Effects of post-mortem aging process on characteristic water-soluble taste-active precursors in yellow-feathered broilers

N Xu, Xinming Zeng, Lingyun Li, Xinyue Zhng, Peng Wng,, Minyi Hn,d, Xinglin Xu,,*

a College of Food Science and Technology, Nanjing Agricultural University, Nanjing 210095, China

b National Center of Meat Quality and Safety Control, Nanjing Agricultural University, Nanjing 210000, China

c Guangdong Wens Jia Wei Foodstuff Co., Ltd., Yunfu 527400, China

d Wens Foodstuff Co., Ltd., Yunfu 527400, China

Keywords:Chicken Post-mortem Flavor precursors Low molecular weight peptides (LMWPs)

A B S T R A C T Chilled chicken has become the mainstream of chicken consumption. In order to explore the effect of postmortem aging on water-soluble f lavor precursors of chicken, pH, adenosine triphosphate (ATP) degradation,flavor nucleosides, free amino acids and water-soluble low molecular weight peptides were determined using Qingyuan partridge yellow-feathered broilers as material during 0–4 °C post-mortem aging in 48 h.The results showed that the pH value fell to the limit pH 5.64 (4 h) in chicken breast and 6.21 (3 h) in thigh.Regardless of chicken breast or thigh, ATP dropped rapidly within 3 h. It was found that the K-value in chicken thigh was the lowest at 2 h indicating the freshness was the best. Considering the equivalent umami concentration (EUC), the value at 3 h and 4 h was relatively high, but the corresponding electronic tongue umami value was not high, which further showed that the water-soluble low molecular taste peptide played an important role on the post-mortem aging process. Combined with cluster analysis and partial least squares discriminant analysis (PLS-DA), it was preliminarily inferred that the optimal time for chilled chicken during 0–4 °C post-mortem aging was 2 h, which could provide a theoretical basis for the further processing of fresh chicken.

1. Introduction

Affected by COVID-19 and African swine fever, the consumption of chicken, which is one of the most common meats in the world with low prices and rich nutrition, has increased signif icantly. Compared with pork, beef, and mutton, chicken is preferred by consumers due to the characteristic of high protein and low fat and has become an indispensable part of the diet [1].

Flavor is the primary sensory impression sensed by taste and smell buds and is one of the most crucial factors indicating the chicken quality and affecting consumers’ purchasing decision [2]. Meat f lavor is primarily composed of aroma and taste [3]. Aroma is generated by a series of chemical reactions during cooking process, including the Maillard reaction, lipid oxidation and thiamine degradation between natural components in raw meat, which has little aroma and only a bloody taste [4]. Taste is related to the non-volatile constituents of fresh meat including low-molecular water-soluble components that are essential precursors and taste contributors of cooked meat [5].There are a number of ante- and post-mortem factors that affect the f lavor of chicken including animal breed, sex, age, diet, post-mortem ageing,method of cooking, etc. [6]. In addition, pre-slaughter management,post-mortem aging, processing and storage will all affect the content and changes of chicken f lavor precursors. The perception of f lavor is also inf luenced by many factors and varies with each individual [7].The major taste-related compounds in chicken include flavoring nucleotides and amino acids, reducing sugars, peptides and organic acids [8]. Generally, during the 0–4 °C post-mortem aging, the concentration of these metabolites in broilers changes dynamically [9].Adenosine triphosphate (ATP), adenosine diphosphate (ADP) and adenosine 5′-monophosphate (AMP) can be quickly decomposed,coupled with the breakdown of inosine-5′-monophosphate (IMP) can led to the boost of inosine and decline in freshness [10].

Traditionally, Chinese consumers believe that the shorter the time from the slaughterhouse to the table, the fresher the chicken carcass. In other words, the best flavor is obtained when the chicken is cooked after slaughter immediately. In fact, after slaughter, a series of physical and biochemical changes, which is a process of postmortem aging, occur in the muscle and fat inside the animal tissues,which is known as the procedure of “from muscle to meat” [11].Only if the post-mortem aging is sufficient, can the unsuitable muscle be transformed into palatable meat [12]. The higher the content of flavor precursors produced during the post-mortem aging, the better the flavor of the corresponding cooked chicken. Therefore,controlling the postmortem aging process is an effective way to improve the flavor of meat [13]. Previous researches on chicken during the post-mortem aging mostly focus on calpain activity.Biswas et al. [14] identified the different domains of calpain and calpastatin and their roles in post-mortem aging of chicken breast and thigh during holding at refrigeration temperature. The activity of μ-calpain in chicken breast and thigh descend very rapidly at 48 h and 24 h respectively, while activity ofm-calpain remained stable.Chen et al. [15] investigated the effects of ultrasonic treatment on the expression of calpain and myofibril structure during the postmortem aging process of chicken. The results showed that low-frequency and high-power ultrasonic treatment can trigger the apoptosis cascade,improve myofibril structure and rate of proteolysis in chicken.Qingyuan partridge chicken (Qingyuan walking chicken), as a special yellow-feather breed in China, commonly was known with numerous sesame-like spots dotted on its back feathers. It is native to Qingxin County, Qingyuan City, Guangdong Province, which is located in southern China and has a subtropical monsoon climate with good natural conditions and aquaculture. The body shape characteristics of Qingyuan partridge chicken can be summarized as “one wedge”,“two thin” and “Three-color mottled body”, as shown in the Fig. 1.“One wedge” means that the hens have a wedge-shaped body with a compact front and a large round back. “Two thin” refers to the thin head and feet. “Three-color mottled body”, which means that the hen’s back feathers mainly have three colors of yellow, light brown,and deep brown, and are distributed in scales, showing a mottled effect. The unique characteristics of Qingyuan partridge chicken are slow growth cycle and feeding cycle, developed tendons, strong muscles, rich in amino acids and moderate fat deposits, which further lead to a particularly strong chicken flavor. The products made by Qingyuan partridge chicken were always enjoyed by shoppers on account of thin and crispy shin with golden color, tender and smooth meat, soft and umami chicken bones. However, effect of post-mortem aging process on characteristic water-soluble taste-active precursors of Qingyuan partridge chicken has not been explored yet.

Fig. 1 Qingyuan partridge chicken.

This article took Qingyuan partridge chicken as the experimental object. The changes of taste-active precursors under different aging times at 0–4 °C were compared to explore the effect of post-mortem aging on the flavor precursor substances in ice fresh chicken carcass under the Chinese policy of “scale farming, centralized slaughtering,cold chain transportation and chilled marketing”. The objective of this article was to provide theoretical guidance for the production and processing of chilled broilers.

2. Materials and methods

2.1 Materials

A total of 36 Qingyuan partridge yellow-feathered broilers with similar age and weight of each carcass (90 days old and 1.0–1.1 kg)were provided by Wens Food Co., Ltd., Xingxin, Guangdong Province in China. After pre-cooling at the slaughterhouse, all the entire chicken carcasses were transported back immediately to the laboratory in foam boxes with ice and stored in a 4 °C freezer for 1, 2, 3, 4, 6, 8, 10, 12, 24, 36 and 48 h. The core temperature of chicken carcass was recorded by inserting a thermometer (RC-4,Jiangsu Jinchuang Electroniic Co., Ltd., China) into three carcasses.At each time, the breast meat of three chickens were ground by a mincing machine (JYL-C020E, Joyoung Co., Ltd., China) and mixed thoroughly after removing the visible fat and excess connective tissue,then the samples were transfered to freezing tubes, and the same procedure was applied for chicken thigh. The freezing tube containing the minced meat was quick-frozen in liquid nitrogen and stored in the -80 °C refrigerator (DW-86L388J, Haier Group, China) until subsequent analysis. Three chicken carcasses in each treatment group were served as a parallel experiment.

2.2 Chemicals

Standards of nucleotides and the related substances including ATP, ADP, AMP, IMP, guanosine 5′-monophosphate (GMP),cytidine 5′-monophosphate (CMP), inosine (In) and hypoxanthine(Hx) were purchased from Shanghai Yuanye Bio-Technology Co.,Ltd. (Shanghai, China). Potassium phosphate monobasic (KH2PO4)potassium phosphate dibasic (K2HPO4), hydrochloric acid, and other common chemicals were all purchased from Nanjing Chemical Reagent Co., Ltd. Standards of norvaline and cytidine were acquired from Shanghai Macklin Biochemical Co., Ltd (Shanghai, China). Most reference compounds, reagents and amino acid standards for amino acid analysis were obtained from Sigma-Aldrich Ltd (Shanghai, China).

