Recent Development and Emerged Technologies of High-Tc Superconducting Coated Conductors

CAI Chuan-bing, MEBROUKA Boubeche, SHU Gang-qiang,LU Yu-ming, LIU Zhi-yong,BAI Chuan-yi, FAN Feng, GUO Yan-qun, LU Qi

(Shanghai Key Laboratory for High Temperature Superconductors,Research Centre for Superconductors and Applied Technologies,Physics Department,Shanghai University,Shanghai 200444,China)

Introduction

Secondary generation(2G)high temperature superconductors(HTS),or named REBa2Cu3O7-δ(YBCO,RE=Y,Nd and Sm etc.rare earths)coated conductors,are expected to be practical application superconductors at liquid-nitrogen temperature due to their high performance and potential low cost of both raw materials and preparation techniques.For power and energy applications,the basic requirement is to realise YBCO films being biaxially textured on flexible substrates to overcome the weak link between grain boundaries as shown in Figure 1(a).

In the past decade,people have tested a variety of thin film techniques to realize the biaxailly textured YBCO epitaxially grown on flexible metallic tapes.Two continuous techniques have been developed as the basis routes to produce biaxial textured superconducting films,including Ion Beam Assisted Deposition(IBAD)[1-2]and Rolling Assisted Biaxially Textured Substrate(RABiTS)[3-4].Compared with IBAD technique,the RABiTS approach is more attractive due to the availability of long textured substrates,the feasibility of controlled buffer growth and the potential for cost-effective processing such as chemical solution deposition(CSD)or metal organic deposition(MOD)for all functional layers[5-6].

Typically the coated conductors include three layers:metallic substrate,buffer layers and YBCO superconductor films as shown in Figure 1(b).The buffer layers on metallic substrate(typically Ni-W alloys)for coated conductors based on the RABiTS technique have two main functions:(i)preventing Ni or O atoms diffusion during the YBCO processing at high temperature;(ii)transferring the texture from substrate to superconducting layer.Different oxide materials have been successfully used as buffer layers to fulfil these requirements.

Figure 1 (a)Biaxially texture grains required by coated conductors;(b)Typical architectures for YBCO coated conductors

By now,the popular buffer architectures used in coated conductor based on the RABiTS approach are multibuffer layer architectures such as CeO2/YSZ/Y2O3[7-8],in which Y2O3acts as the seed layer,YSZ as the chemical barrier layer preventing atoms diffusion,and CeO2as the cap layer supporting lattice match between YSZ and YBCO.Due to high cost and complex process for such multi-layer architectures,finding more effective buffer materials to simplify the architecture is becoming more attractive for RABiTS-based coated conductors.

1 Progress in the Worldwide Development of Coated Conductor

At present,a number of alternative modified combinations are being developed in the world and each of them has actually some advantages and some drawbacks.Nevertheless,a great progress has been made worldwide in enhancing the length and performances of coated conductors as shown in Table 1 and Figure 2,where it is demonstrated that the industrial leadership has been reached based on different compositions,architectures as well as the deposition techniques,such as MOD,MOCVD,PLD etc at AMSC,Superpower of USA,and ISTEC,Fujikura and SWCC of Japan.More recently,a particular outstanding development is that so-called Reactive coevaporation exhibit very promising by deposition and reaction(RCE-DR)approach at SuNAm of Korea,where very fast conversion rates are achieved when an amorphous to crystalline transition is induced by a change in oxygen pressure.

Table 1 Coated Conductor Development in Worldwide Leading Groups*

Figure 2 Progress in the development of long length manufacturing of coated conductors.The best values of the product the critical current at 77K(Ic)and total conductor lengths(L)(Sources as above in Table 1).

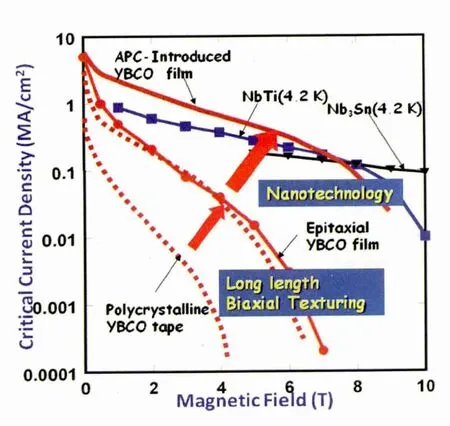

Figure 3 Artificial nanotechnology to enhance the flux pinning,and then to improve the magnetic field dependence of the critical current density Jc(H).

