Effect of sodium replacement on the quality characteristics of pastırma (a dry-cured meat product)

Barış Yalınkılıç*, Güzin Kaan, Mükerrem Kaya

a Department of Gastronomy and Culinary Arts, Faculty of Fine Arts and Architecture, İstanbul Gedik University, Kartal, Istanbul 34876, Turkey

b Department of Food Engineering, Faculty of Agriculture, Atatürk University, Erzurum 25240, Turkey

Keywords:Pastırma Chloride salts Volatile compounds Cathepsin Lipase

A B S T R A C T This study aims to investigate the effect of sodium replacement on the quality characteristics of pastırma. For this purpose, pastırma production with four different salt mixtures (I. 100% NaCl; II. 50% NaCl + 50% KCl;III. 40% NaCl + 40% KCl + 20% CaCl2; IV. 30% NaCl + 40% KCl + 20% CaCl2 + 10% MgCl2) were carried out using traditional method. The use of different salt mixtures for pastırma had no statistically signif icant effect on the microbial counts and residual nitrite of the f inal product. The a* and b* values were affected by this treatment. The salt mixture containing CaCl2 or CaCl2 + MgCl2 signif icantly decreased the pH values and sensory scores. The eighteen volatile compounds were affected by the salt mixtures. Na+, K+, Ca2+, and Mg2+ had a certain increase depending on their ratio in the salt mixtures. The highest Cathepsin activity in all pastırma samples was observed in Cathepsin B + L. The salt mixture with NaCl + KCl + CaCl2 + MgCl2 increased acid lipase activity. However, this mixture had no signif icant effect on neutral lipase activity.

1. Introduction

Sodium chloride is an ingredient used in processed meat products for its role in technological, microbiological, and sensory quality.This component helps to enhance the f lavor of the product by exerting a prooxidant effect on meat lipids, and the formation of the salty taste is mainly caused by negatively charged Cl-ions that present in the salt molecules. Besides, by binding the water that can be used by microorganisms, it acts as an obstacle against the development of undesired microbial flora. The interaction of NaCl with the side chains of actin and myosin also improves the textural properties of the product [1]. Despite being a significant ingredient in the production of dry-cured meat products, the salt ratio in such products can reach to high levels due to the dehydration phenomenon. For this reason, these products lead to an increase in the consumer’s total salt intake [2].

Pastırma, which is a Turkish traditional dry-cured meat product obtained by processing of meats from beef and buffalo carcasses, has been produced in many countries located in Europe and Middle East region [3]. In the production of pastırma, 5% NaCl is generally used,however, high salt levels such as 8%-10% can also be seen in the traditional pastırma production [4]. Besides, the permitted salt level in the Meat and Meat Products Communiqué of Turkish Food Codex is 10% by mass for pastırma [5].

Dry-cured meat products including pastırma are the signif icant sources of NaCl, and the higher levels of sodium (Na+) intake are correlated with cardiovascular disorders, including hypertension,and sodium chloride’s average daily intake level is recommended by health authorities to not exceed 6 g/day [6]. In order to decrease Na+content in dry-cured meat products, different approaches have been implemented in the meat industry including the use of different chloride salts [7-9], amino acids (L-lysine andL-histidine)[10,11].

It is known that the strategies applied to reduce the sodium content of dry-cured meat products affect the proteolytic and lipolytic character of the product. As a matter of fact, phospholipase activity and autoxidation values related to the lipolysis phenomenon occurring in the product [12] and total free amino acid content, proteolysis index, and Cathepsin B + L enzymes related to the proteolysis phenomenon of the product are significantly affected by the change in the curing process [10]. The change in curing mixture to obtain lowsodium dry-cured meat product strongly affects the odor intensity and flavor properties of the dry-cured meat product because of the changes in proteolytic and lipolytic character [11-14]. However, despite the importance of lipolytic and proteolytic changes in the formation of volatile compounds; the volatile component profile of the product was not examined in the studies conducted to reduce the sodium content of pastırma [15-17] and was not addressed with an integrated approach with other technological parameters. Therefore, the aim of the present study was to investigate the effects of sodium, potassium,calcium, and magnesium chloride salts on the lipolytic and proteolytic enzymes, volatile profile, microbial populations, and its chemical,physico-chemical, and sensory properties.