2.3 pH measurements

The pH of chicken breast and thigh were measured at various time by a pH meter (S2-food Kit, Mettler Toledo, Switzerland). The lower,middle and upper parts of the breasts were used for the pH test, and the three random parts for the chicken thigh.

2.4 Determination of ATP and the related nucleotides

In this experiment, the contents of ATP and the related nucleotides were determined using the method described by Aliani et al. [10] with minor modification. After thawing at 4 °C for 30 min,5 g of sample was extracted with 20 mL of 5% (V/V) HClO4under the homogenization at 10 000 ×g(15 s × 2) using an Ultra-Turrax T10 homogenizer (IKA, Staufen, Germany). The degradation of these compounds was greatly affected by temperature, so the extraction process was carried out in an ice bath. The homogenate was centrifuged at 10 000 ×gfor 15 min at 4 °C by cryogenic high-speed centrifuge(Eppendorf Centrifuge 5804R, Germany), then the pH of the supernatant was adjusted to 5.8 with the addition of potassium hydroxide.

The solution was diluted to 50 mL in a volumetric flask and filtered using 0.45 μm MAGNA nylon membrane filters. Agilent 1200LC (Agilent, USA) with an X-Bridge C18column (250 mm ×4.6 mm, 5 μm particle size) purchased from Agela Technologies(Tianjin, China) was used to analyze the related nucleotides. Mobile phase was buffer salt solution (BSS, 0.025 mol/L KH2PO4and 0.002 5 mol/L K2HPO4) and methanol, with a flow rate of 0.6 mL/min for a total run time of 28 min. An injection of 20 μL was eluted with gradient elution procedure, which was as follows, BBS (99%)was used in addition to the buffer between 12 and 20 min at a ratio of 20% methanol to 80% BBS. The column temperature was at 25 °C with a UV detector wavelength of 254 nm. The identification and quantification of each related compounds was confirmed by comparing with the retention time and peak area of standards.

2.5 Free amino acids (FAA) assay

Three grams of samples was extracted with hydrochloric acid,freeze-dried, and re-dissolved in sodium citrate buffer solution. The homogenization and centrifugation procedures were conducted as described above (determination of ATP and the related nucleotides).Prior to FAA analysis, the reconstituted samples were filtered using the needle filter (0.45 μm, Jinteng, Tianjin, China), then the filtrates were used to determine FAA composition refer to the method of Gao et al. [16] with a slight modification using an amino acid autoanalyzer (S-433D, Sykam German). The detection wavelength was setting at 570 nm and 440 nm. The concentrations of FAA in the samples were calculated by an external standard method, calibrating with standard amino acids (mixed amino acid standard solution,Sigma AAS18, USA).

2.6 Extraction of water-soluble low molecular weight peptides (LMWPs)

The extraction method of LMWPs was carried out according to Williamson et al. [17] with slightly modified. Internal standard solution of norvaline and cytidine with concentrations of 40.98 μg/mL and 56.43 μg/mL was prepared with deionized water. Chicken powder of 0.15 g ground with liquid nitrogen was added to 0.5 mL of the above solution. The mixture was centrifuged at 17 000 ×gat 4 °C for 10 min prior to vortexed for 10 min to get the supernatant.The precipitation was added another 0.25 mL of solution containing internal standard for second extraction, and the rest of the steps were the same as before. The combined supernatant was filtered with a 0.22 μm filter membrane, and then transferred to a 3 kDa ultrafiltration tube, centrifuged at 17 000 ×g(TGL-16M, Xiangyi centrifuge instrument Co., LTD., China) for 20 min for further analysis.

2.7 LC/QTOF-MS analysis

An UltiMate 3000 HPLC system (Thermo Fisher Scientific,Mississauga, America) coupled to AB Sciex 5600 Q-TOF-MS was used to analyze the chicken extracts. A ACQUITY UPLC HSS T3 column (2.1 mm × 100 mm, 1.8 μm, waters) set to a temperature of 40 °C was used to separate LMWPs in chicken. A 10 μL aliquot was injected from the autosampler and was eluted with LC mobile solutions at a flow rate of 400 μL/min. In the positive ion mode,the mobile phase composition was A: 0.1% formic acid water, B:0.1% formic acid acetonitrile; the negative ion mode was: A: water(2 mmol/L ammonium acetate), B: acetonitrile.

The AB 5 600 Triple TOF mass spectrometer can collect primary and secondary mass spectrometry data based on IDA functions under the control of the control software (Analyst TF 1.7, AB Sciex). Mass spectra for LMEPs of chicken samples were acquired in a mass dynamic range ofm/z50–1 200. In each data acquisition cycle, the molecular ions with the strongest intensity and greater than 100 are screened out to collect the corresponding secondary mass spectrometry data. The electrospray ionization (ESI) ion source parameters were set as follows: atomization and auxiliary gas pressure(GS1), 60 psig; curtain gas pressure, 35 psig, ion source temperature:650 °C; electrospray voltage: 5 000 V (positive ion mode) or -4 000 V(negative ion mode). Data processing was performed according to the method of Zhou et al. [18] with some modifications. The first step was to convert the data to “.abf” format using Analysis Base File Converter. Then MSDIAL 4.24 software (RIKEN Center for Sustainable Resource Science, Japan) was used to perform data processing including peak search and peak alignment on the converted “.abf” file, and search the independently integrated Metlin database based on the primary and secondary mass spectra to obtain the identification results. The MSDIAL software setting parameters were as follows: Alignment: MS1 tolerance, 0.01 Da; Retention time tolerance, 0.2 min. Identification: accurate mass tolerance, 0.01 Da(MS1), 0.05 Da (MS2); Identification score cut off, 60%.

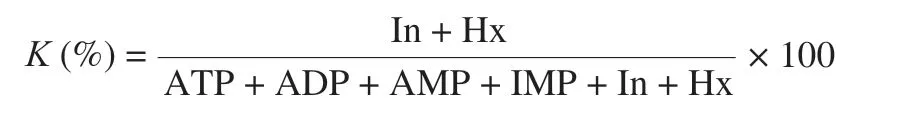

2.8 The K-value

TheK-value is related to the quantification of ATP and its corresponding series of breakdown products, including ADP, AMP,IMP, In and Hx [19]. It is usually calculated as the concentrations of In and Hx over the aggregate concentrations of ATP and degradation products shown as follows:

TheK-value is usually less than 10% in the early postmortem aging [20]. Later, theK-value increases due to the gradual advance of endogenous enzymes with the rapid degradation of ATP, which is usually described according to the following order:ATP→ADP→AMP→IMP→In→Hx [21]. HigherK-value denotes less freshness of meat. TheK-value of 20% is considered as the optimal freshness limit, with 60% being the rejection point [20].

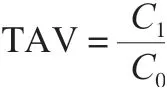

2.9 Taste activity value (TAV)

TAV was calculated as the ratio between the concentration of the taste related compounds in the chicken samples and their taste threshold value [22]. In this article, the taste threshold of flavor compounds (generally measured in a liquid matrix) referenced from Kato’s study [23]. TAV could reflect the contribution of each compound to taste: when the TAV was less than 1, the compound had little or no contribution to the taste; only when the TAV was greater than 1, the compound would contribute to the taste remarkably (the larger the value, the greater the contribution).The calculation formula of TAV is as follows [24]:

C1is the concentration of the flavor compound (mg/L), andC0is the taste threshold (mg/L).

2.10 Equivalent umami concentration (EUC)

Monosodium glutamate (MSG) was first discovered and called as umami taste in the hydrolysate of kelp by Japanese scholar Ikeda Kikunae [25]. The equivalent umami concentration (EUC,g MSG/100 g) refers to the intensity of the umami taste produced by the umami amino acids (aspartic acid, Asp and glutamic acid, Glu)and the 5′-nucleotide (5′-IMP, 5′-GMP, and 5′-AMP). The EUC values of all the samples were calculated by the following addition equation according to Chen et al. [26]:

where EUC unit is g MSG/100 g,αiis the concentration of umami amino acids (g/100 g);βiis the relative umami concentration (RUC)of umami amino acids relative to MSG (Asp, 0.077; Glu, 1);αjis the concentration (g/100 g) of each umami 5′-nucleotides;βjis the RUC of umami 5′-nucleotides to IMP (AMP, 0.18; IMP, 1; GMP, 2.3);1 218 is the synergy constant used in the concentration.

