Environment Adaptability Evaluation for Buffering Airbag of Heavy Equipment During Airdrop Landing

WANG Hong-yan(王红岩),HONG Huang-jie(洪煌杰),LI Jian-yang(李建阳),RUI Qiang(芮强),HAO Gui-xiang(郝贵祥)

(Academy of Armored Force Engineering,Beijing 100072,China)

Introduction

The buffering airbag system is one of the important technologies to reduce the heavy equipment airdrop landing impact.Compared with other landing buffer technologies,such as honeycomb material[1]and retro[2],the airbag system is simple,convenient,efficient and cheap.The airbag can absorb the most of landing impact energy,reduce the impact force and subsequently protect the instrument carried by the heavy equipment.

Currently,the thermodynamic method,finite element method and experiment method are usually used to study the airbag.Based on thermodynamic theory,the thermodynamic method can simplify the airbag's compression process and establish a corresponding theoretical model to obtain the parameter variation[3-4].It is simple,but can not accurately calculate the airbag deformation.The finite element method is based on thermodynamic theory also.However,large deformation,different contact conditions,gas compressibility and gas discharge are all considered in finite element model.It can accurately model the impact behavior,but is usually complex and requires tens of hours of CPU time.The important advantage of the experiment method is its credible results.Therefore,it is usually used to check up validity of results.However,the airdrop experiments for heavy equipment are very expensive.The safety and time consumption are two unforgivable factors for airdrop experiments.In addition,the experiment conditions are always changeful and hard to be controlled.

In our country,engineers and users generally assess the airbag system from the tactical and technical indexes.There are few of studies on its environment adaptability evaluation.In this paper,by using finite element method,the landing buffer process under highaltitude condition is taken as an example to study the environment adaptability of airbag system of heavy equipment,and some solutions to solve the overturn problem are put forward also.

1 Thermodynamic Equations of Airbag

In the modeling for airbag,following assumptions are considered[5].

1)The aerodynamic resistance is infinitesimal and negligible in landing process of heavy equipment.

2)The air leakage of the airbag is ignored,and the air in the airbag is exhausted only through airvents.

3)The pressure in airbags is uniform.

4)Perfect gas law and adiabatic condition are valid for gas in airbags during landing process,because of the short impact duration and limited heat exchange with surrounding atmosphere.

The energy inside airbag meets the energy balance equation

whereEais the energy inside airbag,pthe gas pressure in airbag,Vthe gas volume,Hinthe input enthalpy,Houtis the output enthalpy.

The gas inside airbag meets the perfect gas state equation

wherenis the amount of gas in airbag,Rthe gas constant,Tthe gas temperature.

The gas exhaust velocity of airbag can be expressed as

whereuis the gas exhaust velocity of airbag;γ=cp/cvthe ratio of specific heat,for example,γ=1.4 for air,cpthe specific heat capacity under constant pressure,cvthe specific heat capacity under constant volume.

Based on the perfect gas equation,for the compressed airbag,the pressure in airbag can be written as

wherepais the pressure inside the compressed airbag,P0the initial pressure,V0the initial volume of airbag,Vathe volume of the compressed airbag,m0the initial mass of gas,methe mass of the exhausted gas.

2 Modeling and Verification

2.1 Contact Model for Equipment,Airbag and Ground

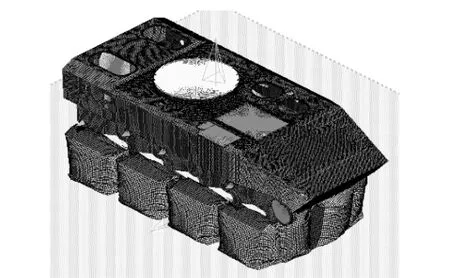

The heavy equipment model consists of armor plates,turret housing washer,engine room,vertical shafts,abutments and reinforcement ribs[6].The turret housing washer and abutments are modeled with Hex8 element,while other parts are modeled with Quad4 element.

The airbag system consists of eight independent and identical airbags.They are connected to the bottom of heavy equipment.Each airbag have a main bag and an assistant bag.The assistant bag intercommunicates with the main bag through air vents.The air intakes are located in the bottom of the main bag in order to implement air inflation when the heavy equipment falls.When the bottoms of airbags contact the ground,the air intakes close.Vent holes are located in the sides of airbags for the air exhaust[7].

