Quantitative analyses of fibers by differential scanning calorimetry

Deng Fei,Lin Xiaodong,He Yonghong,Li Shu,Zi Run,Lai Shijun,and Zeng Xierong

1)Graduate School at Shenzhen,Tsinghua University,Shenzhen 518055,P.R.China

2)Institute of Forensic Science and Technology,Shenzhen Police Bureau,Shenzhen 518040,P.R.China

3)Shenzhen Key Laboratory of Special Functional Materials,Shenzhen Engineering Laboratory of Advanced Technology for Ceramics,Shenzhen University,Shenzhen 518060,P.R.China

Fibers are useful for forensic purposes,as they tend to cling easily and provide useful characteristics for identification purposes[1-3].An object left at the scene of a crime by a suspect may contain fiber evidence that can link a suspect to the crime scene or provide investigative clues about the suspect[4].

Thermal analysis is commonly employed in forensic inves-tigations to provide scientific basis for identifying and authenticating facts[4-12].One of the reliable methods for thermal analysis is differential scanning calorimetry(DSC).DSC is a technique used to measure the amount of heat necessary to achieve a zero difference in the temperatures of a selected sample and reference material.The reference and the sample are kept at almost equal temperature for the duration of the measurement,as the energy and time required to keep them at that level are measured separately for the two items.The advantages of DSC are obvious from the forensic standpoint.Firstly,the required sample size is relatively small.Secondly,very little time for sample preparation is required thus leading to fast analysis.

Forensic identification and characterization offiber samples by DSC have already been carried out[13-16]before.Ionashiro et al[17]used DSC to study the thermal behavior of hair samples and verified the possibility of identifying an individual based on DSC curves from a data Bank.Singh[18]carried out DSC analyses of 25 PET fiber samples.These investigations demonstrated convincingly that it was possible to differentiate between the fibers of different deniers and the fibers of same denier but from different sources.

From a forensic standpoint,examination of fibers is considered difficult when it is required to differentiate between fibers of the same type[4]. In this paper, the results of qualitative analyses for some standard fiber samples by DSC method are investigated.Furthermore,quantitative analyses of composite fiber samples(blend fibers)were also studied by DSC based on melting characteristics.

1 Experiment

DSC analyses were performed with a DSC Q2000(TA instruments,USA)equipped with a Refrigerated Cooling System.The temperature calibration and the heat flow calibration were both done with indium.High-purity helium was chosen as a purge gas applied at 25 mL/min.The reference sample was an empty hermetically sealed aluminum pan.During the DSC process,the sample was contained in an aluminum pan and the reference sat on the raised platform on the sensors.As heat was transferred through the sensor,the differential heat flow to the sample and reference was monitored by area thermocouples.A preheated purge gas was present to provide additional baseline stability as well as the desired sample/atmosphere interaction.

In the present study,10 kinds of standard fiber samples(3.00 mg for each sample),supplied by China Fiber Inspection Bureau,were used to research the qualitative analysis application of DSC method.In addition,7 pure polyester fiber samples with different masses(0.57,0.74,1.04,1.52,2.09,2.44 and 3.00 mg)and 5 polyester-cotton composite fiber samples(100% polyester,80% polyester,60%polyester,40%polyester,20%polyester and 0 polyester)were used to study the quantitative analysis application of DSC method.All samples were analyzed over the temperature range from 20℃ to 400℃.A heating rate of 10℃/min was used with helium atmosphere around the sample.The obtained DSC data was analyzed by TA Universal Analysis software.

Fourier transform infrared spectra(FTIR)were recorded on a Thermo Nicolet 5 700 spectrometer with OMNIC software at frequencies from 400 to 4 000 cm-1(4 cm-1resolution and 64 scans).

