Design of a smart selection box of breeding goose

Feng ZHANG,Yan YANG

(School of Mechanical Engineering, Chongqing University of Technology, Chongqing 400054, China)

Design of a smart selection box of breeding goose

Feng ZHANG,Yan YANG*

(School of Mechanical Engineering, Chongqing University of Technology, Chongqing 400054, China)

Goose has good hearing sensitivity and strong vigilance, and is easily frightened. When they are scared, they will have stress reaction and change the normal egg production. Traditional way of breeding goose is, according to the size of the goose, registering the serial number appearance of a goose respectively in different growth stage; selecting the better goose continuously for many times and recording every goose egg production one by one. In order to solve the problem of low efficiency and the complexity of the traditional breeding methods, a smart breeding boxes based on the pneumatic, mechanism design, optic detection and electronic identification. Its function is to distinguish individual egg production situation in the group. Accordingly weeding out the low yield of goose, selecting the high yield of goose and improving the breeding geese quality.

Breeding geese, Automatic identification, Mechanism design, Smart selection

1 Introduction

With the growing of Chinese animal husbandry production, total livestock products have increased greatly and animal husbandry product quality have improved continuously. Especially, as implementation of strengthening agriculture favorable farmers policies, animal husbandry is presenting to good momentum of development. Positive change in the way of animal husbandry production has happened, which speeds up the pace of scale, standardization, industrialization and regionalization. Modern mode of production is becoming more and more important. Our country has a long history of raising various geese, but the breeding level is relatively backward, and the system of breeding is not scientific [1-3]. At present, there are two main methods for detecting geese eggs: One is inspection with worker fingers in egg production period [4]; the other method is catching and putting a goose regularly, then picking eggs and recording [5]. The first way is effective but easy to cause goose stress reaction, and in the second way, the method is not rigorous, egg production period is not precise, what is more, too much labor is needed. Therefore, this study developed an intelligent selection system, through the intelligent detection of goose egg production situation, the intelligent selection system realized the intelligent breeding goose.

2 Intelligent selection system overall design

The purpose of this system is, without interference of goose, to solve the problem of intelligent in the process of goose breeding. Intelligent monitor and control system for goose breeding consists of selection box installed in house of the goose, lower position machine system, upper computer and ID card in each goose. The selection box consists of the roof installed on the frame, activity board, goose egg boxes and air cylinder. The roof is installed on board above, one end of the activity board is hinged on the rack, air cylinder activity is installed under the activity plate, the top of the cylinder piston rod contact with the surface under active plate, the goose egg boxes is installed under the activity plate, and ID card reader is installed under the surface of the roof.

Working principle of the system is: when the goose goes into active plate area, the goose’s ID card information is read by ID card reader, and the information is stored in the lower position machine; when the ID card reader can’t read the goose ID card information, lower machine sends start signal to the electric control system of cylinder, which makes one end of active board up by the cylinder piston rod; after one end of the activity board up, if there are eggs in the collection box, lower position machine system will read goose ID card information and send it to the upper computer,on the other side, if there are not eggs in the collection box, lower position machine system will not read goose ID card information and send it to the upper computer. The upper computer record every goose egg production. Collection box is equipped with photoelectric door, which is used to determine whether there are goose eggs in collection box.

3 Mechanical system design

The automatic selection box’s mechanical parts are egg box, activity board, and egg collecting basket. The egg box mainly provide production environment, activity board makes the eggs into the egg collecting basket, and egg collecting basket collect eggs. Activity board is made of aluminum alloy materials, which can bear the weight of goose, simultaneously, make the overall structure lightweight. The activity board is supported by silent cylinder. Opening up and down of activity board make the eggs go an into the egg collecting basket. A diagram of a selection box drawn by AutoCAD 2013 is shown in Fig.1.

Fig.1 Selection box front elevation view

The mechanical parts of the system is shown in Fig.2. The goose lay eggs in the egg box, the activity board tilt after egg production, then the egg slide down and collected by the collection box.

1.roof; 2.activity board; 3.egg collection box; 4.air cylinder

Fig.2 The mechanical parts of the system diagram

4 The electronic system design

Electronic system is shown in Fig.3. Reading the test system is controlled by an ARM processor, and data processor storage systems are controlled by one computer.

The information of goose is read by ID card reader and sent to the processor, microprocessor control relays according to the card reader sent information, then the solenoid valve’s and activity’s open and close is controlled. When the system detects a goose entering selection box, then laying eggs and leave, the active plate will be open. If the egg fall, then the photoelectric door switch is triggered. Processor will send the ID card number of the goose to the computer server via the Internet and the computer will store the data received [7-10].

Fig.3 Electronic system structure diagram

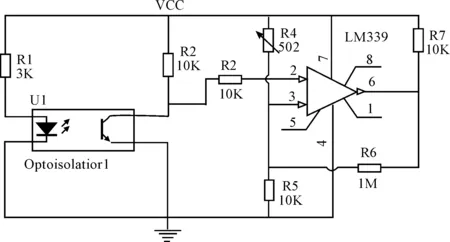

When the launched infrared light is blocked, it proves that eggs slide down. Meanwhile, the U1 photosensitive diode either end is highresistance state, namely cut-off. 2 and 3 pin of LM339 plus or minus the reverse, Vout output is the low level. When no goose eggs sliding down, infrared light to the photodiode, photosensitive diode current increases to conducting state. LM339’s 2 and 3 pin have a forward voltage, Vout output is the high level. According to the above principle, we can detect whether a goose eggs. Principle of photoelectric door is shown in Fig.4.

