzoic acid, chlorogenic acid, vanillic acid, caffeic acid,syringic acid,p-coumaric acid, ferulic acid, naringin, aurantiamarin,quercetin, naringenin, and kaempferol were purchased from Solarbio(Beijing, China). All other chemicals and reagents used in the experiments were of analytical grade and were purchased from Kelon Chemical Reagents Factory (Chengdu, China). And all abbreviation had added in Table S1 in Appendix A.

2.2 Processing of Qingke

Qingke was subject to 7 different thermal processing methods.In each case, the grains were cooked completely. Processing methods were carried out as follows. (1) ST: Qingke was wrapped in gauze in a steamer, cooked for 70 min at 120 °C, then cooled to room temperature and dried at 40 °C [20]. (2) BO: according to the traditional family cooking methods [20], deionized water was added to Qingke with a grain-to-liquid ratio of 1:5 and the mixture was boiled at 100 °C for 40 min until fully cooked. After cooking, the samples were cooled to room temperature and dried at 40 °C. (3) DF:Qingke was fried at 200 °C in soybean oil for 5 s in an electric pan(WK2102T, Guangdong Midea Kitchen Appliance Manufacturing Co. Ltd., China) until it puffed, then it was removed and drained [11].(4) FB: Qingke was cooked in a far-infrared oven (T3-L383b,Guangdong Midea Kitchen Appliance Manufacturing Co. Ltd., China)set at 280 °C for 90 s until it burst [12]. (5) TR: traditional stir-fry based on the method of Gong et al. [10] was used. Qingke was roasted for 2 min in an iron pan at 200 °C with 500 g of sand, sieved out from the hot sand, and then cooled until most of the seeds burst. (6) MB:whole grain Qingke was hydrated for 24 h, and then cooked in a 700 W microwave oven (NJ07-3; Nanjing Jiequan Microwave Apparatus Co. Ltd., Nanjing, China) for 5 min. [16]. (7) SE: the steam explosion device used was the QBS-80 (Hebi Gentle Bioenergy Ltd., Henan, China). Whole grain Qingke was pre-hydrated to 10%moisture before steam explosion treatment. 100 g of Qingke was placed in a 400 mL operating cylinder, then the pressure was set to 2.1 MPa and maintained for 30 s. The sample was then cooled to room temperature [19].

The water contents of raw Qingke and seven kinds of thermalprocessed Qingke were determined as Raw: (9.55 ± 0.08)%,ST: (10.74 ± 0.02)%, BO: (11.99 ± 0.03)%, DF: (2.96 ± 0.08)%,FB: (3.54 ± 0.08)%, TR: (3.48 ± 0.07)%, MB: (4.56 ± 0.06)% and SE: (6.99 ± 0.01)%, respectively. All of the subsequent values were calculated based on dry mass. Other basic components of raw Qingke and 7 kinds of thermal-processed Qingke were in Table S2 in Appendix A as supplementary figures.

2.3 Physicochemical characterization

Dietary fiber (total dietary fiber (TDF), insoluble dietary fiber (IDF),and soluble dietary fiber (SDF)) and vitamin E content were determined using AOAC methods [21]. The content of beta-glucan was determined using the McCleary enzyme-based Megazyme kit [22]. Pentosan was extracted and measured using Rouau’s methods [23].

2.4 Determination of polyphenols and flavonoids

2.4.1 Sample extraction

Extractions were carried out according to previously described protocols with some modifications [24,25]. 1 g of sample was extracted twice with 15 mL of 80% acetone and then the volume was fixed to 10 mL to obtain the free extract (FE). 15 mL of 2 mol/L NaOH was added to the residue of the FE for 2 h, the PH was adjusted to 2 with 6 mol/L HCl, and then lipids were removed with excess n-hexane. Two more extractions were carried out with 15 mL ethyl acetate, and then the volume was fixed to 10 mL with methanol after evaporation to obtain the bound extract (BE).

2.4.2 Determination of polyphenols

Phenolic content of Qingke was measured with the Folin-Ciocalteu method and is expressed as milligram of gallic acid equivalent per g of dry weight (mg GA/g DW) [19,26]. Gallic acid was used as a standard for relative quantification of phenolic content.The absorbance of the solution at 760 nm was measured with a 1-cm colorimeter, and the content of polyphenols was calculated according to the standard curve. Free phenolic (FP) content was measured using the FE, and bound phenolic (BP) content was measured using the BE.Total phenolic (TP) content was the sum of FP and BP.

2.4.3 Determination of flavonoid

Flavonoid content was measured according to the methods of Xia et al. [5] and Hong et al. [19]. Rutin was used as a standard for the relative quantification of flavonoid content, and the data are expressed as milligram of rutin equivalent per g of dry weight(mg Ru/g DW). Absorbance was determined at 510 nm wavelength,and flavonoid content was calculated according to the standard curve.Free flavonoid (FF) content was measured using the FE, and bound flavonoid (BF) content was measured using the BE. Total flavonoid(TF) content was the sum of FF and BF.