2 Results and discussions

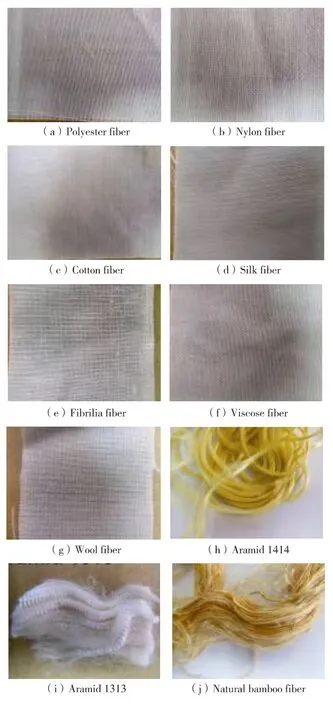

The digital photos of the 10 standard fiber samples are shown in Fig.1.Except for the aramid 1414 and natural bamboo fiber,the other 8 samples could not be identified by the naked eye because of their similar colors and appearance.Furthermore,in actual forensic cases,fiber evidence is almost all composed of composite fiber samples(blend fibers),which are made up of several kinds of fibers.In these cases,identification of fiber evidence by the naked eye is nearly impossible,and the DSC method might be considered.

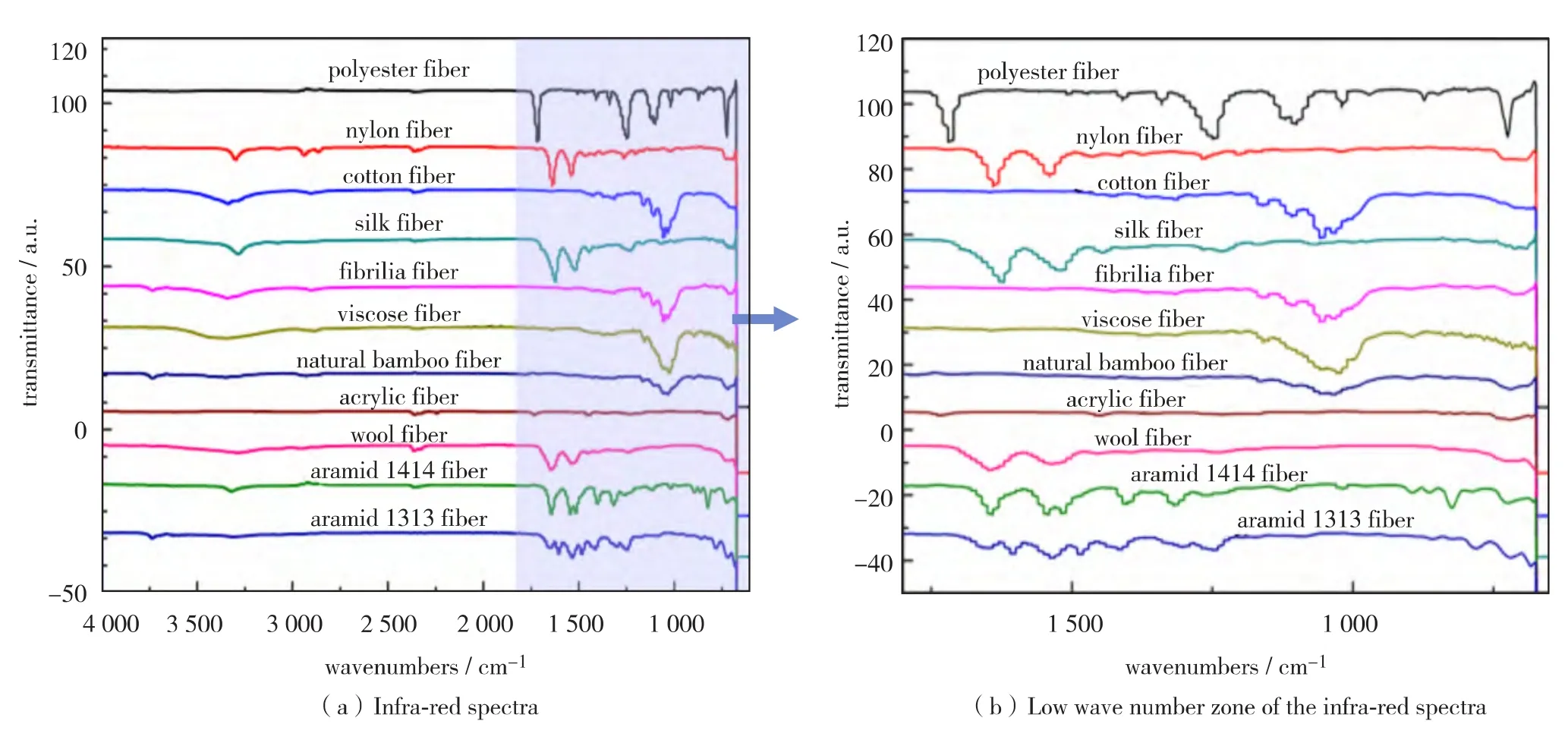

The DSC results obtained on the part of the standard fiber samples for qualitative analyses are displayed in Fig.2.The plots show that the heat flow as a function of the sample temperature and the endothermic response is oriented downwards.There is a broad endothermic transition at 50—150℃ and,given the temperature of this particular event,there is a strong likelihood that this is due to the evolution of water.Besides,because the fibers have different structures such as molecular weight and degree of crystallinity,the molten peak characteristics including the peak position,the peak height and the peak shape are different from each other[19].The above-mentioned difference of DSC curves is valuable for forensic purposes since they provide a‘fingerprint’of the fiber samples which could aid in differentiating the fiber type and tracking down the particular manufacturer of the fibers.However,any technology is not universal because fiber samples at criminal cases are mostly complex and diverse.For example,the DSC profiles of wool fiber,aramid 1414 fiber,and aramid 1313 fiber do not exhibit typical peak characteristics which might be attributed to their special amorphous structures(Fig.3)[20].In these cases,other techniques such as FTIR spectroscopy could be introduced as a supplement into the identification process(Fig.4).However,for fiber quantitative analyses,the DSC method has more advantages compared to other technologies and could theoretically work with any fiber sample if the molten peaks of different fibers do not affect each other.

Fig.1 Digital photos of the 10 standard fiber samples图1 十个标准纤维样品的数码照片

Fig.2 DSC results on 7 standard fiber samples图2 七个标准纤维样品的DSC曲线

Fig.3 DSC results on 3 standard fiber samples图3 三个标准纤维样品的DSC曲线

First,during the DSC quantitative analysis process,the relationship between the molten heat value and the fiber mass for each pure fiber in the composite samples needed to be measured.In this work,7 polyester-cotton composite fiber samples were taken to evaluate the accuracy and feasibility of DSC quantitative analysis.