The development of coated conductors has attracted a wide interest because they suggested new opportunities to develop practical power applications at high magnetic fields and liquid nitrogen temperatures. Furtherenhancementof critical current capacities in the magnetic fields requires the high-density flux pinning centres in the coated conductors,such as a nanocomposite structure where nonsuperconducting nanoparticles or nanorods efficiently pinned vortices at high temperatures(as shown in Fiugure 3). The strategy to follow for nanocomposite coated conductors are subject to the growth techniques applied.It has frequently reported that the in-situ growth techniquessuch asPLD and MOCVD,depend on the simultaneous nucleation and growth of the two phases coexisting in the nanocopmosite,where the secondary phase remain mostly an epitaxial relationship with YBCO matrix and self-assembly mechanism determining the final nanostructures and the associated strain.In the case of the ex-situ growth techniques such as MOD and RCE-DR,however,different nucleation processes,imply that the resultant structure of the nanocomposite differs,mostly exhibiting a large amount of the nanoparticles is randomly oriented and thus the incoherent interfaces lead to a high density of intergrowths in the YBCO matrix.Nevertheless,two cases are frequently reported to enhance the field dependence of the critical current density of YBCO coated conductors.

From the information above,one may wonder what the present status for Chinese scientist achievement in the fields of coated conductors.In reality,Chinese researchers have noticed this field since the first proposal developing biaxially textured YBCO on metallic tapes in 1990’s.In the past decade,the Ministry of Science and Technology of the People’s Republic of China,has organized a couple of programms to develop the emerged superconducting materials,evidenced by the several coated conductor research programs listed in national plans such as 973 and 863 projects.Up to now,significant progresses have been achieved not only for the fundamental researches but also for the industrial-scale manufactures.

2 Research Institutions and Emerged Technologies Development in China

In China,early researches on coated conductor may trace to 1990’s at the Institute of Physics and Shanghai Institute of Metallurgy,Chinese Academy of Sciences,although they both shifted to other new superconducting materials now.

Recently,there exist several active groups working on both RABiTS and IBAD routes,such as University of Electronic Science and Technology of China,Shanghai Jiao Tong University,Shanghai University,Beijing University of Technology,Beijing General Research Institute for Nonferrous Metals,and so on[9-12,18-28].

They prepared the coated conductors for both buffer layers and superconducting layers by using physical vapor deposition techniques either of sputtering or of pulse laser deposition(PLD),as well as using the metallorganic chemical vapor or solution depositions(MOCVD,MOD).Some of them have established the reel-to-reel tools for scaling up of long tapes as summarized in Table 2 below.

Table 2 Main research groups and their technology routes for coated conductors[9-12,18-28]

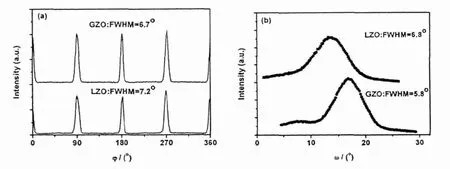

To seek for novel effective buffer layers,Shanghai University and Southwest Jiaotong University have shown that several oxides with pyrochlore structure such as La2Zr2O7(LZO),Ce2Y2O7(CYO),LaMnO3(LMO),SmBiO3(SMO),and Gd2Zr2O7(GZO)were applicable as single buffer layer by pulsed laser deposition(PLD)or by magnetism sputtering(MS)[9-13].Among those,GZO and CYO are demonstrated as good potentials for simplified buffer layer material whose lattice parameters match well with both YBCO and Ni(see Figure 4,and Figure 5).

Figure 4 XRD(111)φ-scan(a)and(002)ψ-scan(b)for 115nm thick CYO films deposited by Sputtering at an optimized water vapor partial pressure of 2.5 × 10-2Pa.The inset shows the corresponding XRD(111)pole figure[12].

Figure 5 In-plane and out-of-plane FWHM values determined from CYO(111)and YBCO(103)φ-scans as well as CYO(002)and YBCO(005)ψ-scans[12].