2. Material and methods

2.1 Pastırma production

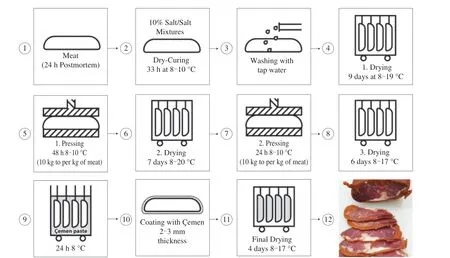

M.Longissimusthoracisetlumborummuscles (24 h postmortem) obtained from three different beef carcasses were used in pastırma production. Each muscle was vertically divided into two parts of equal weight, and four pieces of muscles were obtained from each carcass. One of the four pieces was used as the control group and the other three pieces were treated with curing mixtures containing different levels of chloride salts. Pastırma production was carried out according to the traditional method applied by the Erzurum Meat and Milk Institution (Fig. 1). In this method, excessive fat and connective tissue were removed from the surface of the muscles,and incisions were made at a 45° angle by using a knife. Next, the muscles were dry-cured using a 10% salt/salt mixture (control: 100%NaCl; treatment I: 50% NaCl + 50% KCl; treatment II: 40% NaCl +40% KCl + 20% CaCl2; treatment III: 30% NaCl + 40% KCl +20% CaCl2+ 10% MgCl2) by weight, 0.2% saccharose, 150 mg/kg KNO3, and 100 mg/kg NaNO2. The curing stage was conducted for 33 h at 8-10 °C. After curing, the meat pieces were washed with tap water to remove excessive salt. Then, the meat pieces were dried for 9 days under environmental conditions (min 8 °C-max 19 °C) (I.drying stage). After the first drying stage, meat pieces were pressed at 8-10 °C for 48 h using 10 kg of weight per kg of meat (I. Pressing). Then,the II. drying stage was applied for 7 days (min 8 °C-max 20 °C).The relatively dry meat pieces were then subjected to II. pressing process at 8-10 °C for 24 h. III. drying stage was applied for 6 days under environmental conditions at temperatures of 8-17 °C. After that, the dried pieces were placed in a paste mixture (çemen) for 24 h and then, covered with çemen at 2-3 mm thickness. Çemen is a highviscosity coating paste applied to the surface of pastırma to provide a special appearance, color, texture, taste, aroma, and flavor [3].The çemen mixture in the study was as follows: 800 mL tap water,200 g paprika, 100 g garlic and 500 g flour obtained fromTrigonella foenumgraecumseed. The pieces covered with çemen paste were then subjected to final drying (last drying stage) for 4 days between 8-17 °C. Experimental pastırma samples were produced with three replicates according to the traditional method.

2.2 Sampling

For characterization of proximate composition and pH values of raw material, meat samples were taken from each muscle before production. Other stated analyses were performed on the final product.

Fig. 1 Pastırma production according to the traditional method.

2.3 Microbiological analysis

Enumeration of lactic acid bacteria and Enterobacteriaceae were carried out using De Man ROGOSA Sharpe Agar (MRS, Merck) and Violet Red Bile Dextrose Agar (VRBD-Agar, Merck), respectively,at 30 °C for 48 h under anaerobic conditions.Micrococcus/Staphylococcusand mold-yeast counts were determined under aerobic conditions using Mannitol Salt Phenol-Red Agar (MSA, Merck) at 30 °C for 48 h forMicrococcus/Staphylococcusand Rose Bengal Chloramphenicol Agar (RBC-Agar, Merck) at 25 °C for 3-5 days for mold-yeast.

2.4 Physical and chemical analysis

2.4.1 Proximate composition and physicochemical analysis

The amounts of moisture, crude protein, fat, and ash of the raw material were determined according to AOAC [18]. Water activity(aw) and pH of the pastırma samples was measured using Novasina,TH-500awSprint equipment and pH-meter (ATI ORION 420, MA 02129, USA), respectively. TBARS analysis was carried out with a spectrophotometric (Aquamate Thermo Electron Corporation,England) method as stated by Lemon [19]. Non-protein nitrogenous matter (NPN-M) was titrimetrically calculated according to procedure offered by Anonymous [20]. The amount of free fatty acids was measured as described by Wang [21]. The color intensity of the samples was measured on sliced samples (1.5 mm thickness) using a colorimeter (Minolta, CR-200, Minolta Co, Osaka,Japan) according to criteria stated by International Commission on Illumination (CIELAB, Commision Internationele de I’E Clairage).Residual nitrite analysis was performed according to a method stated by Tauchman [22].

2.4.2 Determination of Cathepsin B, B+L, and H enzymes activities

Catepsin B, B + L, and H enzymes activities were fluorometrically(Perkin Elmer) determined as stated by Toldrá & Etherington, [23]using 2.5 g of grounded pastırma sample. Cathepsin B (EC 3.4.22.1.)and B + L (EC 3.4.22.15) activity were measured at pH 6.0 using 0.05 mmol/L N-CBZ-Arg-Arg-AMC and 0.05 mmol/L N-CBZ-Phe-Arg-AMC substrates, respectively. For the cathepsin H (EC 3.4.22.16)assay, measurement was done at pH 6.8 usingL-Arg-AMC as substrate. One unit of enzyme activity (U) was defined as the amount of enzyme which hydrolyses 1 μmol of substrate per min at 37 °C.

2.4.3 Determination of acid lipase, neutral lipase, and phospholipase activities

Acid lipase, neutral lipase and phospholipase activities were fluorometrically (Perkin Elmer) determined according to a method stated by Motilva, Toldra & Flores [24]. Enzyme activities were determined fluorometrically using 0.92 mmol/L 4-methlyumbelliferyl oleate (Sigma Aldrich) as substrate at pH 5.0. For the reaction buffer,0.2 mol/L disodium phosphate, 0.1 mol/L citric acid, 0.5 mg/mL Triton X-100, 0.8 mg/mL of bovine serum albumin (BSA) (pH 5)were used for acid lipase. In addition to the reaction buffer of acid lipase, 150 mmol/L FNa was additionally used in the reaction buffer for phospholipase analysis. A reaction buffer for neutral lipase was prepared using 0.22 mol/L Tris-HCl containing 5 mg/mL bovine serum albumin at pH 7.5.

