甘蔗收获机剥叶断尾系统的设计与转速优化

谢卢鑫,王 俊,程绍明,胡金冰

(浙江大学生物系统工程与食品科学学院,杭州 310058)

甘蔗收获机剥叶断尾系统的设计与转速优化

谢卢鑫,王 俊※,程绍明,胡金冰

(浙江大学生物系统工程与食品科学学院,杭州 310058)

为了考察碎叶轮、剥叶轮及断尾轮转速对甘蔗剥叶断尾效果的影响规律,设计并制造了作业转速可调的甘蔗割后集成作业试验台,并进行甘蔗剥叶断尾试验。采用二次回归通用旋转组合试验设计方法,以碎叶轮转速、剥叶轮转速和断尾轮转速为试验因素,以甘蔗未剥净率、断尾率、伤皮率和未折断率为试验指标,利用SAS9.3软件进行回归分析和响应面分析,研究单因子及交互效应对响应值的影响规律;结合非线性优化的计算方法,对试验台各工作部件的工作参数进行优化计算,确立影响甘蔗剥叶断尾质量的最佳参数组合为:碎叶轮转速为512.9 r/min、剥叶轮转速为418.8 r/min、断尾轮转速为307.0 r/min,此时未剥净率为4.98%、断尾率为88.39%、伤皮率为5.19%、未折断率为96.21%,试验验证表明未剥净率为4.86%、断尾率为90%、伤皮率为4.78%、未折断率为97.50%,试验验证与理论结果一致,因此所建立的回归模型合理,对设计与提高整杆式甘蔗收获机的收获质量有重要参考价值。

机械化;优化;模型;甘蔗;未剥净率;断尾率;伤皮率;未折断率

谢卢鑫,王 俊,程绍明,胡金冰.甘蔗收获机剥叶断尾系统的设计与转速优化[J].农业工程学报,2016,32(6):50-57.doi:10.11975/j.issn.1002-6819.2016.06.007 http://www.tcsae.org

Xie Luxin,Wang Jun,Cheng Shaoming,Hu Jinbing.Design and speed optimization of leaf-crushing and tail-breaking system of sugarcane harvester[J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2016,32(6): 50-57.(in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2016.06.007 http://www.tcsae.org

0 引言

甘蔗作为主要的制糖原料和经济作物,广泛种植于广西、云南、广东和海南等地,据统计,2012年中国甘蔗种植面积高达179.5万hm2,是世界第三大产糖国[1],尽管如此,国内甘蔗机械化收获水平依然很低,严重制约了中国蔗糖产业的发展。

与国外相比,国内甘蔗机械化收获以整杆式为主[2-4],尽管从20世纪60年代便开始研究甘蔗的机械化收获,但迄今为止还没有生产出性能优良、适应性强的甘蔗联合收获机,市场上推广使用的整杆式甘蔗收获机除了很难适应生长高度、倒伏状况不一的甘蔗外,含杂率也十分严重[5-8]。为此,国内学者做了大量研究工作[9-13],牟向伟等[14]设计了一种弹性齿滚筒式甘蔗剥叶机构;麻芳兰[15]则提出了一种采用三角形布局方式的剥叶断尾机构;罗菊川[16]利用甘蔗茎秆尾部机械强度低于中部和基部的特点设计了一种断尾机构;刘芳建[17]则探索了一种逆剥叶方式。

尽管针对甘蔗剥叶断尾性能优化的研究很多,但上述试验均未涉及碎叶轮,而针对剥叶断尾机构与碎叶机构工作参数组合对甘蔗剥叶断尾效果等影响的研究更鲜有报道。为此,本文利用自行研制的甘蔗割后集成作业系统,采用二次回归通用旋转组合设计的试验方法研究碎叶轮、剥叶轮及断尾轮转速对甘蔗剥叶断尾效果的影响规律,获取因素的最佳作业参数,为整杆式甘蔗联合收获机提高断尾率和未折断率,降低未剥净率和伤皮率提供借鉴。

1 甘蔗割后集成作业系统试验台设计

实践表明,利用滚筒高速旋转产生的离心力和摩擦力将附着在甘蔗表皮的蔗叶剥离是一种非常理想的剥叶方式,但如果在剥叶前将甘蔗表皮的蔗叶划碎则能够大大提高剥叶效果;而利用甘蔗尾部抗变形、抗冲击等机械强度显著低于其他部位的特点设计的防窜动式断尾机构[18]可以有效解决目前前置切梢器适应性差、切割精度低等问题。

基于上述分析,本文旨在设计一种甘蔗割后作业系统,该系统对经切割器切割后的甘蔗依次进行喂入系统、划碎蔗叶、剥离蔗叶、击断末梢及输出系统作业,从而获得含杂率较低的榨糖原料。