Biaxially textured Ce2Y2O7(CYO)films were deposited on Ni-5at.%W(Ni-5W)tapes by a DC reactive sputtering technique in a reel-to-reel system.SubsequentYBa2Cu3O7-δ(YBCO)filmswere prepared using pulsed laser deposition leading to a simplified coated conductor architecture of YBCO/CYO/Ni-5W. X-ray diffraction measurements revealed an epitaxial growth of the CYO buffer layer with a texture spread down to 2.2°and 4.7°for the out-of-plane and in-plane alignment,respectively.Microstructural investigations showed a dense,smooth and crack-free surface morphology for CYO film up to athicknessof350 nm,implying an effective suppression of cracks due to the incorporation of Y in CeO2.The superconducting transitions temperature Tc of about 90 K with a narrow transition width of 0.8 K and the inductively measured critical current density Jc of about 0.7MA/cm2indicate the potential of the single CYO buffer layer.In Japan,GZO is also used as a buffer layer in the IBAD approach for coated conductors[14-15].Furthermore,GZO films combined with Y2O3building GZO/Y2O3simplified buffer architecture were also investigated by CSD[16]or electrodeposition(ED)[17]on Ni-W RABiTS tapes.

Recently,Shanghai University has developed the electrodeposition method for buffer layer of coated conductor as a cost-effective and scale-up processing technology[18].As shown in Figure 6 and Figure 7,the RE4-XZrXO7and RExOyfilms on Ni-5W tapes can reach a good biaxial texture of in-plane FWHM of 5.4-7.2°and their smooth,flat and crack-free surfaces allow the subsequent YBCO epitaxial growth available and effective,suggesting the present electrodeposition is a promising technique for coated conductor industrialization.

式中:0和c分别代表基态和故障状态;C表示预想故障集合;x和u分别表示由状态变量和控制变量构成的向量;指故障c发生后控制变量调节范围的最大值。

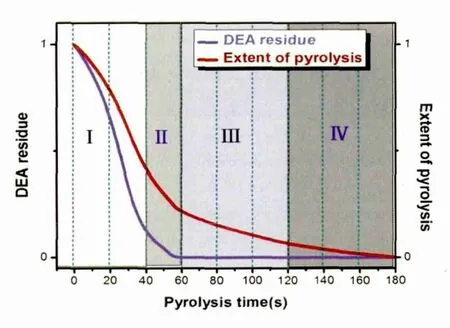

It is well known that TFA-MOD process is very promising for the industrial scaling up for YBCO coated conductors due to low cost.However,the thermal decomposition for conventional TFA-MOD is over than 10h,which is a disadvantage for industrialization.Thus,it is a significant issue to reduce the time for both pyrolysis and crystallization.In the past years,a number of groups have made effort on reducing the pyrolysis time by using low fluorine,additions and modified the solution with trifluoroacetate anhydrid.Several groups have reduced the pyrolysis time to 100min by using low fluorine content in precursor solution.On the other hand,TFA-MOD can be modified by additions such as DE,PEG,and so on,to reduce the pyrolysis time,of which,DEA appears very effective because of its high boiling-point(268℃)which helps stress-relief and suppresses cooper sublimation.With the addition of DEA in TFA-MOD precursor solution,the pyrolysis time can be reduced as short as 20s.However,there are no detailed information regarding DEA-modified pyrolysis process and relevant reaction residuals.

Figure 6 XRD-Phi scan(a)and omeg scacn(b)for(222)GZO and(222)LZO,giving the in-plane,and out-plance textures,repectively.

Figure 7 (a)XRD patterns of CeO2annealed at different temperatures;(b)The XRD phi scan and pole figure for typical ED-CeO2film on biaxially-textured Ni-W tapes[18]

In Shanghai University,a series of precursor films quenched at different pyrolysis time are investigated with respect to the morphology and residual particles,giving more understanding of both pyrolysis and crystallization for MOD-YBCO films which are observed by Metalloscope,SEM,FTIR,XRD,revealing that a pyrolysis time as short as 20s is applicable[19].It appears necessary to keep the proper amount of DEA,which may prevent the films from severe stress,and then give smooth surface.According to the clusters of C=O(amide),C-O(ester)are generated in the esterification reaction between DEA and TFA acid radical,and the residual particles of C16HNO3,BaYF or Ba2CuO3are present based on XRD measurement,both of which give the evidences of the evaporation of DEA and the pyrolysis occurs simultaneously.Longer pyrolysis time than 50s would lead the cracks and the Cu-rich particles appeared without the protection of DEA,in case of excessively short pyrolysis time which shorter than 10s would lead insufficient pyrolysis,and the surface is almost soft(as shown in Figure 8 below).