Because of an autohydrolysis detected in 4-methlyumbelliferyl oleate at pH 7.5 in the analysis of neutral lipase, some modifications were made. Before running the neutral lipase analysis in well-plate,four different wells were filled with a reaction buffer and substrate without enzyme extract, and these four wells were used as blank testing. After completing the neutral lipase analysis, the mean value obtained in the blank test was subtracted from the results obtained in the neutral lipase analysis, and net fluorescence values were detected for neutral lipase. One unit of enzyme activity (U) was defined as the amount of enzyme which hydrolyses 1 μmol of substrate per hour at 37 °C.

2.4.4 Determination of mineral matters

Minced pastırma samples that were dried at 100-102 °C were crushed into powder with a muddler. 0.5 g of the powdered sample was taken and 3 mL of 30% H2O2and 2 mL of 70% nitric acid were added to the sample. Then, the samples put into a microwave oven (Berghof Speedwave Microwave Digestion Equipment MWS-2) to get burned, and the burning process took place in three different phases; first phase: temperature: 145 °C, duration: 5 min,radiofrequency: 75%; second phase: temperature: 190 °C, duration:10 min, radiofrequency: 90%; third phase: temperature: 100 °C duration:10 min, radiofrequency: 40%. Then the mineral matter content of the samples, which were diluted to 25 mL after the burning process,was measured with an ICP-OES (Perkin Elmer Optical Emission Spectrometer Optima 2100 DV) device. The wave lengths used for Ca2+, Fe2+, K+, Mg2+, and Na+elements were 317,933, 238.204, 766.490,285.213, and 589.592 nm, respectively. The results of the analysis were expressed as mg mineral matter/kg dry matter [25,26].

2.4.5 Analysis of volatile compounds

Analysis of volatile compounds was performed according to the method given by Kaban [27]. 5 g of grounded pastırma sample that was transferred to a 40 mL vial (Supelco, Bellefonte PA, USA) was held in a thermal block for 1 h at 30 °C to provide the accumulation of volatile compounds in the headspace. In order to extract the volatile compounds, CAR/PDMS fibre (Supelco 75 μm, USA) was used.Analysis was performed using a gas chromatograph (GC, Agilent Technologies 6890 N)/mass spectrometer (MS, Agilent Technologies 5973) device. The volatile compounds were identified with the library of the mass spectrometer (NIST, WILEY, FLAVOR) and standard molecules (Supelco 44585-U, Bellefonte PA USA).

2.5 Sensory analysis

Sensory assessments of the samples were carried out by the trained staff and graduate students (a total of 36 panelists for all replicates) of the Food Engineering Department. The sliced pastırma samples were evaluated with regard to color, odor, texture, taste, and general acceptability, using a hedonic scale numbered from 1 to 9 for each sensory parameters.

2.6 Statistical analysis

The research was performed according to a randomized complete block design with three replicates. The obtained data were subjected to analysis of variance (two-way), and the main effects of chloride salts were evaluated with Duncan’s multiple range test. All data were analyzed with SPSS 13 software (USA, 2004).

3. Results and discussion

The proximate composition ranges and the pH values of the raw meat are presented in Table 1.

Table 1 The proximate compositions (%) and pH values of the raw meat.

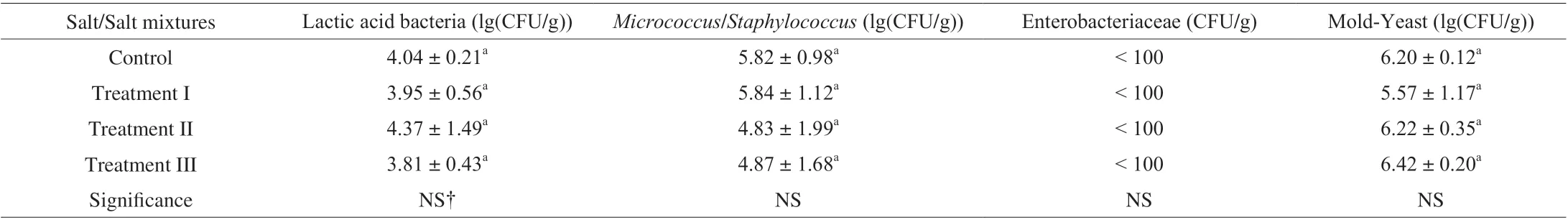

3.1 Microbiological results

The use of different salt mixtures had no significant effect(P> 0.05) on the final counts of the microorganisms investigated in the study (Table 2). Besides, Enterobacteriaceae counts were below the detectable level in all pastırma groups, probably due to the decreases in water activity (Table 3) [28]. The results obtained for lactic acid bacteria and Enterobacteriaceae in dry-cured loins treated with different chloride salts [29,30] were similar with our findings. Blesa et al. [31]found no differences among mean values of salt-tolerant bacteria in dry-cured hams salted with different chloride salts. In contrast,Lorenzo et al. [32] detected higher numbers for salt-tolerant bacteria in dry-cured lacon salted with KCl and NaCl. On the other hand, in contrast to our findings, the replacement of NaCl by other chloride salts in dry-cured lacon was found to increase the yeast numbers [32].This could be explained by the differences in raw materials and processes between the pastırma and dry-cured lacon.