Fig.4 Principle of photoelectric door

5 Software system design

Based on the above function, we created a goose breeding service system software. After the command is taken in software from ARM processor, computer will store the the goose ID number in data base. The software can support to monitor multiple breeding boxes, and can monitor 5 000 geese at most, which are far beyond the number of actual goose in general breeding farm. Lower position machine software design flow chart and software operation interface are shown in Fig.5 and Fig.6.

Fig.5 Lower position machine software design flow chart

6 Intelligent selection system test and application

Based on the analysis of system design theory, we developed a smart goose breeding system prototype. The state diagram when system work and collect the egg is shown in Fig.7 and Fig.8.

Fig.6 Software operation interface

Fig.7 Selection box working condition

Fig.8 Breeding box collect egg state

ID card reader is mounted on the top of egg box, which is used to read the goose’s ID card information. When the goose goes into the activity board area, ID card reader reads the goose’s ID card information, and stores the information in the machine. Since then, ID card reader will read the goose’s ID card information all the time. When the ID card reader cannot read goose ID card information in 32 s, the goose has left the activity board area. Then lower machine electric control system send start signal to the cylinder, which makes one end of the activity plate jacked up by cylinder piston rod. Cylinder of electronic control system includes the relays and solenoid valves. One end of the activity board will be jacked up by the piston rod, then cylinder piston rod reset, which makes the activity board back to the original level. When there is a goose egg going by, the launch of the infrared light emitting diode is blocked, we can detect whether a goose eggs through the reading of the photoelectric switch. In order to guarantee the reliability of the card reader, we chose the RD series 125 kHz and 13.56 MHz non-contact rf ID card and M1 wiggins card reader, and adopt advanced rf receiving circuit design and embedded microcontroller controller, combined with efficient decoding algorithm, completing 64 bits Read-Only. Due to living environment of goose is dirty and wet, for the ID card to receive em4100 compatible type, RD-wigan card reader has advantage of received high sensitivity, small work current, single dc power supply, low price, and high performance, etc. This reader can ensure stability in the complex high humidity environment.

The upper machine primary uses PC to record every goose’s egg production, while the lower machine adopts a STM32f107 embedded ARM processor, which is an embedded application of the ARM Cortex-M3 kernel specifically designed by ARM company for the requirements of low power-consumption, low cost and high performance, then manufactured by STMicroelectronics. PC server software stores each data received from the lower machine on a hard disk. Thus it can record each goose’s egg production for a certain time (1 day or 1 week, etc.), which is easy for goose’s detection and selection.

7 Conclusions

This study designed and developed a new kind of intelligent breeding system breeding goose by integrating pneumatic, mechanism design, photoelectric detection and electronic identification technology. Solving the problem of traditional mode of goose breeding inefficient and low reliability through research and development of this intelligent geese breeding system, can distinguish the merits of the individual situation of egg production, and carry out automatic intelligent detection on egg production situation.

Acknowledgements

This paper is supported by National Modern Agriculture (Waterfowl) Special Industry Technology System Construction Project (No. CARS-43-15) and the Chongqing Basic Scientific Research Business Expenses Project (No.2013cstc-jbky-00901).

[1]ZHANG Xiang-ying, TANG Xian-wen. Current situation and prospect of goose breeding in China[J]. Journal of Anhui Agri., 2009(22): 10511-10513.

[2]WANG Hao-jiao. Animal husbandry five-year plan released plate investment opportunities[N]. Beijing Times, 2011-09-23.

[3]CHEN Kuan-wei. Raising goose industry production in our country present situation and the the problem need to solve[J]. Guide to Chinese poultry, 2003(11): 3-8.

[4]Yang Guang-rong, Zhang De-u, Huang Zhi-qiu, et al. Research on the laws of the goose egg production and egg production[J]. China Poultry, 1997(10): 18-19.

[5]Yang Cheng-zhong, Cai Lai-chang, Rong Zhen-kun et al. Maconnaise geese nest laws and the related research of the egg production[J]. China Poultry, 2001, 23(8): 54-55.

[6]Hu Cong-lin, Rong Zhi-jun, Chen Kui-sheng, et al. Research on clustering optimization of product design task[J]. Machinery Design and Manufacture, 2014(7): 259-261.

[7]Zeng Jing-song, Shi Wei-long, Huang Jiang. The key technology and research progress of piezoelectric power supply [J]. Mechanical design and manufacture,2014(7): 262-264.

[8]Qi Long, Xiao Su-mei, Tang Fang-ming. Research on electronic confidentiality level identifier for information devices [J]. Mechanical design and manufacture, 2013(1): 122-125.

[9]Wu Bin, Huang Yuan-dian, Lu Wei-yi, et al. A new protable optical gate based on USB and computer’s sound card[J]. Physical experiment of college, 2011(6):14-15.

[10]Chu Yan, Shao Yan, Chen Liang, et al. Study of License plate recognition software system[J]. Electronic Design Engineering, 2013(4): 149-151,155.

(Continued on 98 page)

27 January 2015; revised 15 April 2015;

Yan YANG, Professor, Ph.D.,

E-mail: yangyan@cqut.edu.cn.

10.3969/j.issn.1001-3881.2015.18.017 Document code: A

S126;TH122

accepted 1 July 2015

Hydromechatronics Engineering

http://jdy.qks.cqut.edu.cn

E-mail: jdygcyw@126.com

- 机床与液压的其它文章

- Design and simulation of the hardware in the loop simulation platform for vehicle ACC system

- A research on film thickness of a typical dynamic seal for hydraulic actuators

- The research on aero-engine gas path fault diagnosis by genetic algorithm-BP neural network

- The design of the hydraulic cylinder test bed based on cartridge valves

- Numerical simulation on the aerodynamic performance of ice coating airfoil of wind turbine blade

- Manufacturing of self-lubricating diamond tools with Ni-Cr alloy adding with Ni/C