On the other hand,Shanghai University has developed various low-fluorine solutions consisting of different fluorine content,including the low-Fluorine TFA-MOD(CLF-MOD)with F-content 54%and extreme lowest-Fluorine TFA-MOD(ELF-MOD)with F-content 7%.The production rates of YBCO film have been improved effectively using the Low Fluorine solutions compared with TFA solution as plotted in Figure 9(a).

As a consequent,smooth and dense films are obtained at a pyrolysis rate as high as 25 K/min using ELF solution.By optimizing the crystallization temperature,high-performance YBCO films with smooth surface and better texture can be achieved(see Figure(b)).To combine the electrodeposition technique for buffer layers and extremely low-Fluorine chemical solution for YBCO superconducting layers,one may clearly see a promising costeffective,and high-rate technical routes for industrialization of YBCO coated conductor.After then,the reel-to-reel tools for MOD-YBCO coating have been built up at Shanghai Creative Superconductor Technologies Co.Ltd.(As shown in Figure 10 below)

As well in Tsinghua University,a low fluorineprecursorsolution forMOD YBCO fabrication was developed recently.The fluorine content of this solution was approximately only 10.3% of that used in the conventional TFAMOD solution,corresponding to a starting F=Ba mole ratio of 2:1.ATRFTIR revealed that BaCO3was remarkably suppressed in the as pyrolyzed film and eliminated at 700℃ .Thus,YBCO films with Jc of 5.1MA/cm2(77 K,0 T,200 nm thickness)were obtained on LAO substrates.

Figure 8 Morphology diagram of DEA-modified TFA-MOD pyrolysis[19]

Figure 9 (a)Pyrolyzation time dependence of precursor films on the fluorine content applied in the solutions;(b)Magnetic field dependence of Jc(77K)for YBCO films coated with the solutions of F/Ba=2 in 1.2M and 1.6M[20]

Figure 10 Reel-to-reel pilot for MOD-YBCO coating have been built up at Shanghai Creative Superconductor Technologies Co.Ltd.

In situ FTIR spectra showed that no obvious fluorinated gaseous by products were detected in the pyrolysis step,indicating that all F atoms might remain in the film as fluorides.XRD patterns showed the presence of BaF2(or OF)but not of YF3or CuF2in the films quenched at 400-800℃,which together with Y2Cu2O5,CuO and H2O could react to form YBCO.The formation priority of BaF2over YF3and CuF2was interpreted by examining the chemical equilibrium of the potential reactions. The 10. 3% fluorine content of the precursor solution in this study was lower than thatin all previously reported low fluorine studies.Therefore,our findings could enlarge the synthesis window of precursor solutions for MOD YBCO fabrication.This study could also serve as a foundation for continuously and systematically studying the influence of the fluorine content in the precursor solutions,which may be beneficial for the fabrication of YBCO thick films.

3 Artificial Flux Pinning and Potential Application for coated conductors

As for the envisioned application,high-performance YBCO tapes are required to be operated under different magnetic fields.While Jc value,one of the most important aspects for strong current application,would decrease rapidly along with the increasing magnetic field,resulting in an obstacle for its widely commercial use.The flux pinning theory,which well explains the reduction of Jc value,suggests tailoring the defect structure of the superconductor to maximize Jc[29,30].

As mentioned before,many attempts around the world have been made on improving the field dependence of Jc for YBCO,and they may be classified into three categories:(1)Substrate surface decoration,which can be accomplished by depositing metal or oxide nanoparticles on the substrate before YBCO film growth;(2)Impurity additions,which can be realized by inserting non-superconducting phase into YBCO matrix using a second laser-deposition target or by simply adding the impurity to the YBCO source materials;(3)Rare-earth additionsand/orsubstitutions,which is usually achieved by adding rare-earth elements into YBCO matrix or by replacing yttrium with other rareearth elements(such as Nd,Eu,Gd,Dy,Ho,Sm)using PLD,MOCVD and MOD,etc.[31].