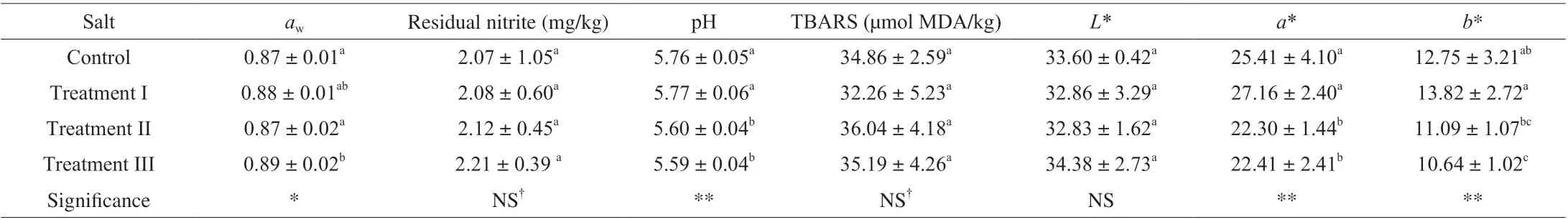

3.2 Water activity and residual nitrite

Mean water activity and residual nitrite values are presented in Table 3. Theawvalues of all treatments were lower than 0.90 which is a characteristic value for such products [1]. Considering the higher pH values in pastırma, water activity can be thought of as an important obstacle factor for the microbiological safety of the product. On the other hand, the use of different salt mixtures had significant (P< 0.05)but a slight differences inawvalues on the samples. In the studies investigating the effect of chloride salts on dry cured meat products,different water activity results were encountered depending on the salt mixture and product type [15,29,32]. On the other hand, different salt mixtures had no statistically significant effect on the residual nitrite levels of pastırma (P> 0.05). The results (Table 3) are in harmony with TSE 1071 (Pastırma Standard of Turkish Standards Institution)in which the residual nitrite level is stated to be lower than 50 mg/kg.The residual nitrite levels were also lower than 50 mg/kg in other drycured meat products salted with different chloride salts [16,33,34].

3.3 pH and color intensity

The pH values of all treatments detected in the present study are in accordance with TSE 1071 in which the pH limit is ≤ 6.0. The use of different salt mixtures had a very significant (P< 0.01) effect on the pH values of pastırma (Table 3). Except for the monovalent salts,use of CaCl2and/or MgCl2decreased the pH values of the samples.This result is probably due to a decrease observed in the isoelectric pH owing to the relative binding properties of divalent salts to negative charges of proteins [35]. Likewise, similar results were also detected by other authors [7,16] in dry-cured meat products.

Different salt mixtures had very significant (P< 0.01) effects ona* andb* values except forL* parameter (P> 0.05) (Table 3).The highesta* values were obtained with the use of monovalent salts,however, divalent salt usage revealed lowera* values. Similar toa*parameter, lowerb* values were measured in samples with CaCl2and/or MgCl2. In contrast to our findings, Aliño et al. [29] and Hastaoğlu &Vural [15] detected no differences between samples in terms ofL*,a*, andb* values when different chloride salts were used. Besides,there are other studies [16,30] with different results, too.

Table 2 The overall effects of different chloride salts on microbiologic counts of pastırma samples.

Table 3 The overall effects of different chloride salts on aw, residual nitrite, TBARS, pH, L*, a* and b* values of pastırma samples.

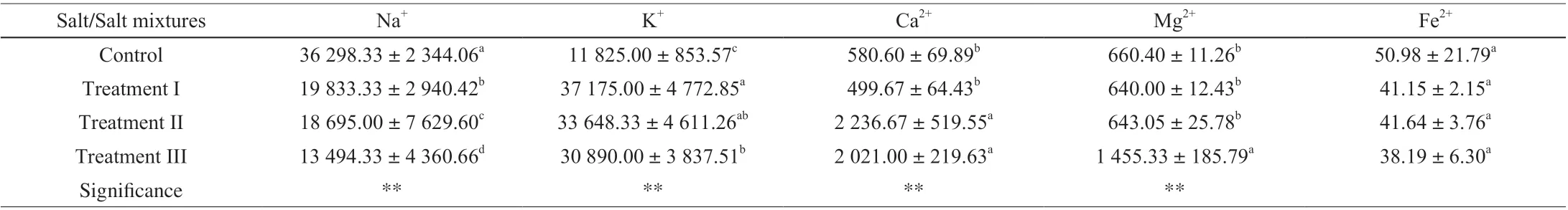

3.4 Mineral matter and non-protein nitrogen

The elements (Na+, K+, Ca2+, Mg2+) except for Fe2+had a certain increase (P< 0.01) depending on their ratio in the curing mix(Table 4). To reduce the NaCl ratio in curing mix to provide to obtain low-sodium pastırma ((13 494.33 ± 4 360.66) mg/kg dry matter) was especially succeeded with 30% NaCl + 40% KCl + 20% CaCl2+ 10%MgCl2mixture. However, use of 100% NaCl in curing mix resulted in more than two fold Na+content ((36 298.33 ± 2 344.06) mg/kg dry matter) compared to the aforementioned mix. Decrease in Na+content in dry-cured meat products with the use of different chloride salts was also observed in other studies [36,37].