2.11 Taste traits by electronic tongue analysis

An electronic tongue (INSENT SA402B, Tokyo, Japan) equipped with six potentiometric chemical sensors (AAE for umami, CT0 for saltness, CA0 for sourness, C00 for bitterness, AE1 for astringency and GL1 for sweetness) was employed to characterize raw chicken samples during storage following the method of Hwang et al. [27]and electronic tongue analysis were investigated at different aging periods (1, 7, 14, and 21 days. The sensors were soaked in the reference solution (30 mmol/L KCl solution containing 0.3 mmol/L tartaric acid) for 24 h prior to analysis, with GL1 sensor at least 48 h.Twenty gram of chicken sample was mixed with deionized water(100 mL) for extraction at 4 °C for 30 min followed by centrifugation at 10 000 ×gfor 10 min. The supernatant was used for electronic tongue determination after vacuum filtration through a 0.45 μm filter membrane. The two-step cleaning method was used to determine the primary taste of sour, salty, umami and bitter, while the sweet taste needed to be detected separately by a specific sensor due to the different sensor type. Finally, the data of the two steps were combined for taste transformation to get the taste eigenvalue.

2.12 Statistical analysis

The determination of all the components were carried out in triplicate and represented as mean ± SD. One way ANOVA with Duncan’s multiple test (P< 0.05) and was performed to determine the differences among all the data using package of IBM SPSS Statistics version 25 (IBM SPSS Inc., Chicago, IL, USA), which was also carried out to the cluster analysis of samples. The correlations between individual chemical parameter and electronic tongue attributes were analyzed by partial least squares discriminant analysis(PLS-DA, SIMCA14.1, Sartorius Stedim Data Analystics AB,Sweden).

3. Results and discussion

3.1 Changes in temperature and pH during post-mortem aging

The chicken carcass was reduced to about 7 °C by pre-cooling in the pre-cooling pool of the slaughterhouse. After that, it was transferred to a 0–4 °C cold storage, and the temperature in the core of the chicken carcass was as shown in the Fig. 2. The dynamic change state of the temperature, dropping rapidly within 4h and slowly after 4 h demonstrated in the small inset, will influence the formation of flavor precursors memorably [28]. After 24 h, the temperature was stabilized at 0.6 °C, the muscle had been completely converted to edible meat.

Fig. 2 Changes of core temperature of chicken carcass during 0-4 °C postmortem aging. The small inset indicates the temperature change within 12 h after slaughter.

During the post-mortem aging process, glycolysis leads to the conversion of glycogen into lactic acid in chicken muscles, causing the reduction of the pH. The value of pH at this stage is very momentous for the occurrence of certain biochemical reactions. For most animals, rigor mortis usually occurs within 12 h after slaughter and is characterized by the gradual muscle stiffness and a decrease in pH. The limit pH of most species is attained within the first 24 h postmortem period [17].

The variation trends of muscle pH in experimental chickens after slaughter were shown in Fig. 3. The pH value of chicken breast and thigh exhibited similar trend in post-mortem aging process. It’s obvious that the pH of breast and thigh decreased to the lowest value 5.64 and 6.21, at 4 h and 3 h, respectively, the relatively high pH of all samples was at 6 h after which the pH decreased gradually. The result was slightly different from the results of Zhang et al. [29],which might be affected by chicken breeds and post-mortem aging temperature. In addition, the pH of chicken thigh ranged from 6.20 to 6.58 was notably higher than breast from 5.58 to 6.34 at each time.The change of pH value will affect the process of protein degradation during the post-mortem aging process, and further affect the formation of chicken flavor precursors [12].

Fig. 3 pH change of chicken breast and thigh during 0-4 °C post-mortem aging. Different uppercase letters of chicken breast samples indicate significantly different (P < 0.05, Ducan’s multiple range test). Different lowercase letters of chicken thigh samples indicate significantly different(P < 0.05, Ducan’s multiple range test).

3.2 ATP and related nucleotides

The flavor precursors in raw meat can be divided into two categories: water-soluble components and lipids [30], which will generate the characteristic flavor of meat by a series of chemical reactions during the heating process. The flavor of meat mainly comprises of the taste and aroma [8]. Lipid oxidation has a greater impact on aroma compounds, and water-soluble components mainly affect the taste of meat [31]. This study focuses on the taste of chicken, so only the water-soluble components were measured and discussed.