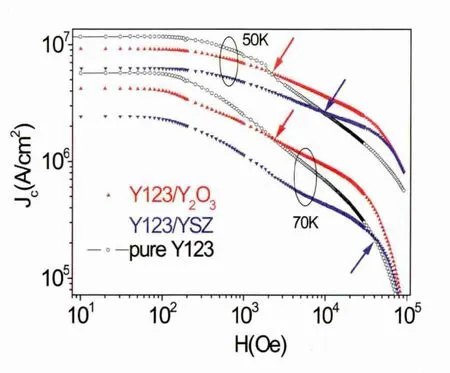

Figure 11 the magnetic field dependence of Jc at 50 and 70 K,respectively for YBCO films doped by Y2O3and YSZ particles

Figure 12 Critical current density versus magnetic field parallel to the c-axis at 77 K for the pure YBCO film and the BaTiO3-doped YBCO film[32]

Considerable efforts in China has also been put on the enhancement of flux pinning in order to maximize the Jc value of YBCO under applied magnet field.Our group has studied the magnetic field dependence of Jc for so-called YBCO/oxide quasi-multilayers,i.e.,YBCO films doped by Y2O3and YSZ particles using target rotation and periodic deposition of YBCO and secondary phases during PLD deposition.Figure 11 below shows the improved Jc in higher fields,exhibiting a crossover behaviours(indicated by arrows)compared with no-doping case.

Researchers in Institute of Electrical Engineering,Chinese Academy of Sciences have successfully fabricated YBCO thin films with self-assembled BaTiO3nanocolumns on(00l)oriented LaAlO3substrate by MOD.Improved Jc values over a wide range of magnetic field in the BaTiO3-YBCO composite films were found,as shown in figure 8.These BaTiO3nanocolumns had no preferential orientation and were distributed randomly in the YBCO matrix[32].According to Institute of Solid State Physics, Chinese Academy of Sciences,Gd doped Y1-xGdxBCO and(Gd,Eu)co-doped Y0.9-yEuyGd0.1BCO were prepared on LaAlO3(00l)substrates by TFA-MOD,and their results revealed that the Jcvalue under magnetic fields was enhanced largely due to(Gd,Eu)codoping[33].

Still some other research groups,such as Southwest Jiaotong University,Beijing University of Technology and Xi’an University of Technology,have demonstrated similar results by Co-doped superconducting YBCO films derived from a newly developed polymer-assisted metal organic deposition method,BaZrO3-Doped Y0.75Gd0.25Ba2Cu3O7-xsuperconducting films prepared with advanced low-fluorine solution,and simply substrate surface decoration with ZrO2, Y0.15Zr0.85O2(YSZ)and CeO2/ZrO2=0.15/0.85(CZO)nanoparticles,respectively[34,35,36].Despite the efforts and advancement,the commercial demands remain unsatisfied with the performance of YBCO film under applied magnet field,implying that there are still some way to go for the domestic researchers and institutions.

At the same time,the potential application of high temperature superconductor is moving forward rapidly in China.A variety of devices,such as the superconducting fault current limiter(SFCL)[37],HTS cable[38,39,40],the superconducting magnetic energy storage(SMES)devices[41,42,43],have been successfully fabricated and put into use.

Figure 13 Application demonstrations in power grid for high temperature superconducting materials in China:(a)Electric cable in Yunan produced by Beijing Innopower;(b)Fault current limiter in Tianjing produced by Beijing Innopower;and(c)Transformer in Gansu produced by Institute of Electric Engineering,Chinese Academy of Sciences

Compared with the large number of devices mentioned above,which are,however,based on the first generation high temperature superconductor of Bi-2223,the practical application of YBCO coated conductor is less thriving,despite the accelerating research and industrialization progress for YBCO coated conductor in China.

Up to now,A 10 MW HTS wind generator with A novel structure of“YBCO+MgB2combined field coil”is under development in Dongfang Electric Corporation(DEC)[44].The Institute of Electrical Engineering Chinese Academy of Science(IEE,CAS)has made a 2-pole 150 W reluctance motor prototype with improved output torque,power density and efficiency by using HTS YBCO bulks as the magnetic resistance medium[45]in 2004.And the people-carrying HTS maglev vehicle with 4 seats and 8 HTS maglev modules each consisting of 43 YBCO bulks in a liquid nitrogen vessel,was manufactured and tested successfully by Southwest Jiaotong University(SWJTU)at the end of 2000[46].