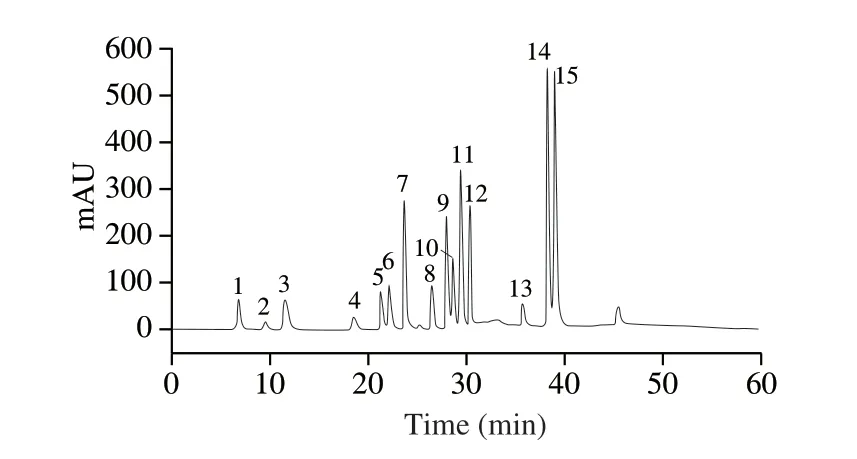

2.4.4 Determination of phenolic compounds by HPLC-PDA

Phenolic content was measured according to Yang et al. [25].Phenolic compounds of FE and BE were quantified using an HPLC system (Agilent, USA) with an ultraviolet detector. Coumaric acid,p-hydroxybenzoic acid, chlorogenic acid, vanillic acid, caffeic acid,syringic acid,p-coumaric acid, ferulic acid, naringin, aurantiamarin,quercetin, naringenin, and kaempferol were used as a standard for the relative quantification, and the results were acid in micrograms per g of dry weight (μg/g DW). An Agilent Eclipse AQ-C18column(4.6 mm × 250 mm, 5 μm) was used. The column temperature was set to 40 °C. The injection volume was 20 μL. 0.1% (V/V) formic acid water(phase A) and acetonitrile (phase B) were used with a flow rate of 1 mL/min. The gradient was 0 min, 5% B; 20 min, 15% B; 50 min,35% B; 60 min, 70% B; 65 min, 100% B and then returned to 10%B in 1 min, followed by 5 min to re-equilibrate the column. The UV absorbance for phenolic compounds was measured at 283 nm.The individual phenolic compounds were quantified using their respective standard curves. HPLC diagram of standard phenolic compounds is shown in Fig. 1. HPLC diagrams of free and bound phenolic compounds of Qingke after processing with different thermal methods are shown in Table 1S and 2S in Appendix A as supplementary figures.

Fig. 1 HPLC diagram of standard phenolic compounds. 1- Gallic acid;2- Coumaric acid; 3- Protocatechuic acid; 4- p-Hydroxybenzoic acid;5- Chlorogenic acid; 6- Vanillin acid; 7- Caffeic acid; 8- Syringic acid;9- p-Coumaric acid; 10- Naringin; 11- Ferulic acid; 12- Aurantiamarin;13- Quercetin; 14- Naringenin; 15- Kaempferol.

2.5 Antioxidant activity analysis

2.5.1 Antioxidant extraction

Astrid and Prior’s method [27,28] was used to extract free antioxidants (FAO) and bound antioxidants (BAO). 0.1 g of sample was weighed and extracted 3 times with 5 mL of 50% ethanol. The supernatant was combined with 75 mmol/L phosphoric acid buffer(pH 7.4) and the volume was fixed to 50 mL to obtain FAO. 10 mL of 4 mol/L NaOH was then added to the residue of FAO for 1 h and the pH was adjusted to 3.5 with 3 mol/L HCl. Alkali extraction antioxidants (AEAO) were obtained by washing with 10 mL distilled water for 5 times, the supernatants were combined and the volume was set to 50 mL with 75 mmol/L phosphoric acid buffer (pH 7.4).Next, samples were washed with 10 mL of methanol or water 5 times and their volumes were fixed to 50 mL to obtain methanol extraction antioxidants (mol/L EAO) and water extraction antioxidants (WEAO).BAO were the sum of AEAO, mol/L EAO and WEAO. Total antioxidants (TAO) were the sum of FAO and BAO.

2.5.2 Determination of ABTS radical scavenging

The ABTS radical scavenging activity was determined using a previously reported method [19] with modifications. Briefly, the diluent of 100 μL of sample was added to 200 μL of prepared ABTS solution on the enzyme plate, and the absorption was determined at 734 nm. Ascorbic acid was used as a standard and the ABTS content was calculated according to a standard curve and is expressed in units of micrograms of ascorbic acid equivalent per gram of dry weight(mg ASC/g DW).

2.5.3 Determination of hydroxyl radical scavenging

The hydroxyl radical scavenging activity was analyzed based on a previously reported method [29]. Typically, 50 μL solutions with different extractions were supplemented with 1,10-phenanthroline solution (50 μL, 0.75 mmol/L), FeSO4solution (50 μL, 0.75 mmol/L),H2O2solution (50 μL; 0.01%,V/V) and sodium phosphate buffer(75 μL; pH 7.4, 0.15 mol/L) in sequence in an enzyme-labelled plate. The reaction solution was placed at 37 °C for 60 min and the absorbance was measured at 536 nm. Ascorbic acid was used as a standard and the unit was micrograms of ascorbic acid equivalent per gram of dry weight (mg ASC/g DW).

2.5.4 Determination of chelating Fe2+ability

Fe2+chelating ability was determined according to a previously reported method [29]. 0.1 mL of 2.0 mmol/L FeCl2solution and 3.7 mL of distilled water were added to 2.0 mL of solutions and maintained at room temperature for 3 min. Subsequently, 0.2 mL of 5 mmol/L ferrozine solution was added, the samples were shaken and maintained at room temperature for 10 min prior to absorbance measurement at 562 nm. Ethylenediaminetetraacetic acid (EDTA)was used as a standard and the unit used was micrograms of EDTA equivalent per gram of dry weight (mg EDTA/g DW).

2.5.5 Determination of reduction capacity

According to Chen’s method [30], 1.0 mL of sample was supplemented with 2.5 mL of 0.20 mol/L sodium phosphate buffer(pH 6.6) and 1.0 mL of 1% (m/V) potassium ferricyanide solution. The reaction was allowed to proceed at 50 °C for 20 min, then the samples were cooled to room temperature and supplemented with 2.5 mL of 10% (m/V) trichloroacetic acid solution. After centrifugation for 10 min, 2.5 mL of the clear liquid was removed and mixed with 0.5 mL of 1% (m/V) FeCl3in 2.5 mL water. The absorbance of the mixture was measured at 700 nm. Ascorbic acid was used as a standard and the unit was micrograms of ascorbic acid equivalent per gram of dry weight (mg ASC/g DW).