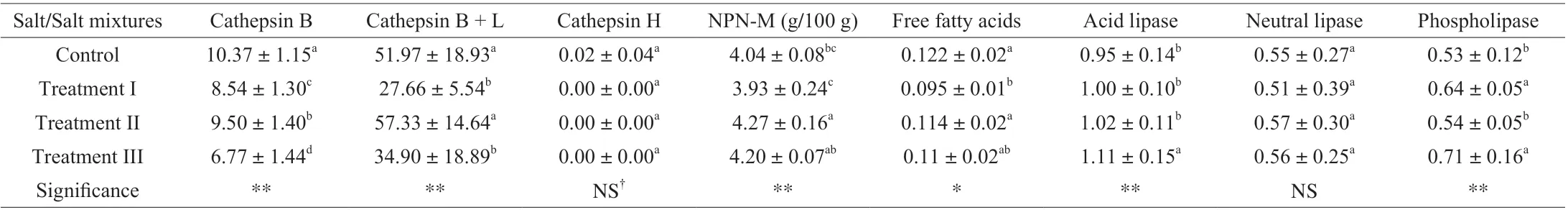

NPN-M amounts of the samples were between 3.66-4.45 g/100 g pastırma and use of salt/salt mixtures in curing was found to have a very significant effect (P< 0.01) on NPN-M values (Table 5). The highest mean value ((4.27 ± 0.16) g/100 g) for NPN-M was obtained in samples salted with NaCl/KCl/CaCl2combination. On the other hand, the lowest mean value ((3.93 ± 0.24) g/100 g) was obtained in samples salted with 50% NaCl + 50% KCl mixture. As an overall assessment, NPN-M value was slightly increased in the presence of CaCl2and/or MgCl2. Similar results were also found by Kızılkaya [17]in NPN values of pastırma in the presence of CaCl2.

3.5 Enzyme activities

Salt/salt mixtures were found to have very significant (P< 0.01)effects on Cathepsin B and B + L (Table 5). The highest Cathepsin activity in all samples was observed in Cathepsin B + L. Cathepsin B activity was lower compared to Cathepsin B + L and was higher than Cathepsin H. Cathepsin H activity was only observed in a few samples with no statistical significance (P> 0.05). Similar trends in Cathepsin B, B + L, and H activities have also been shown in other studies [36-38] in which different chloride salts were used in as curing agent. The highest and the lowest Cathepsin B activity were detected in control group and treatment III, respectively. The highest Cathepsin B + L activity ((57.33 ± 14.64) × 10-3U/g dry-matter) was detected in samples of the treatment II and this treatment had statistical difference(P> 0.05) with the control group. The lowest Cathepsin B + L activity was determined in treatment I. Including this study, there is a significant variation between Cathepsin B and B + L activity values(except for Cathepsin H) of dry-cured meat products obtained with different chloride salts [8,36-38].

The lipolytic enzymes investigated in the study were found to retain their activity (Table 5) at a certain level during the production of pastırma. The use of different salt mixture in pastırma production was found to have very significant effects on acid lipase and phospholipase (P< 0.01) except for neutral lipase (P> 0.05). The use of MgCl2in the mixture was found to increase the acid lipase activity ((1.11 ± 0.15) U/g dry matter). This could be due to the lower inhibitory effect MgCl2on acid lipase compared to NaCl and KCl [39].The highest mean values for phospholipase activity were detected in samples salted with NaCl/KCl/CaCl2/MgCl2and NaCl/KCl,respectively. Considering these results, the highest mean values of acid lipase and phospholipase were detected in samples salted with NaCl/KCl/CaCl2/MgCl2. In a study by Zhang et al. [12], use of KCl in the salting mixtures of dry-cured loins revealed similar results for acid lipase, phospholipase, and neutral lipase, as in this study. However,Ripolles et al. [39] detected no significant variation among lipolytic enzyme activities of dry-cured hams salted with different chloride salts at the end of an eleven-month production period.

3.6 TBARS and free fatty acids

TBARS values of pastırma samples (μmol MDA/kg) salted with different salt mixtures are presented in Table 3. No differences(P> 0.05) were observed among the samples salted with different chloride salts with respect to TBARS values. Similar results forTBARS values obtained in dry-cured ham [39] salted with different chloride salts are in agreement with our findings. However, use of KCl withL-histidine andL-lysine in salting was found to decrease the TBARS values of dry-cured loins [12].

Table 4 The overall effects of different chloride salts on moisture (%), Na+, K+, Ca2+, Mg2+, and Fe2+contents (mg/kg dry matter) of pastırma samples.