In 2007,University of Electronic Science and Technology of China(UESTC)has developed a 1 kN levitated single-sided HTS linear synchronous motor(HTSLSM)with an YBCO bulk magnet array[47].And for the superconducting magnet applied in the areas of extreme condition of experimental science facility(ExCES),Magnetic Resonance Imaging(MRI)system and High-Q Power Resonator,superconducting materials such as Bi-2223 and NbTi,rather than YBCO coated conductor are used[48,49,50].While a promising prospect for replacing Bi-2223 and NbTi with YBCO coated conductor is expected after the improvements mainly in its mechanical and superconducting properties are achieved.

4 Conclusions

In summary,the international and domestic research institutes and industrialization status for YBCO coated conductor have been presented briefly.For the most institutions working on the preparation of YBCO coated conductor,both IBAD and RABiTS have been used as popular technical routes due to their availability of long textured substrates,the feasibility of controlled buffer growth and the potential for cost-effective processing.At the same time,various thin film coating techniques including sputtering,pulse laser deposition(PLD),metallorganic chemical vapor or solution depositions(MOCVD,MOD)are employed to prepare the coated conductors for both buffer layers and superconducting layers.Particularly,Some emerged technologies for preparing buffer layers by electrodeposition(ED)and preparing superconducting layer by metallorganic deposition(MOD)with organic addition into the precursor solution or reduced fluorine content precursor solution have been addressed in details,due to their great potential for a cost-effective and rapid technical route to prepare YBCO coated conductor.It is also demonstrated that the considerable efforts for artificial flux pinning in YBCO coated conductor by introducing nanoparticles and substrate surface decoration have effectively improved the Jc value of YBCO coated conductor under applied magnet field.Moreover,several demonstration for the power applications of high temperature superconductor have been introduced lastly,suggesting the great potential and significance for people to do further researches on coated conductors.

[1] IIJIMA Y,MATSUMOTO K.High-temperature-superconductor coated conductors:technical progress in Japan[J].Superconductor Science &Technology,2000,13:68.

[2] MUROGA T,ARAKI T,NIWA T,et al.CeO2buffer layers deposited by pulsed laser deposition for TFA-MOD YBa2Cu3O7-xsuperconducting tape[J].IEEE Transactions on Applied Superconductivity,2003,13:2532.

[3] NORTON D P,GOYALA,BUDAI J D,CHRISTEN D K,et al.Epitaxial YBCO on biaxially textured nickel(001):an approach to superconducting tapes with high critical current density[J].Science,1996:274:755.

[4] GOYALA,NORTON D P,BUDAI J D,et al.High critical current density superconducting tapes by epitaxial deposition of YBa2Cu3Oxthick films on biaxially textured metals[J].Applied Physics Letters,1996,69:1795.

[5] GOYALA,PARANTHAMAN M P,SCHOOP U.The RABitS approach:using rolling-assisted biaxially textured substrates for high-performance YBCO superconductors[J].MRS Bull,2004,29:552.

[6] VAN Driessche I,FEYS J,HOPKINS S C,et al.Chemical solution deposition using ink-jet printing for YBCO coated conductors[J].Superconductor Science& Technology,2012,25:065017.

[7] VEREBELYI D T,SCHOOP U,THIEME C,et al.Uniform performance of continuously processed MOD-YBCO-coated conductors using a textured Ni-W substrate[J].Superconductor Science & Technology,2003,16:L19.

[8] CAI C,CHAKALOVA R I,KONG G,et al.Effect of film thickness on properties of YBa2Cu3O7-ycoated on single or multi-layer oxide buffered biaxially textured nickel tapes[J].Physica C,2002,372-376;786.

[9] YING LL,LIU Z Y,LU Y M,et al.Epitaxial growth of La2Zr2O7buffer layers for YBa2Cu3O7-δcoated conductors on metallic substrates using pulsed laser deposition[J].Physica C,2009,469:288.

[10] YING LL,LU Y M,LIU Z Y,et al.Thickness effect of La2Zr2O7single buffers on metallic substrates using pulsed laser deposition for YBa2Cu3O7-δcoated conductor[J].Superconductor Science & Technology,2009,22:095005.