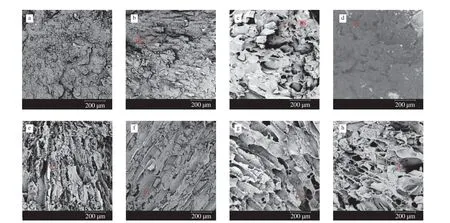

2.6 Scanning electron microscopy (SEM) analysis

SEM was carried out according to Farahnaky’s method [31]with some modifications. Scanning electron micrographs of raw and treated Qingke were captured using Phenom Pro, Phenom World. The samples were fixed on metal carriers with conductive double-sided adhesive, and palladium was sprayed with an E-1045 ion sputtering apparatus. The coating samples were observed and photographed under a 10 kV electron beam.

2.7 Surface morphology analysis

About 80 kinds of grains of Qingke processed with typical raw and thermal processing methods were selected and placed on white paper respectively. The images were captured using a single-lens reflex camera (EOS 850D, Canon Corporation, Tokyo, Japan) under the same environment.

2.8 Statistical analysis

All measurements were performed in triplicate and analyzed using analysis of variance (ANOVA) with Excel 2010 and SPSS Statistics 19. Principal component analysis (PCA) was conducted using SPSS Statistics 19. Photograph and Origin Pro 2016 were used to analyze initial data and plot. The means were considered to be significantly different atP< 0.05 (*) and very significantly different atP< 0.01 (**).

3. Results and discussion

3.1 Surface morphology of Qingke processed with different thermal methods

The appearance of raw Qingke and processed Qingke with seven different thermal methods is shown in Fig. 2. As shown in Figs. 2b and 2c, starch gelatinization and epidermis cracking occurred in STand BO-treated Qingke. Figs. 2d–2h show that after processing with dry heat, obvious swelling phenomenon appeared, and strip cracks appeared on the surface of grains to varying degrees, which may be because high temperature caused the liquid water inside Qingke to evaporate into water vapor [13]. The dense pericarp structure and the accumulated water vapor inside Qingke lead to increased internal pressure. When the internal pressure reaches the limit, the cells rupture, resulting in changes in the internal structure of grain [16,31].More specifically, DF- and SE-Qingke had the most intense external expansion, while MB-Qingke had the weakest one. DF-Qingke had obvious oil adhesion on the surface, and SE-Qingke had peel-off surface;these phenomena may be related to different thermal methods [18].In general, thermal processing could significantly destroy the surface structure and shape integrity of Qingke. Damage of grain appearance caused by different thermal processing was explored.

Fig. 2 Appearance of Qingke after processing by different thermal methods.

3.2 Microstructure of Qingke processed with different thermal methods

SEM images of Qingke are shown in Fig. 3. After thermal processing, the gelatinous tearing structure between the seed skins of Qingke is composed of starch particles, proteins and other macromolecules melted at high temperature and pressure [16,19]. Due to the rapid release of internal water vapor by heat, large irregular cavities formed in Qingke treated by SE, DF, FB, TR and MB, which would provide more surface area for digestive enzymes in the human body [32,33]. Additionally, the bound force of protein and starch decreased, which is more conducive to the hydrolysis of protein and starch by enzymes [13]. Fig. 3d shows that the oil was attached in DF-Qingke, indicating that the oil penetrated deeply into the internal tissues of Qingke. The penetration of microwave radiation led to rapid vaporization of the moisture inside Qingke, so MBQingke showed a more obvious swelling phenomenon [34]. Under the condition of high temperature and high pressure treated by SE,the moisture of Qingke vaporized rapidly, and the water vapor was released rapidly when the pressure was released instantly, and a large number of irregular pores can be formed [13]. However, STand BO-treated Qingke had compact structure and uneven surface,and were mainly characterized by starch gelatinization and protein denaturation within the void.

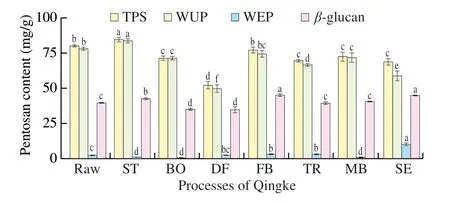

3.3 Effect of thermal processing on β-glucan and pentosane

Qingke is widely recognized for its abundantβ-glucan content,a nutrient newly appreciated for its unique combination of water solubility, viscosity and gelation properties [4]. A meanβ-glucan content of (39.28 ± 0.25) mg/g was measured in raw Qingke (Fig. 4),which was consistent with the range of 29.8-86.2 mg/g reported by Zhang et al. [35]. After processing by ST, FB and SE,β-glucan content in Qingke was significantly increased to (42.47 ± 0.77),(44.89 ± 1.06) and (44.54 ± 0.34) mg/g, respectively. The cell and cell wall structures of Qingke were changed due to thermal processing, and the insoluble dietary fiber degraded to generate newβ-glucan, thus the content, structure and properties ofβ-glucan were affected [19]. The ST and BO processing used a low temperature,making it difficult to break the glycosidic bond and then to cause conversion of insoluble dietary fiber to soluble dietary fiber.Moreover, theβ-glucan of BO-Qingke would be dissolved into water, so the content ofβ-glucan was decreased [36]. However,DF-treatment decreasedβ-glucan content to (34.45 ± 2.14) mg/g,which may be because high temperature of frying caused the breaking of molecular hydrogen bonds and oxidation of hydroxyl groups,leading to degradation ofβ-glucan [11].β-Glucan has indirect antioxidant activity and positive effects on lowering cholesterol and blood sugar [4]. Studies have shown that the solubility, molecular weight,α-amylase inhibitory activity, and cholesterol adsorption capacity ofβ-glucan can be affected by thermal processing, and that appropriate choice of thermal processing method is beneficial for maximizing the nutritional value of Qingke [3,18].