1.1 主要工作部件结构设计

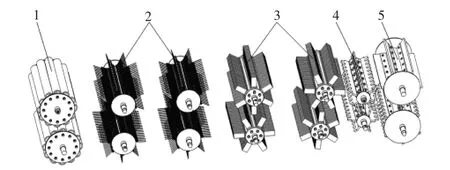

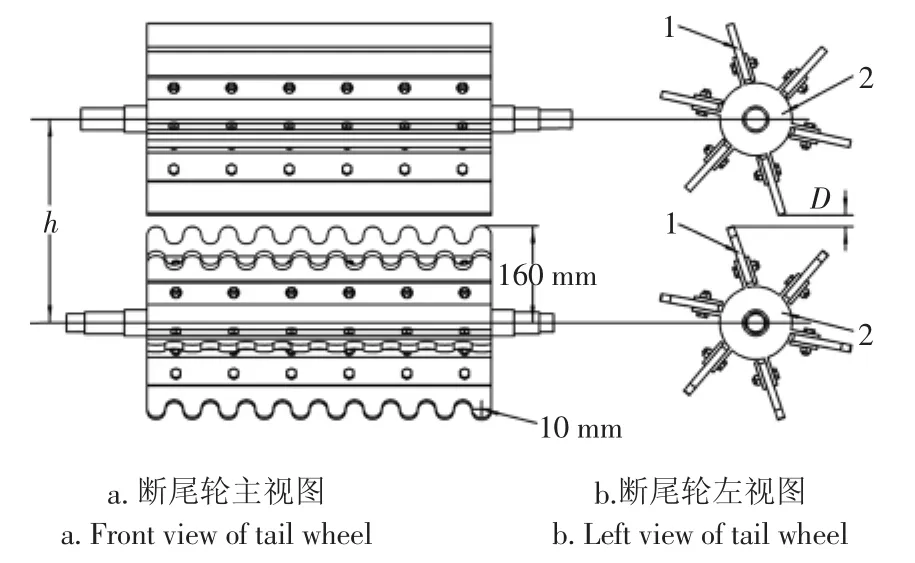

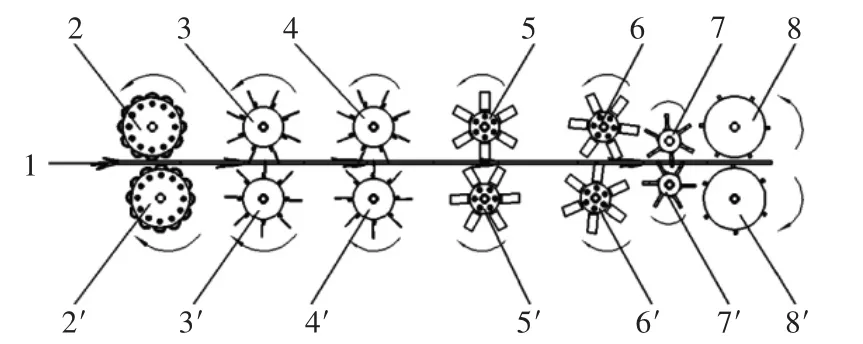

如图1所示,甘蔗割后集成作业系统主要由喂入滚筒1、一二级碎叶轮2、一二级剥叶轮3、输出滚筒4和断尾轮5等组成,各轮转速均在200~1 000 r/min范围内独立可调。其中,喂入滚筒半径为115 mm,其边缘均匀分布12个外径为54 mm的空心橡胶管,管壁厚6 mm,上下滚筒间距为20 mm;碎叶轮直径为120 mm,表面均匀安装8排碎叶元件,碎叶元件底部为螺旋状,直径和总长度分别为2、90 mm,采用冷拉弹性钢丝齿;上下剥叶轮采用对称布置,其直径为120 mm,外缘均匀分布6排长度为75 mm、厚度为10 mm的橡胶剥叶板;断尾轮半径为160 mm,上下断尾元件采用高度分别为45、63 mm的弹性筋条,且下滚筒外侧端面为锯齿状,可有效防止甘蔗窜动(如图2所示);输出滚筒直径为90 mm,输送元件高32 mm并开有梯形槽。作业前,通过转速表调节好各滚筒转速,分别保持一、二级碎叶轮及剥叶轮转速一致并稳定运行,将甘蔗由根部喂入喂入滚筒,经过碎叶、剥叶和断尾工序后,甘蔗由试验台后方输出,即完成一次剥叶断尾试验。