[11] YING LL,FAN F,GAO B,et al.Deposition of Gd2Zr2O7single buffer layers with different thickness for YBa2Cu3O7-δcoated conductors on metallic substrates[J].Physica C,2010,470:543.

[12] FAN F,LU Y M,YING LL,et al.Epitaxial growth of Ce2Y2O7buffer layers for YBa2Cu3O7-delta coated conductors using reel-to-reel DC reactive sputtering[J].Physica C,2011,471:471.

[13] LIU J,LU Y M,FAN F,et al.Epitaxial growth of LaMnO3buffer layer for YBa2Cu3O7-delta coated conductors using pulsed laser deposition[J].Electronic Components & Materials,2012,31:26.

[14] KUTAMI H,HAYASHIDA T,HANYU S,et al.Progress in research and development on long length coated conductors in Fujikura[J].Physica C,2009,469:1290.

[15] IIJIMA Y,KAKIMOTO K,YAMADA Y,et al.Research and development of biaxially textured IBAD-GZO templates for coated superconductors[J].MRS Bull,2004,29:564.

[16] PARANTHAMAN M,AYTUG T,KIM K,et al.Strategic buffer layer development for YBCO conductors[J].IEEE Trans Appl Supercond,2009,19:3303.

[17] BHATTACHARYA R,PHOK S,ZHAO W,NOORMAN A.Electrodeposited biaxially textured buffer layers for YBCO superconductor[J].IEEE Trans Appl Supercond,2009,19:3451.

[18] SANG Lina,LU Yuming,ZHANG Yibing,et al.Cost-effective electrodeposition of an oxide buffer for high-temperature superconductor coated conductors[J/OL]Supercond Sci Technol,2014,27:065016.http://dx.doi.org/10.1088/0953-2048/27/6/065016.

[19] ZHANG Q Q,ZHAO S C,LIU Z Y,et al.Rapid thermal decomposition for YBa2Cu3O7-δfilms derived by DEA-modified TFA-MOD[J/OL]J Phys:Conf Ser,2014,507:012055.http://dx.doi.org/10.1088/1742-6596/507/1/012055.

[20] WU Wei,FENG Feng,ZHAO Yue,et al.A low-fluorine solution with a 2:1 F/Ba mole ratio for the fabrication of YBCO films[J].Supercond Sci Technol,2014,27:055006.

[21] LU Y M,LIU Z J,BAI C Y,et al.Epitaxial growth of Gd2Zr2O7/Y2O3buffer layers for YBa2Cu3O7-δcoated conductor[J].Physica C,2013,485:15.

[22] ZHAO R,FAN F,QIU W B,et al.Effect of Y2O3seed layer on epitaxial growth of oxide barrier layer for YBCO coated conductor[J].IEEE Tran Appl Supercond,2013,23:6602104.

[23] XU Yan,LIU Min,SUO Hongli,et al.An effective substrate surface decoration to YBCO lms by multiphase nanoparticles[J].Physica C,2013,495:187.

[24] ZHANG Hua,YANG Jian,WANG Shuming,et al.Film thickness dependence of microstructure and superconductive property of PLD prepared YBCO layers[J].Physica C 499(2014)54.

[25] XU Da,WANG Ying,LIU Linfei,LI Yijie.Dependences of microstructure and critical current density on the thickness of YBa2Cu3O7-xfilm prepared by pulsed laser deposition on buffered Ni-W tape[J].Thin Solid Films,2013,529:10.

[26] DING Fazhu,GU Hongwei,ZHANG Teng,et al.Enhanced flux pinning in MOD-YBCO films with co-doping of BaCeO3and Y2O3nanoparitcles[J].Acta Phys Sin,2013,62:137401.

[27] XIA Yudong,XIONG Jie,ZHANG Fei,et al.Reel-to-reel deposition of epitaxial double-sided Y{sub2}O{sub3}buffer layers for coated conductors[J].Physica C,2012,476:48.

[28] LI Wei,LI Guoxing,ZHANG Baolin,et al.Fabrication of GdBa2Cu3O7-δfilms by photo-assisted-MOCVD process[J].Physica C,2014,501:1.

[29] LARABLESTIER D,GUREVICH A,MATTHEW Feldmann D,Polyanskii A.High-Tc superconducting materials for electric power applications[J].Nature,2001,414:368-377.