Fig. 3 SEM of Qingke after processing by different thermal methods.The characteristic structures was indicated: C: cavity, TS: tearing structure.(a) Raw; (b) ST; (c) BO; (d) DF; (e) FB; (f) TR; (g) MB; (h) SE.

Pentosan, also known as arabinose, is a polysaccharide formed by various pentose sugars that is widely found in plant cells containing cellulose [37]. Pentosan contributes to a variety of physiological functions, including lowering cholesterol, lowering blood lipids,immune regulation, preventing colon cancer, and weight loss [38].Studies had shown that total pentosans (TPS) content of wheat,barley and oat powder was 6.6, 6.6, and 5.8 mg/g, respectively, and water-extractable pentosans (WEP) content of French wheat ranged 3.6-7.6 g/100 g [3,5]. In this study, TPS content of Qingke treated by different thermal processes was 51.87-84.37 mg/g (Fig. 4),which was higher than that of other grains showed above. The WEP content ranged 0.17-9.85 mg/g, indicating that thermal processing strongly influenced Qingke WEP content. The most significant increase was observed after SE-treatment, this is related to the rupture of cell wall in the high temperature and pressure environment of SE [13]. In addition, the content of water-unextractable pentosans(WUP = TPS − WEP) in Qingke was 49.61–83.61 mg/g, indicating that pentosans in Qingke mainly exist in the bound state.

Fig. 4 β-Glucan and pentosane content of the whole Qingke after processing by different thermal methods. Different lowercase letters in the same index mean significantly different (P < 0.05).

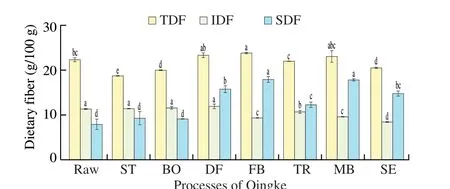

3.4 Effects of thermal processing on dietary fiber

Dietary fiber is a biodegradable substrate for gut microbes,which promotes the proliferation of probiotics [13]. Whole grains are a good source of dietary fiber, and TDF, IDF and SDF of Qingke after treatment with different thermal processing methods ranged 18.58-23.73 g/100 g, 8.31-11.83 g/100 g and 7.8-17.8 g/100 g,respectively (Fig. 5). DF, TR, FB, MB, and ST all increased SDF content, suggesting that dry heat treatment may dissolve SDF more effectively than wet heat treatment. Under conditions of high temperature, high pressure or strong shear force in dry heat processing, cell wall and molecular structure were destroyed, and insoluble dietary fiber was more easily degraded into soluble small molecule compounds [18]. Compared with IDF, SDF has higher physiological activity and can help to prevent obesity and control diabetes, possibly because SDF can absorb water to produce gel and delay gastric emptying time [39]. It can be inferred that, compared with wet heat of ST and BO, dry heat treatment is more beneficial for increasing the content of soluble dietary fiber and improving the physiological activity and nutritional value of Qingke [36].

Fig. 5 Dietary fiber content of the whole Qingke after processing by different thermal methods. Different lowercase letters in the same index mean significantly different (P < 0.05).

3.5 Effect of thermal processing on tocopherol

Vitamin E is an important antioxidant that plays an important role in growth and reproduction [16]. The contents ofα-,β-,γ-,andδ-tocopherol of processed Qingke are reported in Table 1.β-Tocopherol is the main tocopherol in raw Qingke, accounting for 79.41% of the total tocopherol content. FB- and TR-treatment significantly increasedγ-tocopherol content, while ST- and TRtreatment significantly increasedδ-tocopherol (Table 1). However,SE- and DF-treatment significantly increased all four tocopherols by 7.8-fold and 1.8-fold, respectively. Fried cooking oil was attached to DF-Qingke while tocopherol was a common antioxidant in vegetable oil in Table S2 in Appendix A. [11]. SE is conducive to cell rupture,promoting the release of vitamins, while also reducing the loss of vitamins at high temperature due to the short processing time [40].

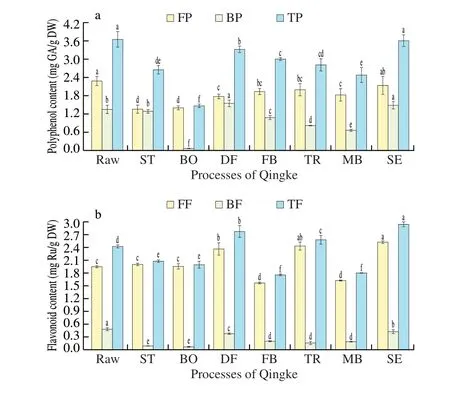

3.6 Effects of thermal processing on phenolic compounds and flavonoid content

Different thermal treatments had variable effects on TP, FP,BP, TF, FF and BF contents of Qingke samples (Fig. 6). BP((1.34 ± 0.13) mg GA/g DW) and BF ((0.47 ± 0.02) mg GA/g DW)contents were higher than FP ((2.28 ± 0.14) mg GA/g DW)and FF ((1.95 ± 0.02) mg GA/g DW) contents in raw Qingke,similar to previous reports [19]. However, TP, FP, and BP contents after thermal processing decreased to varying degrees due to decomposition at high temperature [12]. BO-treated Qingke had the lowest TP ((1.48 ± 0.02) mg GA/g DW) and BP((0.05 ± 0.01) mg GA/g DW) contents because phenolic compounds dissolved in water and were discarded. BP ((1.48 ± 0.12), (1.54 ±0.10) mg GA/g DW) and TP ((3.59 ± 0.19), (3.31 ± 0.11) mg GA/g DW)contents were higher in SE- and TR-treated Qingke, indicating that processing conditions with shorter times and higher temperatures were conducive to the retention of polyphenols [13].