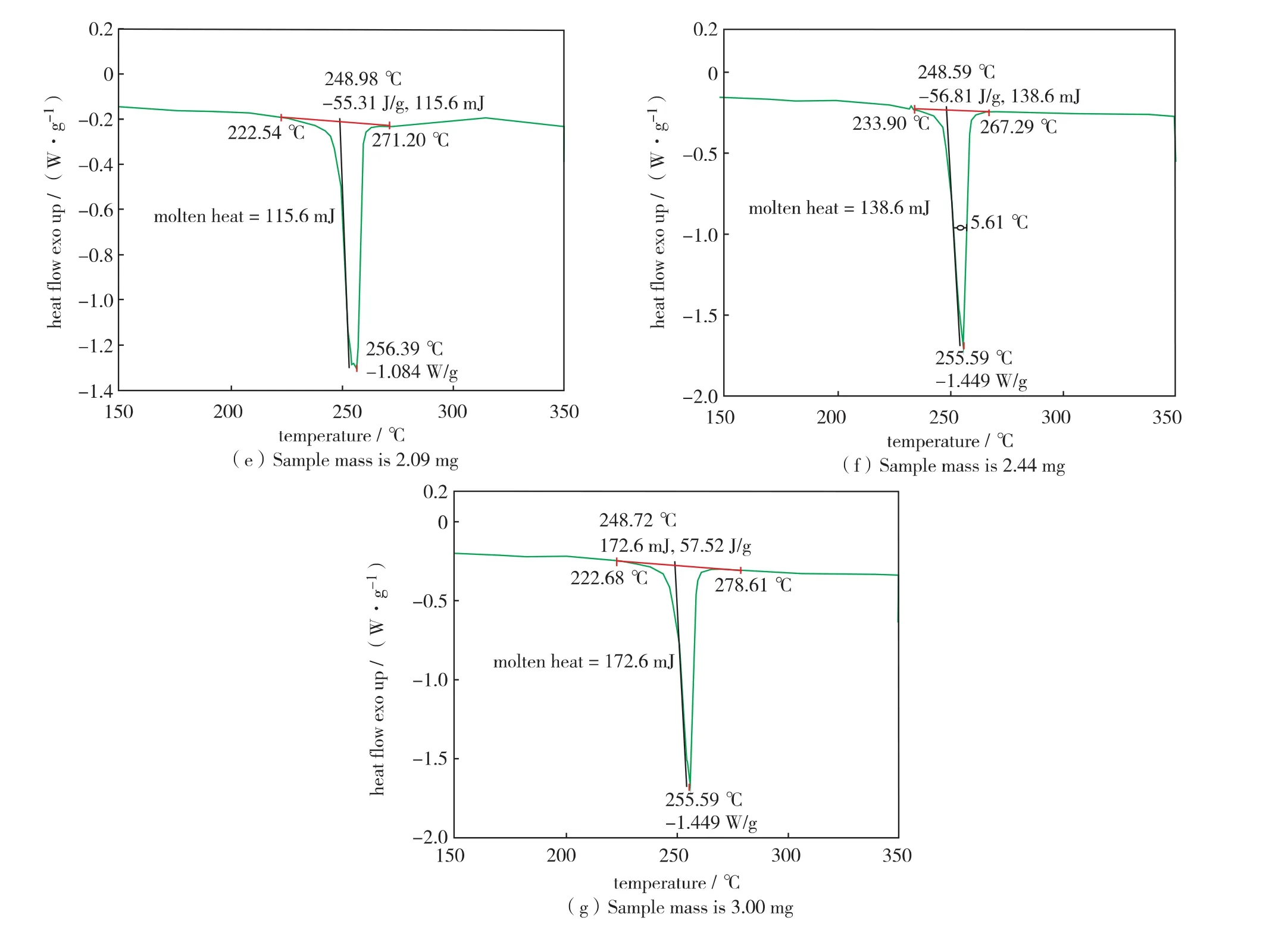

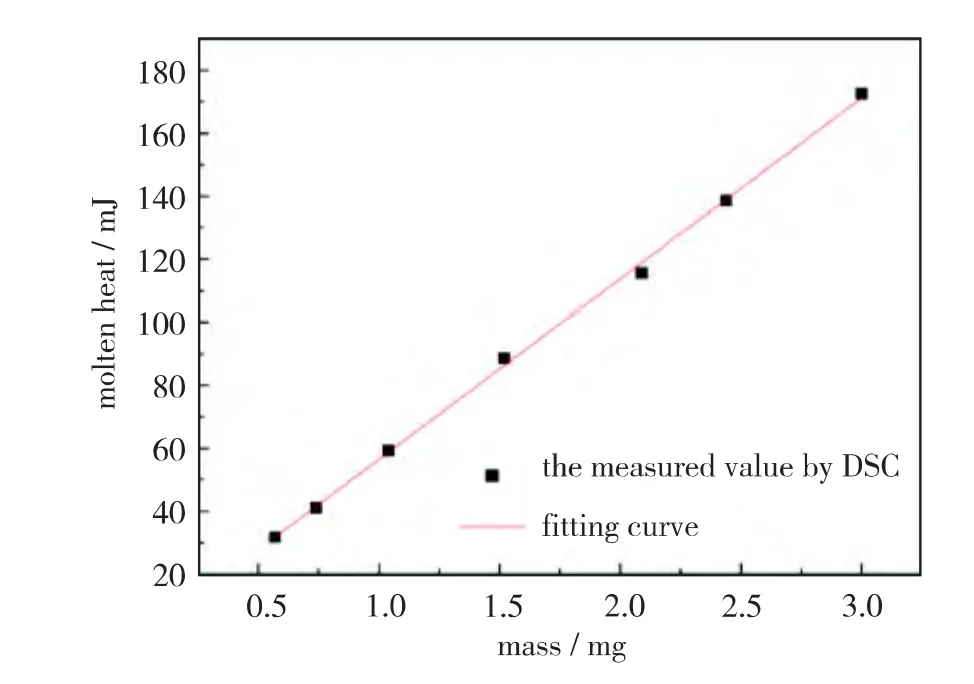

The DSC curves of the 7 polyester samples with different masses are shown in Fig.5.The molten heat value is calculated with integral method integrated in the TA Universal Analysis software.The relationship between the molten heat value and the fiber mass is also presented in Fig.6.A linear function is adopted to fit the data.It is found that the fitting quality factor(adjusted R-square)is up to 0.99,which suggests a good data dependency(Table 1 ).Therefore,the melting enthalpy of the polyester fiber could finally be obtained from the slope of the fitting linear function(57.31 J/g,with a standard error of 0.88 J/g).

Fig.4 Infra-red spectra of the 10 standard fiber samples图4 十个标准纤维样品的红外光谱

Fig.5 DSC results on the 7 polyester samples with different masses图5 七种不同质量涤纶样品的DSC曲线

(Joins Fig.5)

Fig.5 DSC results on the 7 polyester samples with different masses图5 七种不同质量涤纶样品的DSC曲线

Fig.6 Rrelationship between molten heat value and polyester mass图6 熔融热与涤纶质量之间的关系

Secondly,5 samples with different weight ratios of polyester and cotton are measured by DSC.It can be seen that the molten peak area of the polyester fiber increases with its increasing content in the composite samples,which can be observed distinctively by its vertically stretched plot(Fig.7).This reveals the relationship between the fiber content and the molten heat value to some extent.

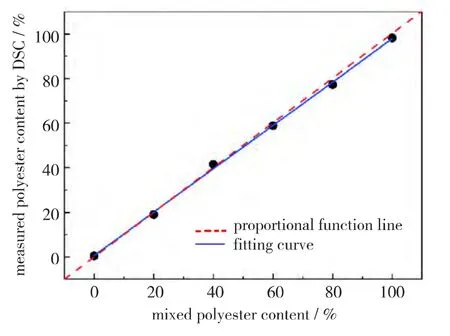

Based on the melting enthalpy of polyester fiber(57.31 J/g)calculated above and the molten heat value presented in Fig.7 and Table 2 ,the quantitative analysis results are obtained by the DSC method.A visual representation of both the measured value and the mixed value of polyester content are given in Fig.8.The data are fitted by