Since the wall of airbag is very thin,the shell element can be used in its FE model.In the landing process,the airbags may be compressed and deformed greatly,and they will contact with each other.Therefore,it is very important to describe the contacts of airbags between each other.Here,the penalty method[8]is adopted to solve the self-contact of airbag.Each side of airbag is either the slave surface or the master surface.For each time step,it should be checked whether the slave nodes penetrate the master surfaces or not first.If the slave nodes do not penetrate the master surface,no treatment is required.Otherwise,a normal contact force is introduced between the slave node and master surface.It can be considered as a normal spring between the slave node and the master surface.Thus,the force is direct proportional to the penetration l and the master surface stiffnesski,i.e.,

wherefnis the normal contact force between the slave and master nodes,nithe normal unit vector in contact point of main surfaceSi.

The top of airbag system is fixed with the bottom armor plate.There is no slip between these two parts.The contact between the top of airbag system and the bottom armor plate can be described by a tied contact model.The bottom armor plate is defined as a master surface,while the top of airbag system is defined as slave surface.With a tied contact model,it is possible to connect rigidly the slave surface nodes with a master surface.This kinetic constraint is applied on all slave nodes.They remain at the same position on their master surfaces.The acceleration and velocity of each master node are calculated from the force and mass applied by the slave nodes.

Similarly,the FE model of interaction between airbag and ground is established by using the penalty method.The ground is modeled as an infinite plane.The contact between airbag and ground is described by the similar equation and solved by the same method.The FE model of equipment,airbag system and ground is shown in Fig.1.

Fig.1 FE model for equipment,airbag and ground

2.2 Simulation for Landing Process

The landing simulation conditions are the initial vertical velocity of 7.0 m/s,initial horizontal velocity of 0 m/s,and the flat ground.The landing process lasts about 300 ms as shown in the simulation.It can be obtained that the maximum acceleration is 7.18gand less than the safe acceleration of 20g.The equipment lands without bounce and overturn.

The stress distributions of equipment and airbag system are shown in Fig.2.The stress of armor plate is in a low level(0 ~30 MPa)during landing process,while the vertical shafts,reinforcement ribs,abutments of engine and gear box are the locations with larger stress.As shown in Fig.3,the maximum Von Mises stress locates on the bottom of right vertical shaft,with a value of 151.30 MPa.

Fig.2 Stress distribution of equipment and airbags

Fig.3 Location with maximum Von Mises stress

2.3 Comparison of Simulation and Test Results

As mentioned above,the FE models of heavy equipment and airbag system are established on the basis of some assumptions,which may lead to unexpected errors.Thus,the models should be validated by experiments.

The experiment conditions are the same as the simulation conditions.Four acceleration test points distribute on the engine,top,bottom and side armor plates.The experiments are thoroughly discussed in Ref.[9].The accuracy of the model is validated by the comparison of acceleration results,as shown in Fig.4.

In Fig.4,the simulation and experiment results coincide with each other better.The maximum acceleration errors in 4 test points are 8.1%,8.4%,2.9%and 12.8%,respectively.Thus,the established mod-el can be used for further research.

Fig.4 Accelerations in different positions

3 Adaptability Evaluation for Highaltitude Airdrop

In high-altitude area,the air density and atmospheric pressure are quite different from the standard atmosphere.Airbag takes the air as the working substance,and its characteristics change in a wide range.Meanwhile,the deceleration performance of the parachute is largely affected by the air density and pressure.Therefore,the landing velocity of equipment under high-altitude condition is higher than that under the standard atmosphere condition.

Seeing from the information provided by the equipment test department,the landing stability is not so good in the high-altitude airdrop.The buffering effect is poor,the impact force is large,and the overturn occurs in about 10%of the airdrop.In the case of overturn,there are no obvious abnormalities in the initial stages,parachute can open normally,and the attitude of equipment is normal in the air,but the equipment capsizes during landing.Therefore,it is necessary to analyze the landing buffer process based on the finite element model.