Table 1 α, β, γ and δ-tocopherol of Qingke after processing by different thermal methods.

Fig. 6 Polyphenol (a) and flavonoid (b) content of the whole Qingke after processing by different thermal methods. Different lowercase letters in the same index mean significantly different (P < 0.05).

FF and TF contents in raw Qingke were (1.95 ± 0.02) and(2.43 ± 0.04) mg Ru/g DW, respectively, and both increased significantly in DF-, TR-, and SE-treated Qingke. MB and FB processing lost the most flavonoids; studies have shown that microwave and far-infrared penetration can cause degradation of flavonoids [41]. The change in polyphenol and flavonoid contents after thermal processing mainly depends on the raw materials and the processing method [42]. The higher temperature of TR and SE is more conducive to the release of polyphenols and flavonoids, while the longer processing time of other thermal methods leads to the decomposition of more polyphenols and flavonoids [12,15].

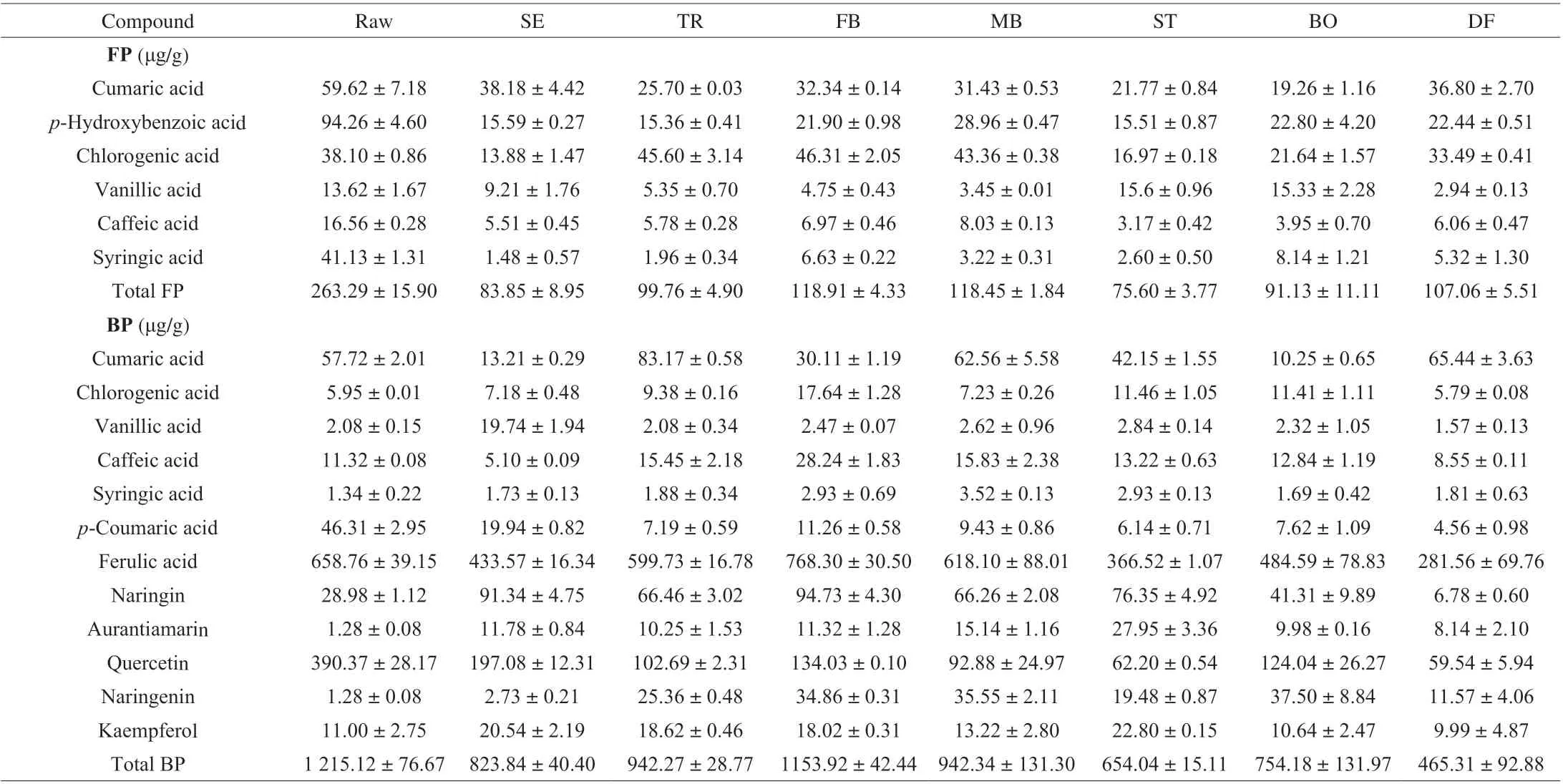

3.7 Effects of thermal processing on phenolic compounds

Qingke is considered a good source of phenolic compounds,which have antioxidant properties, anti-tumor activity, and can help to lower blood fat and blood sugar [43]. Phenolic compounds were quantified as the free and bound fractions in Qingke processed by different methods. A total of 13 kinds of phenolic compounds were identified in the extraction of Qingke, including 6 free phenolic compounds and 12 bound phenolic compounds (Table 2). Coumaric acid, chlorogenic acid, and eugenic acid were the main free phenolic compounds and ferulic acid and quercetin were the main bound phenolic compounds in all samples, in accordance with previous reports [43,44]. The differences in phenolic composition may be attributed to different origins and types of Qingke, methods of extraction, and solvents used [43].