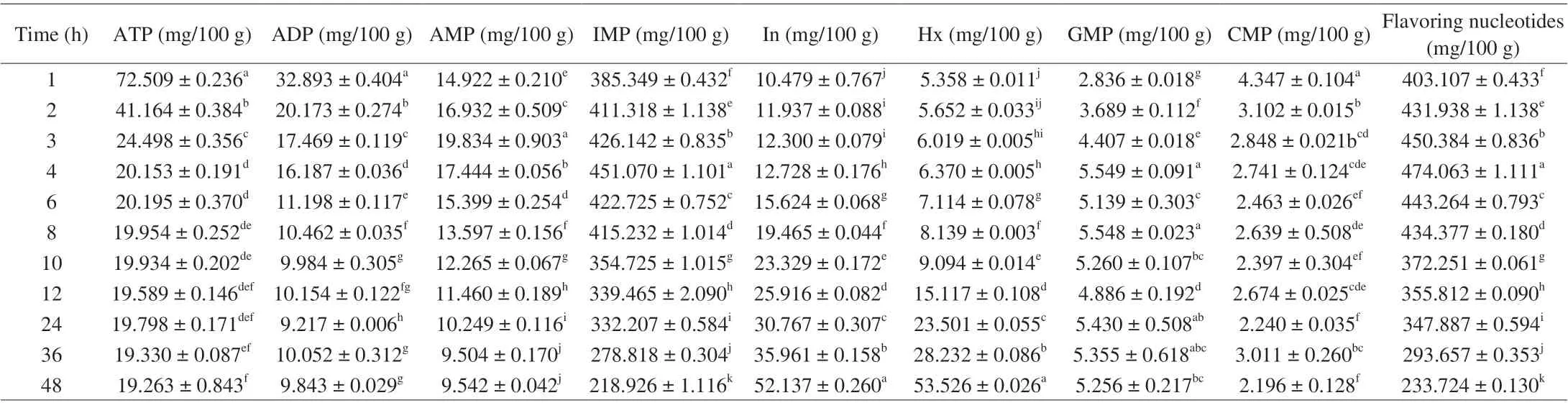

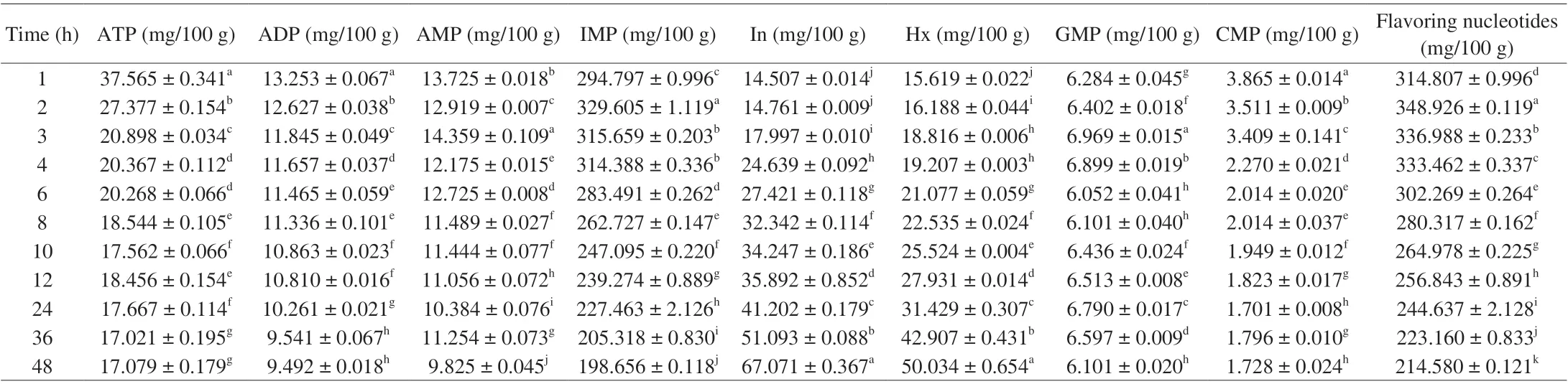

Table 1 and Table 2 provide information on the degree of decomposition of ATP and its metabolites during the 0–4 °C postmortem aging in chicken breast and thigh, respectively. The results indicated that ATP, ADP degraded faster within 3 h after slaughter,AMP increased markedly within 3 h and then decreased gradually.The degradation of ATP into ADP, AMP and IMP will be completed within a few hours to a few days, making IMP reach its peak, and the process of further degradation of IMP into In and Hx is relatively slow [32]. In and Hx are the final products of ATP degradation, in which Hx can cause bitter taste in food and worsen the off-flavor [33],the content of both compounds rose observably with time. IMP, one of the main components of umami taste substances in meat, was the most abundant metabolite. The highest content of IMP in chicken breast was 4 h after slaughter, and in thigh was 2 h, besides it’s content in chicken breast was signally higher than in thigh, which may be related with the different pH of breast and thigh. Although the content of GMP and AMP was very low, both of them attribute to the umami taste. Within a short period of time after slaughter, the GMP content gradually rose, and then there was no significant increase or decrease trend, showing a dynamic change of augment and reduction. The change of CMP was opposite to that of GMP, decreased gradually at first and then stabilized.

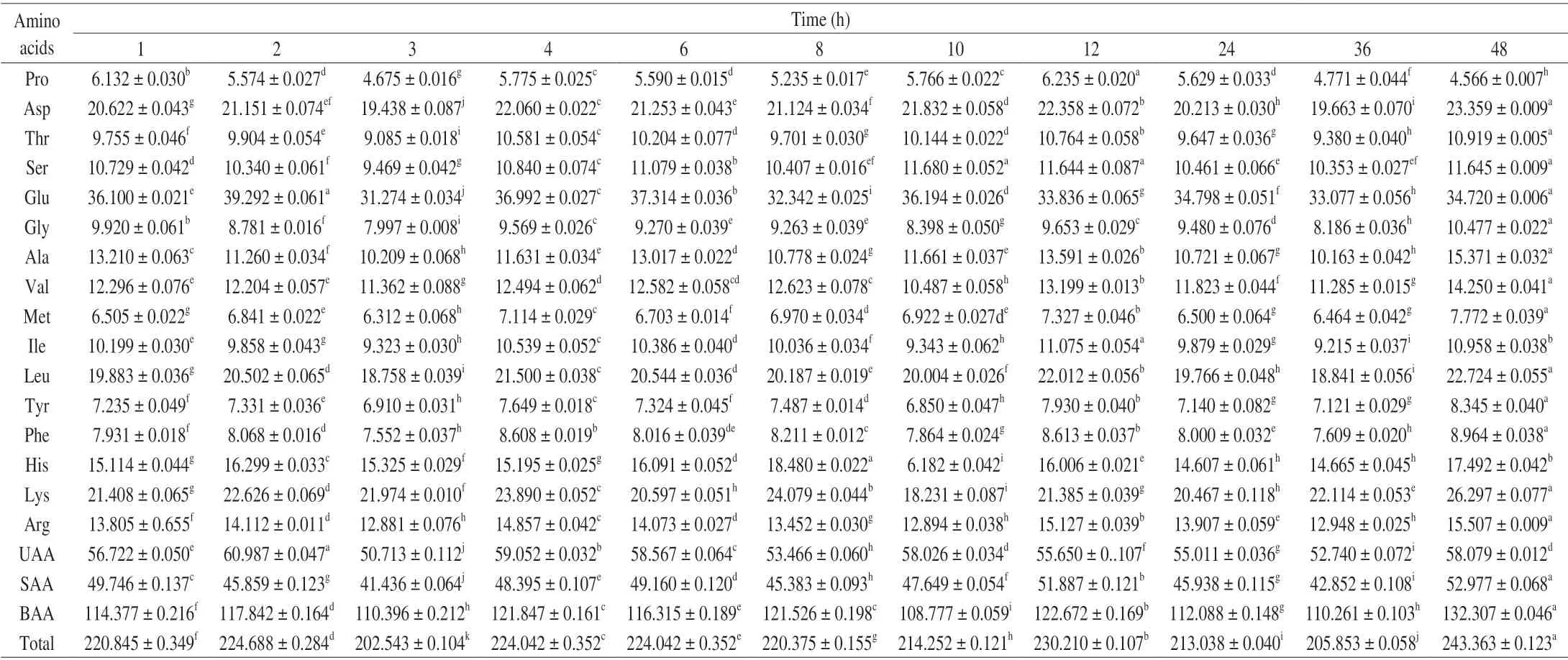

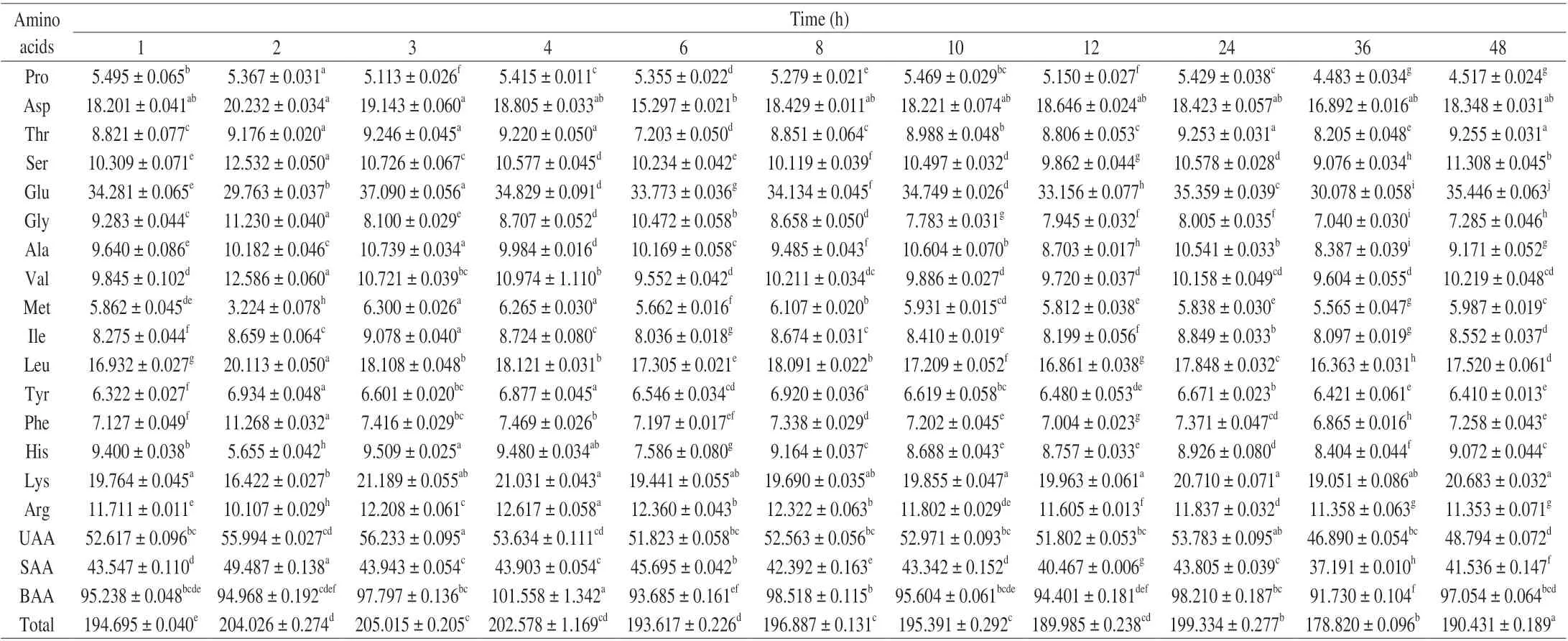

3.3 FAA

As indicated in Table 3 and Table 4, sixteen FAA in chicken were identified. The total FAA concentration was around 200 mg/100 g,lower than values of Xueshan yellow-feathered broilers [9]. However,the content of Glu and Asp in Qingyuan partridge chicken, especially Asp, was much higher than Xueshan Chicken, another local yellowfeathered breed, which is mainly grown in Jiangsu Province and suitable for soft-boiled chicken. The highest content in Xueshan chicken was 5.50 mg/100 g, and the lowest content in Qingyuan partridge chicken was about three times of Xueshan chicken,15.297 mg/100 g, which indicates that Qingyuan partridge chicken has obvious advantages in umami taste. The most abundant free amino acid detected in Xueshan chicken was lysine (Lys), which was usually present at levels higher than 120 mg/100 g, indicating that Lys was the main amino acid that forms the characteristic flavor of Xueshan chicken. In this article, the concentration of Lys was onlyabout 20 mg /100 g, and Glu was the most abundant amino acid. With the extension of post-mortem time, the content of each amino acid did not show a clear trend, with a dynamic changing.