图1 甘蔗割后集成作业系统Fig.1 Integrated operating system test bench after sugarcane harvest

图2 断尾轮示意图Fig.2 Structure of tail wheel

1.2 工作原理

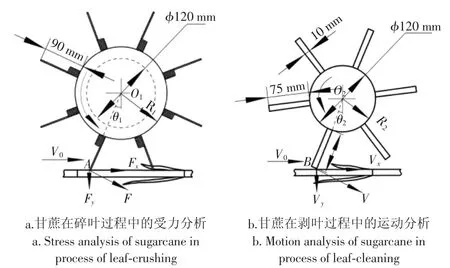

甘蔗进入作业系统后,首先需要喂入滚筒对其产生向前的摩擦力以保证顺利输送,但是又不能损伤蔗皮。因此,本试验台将输送元件设计为柔性橡胶管的形式;随后碎叶轮上的碎叶元件接触甘蔗表皮并在高速旋转作用下不断对蔗叶产生划切作用,最终将蔗叶破碎,如图3(a)所示,碎叶轮上安装有弹性钢丝齿[19],该装置能够在甘蔗通过时划碎蔗叶但不损伤蔗皮,有利于提高剥叶效果;剥叶轮上的剥叶刷在转动过程中会对蔗茎产生全方位的挤压疏刷作用,并能够切入紧密包裹在蔗茎表面的蔗皮,将其撕扯剥离蔗茎[20-21],其在剥叶过程中的运动情况如图3(b)所示。为了能够将蔗叶彻底剥离干净,本作业系统采用两级碎叶装置和剥叶装置;经过2次碎叶和剥叶工序后,蔗叶基本被剥离干净,随后甘蔗在输出滚筒的作用下继续向后输送至断尾轮,其下滚筒对甘蔗起支撑作用,而上滚筒则不断旋转击打蔗茎,工作机理与剥叶轮类似。由于甘蔗尾部较脆弱,机械强度明显低于中部和根部[16],当试验台参数调整到适当水平时,蔗尾3~5节便会在断尾轮高频率的打击作用下折断。

图3 甘蔗在碎叶轮和剥叶轮作用下的受力及运动分析Fig.3 Analysis of stress and motion of Sugarcane with action of leafcrushing and leaf-cleaning impeller

整机工作原理如图4所示,经过该作业系统的甘蔗含杂率低,断尾效果好,有利于提高榨糖品质。

图4 甘蔗割后集成作业系统工作原理Fig.4 Working principle of integrated operating system

2 试验方案

2.1 试验材料

试验甘蔗采用云南省甘蔗研究所种植的云蔗07—2178,试验前统计甘蔗中部的平均直径为27.1 mm,标准差为1.3 mm;甘蔗平均高度为1 643 mm,标准差为4.8 mm;甘蔗平均节数为14.5节,标准差为0.9节;随机选取10根甘蔗,对茎秆及根部、中部和顶部叶片进行含水率测试,测得节间平均含水量为74.1%,节点处平均含水率为67.6%,各部位叶片平均含水率分别为33.2%、54.2%和61.3%;随机选取10根甘蔗,截取中部的4节并榨汁,利用折射仪分别测量其糖度[22],平均值为22.3°Bx,测试环境温度为21.5℃。