Different thermal processing methods resulted in different changes to the composition and content of phenolic compounds, but the trends were similar: cumaric acid,p-hydroxybenzoic acid, vanillic acid, caffeic acid, syringic acid, and quercetin contents all showed a considerable decrease, whereas aurantiamarin increased significantly.After thermal processing, the content of free phenolic compounds in Qingke was decreased, possibly due to the fact that high temperature and long processing time lead to the decomposition of free phenoliccompounds more easily [45]. MB- and FB-treated Qingke retained more free phenolic compounds, consistent with our measurements of phenolic compounds and flavonoids. Thermal processing had less of an effect on bound phenolic compounds in Qingke, with the most losses in Qingke processed by ST, DF and BO.

Table 2 phenolic compound profiles of processed Qingke.

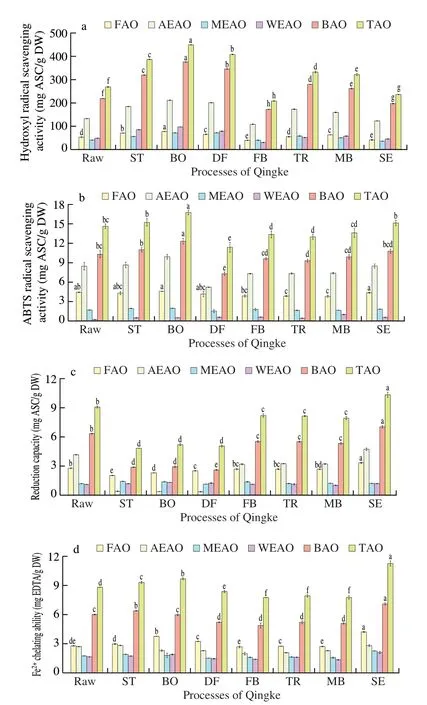

3.8 Effects of thermal processing on antioxidant activity of Qingke

Grains are a major source of antioxidants that help prevent or reduce potential oxidative damage and reduce the risk of chronic diseases such as diabetes, cardiovascular disease and cancer [4,46]. In this study, FAO were extracted with ethanol and BAO were extracted by alkaline hydrolysis (AEAO), methanol (MEAO), and water(WEAO). Antioxidant activity of Qingke extracts was evaluated using hydroxyl radical scavenging activity, ABTS, reduction capacity, and Fe2+chelating assays (Fig. 7).

Fig. 7 Antioxidant values of whole Qingke after processing by different thermal methods. (a) Hydroxyl radical scavenging activity; (b) ABTS radical scavenging activity; (c) reduction capacity; (d) Fe2+ chelating ability. Different lowercase letters in the same index mean significantly different (P < 0.05).

The results in Fig. 7a indicate that total hydroxyl radical scavenging capacity of raw Qingke was (265.72 ± 3.66) mg ASC/g DW.The antioxidant activity of BAO was higher than that of FAO, and the antioxidant activity of AEMO was higher than that of MEAO and WEAO. BO-treated Qingke had the strongest hydroxyl radical scavenging activity ((446.06 ± 2.91) mg ASC/g DW), followed by ST- ((383.91 ± 2.84) mg ASC/g DW) and DF-treated Qingke((405.17 ± 2.07) mg ASC/g DW). FB-treated Qingke ((204.79 ±4.35) mg ASC/g DW) had the weakest activity (Fig. 7a). Of the processing methods tested, only FB and SE failed to increase hydroxyl radical scavenging activity compared to raw Qingke. Therefore, wet heat treatments such as ST and BO could maximize the hydroxyl radical scavenging ability of Qingke and were more conducive to play a role in human body, while dry heat treatments were relatively weak [16].

The ABTS values of FAO after treatment by TR and MB and of BAO after treatment by DF and TR were significantly reduced compared to raw Qingke (Fig. 7b). TAO, ST, BO, and SE treatments all retained the ABTS clearing ability of Qingke. BO and SE treatment retained ABTS best because of their lower processing temperature,whereas DF treatment led to the greatest loss of ABTS due to the higher frying temperature. Our results indicate that the temperature of thermal processing has a significant effect on the ABTS antioxidant capacity of Qingke.

Evaluation of antioxidant capacity by reducing capacity of Fe3+has been widely used as an important index to characterize the antioxidant activity of food [30]. With the exception of SE, the reduction capacity of TAO, BAO and FAO compared to raw Qingke was decreased by thermal processing (Fig. 7c). ST-, BO-, and DF-treated Qingke decreased most dramatically, while SE, FB, MB and TR treatment better retained the reduction capacity of Qingke.Results showed that dry heat treatment can better retain the reducing capacity of Qingke, and the effect of SE-Qingke was the best.

Fe2+is the most important pro-oxidant for lipid oxidation in human body, antioxidants in Qingke can exert their antioxidant effect by chelating Fe2+[30]. Fe2+chelation capacity of FAO from processed Qingke ranged from 2.61 mg EDTA/g DW to 4.13 mg EDTA/g DW(Fig. 7d). BO-, ST-, and SE-processed Qingke showed the highest Fe2+chelating abilities, similar to the results of the ABTS assay.

Studies have shown that FAO in cereals could directly play an antioxidant role in the human body, while BAO is more tightly connected to cells and therefore not easily digested by gastrointestinal enzymes [47]. In general, processing methods with higher temperature such as baking and roasting can easily lead to the degradation and destruction of antioxidants in grains [40,48]. However, hot and humid treatments such as ST and BO may be more conducive to the preservation of the antioxidant capacity of Qingke. In addition,SE destroys grain cells instantaneously under high temperature and pressure, effectively releasing antioxidants and retaining the antioxidant capacity of Qingke [19].