Table 1 Degradation of ATP and its related substances in chicken breast during 0–4 °C post-mortem aging.

Table 2 Degradation of ATP and its related substances in chicken thighs during 0–4 °C post-mortem aging.

Table 3 FAA (mg/100 g) in chicken breast during 0–4 °C post-mortem aging.

Table 4 FAA (mg/100 g) in chicken thigh during 0–4 °C post-mortem aging.

Asp and Glu are the umami-taste characteristics FAA, the sum of them was the highest at 2 h and 3 h in chicken breast and thigh respectively. The content of total umami nucleotide and sweet nucleotide in chicken thigh was relatively high at 2 h after slaughter, and the content of bitter amino acid was relatively low.Combined with theK-value, it can be inferred that chicken thigh had superior flavor at 2 h during 0–4 °C post-mortem aging. FAA have a strong influence on the taste of chicken even when present in low concentrations which result in the low taste threshold values. Some FAA, especially sweet amino acids, would have a synergistic effect on the umami taste.

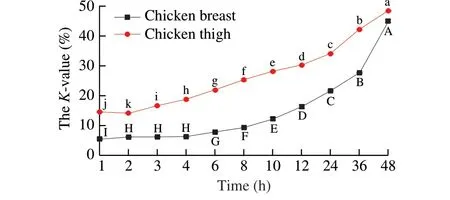

3.4 The K-value and EUC

TheK-value is an key chemical indicator for determining meat freshness assessment based on nucleotide degradation [34]. It has been widely used as a freshness indicator in meat, especially in fish and chicken [35]. According to the freshness level, chicken breasts were still in first-class fresh (less than 20%) within 12 h during storage at 0–4 °C after slaughter as shown in Fig. 4. Compared with breast, theK-value of chicken thigh was relatively high, which was higher than 20% after 6 h. This was largely due to the relatively low content of IMP in chicken thigh. Although theK-value of chicken breast and thigh enhanced gradually during the post-mortem aging at 0–4 °C, the increasing trend was different. The curve in the breast was more in line with the logarithmic procedure, while the leg tended to be a linear one. It can be inferred that, in addition to the concentration,the degradation rate of IMP in breast and thigh meat was also distinct,which may be one of the reasons for the variation in flavor between breast and thigh.

Fig. 4 The K-value of chicken breast and thigh during 0–4 °C postmortem aging. Different uppercase letters of chicken breast samples indicate significantly different (P < 0.05, Ducan’s multiple range test). Different lowercase letters of chicken thigh samples indicate significantly different(P < 0.05, Ducan’s multiple range test).

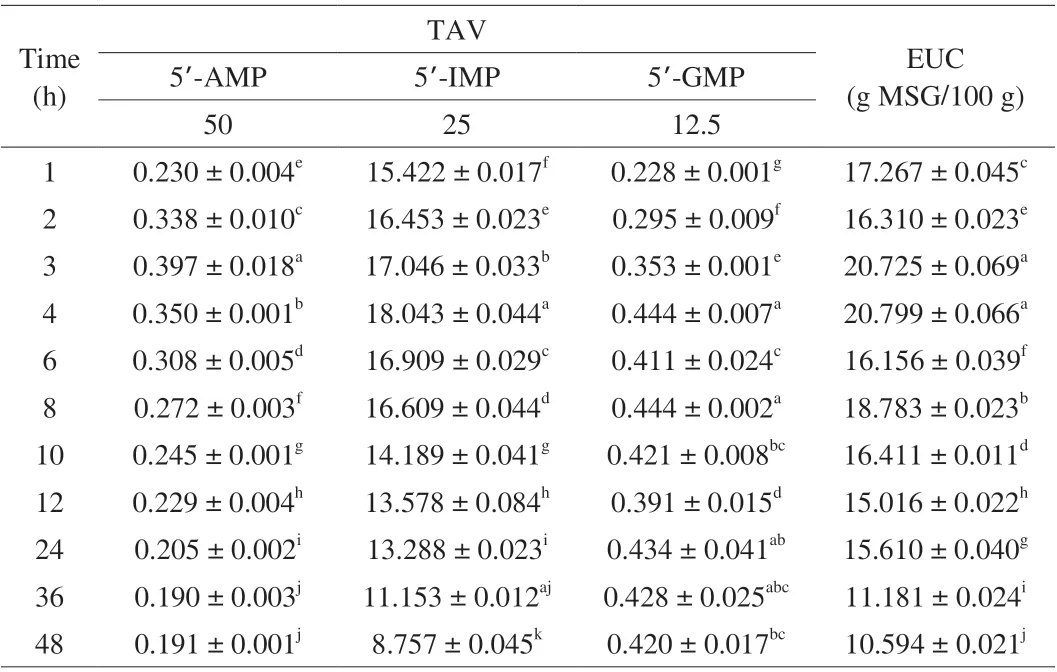

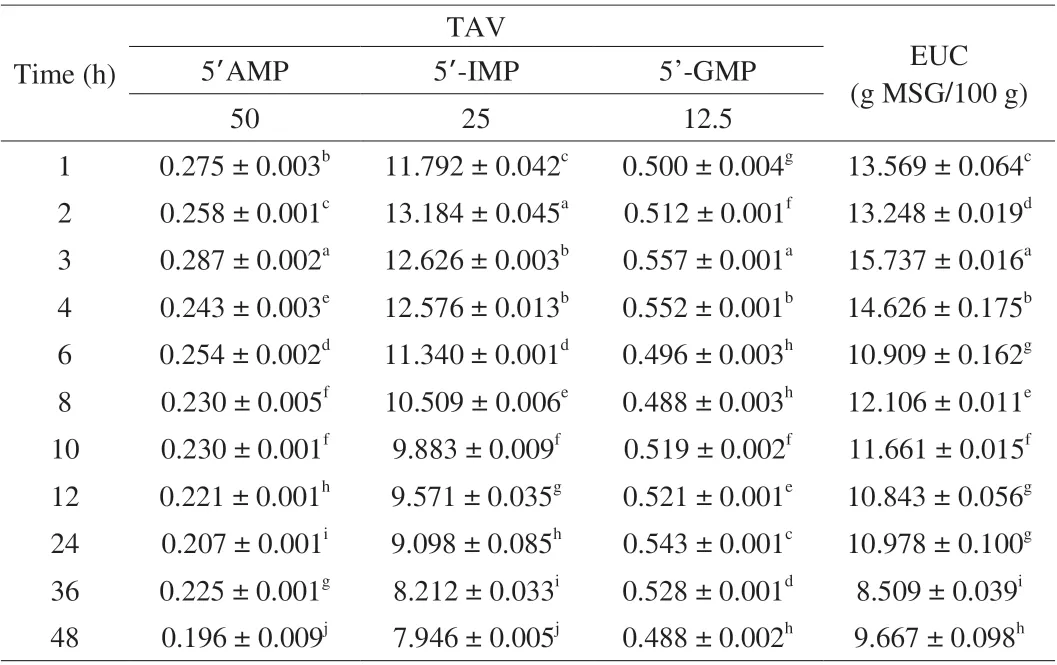

The EUC of chicken breast and thigh in different post-mortem aging time from 5′-nucleotides and umami-taste amino acids was calculated as shown in Table 5 and Table 6. The results indicated that the individual contents of different umami-taste compounds in chicken were different. The synergistic effect of flavor nucleotides(AMP, GMP, and IMP) with MSG-like components (Asp and Glu) enhance umami-taste dramatically [36]. During the 0–4 °C post-mortem aging, the EUC value of chicken breast and thigh were relatively high at 3 and 4 h. The EUC value of chicken breast was greatly affected by flavor nucleotides while umami amino acids had a non-negligible effect on the EUC value of chicken thigh.