2.2 试验方法

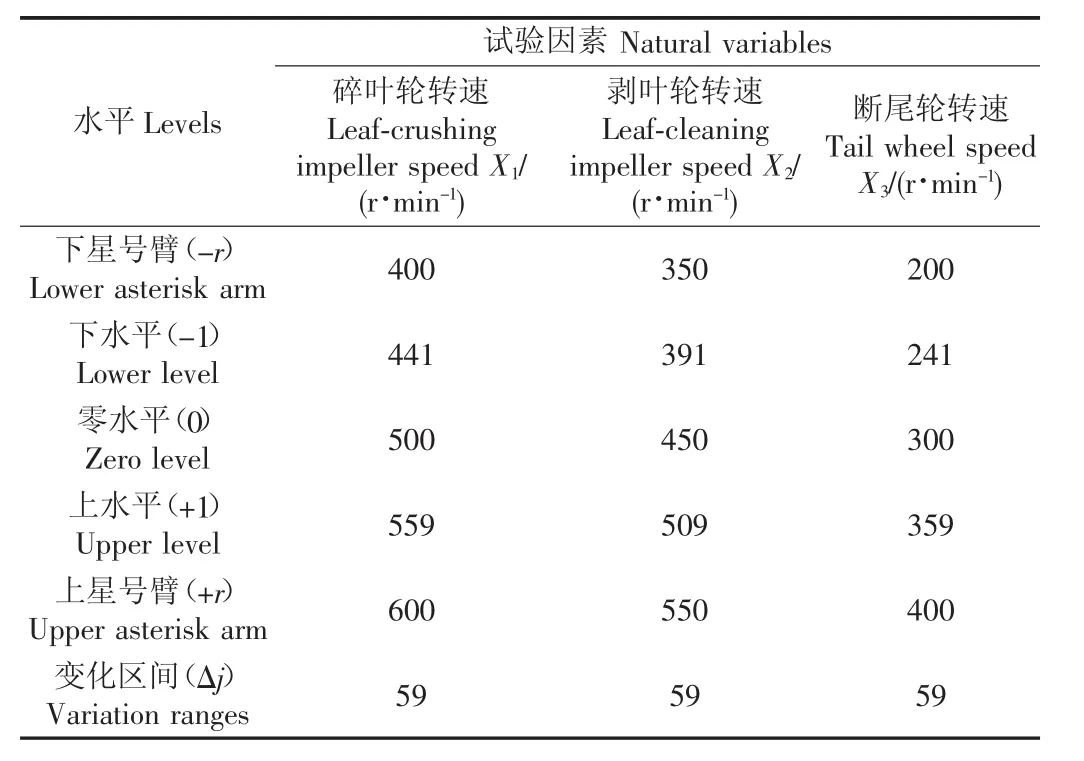

选择碎叶轮转速X1、剥叶轮转速X2与断尾轮转速X3作为试验因素,控制喂入滚筒转速恒定为260 r/min[13],采用三因素二次回归通用旋转组合设计安排试验,试验因素水平编码表如表1所示。试验时,甘蔗由根部分别喂入,每组试验使用6根甘蔗,取其平均值。

表1 因素水平编码表Table 1 Coding levels for factors of experiment

2.3 试验指标

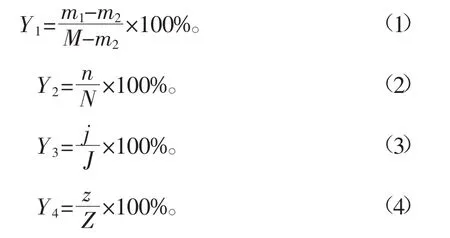

以未剥净率Y1、断尾率Y2、伤皮率Y3和未折断率Y4为考察指标。试验时,先测量甘蔗质量,经过试验台试验后再测量甘蔗的质量,最后手工剥掉残留蔗叶后再测量甘蔗质量[23-24]。

式中m1为经过试验台试验后甘蔗的质量,kg;m2为手工剥掉残留蔗叶后甘蔗的质量,kg;M为试验前甘蔗的质量,kg;n为完成一组试验后成功断尾的甘蔗数,根;N为每组试验所用甘蔗数,根;j为完成一组试验后甘蔗伤皮的节数,节;J为每组试验甘蔗的总节数,节;z为完成一组试验基部未折断的甘蔗数,根;Z为每组试验所用甘蔗数,根。