Table 5 The overall effects of different chloride salts on NPN-M, free fatty acids (g oleic acid/100 g fat), proteolytic (× 10-3 U/g dry-matter) and lipolytic (U/g dry-matter)enzyme activities of pastırma samples.

The different salt mixtures treatment was found to have a statistically significant (P< 0.05) effect on the amount of free fatty acid content of pastırma samples (Table 5). According to these results,the highest free fatty acid amount was detected in samples salted with 100% NaCl. On the other hand, the lowest amount was determined in 50% NaCl + 50% KCl treatment. These results are in agreement with Ripolles et al.[39] who detected significant effect of different chloride salts on the amount of free fatty acids of dry-cured hams. In contrast to these findings, some studies revealed no statistically significant effects of different chloride salts on the amount of free fatty acids [36,37].

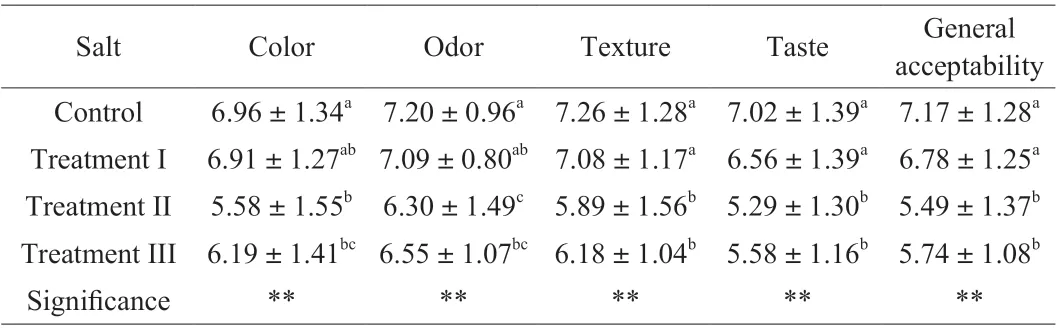

3.7 Sensory evaluation

Different salt mixtures had very significant (P< 0.01) effects on all sensory parameters (Table 6). Considering the results, the highest scores were detected in samples treated with 100% NaCl and 50%NaCl + 50% KCl for each parameter. Use of KCl alone did not alter the sensory scores negatively. In contrast, the lowest scores were found in samples salted with mixtures containing divalent salts.On the other hand, the addition of MgCl2into the salting mixture improved all sensory parameters compared to the mixture containing only CaCl2as a divalent salt. Our results were found to be consistent with the literature findings on dry-cured hams [36,38]. Besides, the use of KCl in the salting mixture was stated to provide desirable results in sensory features [15]. However, in a study on dry-cured lacon [32], the addition of CaCl2and MgCl2into the curing mixture didn’t alter the color and odor parameters.

Table 6 The overall effect of different chloride salts on sensory properties of pastırma samples.