[30] HAUGAN T,BARNES P N,WHEELER R,et al.Addition of nanoparticle dispersions to enhance flux pinning of the YBa2Cu3O7-xsuperconductor[J].Nature,2004,430:867-870.

[31] FOLTYN S R,CIVALE L,MACMANUS-DRISCOLLJ L,et al.Materials science challenges for high-temperature superconducting wire[J].Nature materials,2007,6:631-642.

[32] DING Fazhu,GU Hongwei,ZHANG Teng,et al.Strong enhancement flux pinning in MOD-YBa2Cu3O7-xfilms with self-assembled BaTiO3nanocolumns[J].Applied Surface Science,2014,314:622-627.

[33] JIAN Hongbin,SHAO Dingfu,YANG Zhaorong,et al.Jcenhancement and flux pinning in Y1-xGdxBCO and(Gd,Eu)codoped Y0.9-yEuyGd0.1BCO thin films by TFA-MOD[J].Physica C,2013,488:39-45.

[34] WANG W T,PU M H,LEI M,et al.Enhanced flux pinning properties in superconducting YBa2Cu3O7-zfilms by a novel chemical doping approach[J].Physica C,2013,493:104-108.

[35] XU Yan,LIU Min,SUO Hongli,et al.An effective substrate surface decoration to YBCO films by multiphase nanoparticles[J].Physica C,2013,495:187-191.

[36] CHEN Yuanqing,YAN Fangyuan,JIN Lihua,ZHAO Gaoyang.Enhanced flux pinning and critical current density of BaZrO3-Doped Y0.75Gd0.25Ba2Cu3O7-xsuperconducting films prepared using advanced low-fluorine solution[J].IEEE Tran Appl Supercond,2013,23:8003105.

[37] XIN Y,GONG W Z.Factory and field tests of a 220 kV/300MVA statured iron-core superconducting fault current limiter[J].IEEE Trans Appl Supercond,2013,23:5602305.

[38] XIN Y,HOU B.Introduction of China’s first live grid installed HTS power cable system[J].IEEE Trans Appl Supercond,2005,15:1841-1847.

[39] XIAO LY,DAI S T.Development of HTS AC power transmission cables[J].IEEE Trans Appl Supercond,2007,17:1652-1655.

[40] DAI S T,XIAO LY.Testing and demonstration of a 10-kA HTS DC power cable[J].IEEE Trans Appl Supercond,2014,24:5400104.

[41] WANG Q L,SONG S S.Design and fabrication of a conduction-cooled high temperature superconducting magnet for 10 kJ superconducting magnetic energy storage system[J].IEEE Transactions on Applied Superconductivity,2006,16:570-573.

[42] DAI S T,XIAO LY.Design of a 1 MJ/0.5 MVA HTS magnet for SMES[J].IEEE Transactions on Applied Superconductivity,2007,17:1977-1980.

[43] SHI J,TANG Y J.Development of a conduction-cooled HTS SMES[J].IEEE Trans Appl Supercond,2007,17:3846-3852.

[44] JIANG Y.HTS wind turbine project in DEC[J].Int:Workshop on HTS Wind Generators.Chengdu:2013.

[45] QIU M,XU Z.Technical analysis on the application of HTS bulk in“permanent magnet”motor[J].IEEE Trans Appl Supercond,2005,15:1480-1483.

[46] WANG J S,WANG S Y.The first man-loading high temperature superconducting maglev test vehicle in the world[J].Physica C,2002,378-381;808-814.

[47] JIN J X,ZHENG LH.Analysis and experimental validation of a HTS linear synchronous propulsion prototype with HTS magnetic suspension[J].Physica C,2011,471:17-18;520-527.

[48] WANG Q L,DAI Y M.High magnetic field superconducting magnet system up to 25 T for ExCES[J].IEEE Trans Appl Supercond,2013,23:4300905.

[49] WANG Z M.Superconducting magnet of magnetic resonance imaging system[J].Int:Conf Appl Supercond & Electromag,Beijing:2013:25-27;530-534.

[50] JIN J X,ZHANG C M.Theory and operation principle of a HTS high Q resonant circuit[J].IEEE Transaction on Applied Superconductivity,2007,17:2022-2025.