Table 5 The EUC of chicken breast during 0–4 °C post-mortem aging.

Table 6 The EUC of chicken thigh during 0–4 °C post-mortem aging.

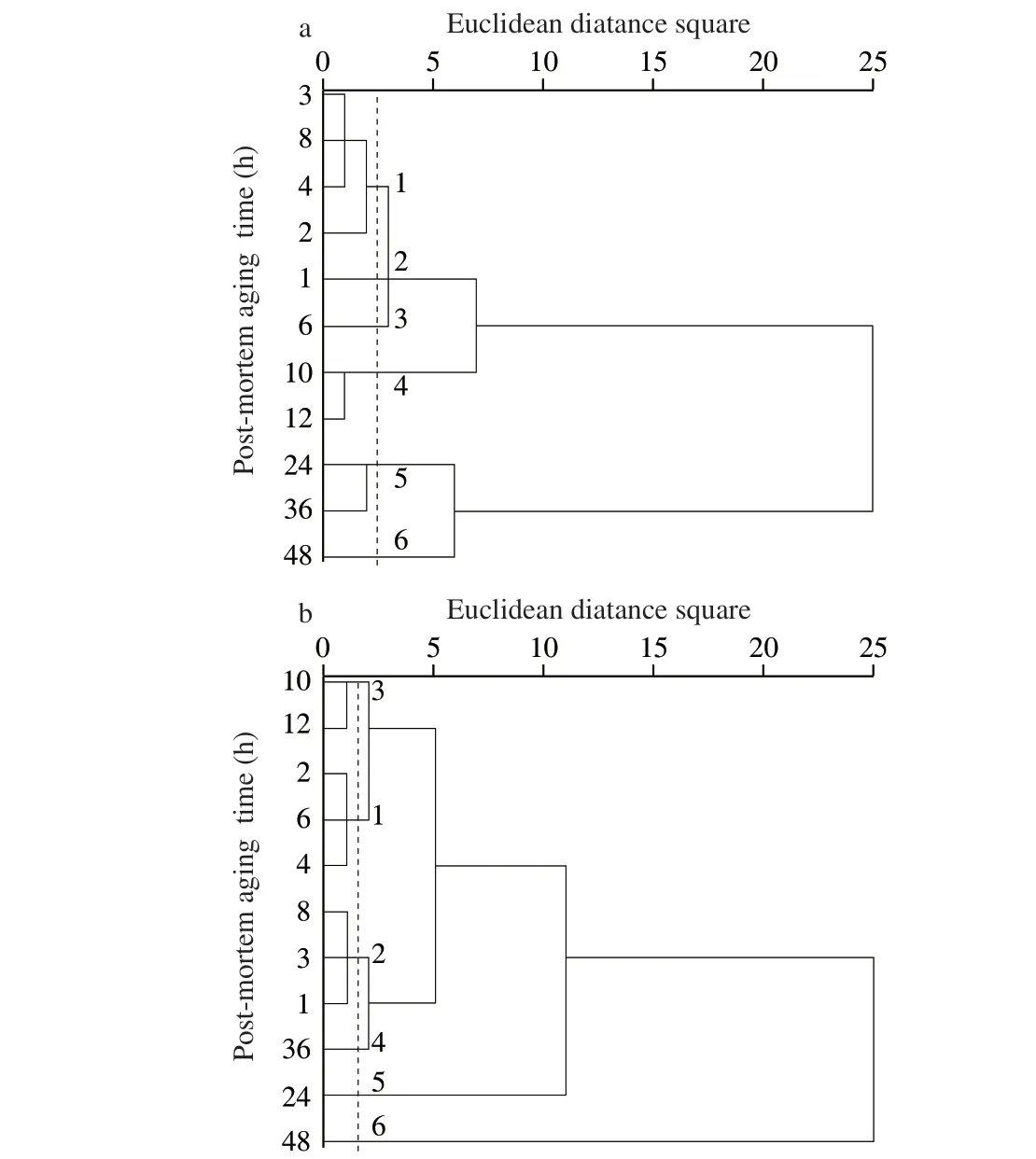

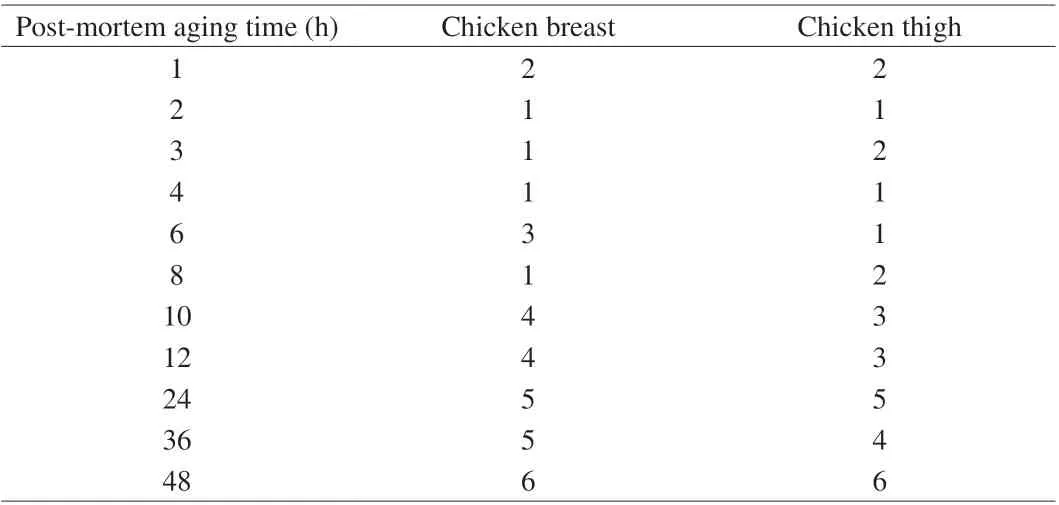

3.5 Cluster analysis of samples based on pH, nucleotides and FAA

Cluster analysis is a statistical analysis technique that divides research objects into relatively homogeneous groups through data modeling. In general, it can be divided into two categories:Q-type hierarchical clustering analysis and R-type clustering analysis according to different classification objects. The Q-type hierarchical clustering method is an exploratory analysis with no clear classification criteria and the samples can be classified from the original data during the classification process [37]. It was adopted to analyze the pH, nucleotides and FAAs of different aging times, and the samples with common characteristics were gathered together. The square of the Euclidean distance was used as the metric, and the results were shown in the Fig. 5. According to the results of the cluster analysis, the different samples of chicken breast and thigh were divided into 6 groups with 2.5 and 1.5 squared Euclidean distance, respectively, and the results were shown in Table 7. The samples of chicken breast at 2, 3, 4, and 8 h post-mortem aging time were classified into one category with similar result at 2,4, and 6 h in chicken thigh. Comprehensive analysis, the samples of categories 1, 2, and 3 (1–8 h post-mortem aging time) were selected for subsequent analysis.

Fig. 5 System clustering analysis of chicken breast (a) and thigh (b) during 0–4 °C post-mortem aging.

Table 7 Cluster group of chicken breast and thigh.