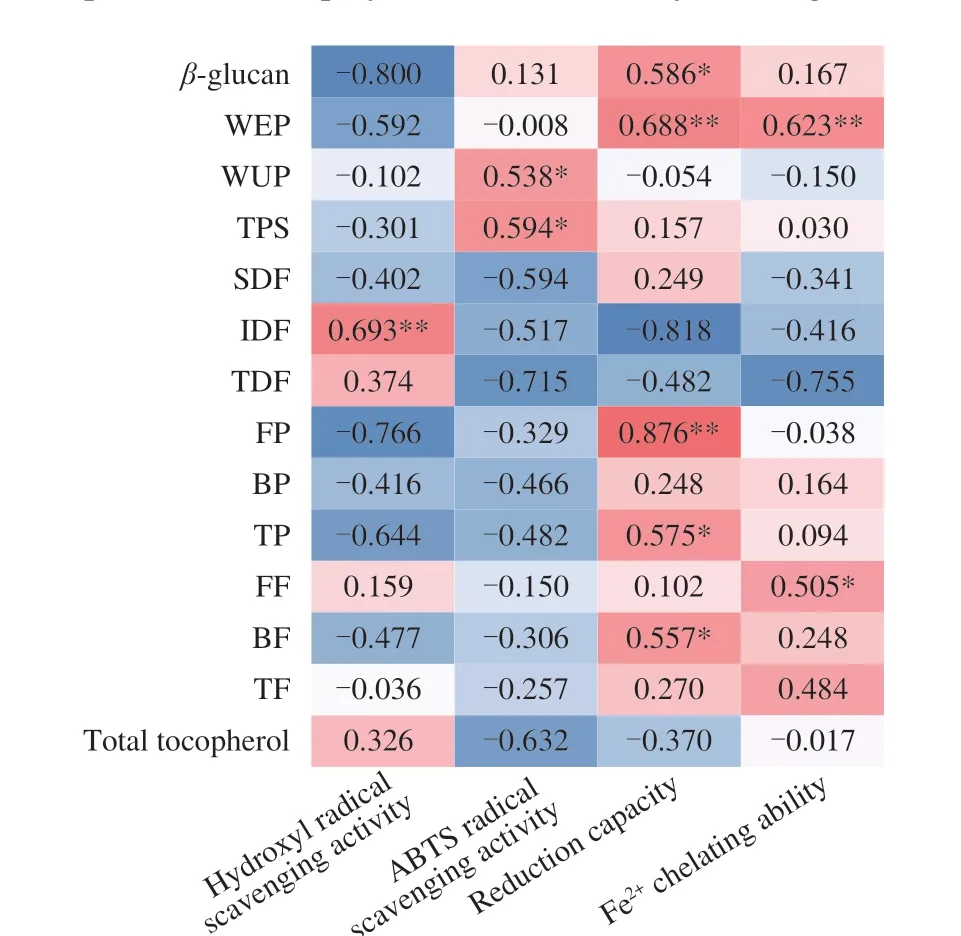

3.9 Correlation between antioxidant activity and bioactive components of Qingke

Pearson correlation was used to determine if there is a relationship between the main bioactive components of Qingke and its antioxidant capacity (Fig. 8) [12]. Hydroxyl radical scavenging capacity was highly correlated with IDF (r= 0.693,P< 0.05) and positively correlated with TDF, FF and total tocopherol. Additionally, WUP(r= 0.538,P< 0.05) and TPS (r= 0.594,P< 0.05) were significantly positively correlated with ABTS values. Studies have shown that phenolic compounds based on ferulic acid can be esterified at the C(O)-5 position of arabinose to increase the antioxidant capacity of pentosan [38]. In addition,β-glucan (r= 0.586,P< 0.05),WEP (r= 0.688,P< 0.05), FP (r= 0.896,P< 0.05), and TP(r= 0.575,P< 0.05) were highly positively correlated with reduction capacity. Water-soluble bioactive substances such asβ-glucan, pentosan, and phenols seemed to contribute more to the reduction capacity of Qingke. Our results also indicated that there was positive correlation between Fe2+chelation capacity of extracts from Qingke and WEP (r= 0.623,P< 0.05) and FF (r= 0.505,P< 0.05). It can be speculated that in addition to phenolic compounds in Qingke with antioxidant activity,β-glucan, pentosan, dietary fiber and tocopherol can also play the role of auxiliary stacking.

Fig. 8 Heat map of Pearson’s correlation coefficient among antioxidant activity and bioactive components. Gradient color barcodes at the left indicated the minimum value in blue and the maximum in red (for interpretation of the references to color in this figure legend). *Significant at P < 0.05,**Significant at P < 0.01.