3 试验结果与分析

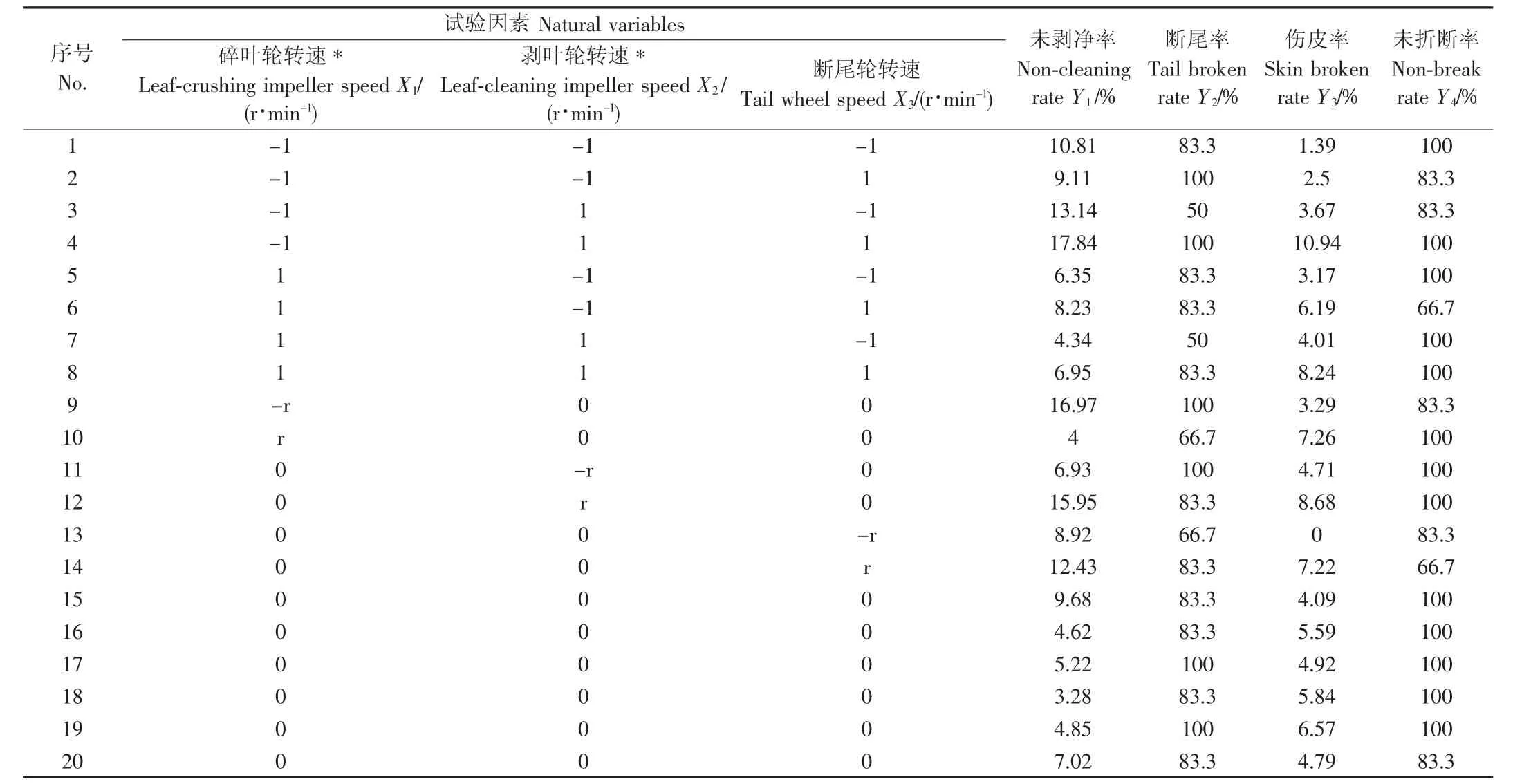

采用SAS9.3分析软件并结合MATLAB优化工具箱对试验数据进行分析,三因素二次通用旋转组合设计试验安排与结果如表2所示。

表2 试验方案及结果Table 2 Experiment scheme and results

3.1 回归方程的建立与检验

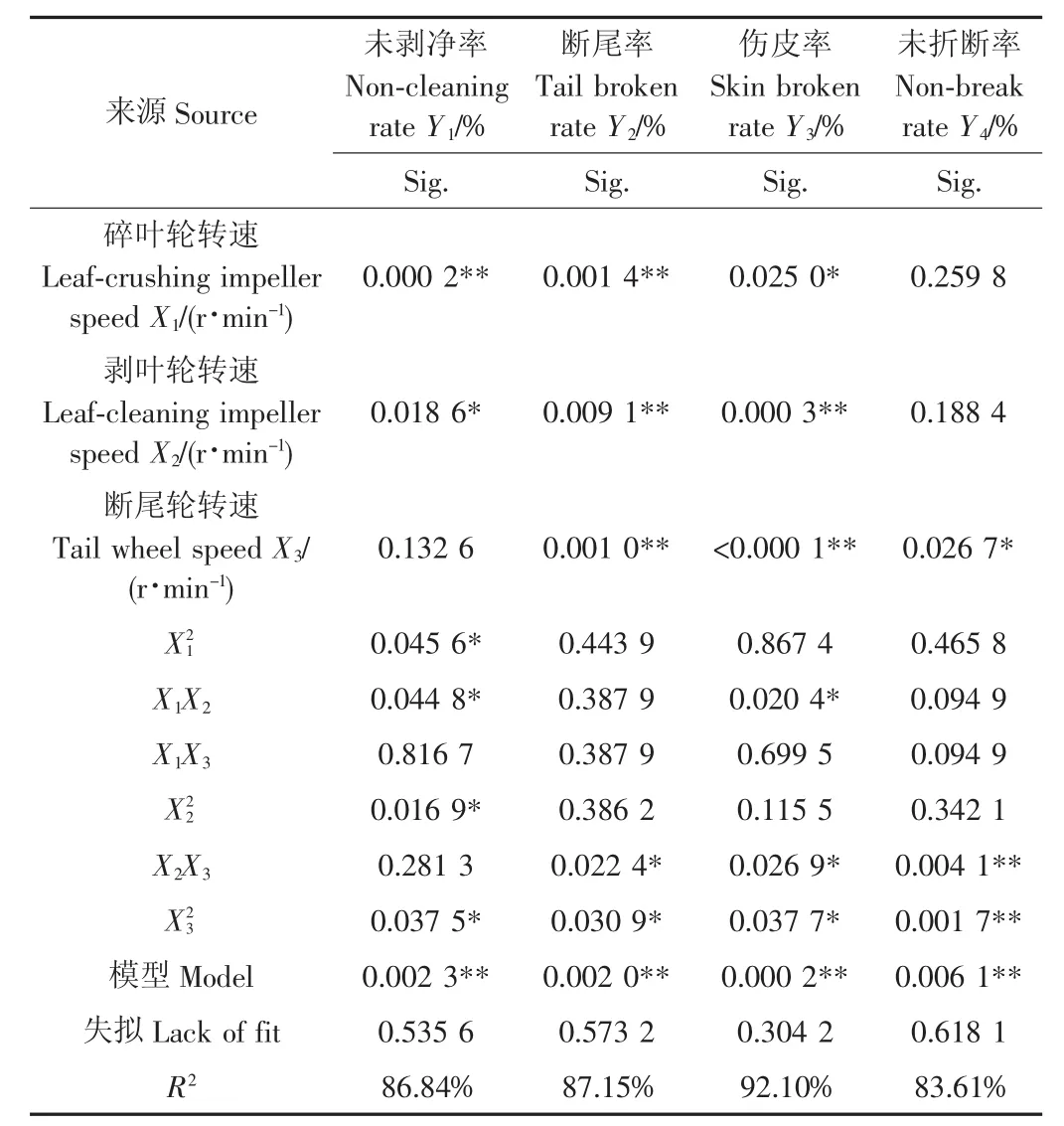

由表2试验结果,运用SAS9.3软件进行统计分析,结果如表3所示。方差分析表明,在99%的置信区间内,对未剥净率Y1影响极显著的因素是X1,而在95%的置信区间内影响显著,模型的P值和复相关指数(R2)分别为0.002 3、86.84%,失拟项的P值为0.535 6,说明回归模型极显著且拟合精度较高;失拟不显著,说明未控制因素对试验结果影响很小,所选的二次回归模型是适当的。同理,对断尾率、伤皮率和未折断率显著性检验可知,回归方程与实际拟合较好。剔除不显著项,简化后的回归方程如表4所示。