a linear function.The high quality factor(adjusted R-square)of 0.99 illustrates a good data dependency(Table 3 ).Moreover,the slope of the fitting line is up to 0.97,which is close to the slope of the proportional function line(slop=1,marked by dashed lines).The weight percent difference between the mixed values and the measured values by DSC of all samples ranges from 0.9%to 2.6%.It means that the errors could be less than 3.0%absolute.This indicates that quantitative analysis of fibers by DSC method for forensic identification is satisfactory and feasible.

Table 1 Fitting parameters of the coordinates shown in Fig.6表1 图6中坐标点的拟合参数

Fig.7 DSC results on 5 samples with different weight ratio of polyester and cotton图7 不同质量分数涤纶-棉纤维样品的DSC曲线

Fig.8 Comparison between the mixed and measured polyester fractions by the DSC method图8 涤纶-棉样品中涤纶纤维的实际质量分数与DSC定量分析计算质量分数的对比分析

Table 2 The weight percent difference between the mixed values and the measured values by DSC表2 DSC计算含量与实际含量对比

Table 3 Fitting parameters of the coordinates shown in Fig.8表3 图8中坐标点的拟合参数

Conclusions

The results obtained in this paper show that the DSC curves for some fiber samples are different from each other.This difference is determined by a complex variety of structural factors such as molecular weight and the degree of crystallinity.Thus,on the basis of the DSC data obtained for 10 pure fiber samples,it is concluded that it is possible to do qualitative analysis with the DSC method for forensic comparison of fiber samples.In addition,the quantitative analysis of 5 polyestercotton composite fiber samples yields precise results,with absolute errors being generally less than 3.0%.Therefore,it might be feasible to do quantitative analysis for polyester-cotton composite fiber samples with DSC method for forensic identification.