3.1 Vertical Landing Buffer Process Analysis under High-altitude Condition

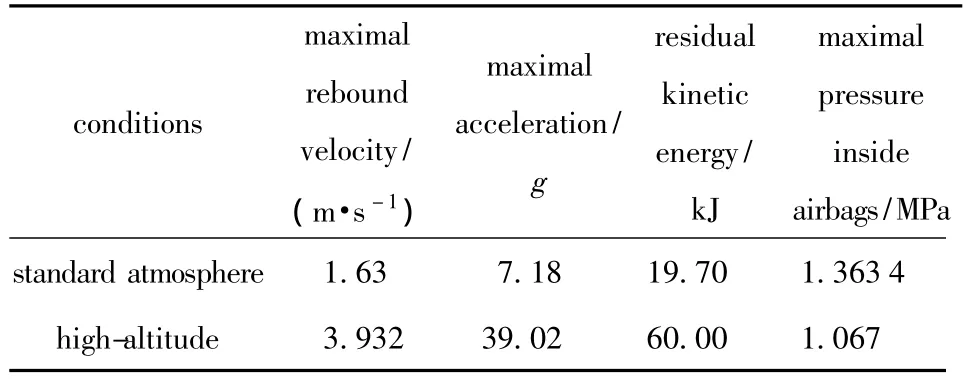

Considering the air pressure of 57 715 Pa and the air density of 0.77695 kg/m3under high-altitude area,the steady drop velocity of the equipment with parachute system is 8.92 m/s[10]Because the air is inflated into airbags through the intakes in the bottom when the heavy equipment falls down,the air pressure and density inside airbag are the same as the outside air pressure,i.e.57 715 Pa and 0.776 95 kg/m3,respectively.Then,based on the finite element model,the velocity,acceleration,energy absorbed by airbags,pressure can be obtained and compared with the results under standard atmosphere condition,as shown in Fig.5 and Tab.1.

Tab.1 Comparison of buffer characteristics in different conditions

The results show that the characteristic of airbag under high-altitude condition is evidently different from that in standard atmosphere.For example,the air pressure and density at an elevation of 4 500 m are 63.4%and 57.0%of those in standard atmosphere condition.The buffer performances of parachute and airbag sys-tems worsen greatly.They can not accomplish their objects.As a result,the residual kinetic energy of the equipment increases,and the impact load becomes larger.A notable rebound appears,but there is not overturn in such case.

Fig.5 Buffer characteristics of airbag

3.2 Analysis for Landing Buffer Process with Lateral Inclination in High-altitude Condition

The actual airdrop landing is not absolutely vertical.That is,the bottom of the airbag system has an uncertain inclination angle with the ground,and it obeys some statistical law.Ref.[10]considers that the inclination angle obeys the normal distribution ofN(0.053 46,3.020 12)when the equipment lands on the ground.

In order to explore the reason of overturn,the landing process with lateral inclination should be taken into account.As the inclination angle is a statistical quantity,a representative inclination angle must be chosen as the analysis condition.It can be deduced from the normal distribution and half of overturn probability 10% that the upper and lower boundaries are 5.02°and - 4.91°,respectively.In addition,the center of gravity is very close to the centerline in the width direction.Thus,5°can be chosen as the inclination angle in the simulation.

The FE model above is calculated by the steady drop velocity of 8.92 m/s and the inclination angle of 5°,as shown in Fig.6.

Fig.6 Overturn in high-altitude airdrop

The simulation results show that the equipment re-bounds after the end of airbag buffer process,and rollover occurs because of overturn moment,as shown in Fig.6.However,there is not the overturn under the standard atmosphere condition with the inclination because the acceleration and overturn moment are smaller.Therefore,it is found out that the overturn under high-altitude condition results from poor performances of parachute system and airbag system,which are affected by the atmospheric conditions,such as air pressure and density.The rebound appears obviously under high-altitude condition.Also,the landing process under high-altitude condition is sensitive to the variation of the inclination angle,and it leads to large overturn moment.Thus,the equipment capsizes during landing.

3.3 Solutions

Based on the reason of overturn analyzed above,following solutions can be considered.

1)Increase the number of parachute or choose larger canopy to increase the total resistance,thereby reduce the steady drop and landing velocities.This method can reduce the impact,the acceleration of equipment,and avoid overturn.