表3 试验结果统计分析Table 3 Statistical analysis for results of experiment

表4 响应值回归方程Table 4 Regression equations of response value

3.2 各因素对各项指标影响主次分析

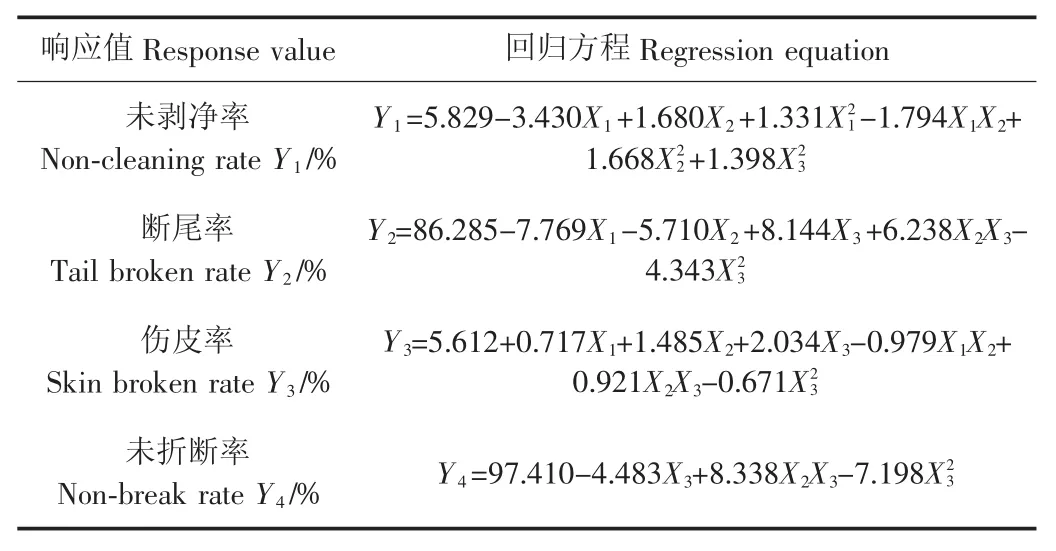

由于试验所建立的回归方程中3个变量均为无量纲的标准化编码值,其偏回归系数不受因素取值的大小和单位的影响,因此可利用其绝对值大小来判定各因子的重要程度[25],另外,回归系数的正负可以反应因子效应对目标函数的作用方向,即正(负)值反应因子的提升有利于提高(降低)试验指标。各因素在试验取值范围内对试验指标的贡献率如表5所示。其中,各试验因子对未剥净率的贡献率依次为:X1>X2>X3;对断尾率的贡献率依次为:X3>X1>X2;对伤皮率的贡献率依次为:X3>X2>X1;对未折断率的贡献率依次为:X3>X2>X1。