3.6 Determination of water soluble taste LMWPs

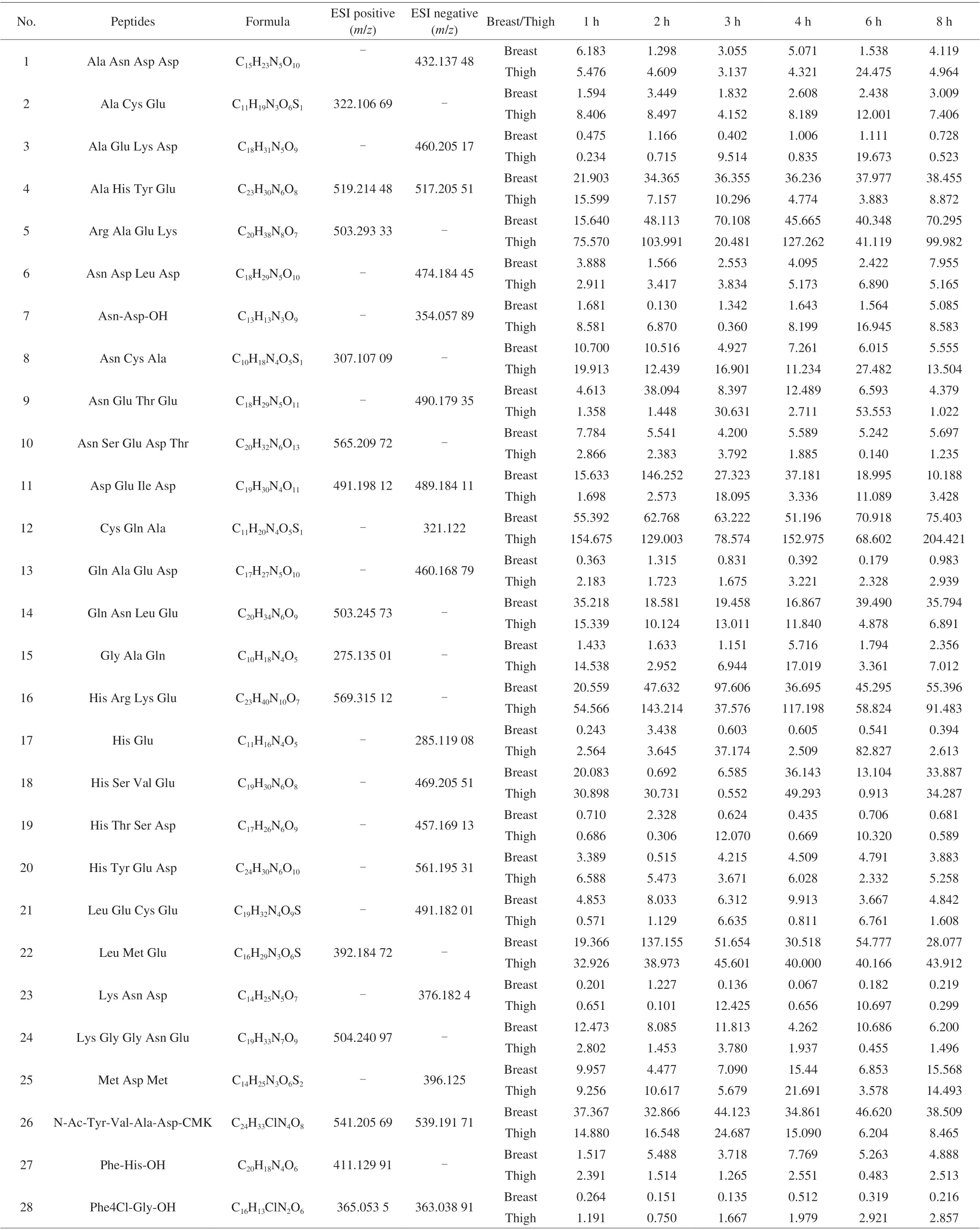

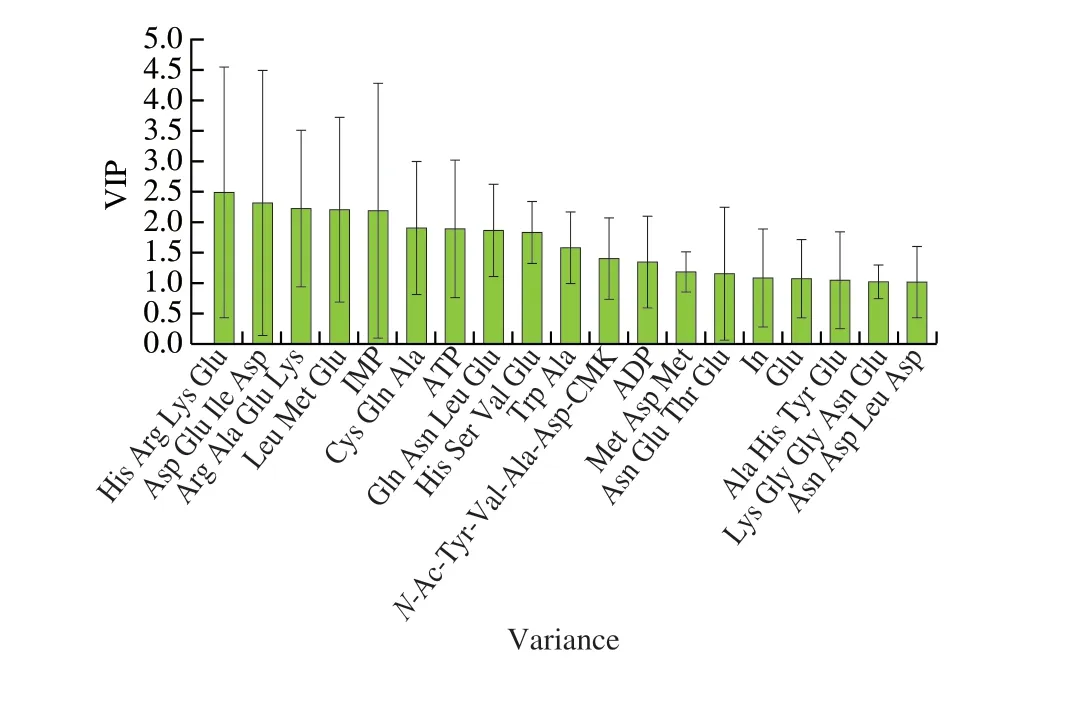

During the post-mortem aging process, the protein degradation of the chicken carcass will produce a large number of flavor precursor peptides, which can participate in a series of physical and chemical reactions in the subsequent processing process, thereby affecting the flavor of the chicken. Oligopeptides with a molecular weight of less than 3 kDa could bind to a specific taste receptor on the tongue and present a characteristic taste [38]. Flavor peptides with various structures and lengths can contribute to unique taste properties including sweet, bitter, umami, sour and salty and kokumi properties.Umami peptides are widely present in meat, which do not affect other tastes and can enhance the flavor characteristics [39]. Umami amino acids including Glu and Asp are the basic elements of umami peptides. Dipeptides with acidic amino groups at the N-terminus and basic amino groups at the C-terminus can present umami taste characteristics. Most umami-taste peptides are composed of positively charged molecular groups, negatively charged molecular groups and hydrophobic molecular groups [38]. According to the above research,flavor peptides containing umami amino acids were screened out in the experimental results. The Table 8 lead the conclusion that thirty-six LMWPs may influence the composition of umami flavor components during the 0–4°C post-mortem aging process.

3.7 Sensory evaluation by electronic tongue system

The taste characteristic value of each sample was shown in Fig. 6. According to the characteristics of the instrument, the taste had no effect on its overall sensory organs if the taste characteristic value was lower than zero. The taste characteristic values of sourness and saltiness were far less than zero with meaningless for further research and were not listed in the chart. In addition, the so-called aftertaste-A(aftertaste astringency) and aftertaste-B (aftertaste bitterness) were evaluated immediately after cleaning. It can be found that there was no conspicuous difference in the richness (which can be seen as the aftertaste of umami) and astringency during 0–4 °C post-mortem aging no matter in chicken breast or chicken thigh through the analysis of variance. Although the EUC of the sample was relatively high at 3 and 4 h after slaughter, the umami taste characteristic value was relatively low. It could be speculated that the perception of umami taste can be affected by the low molecular weight peptides greatly [40]. In contrast, the taste characteristics of the samples at 2 h were relatively better, indicating that the taste peptides had a positive effect. Based on the afore mentioned factors, it was preliminarily judged that 2 h was the best maturity time during 0–4 °C post-mortem aging process.