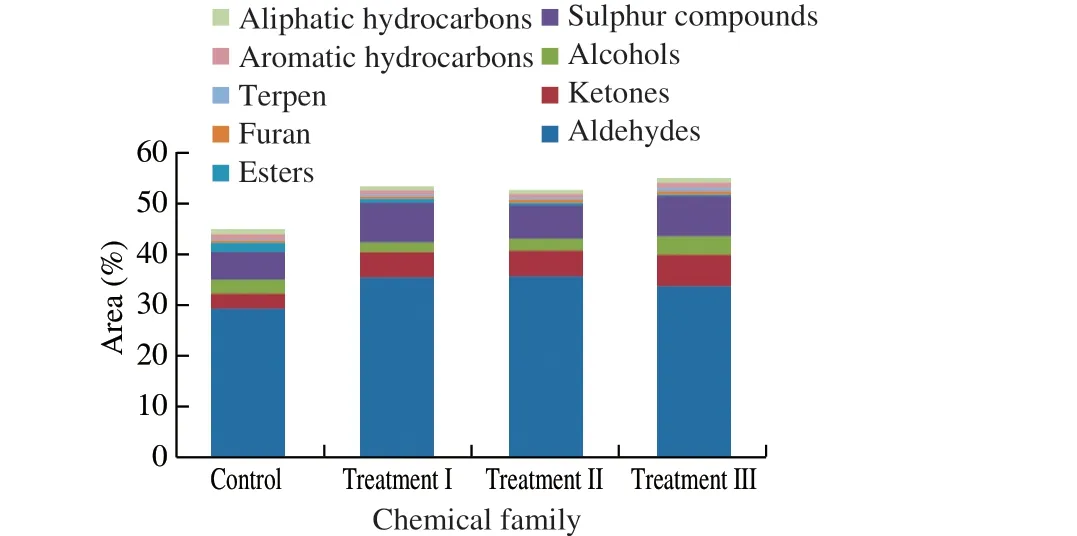

3.8 Volatile compounds

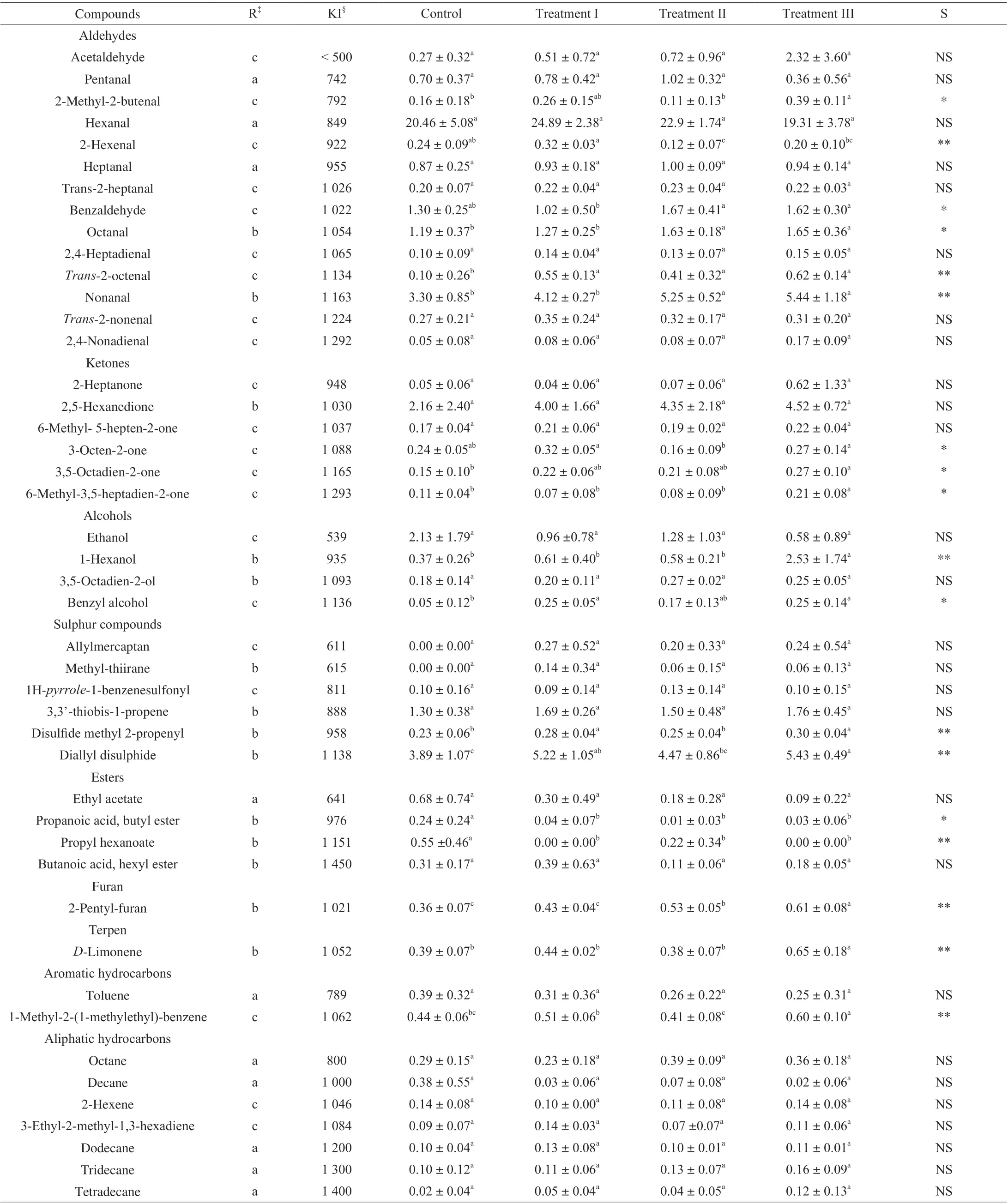

Forty-five volatile compounds belonging to nine chemical groups were identified (Table 7). The highest measured total volatile compound family was aldehydes as also found in dry-cured hams [14].On the other hand, the replacement of NaCl with other chloride salts increased the total amount of volatile compounds in each replacement(Fig. 2). Similar results were detected in dry-curedbicepsfemoriscured with KCl and/or KCl + CaCl2[40].

The use of different chloride salts had very significant effects on 2-hexenal,trans-2-octenal, and nonanal (P< 0.01) and significant effects on 2-methyl-2-butenal, benzaldehyde, and octanal (P< 0.05)(Table 7). The highest mean value of 2-hexenal was determined in samples treated with NaCl/KCl. The lowest trans-2-octenal content was detected in the control group. The most intensive nonanal content was determined in treatment III as 5.44 ± 1.18. Parallel to our findings, the highest nonanal content in dry-cured hams was detected by Armenteros et al. [14] in a 55% NaCl + 25% KCl + 15% CaCl2+5% MgCl2salt treatment. The highest mean values for 2-methyl-2-butenal and octanal in pastırma samples were obtained with the NaCl/KCl/CaCl2/MgCl2mixture. The changes in the NaCl ratio in salt formulation with KCl revealed a higher octanal value in Jinhua ham [41].The highest benzaldehyde peak was detected with the NaCl/KCl/CaCl2treatment. These results obtained for benzaldehyde are in agreement with Armenteros et al. [14] and Nachtigall et al. [40] who found divalent salt’s effect on benzaldehyde level.

Fig. 2 Total chromatographic areas of the volatile compounds measured in each treatment.