3.3 各因素对各项性能指标的影响规律

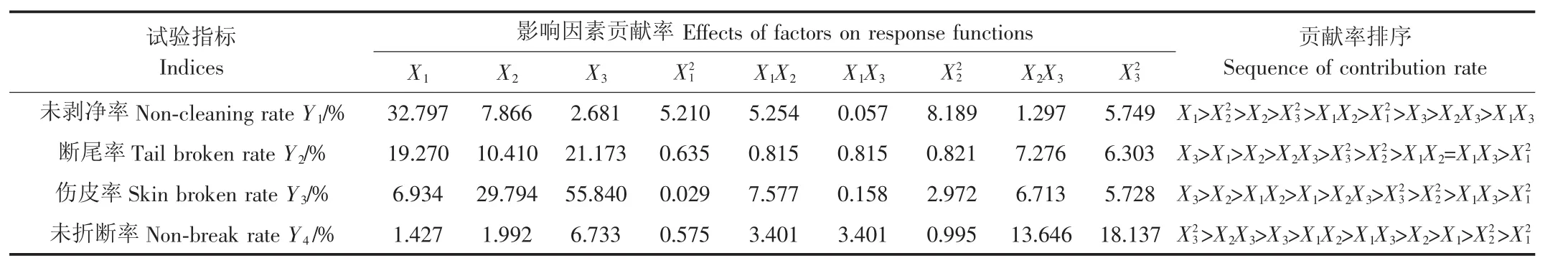

为进一步探讨各因素的单独作用对目标函数的影响效应,对数学模型进行降维分析,分别将三因素中的两因素固定在零水平,即可得到单因素为决策变量的偏回归模型。如图5所示。

表5 各因子对试验指标的贡献率Table 5 Contribution of factors on response indices

3.3.1 未剥净率

由图5a可知,在-1.682≤Xi≤1.682(i=1,2,3)范围内,Xi表征的效应曲线均为开口向上的抛物线,即随着碎叶轮转速X1、剥叶轮转速X2及断尾轮转速X3的增加,未剥净率均表现出先减小后增大的趋势,当碎叶轮转速的编码值为1.29(此时碎叶轮实际转速为576 r/min)时,未剥净率Y1最低为3.62%;当剥叶轮转速的编码值为-0.5(此时剥叶轮实际转速为480 r/min)时,未剥净率Y1最低为5.41%;当断尾轮转速的编码值为0(此时断尾轮实际转速为300 r/min)时,未剥净率Y1最低为5.83%。

3.3.2 断尾率

由图5b可知,在-1.682≤Xi≤1.682(i=1,2,3)范围内,X1、X2表征的效应曲线均为斜率为负的直线,即随着碎叶轮转速X1、剥叶轮转速X2的增加,断尾率均减小,当碎叶轮和剥叶轮转速的编码值为-1.682(此时碎叶轮实际转速为400 r/min,剥叶轮实际转速为350 r/min)时,断尾率Y2最高,分别为99.35%、95.89%;而X3表征的效应曲线为开口向下的抛物线,当断尾轮转速的编码值为0.94(此时断尾轮实际转速为356 r/min)时,断尾率Y2最高为90.10%。

3.3.3 伤皮率

由图5c可知,在-1.682≤Xi≤1.682(i=1,2,3)范围内,X1、X2表征的效应曲线均为斜率为正的直线,即随着碎叶轮转速X1、剥叶轮转速X2的增加,伤皮率均增大,当碎叶轮和剥叶轮转速的编码值为-1.682(此时碎叶轮、剥叶轮实际转速分别为400 r/min、350 r/min)时,伤皮率Y3最低,分别为4.41%、3.11%;而X3表征的效应曲线为开口向下的抛物线,当断尾轮转速的编码值为-1.682(此时断尾轮实际转速为200 r/min)时,伤皮率Y3最低为0.29%。

3.3.4 未折断率

由图5d可知,在-1.682≤X3≤1.682范围内,X3表征的效应曲线为开口向下的抛物线,当断尾轮转速的编码值为-0.31(此时断尾轮实际转速为282 r/min)时,未折断率Y4最高为98.11%。