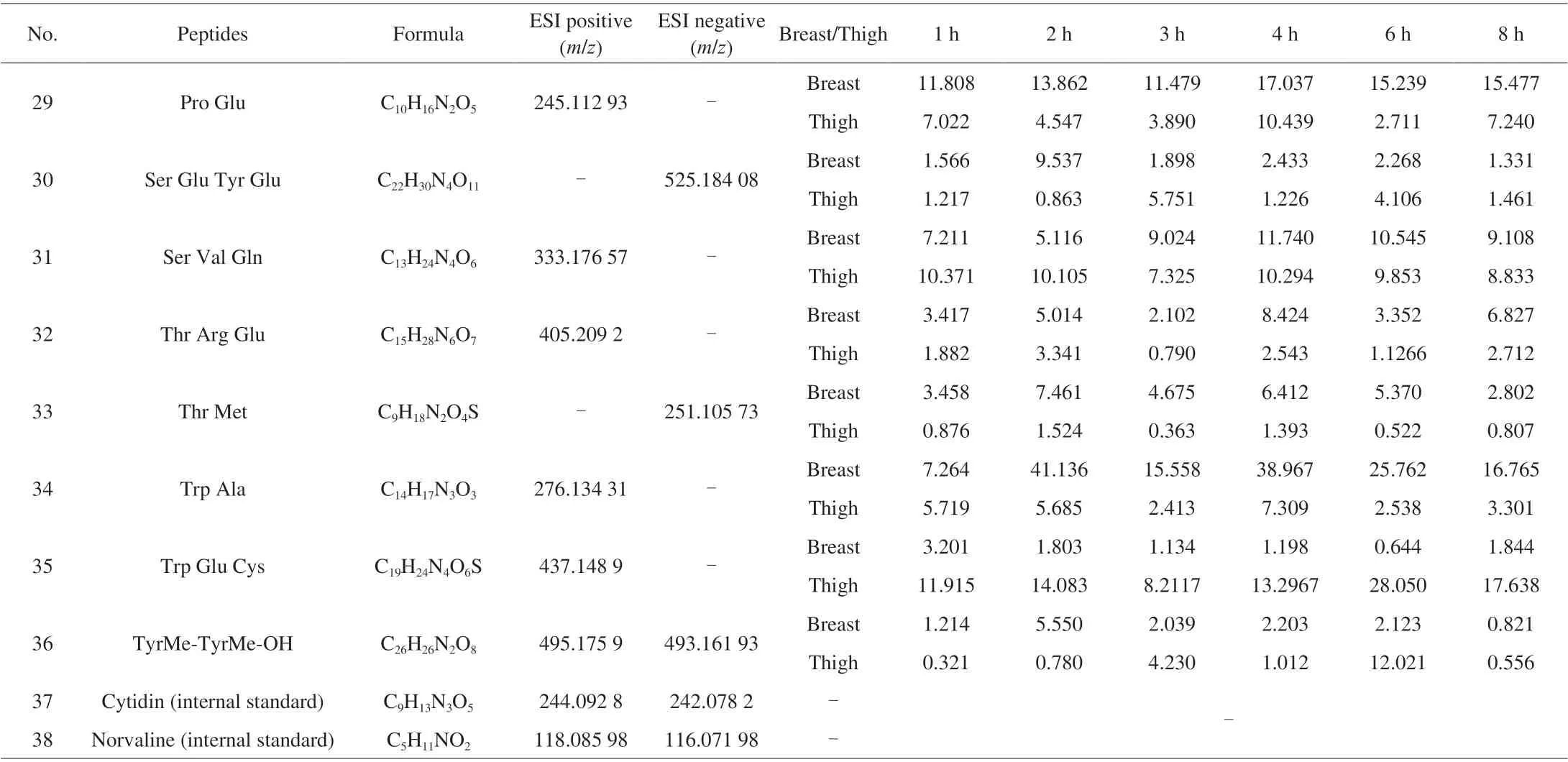

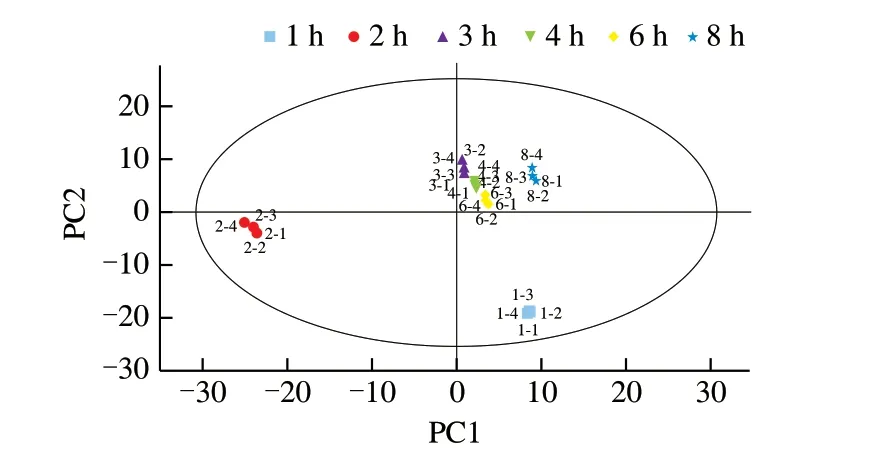

3.8 The relationship between taste-active precursors, taste characteristics and post-mortem aging time by PLS-DA

PLS-DA is a new type of multivariate statistical data analysis method used for discriminant analysis. It is a common statistical analysis method that judges how to classify research objects based on the values of several detected variables. By establishing a model of the relationship between variables and sample categories, and reducing the dimensionality of the data, this kind of supervision mode made by PLS-DA can establish the relationship between samples better and realize the prediction of sample categories The observations and influencing variables between groups can be effectively distinguished by properly rotating the principal components [41]. It was done to explore the main factors and discrimination of different post-aging time. In this regression model, five principal components were extracted.R2Xcum,R2Ycum, andQ2cumare 0.979, 0.995, and 0.987 respectively, indicating strong reliability and superb predictive ability of the model. The scores scatter plot (Fig. 7) indicated that 1 h and 2 h can be better separated from the other periods. The variable importance for the projection (VIP) summarizes the importance of the variables both to independent and to dependent. It is generally believed that independent variables with VIP better than 1.0 are the paramount, those less than 1 make no sense. The VIP plot was sorted from high to low, and showed confidence intervals for the VIPvalues, normally at the 95% level. Fig. 8 lists 19 compounds with VIP higher than 1, including 14 water-soluble low molecule peptides,four nucleotides (IMP, ATP, ADP, In) and Glu. It’s obvious that most peptides contained Asp and Glu, both of them were vital contributors to umami taste.

Table 8 Water-soluble LWMPs during 0–4 °C post-mortem aging.

Table 8 (Continued)

Fig. 6 Taste characteristic values in chicken breast (a) and thigh (b) during 0–4 °C post-mortem aging. Different lowercase letters of the same index indicate significant difference (P < 0.05, Ducan’s multiple range test).

Fig. 7 Scores scatter plot of different post-mortem aging time.

Fig. 8 VIP of flavor precursors affecting the distinguish of different postmortem aging time. The lines represent confidence intervals for the VIP values at the 95% level.

4. Conclusion

Post-mortem aging is of great importance for formation of watersoluble flavor precursors, especially umami substances in chicken.This paper investigated the changes of freshness and umami-related compounds in chicken during at 0–4 °C post-mortem aging. It was found that the content of umami nucleotides in chicken breast was higher than that in chicken thigh, and the EUC value was mainly affected by flavoring nucleosides. TheK-value of chicken thigh at 2 h was the lowest, indicating the freshness was the highest. Samples within 8 hours were screened out by Euclidean distance calculation for sensory analysis of electronic tongue and flavored peptides detection.Combined with the dynamic changes of water-soluble LMWPs, it was speculated from the PLS-DA that 2 h was the best maturation time for chicken during 0–4 °C post-mortem aging, which could provide a theoretical guidance for deep processing and production of chicken.

Declaration of interest

There was no conflict of interest.

Acknowledgments

This work was supported by China Agriculture Research System of MOF and MARA (CARS-41) and Wens Fifth Five R&D Major Project (WENS-2020-1-ZDZX-007).

- 食品科学与人类健康(英文)的其它文章

- Wine, beer and Chinese Baijiu in relation to cardiovascular health:the impact of moderate drinking

- Comparative analysis of physicochemical properties, ginsenosides content and α-amylase inhibitory effects in white ginseng and red ginsen

- Monitoring and identif ication of spoilage-related microorganisms in braised chicken with modif ied atmosphere packaging during refrigerated storage

- Effect of cooking processes on tilapia aroma and potential umami perception

- Formation mechanisms of ethyl acetate and organic acids in Kluyveromyces marxianus L1-1 in Chinese acid rice soup

- Volatile prof ile and multivariant analysis of Sanhuang chicken breast in combination with Chinese 5-spice blend and garam masala