Within 6 ketone compounds, only 3-octen-2-one, 3,5-octadien-2-one and 6-methyl-3,5-heptadien-2-one were significantly affected by different chloride salts (P< 0.05) (Table 7). These compounds in the ketone group were not detected in other dry-cured meat products salted with other chloride salts [40-42]. The highest mean 3-octen-2-one value was determined in samples salted with NaCl/KCl. On the other hand, 3,5-octadien-2-one and 6-methyl-3,5-heptadien-2-one were most abundant in samples salted with the mixture containing MgCl2.

Different chloride salts were found to have significant effects on benzyl alcohol (P< 0.05) and very significant effects on 1-hexanol(P< 0.01) (Table 7). The highest mean value for 1-hexanol was detected in samples treated with NaCl/KCl/CaCl2/MgCl2. However,benzyl alcohol was found in almost equal amounts in the NaCl/KCl/CaCl2/MgCl2and NaCl/KCl treatments. Similarly, use of mono and divalent NaCl substitutes significantly affected the 1-hexanol values in dry-cured meat products [42,14] and this compound was previously detected in the second drying stage and in the final product of pastırma [28]. In contrast, these compounds weren’t detected in Jinhua ham [41] and dry-cured biceps femoris [40].

For sulphur compounds, only methyl 2-propenyl disulfide and diallyl disulphide were very significantly affected by different chloride salts (P< 0.01) (Table 7). The highest peaks for methyl 2-propenyl disulfide and diallyl disulphide were detected in the samples treated with NaCl/KCl/CaCl2/MgCl2. Diallyl disulphide is known as the characteristic garlic odor and probably originated from the garlic used in the çemen mixture [28] in traditionally produced pastırma samples just after çemen coating. In contrast, these sulphur compounds weren’t detected in other dry-cured meat products salted with different chloride salts [14,40-42].

Table 7 The overall effects of different chloride salts on volatile profile of pastırma (mean chromatographic area ± standard deviation).

Propanoic acid, butyl ester, and propyl hexanoate were significantly affected by different chloride salts at the levels ofP< 0.05 andP< 0.01, respectively (Table 7). Use of NaCl substitutes decreased the chromatographic area of these compounds. These compounds were not detected in other dry-cured meat products produced with KCl/CaCl2/MgCl2[40-42].

2-Pentyl-furan, an oxidation product of linoleic acid [40], was detected in samples as a unique furan compound, presented in Table 7.Different chloride salts had very significant effect on this compound(P< 0.01). Decrease in NaCl levels caused an increase in the amount of 2-pentyl-furan, and the highest peaks were observed in treatment III and II, respectively. These results were also observed in dry-cured meat samples salted with CaCl2and MgCl2[40].

Only one terpen (D-limonene) compound was detected in the samples and significantly (P< 0.01) affected by MgCl2(Table 7).Similarly, Zhang et al. [41] found no alteration in the percentage ofD-limonene when KCl used. For aromatic hydrocarbons (Table 7),1-methyl-2-(1-methylethyl)-benzene was very significantly affected by the salting procedure (P< 0.01). The highest peak for this compound was determined in treatment III. However, 1-methyl-2-(1-methylethyl)-benzene wasn’t detected in other products [14,42,40].The aliphatic hydrocarbons (Table 7) that were identified in the samples weren’t affected by different chloride salts (P> 0.05).

4. Conclusion

The consumption of dry-cured meat products that contain high levels of sodium is a major concern for individuals that suffer from cardiovascular diseases. Considering the results, It has been determined that the addition of different chloride salts to the curing mixture had significant effects on the physicochemical, biochemical,and sensory properties with volatile profile of pastırma. Since many volatile chemical compounds found in dry-cured meat products have low odor threshold values, any change in the curing mix should be investigated in terms of volatile profile. On the other hand, the replacement of NaCl with KCl at the level of 50% was found not to cause a significant alteration in the product, especially for the sensory and volatile profile. However, the use of CaCl2and MgCl2in the formulation resulted in lower sensory scores. Besides, considering the results obtained from the groups salted with CaCl2and MgCl2in this study; as a suggestion, the future works that will be on low sodium dry-cured meat products should be carried out by investigating the evolution of the volatile and sensory profile of the product.

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgment

This study has been supported by Scientific Research Projects Council of Atatürk University (BAP 2012/251). The authors of the paper are grateful to Prof. Dr. Fidel Toldrá Vilardell for his valuable contribution to enzyme analysis.

- 食品科学与人类健康(英文)的其它文章

- Wine, beer and Chinese Baijiu in relation to cardiovascular health:the impact of moderate drinking

- Comparative analysis of physicochemical properties, ginsenosides content and α-amylase inhibitory effects in white ginseng and red ginsen

- Monitoring and identif ication of spoilage-related microorganisms in braised chicken with modif ied atmosphere packaging during refrigerated storage

- Effect of cooking processes on tilapia aroma and potential umami perception

- Formation mechanisms of ethyl acetate and organic acids in Kluyveromyces marxianus L1-1 in Chinese acid rice soup

- Volatile prof ile and multivariant analysis of Sanhuang chicken breast in combination with Chinese 5-spice blend and garam masala