/References:

[1] Marcia M L Y,Sandercock M P L.Principal component analysis and analysis of variance on the effects of entellan new on the raman spectra of fibers[J].Journal of Forensic Sciences,2012,57(1):70-74.

[2] Michael C,Andrew P,Tegan E,et al.The effect of ionizing gamma radiation on natural and synthetic fibers and its implications for the forensic examination of fiber evidence[J].Journal of Forensic Sciences,2011,56(3):591-605.

[3] Patrick B,Genevieve M.A simple solubility tests for the discrimination of acrylic and modacrylic fibers[J].Journal of Forensic Sciences,2013,58(6):1593-1600.

[4] Roberston J,Grieve M.Forensic examination of fibers[M].London:Taylor& Francis,2003.

[5] Ehrensttein G,Riedel G,Trawiel P.Thermal analysis of plastics[M].Munich(Germany):Carl Hanser Verlag,2004.

[6] Riga A.Thermal analysis as an aid to forensics:alkane melting and oxidative stability of wool[C]//The 25th North American Thermal Analysis Conference.Virginia(USA):Thermochimica Acta,1998:151-163.

[7] Zhao H F,Zhu Y B,Sha L Z.Study of the relationship between characteristics of aramid fibrids and mechanical property of aramid paper using DSC [J].Polymers,2014,14(2):139-144.

[8] Huang J,Manisha D.Evaluation of integrated raman-DSC technology in early pharmaceutical development:characterization of polymorphic systems[J].Journal of Pharmaceutical and Biomedical Analysis,2013,86:92-99.

[9] Mlcoch T,Kucerik J.Hydration and drying of various polysaccharides studied using DSC [J].Journal of Thermal Analysis and Calorimetry,2013,113(3):1177-1185.

[10] Mahato D N,Mathur B K,Bhattacherjee S.DSC and IR methods for determination of accessibility of cellulosic coir fibre and thermal degradation under mercerization [J].Indian Journal of Fibre& Textile Research,2013,38(1):96-100.

[11] Hassan A,Normasmira Y.Extrusion and injection-molding of glass fiber/MAPP/polypropylene:effect of coupling agent on DSC,DMA,and mechanical properties[J].Journal of Reinforced Plastics and Composites,2011,30(14):1223-1232.

[12] Fu Z J,Huang H F,Yu L S.DSC Studies on the dyeing properties of PLA fiber[C]//The 3rd International Conference on Advanced Engineering Materials and Technology.Zhangjiajie(China):Advanced Materials Research,2013:1393-1396.

[13] Ihms E C,Brinkman D W.Thermo gravimetric analysis as a polymer identification technique in forensic applications[J].Journal of Forensic Sciences,2004,49(3):505-510.

[14] Foldes E,Keresztury G,Iring M,et al.Crystallinity of polyethylene measured by density,DSC and Raman spectroscopy:a comparison [J].Ange Wandte Makromolekulare Chemie,2003,187(1):87-91.

[15] Sajwan M,Aggarwal S,Singh R B.Forensic characterization of HDPE pipes by DSC [J].Forensic Science International,2008,175(2/3):130-133.

[16] Tsukame T,Kutszaw M,Selane H,et al.Identification of polyethylene by DSC:application to forensic science [J].Journal of Thermal Analysis and Calorimetry,1999,57(3):847-851.

[17] Ionashiro E Y,Hewer T S R,Fertonani F L,et al.Application of differential scanning calorimetry in hair samples as a possible tool in forensic science[J].Ecletica Quimica,2004,29(2):53-56.

[18] Singh D.Characterization of PET fibers by some physical methods[D].New Delhi(India):University of Delhi,1994.

[19] Bershtein V A,Egorov V M,Kem T J.Differential scanning calorimetry of polymers:physics, chemistry,analysis,technology[M].Chichester(UK):Ellis Horwood,1994.

[20] Hohne G W H,Hemminger W F,Flammersheim H J.Differential scanning calorimetry[M].New York(USA):Springer-Verlag,2003.