2)Select a relatively flat landing site and a smaller wind speed weather conditions to reduce the variable range of the inclination angle,thereby reduce the probability of large inclination angle,and thus reduce the possibility of overturn.

The second solution can be understood easily,but it can not resolve the problem drastically.Then,the first solution will be discussed further.Through simulations of vertical landing process under high-altitude condition,it can be confirmed that the maximum acceleration of equipment is approximately 20gwhen the steady drop velocity is 6.7 m/s,as shown in Fig.7.It meets the design and application requirements of equipment.

Furthermore,for the inclination angle of 5°and the steady drop velocity of 6.7 m/s,the simulation results show that the equipment keeps steady state,the residual kinetic energy is small,and the acceleration is within the permissible range,as shown in Fig.8.Thus,it is suggested to increase the number of parachutes or choose larger canopy to keep the steady drop velocity less than 6.7 m/s to avoid overturn.

Fig.7 Simulation results for high-altitude airdrop of 6.7 m/s in drop velocity

Fig.8 Simulation results for high-altitude airdrop of 6.7 m/s in drop velocity and 5°in attitude angle

4 Conclusions

1)The model of heavy equipment with buffer airbag system is established by using nonlinear finite element method in this paper.The virtual landing process is obtained through simulation.The established model is validated by using on-site landing experiments.The simulation results coincide with the experiment results better.

2)The high-altitude condition is remarkably different from the standard atmosphere in air density and pressure,etc.These differences should be fully considered in the buffer design and application.

3)The simulations of landing process under highaltitude condition show that it is feasible and effective to study the environment adaptability of airbag system by using finite element method.It can reduce the costs and improve the efficiency.Its accuracy can be accepted.

[1]Taylor Anthony P.Investigation of the application of airbag technology to provide a softlanding capability for military heavy airdrop[C]∥AIAA 2001-2046,2001:284-292.

[2]Ewing D G,Bixby H W,Knacke T W.Recovery system design guide[M].Beijing:Aviation Industry Press,1988.

[3]WANG Ya-wei,YANG Chun-xin,Peng K E.Airbag cushion process simulation for cargo airdrop system[J].Journal of System Simulation,2007,19(14):3176 -3179.(in Chinese)

[4]SUN Xiao-wei.Common method of design calculation for airbags[J].China Aeronautical& Astronautical Lifesupport,2005,(4):29 -31.(in Chinese)

[5]WANG Hong-yan,HAO Gui-xiang.Research on matching and evaluating for recovery system of heavy equipment based on FEM[C]∥Proceedings of the 7th China CAE Annual Conference,Kunming:2011:120 - 127.(in Chinese)

[6]LI Jian-yang,WANG Hong-yan,HAO Gui-xiang.Simulation of landing process base on explicit Finite Element Method[J].Journal of Academy of Armored Force Engineering,2010,24(3):25-28.(in Chinese)

[7]NIU Shi-bo,WANG Hong-yan,CHI Bao-shan.Optimal design of airbag Curshion process for airdropping equipment[J].Journal of Academy of Armored Force Engineering,2010,24(5):36-40.(in Chinese)

[8]WANG Xu-cheng.Finite element method[M].Beijing:Tsinghua University Press,2003.(in Chinese)

[9]DU Zhi-qi,SHAO Peng-li.Dynamic finite element simulation of the aluminum alloy hull at landing[J].Acta Armamentarii,2009,30(1):1-4.(in Chinese)

[10]HAO Gui-xiang.Research on impact responses of airborne tracked equipment and parameter optimization for airbag system[D].Beijing:Academy of Armored Forces Engineering,2011.(in Chinese)

- Defence Technology的其它文章

- Velocity Correction and Measurement Uncertainty Analysis of Light Screen Velocity Measuring Method

- Research on Hybrid Power System with Dual Stator-winding and Its Decoupled Control Strategy

- Computational and Experimental Investigation on Aerodynamic Characteristics of Terminally Sensitive Projectile with S-C Shaped Fins

- Research on Top-layer Planning and Overall Design Project Decision of Weapon System Based on Analytic Hierarchy Process

- Research on Matching Relationship Between Number of Initiation Points and Charge Diameter

- Experimental Investigation on the Ballistic Resistace of Metal Plates Subjected to Impact of Rigid Projectiles