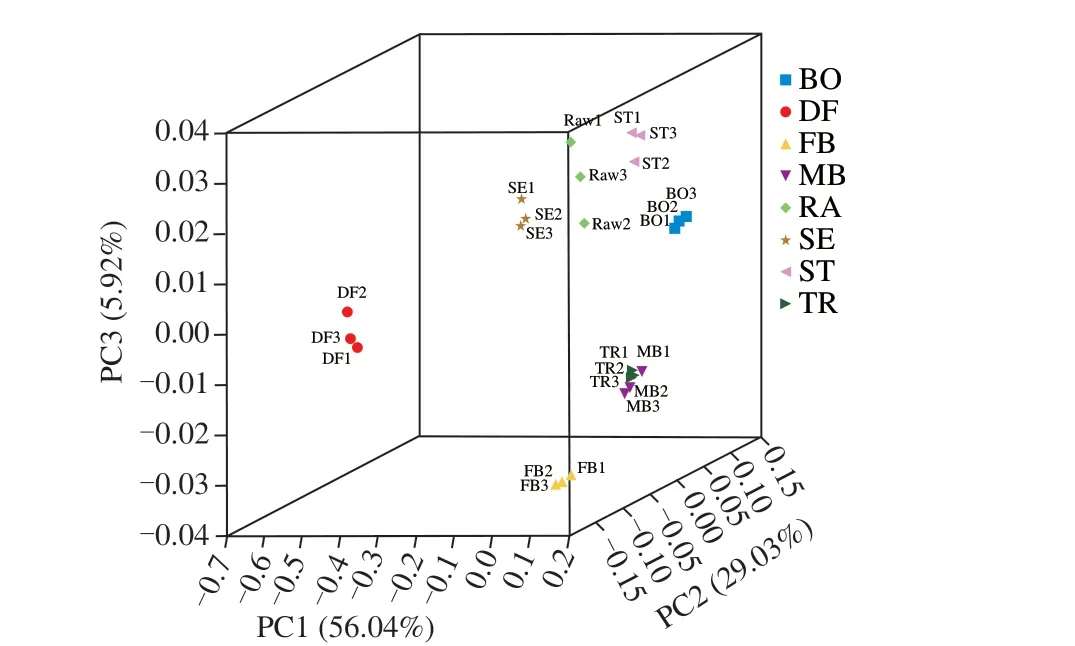

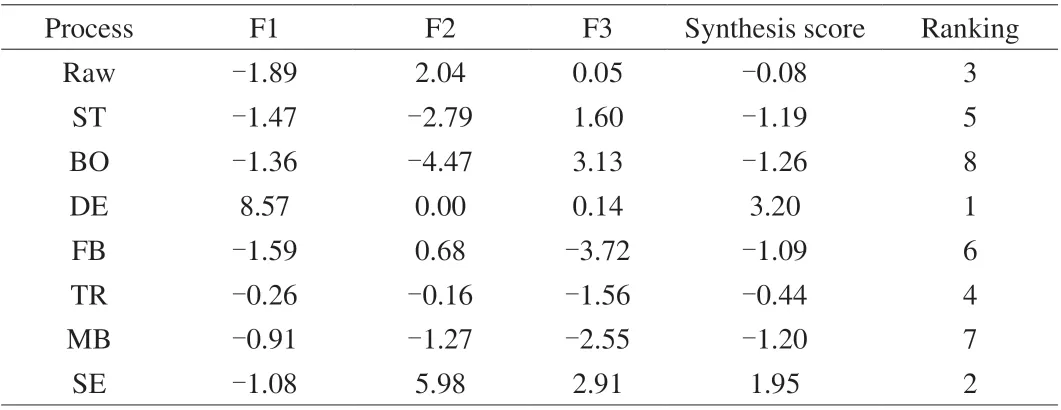

3.10 Principal component analysis

PCA showed that three components explained 90.99% of the total variability of the data (Fig. 9). DF and SE were located on the right side of t1 and the upper side of t2 respectively, indicating that there were significant differences in the effects of DF and SE processing on the active ingredients and nutrients of Qingke. MB and FB were closer together and both further from raw, indicating that the effects of roasting on the nutrients of Qingke were similar. ST and BO had the same pattern, however, a large number of nutrients in Qingke would dissolve in water during cooking and caused loss [8]. The contributions of each of the three principal components to the total variance were taken as the coefficients, and comprehensive scores were calculated based on the feature vectors of the eight processing methods (Table 3) [49]. The score of DF was the highest, followed by SE. However, DF is not conducive to human health and storage because of the high fat content in Table S2 in Appendix A [50].Therefore, we conclude that SE is more suitable for the processing of Qingke.

Fig. 9 PCA score plot for properties of Qingke after processing by different thermal methods.

Table 3 Principal component loading matrix of PCA.

4. Conclusion

This is the first report to comprehensively study the effects of different thermal processing methods on the nutrients and active ingredients of Qingke. In this study, we quantified changes inβ-glucan, pentosane (TPS and WEP), dietary fiber (TDF, IDF, and SDF), vitamin E (α-,β-,γ- andδ-tocopherol), phenolic compounds,and antioxidant activity of Qingke after processing by TR, BO, ST,MB, FB, SE and DF. The results showed that the contents of soluble dietary fiber,β-glucan and water-soluble pentosan of Qingke could be increased by dry heat treatments (TR, MB, FB and SE). The insoluble pentosan of Qingke accounted for 96% of the total pentosan, and the content of insoluble pentosan could be significantly increased by traditional roasting.β-Tocopherol was the main tocopherol of Qingke.The total tocopherol in Qingke could be well preserved after DF and SE. After SE treatment, polyphenols and flavonoids contents of Qingke were high. Phenolic compounds in Qingke were analyzed, and 6 free phenolic compounds and 12 bound phenolic compounds were identified. Among these, the free phenolic compounds were mainly coumaric acid, chlorogenic acid and eugenic acid, while the bound phenolic compounds were mainly ferulic acid and quercetin. Wet heat treated Qingke including steamed and boiled Qingke had strong hydroxyl radical scavenging ability, Fe2+chelating ability and ABTS rodical scavenging ability, while dry heat treatments could retain the hydroxyl radical scavenging ability and reducing ability of highland barley better. PCA showed significant release of active substances in Qingke after SE. In general, SE had most advantages in retaining and improving the main biological active ingredients of Qingke, and it may be the best method for treating Qingke.

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of,the manuscript entitled.

Acknowledgments

This study was financially supported by the 2018 annual three gorges follow-up research project of the three gorges office of the State Council (YYNY-2017-01).

Appendix A. Supplementary data

Supplementary data associated with this article can be found, in the online version, at http://doi.org/10.1016/j.fshw.2022.07.030.

- 食品科学与人类健康(英文)的其它文章

- Wine, beer and Chinese Baijiu in relation to cardiovascular health:the impact of moderate drinking

- Comparative analysis of physicochemical properties, ginsenosides content and α-amylase inhibitory effects in white ginseng and red ginsen

- Monitoring and identif ication of spoilage-related microorganisms in braised chicken with modif ied atmosphere packaging during refrigerated storage

- Effect of cooking processes on tilapia aroma and potential umami perception

- Formation mechanisms of ethyl acetate and organic acids in Kluyveromyces marxianus L1-1 in Chinese acid rice soup

- Volatile prof ile and multivariant analysis of Sanhuang chicken breast in combination with Chinese 5-spice blend and garam masala