图5 单因子效应曲线Fig.5 Curves of single factor effect

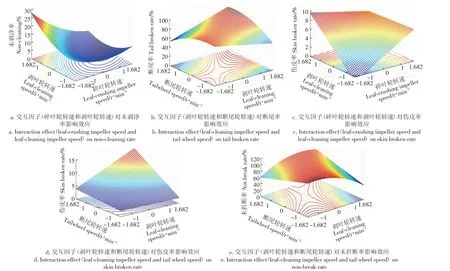

3.4 互作效应分析

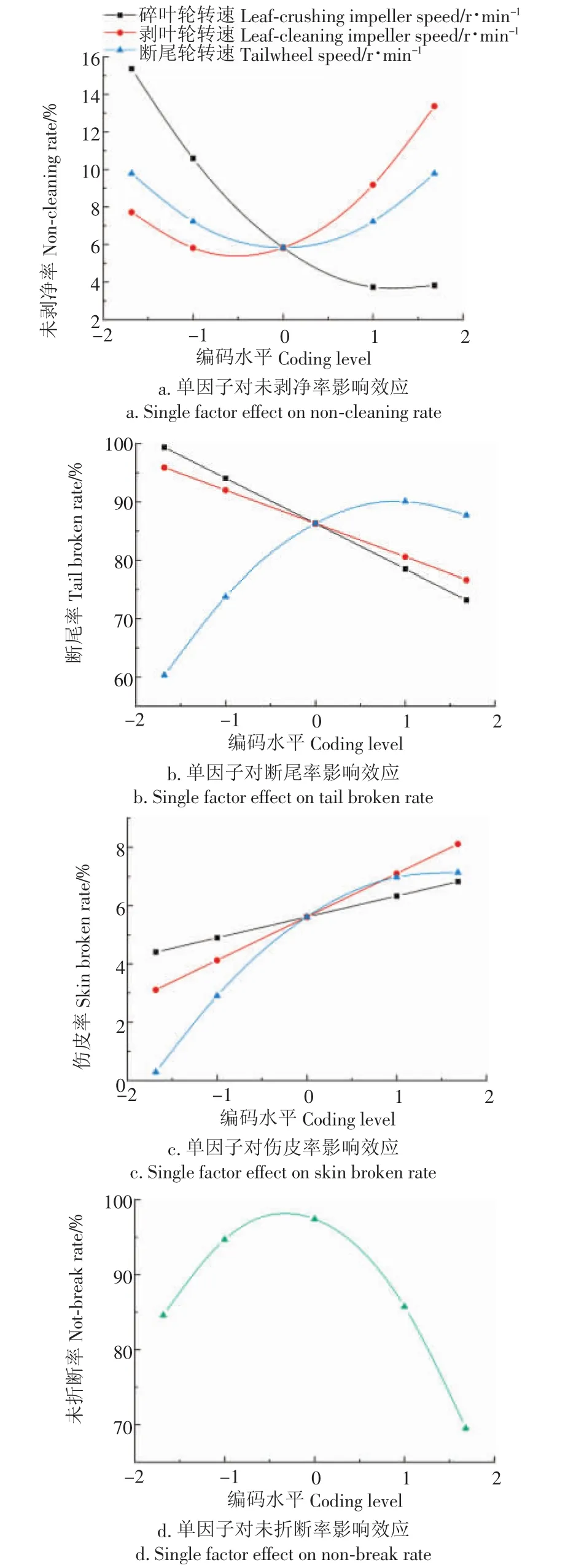

3.4.1 未剥净率互作效应分析

由未剥净率方差分析可知,在ɑ=0.1水平只有X1X2达到显著水平,对其作图如图6a所示。分析可知,随着碎叶轮转速和剥叶轮转速的增加,未剥净率表现出不断降低且逐渐变缓的趋势,这是由于转速的增加可以提高碎叶轮和剥叶轮对甘蔗的作用频率,从而更充分地将蔗叶剥离,且剥叶轮转速对未剥净率的影响强度更大。当碎叶轮转速的编码值在1.5附近、剥叶轮转速编码值在零水平附近时,未剥净率最低。

3.4.2 断尾率互作效应分析

由断尾率方差分析可知,在ɑ=0.1水平只有X2X3达到显著水平,对其作图如图6b所示。分析可知,随着剥叶轮转速X2和断尾轮转速X3的增加,断尾率表现出先降低后增加的趋势,但均维持在较高水平。在较低的断尾轮转速下,断尾率随剥叶轮转速的升高反而降低,这是因为剥叶轮对甘蔗有辅助输送功能,提高剥叶轮转速会加快甘蔗的传送速度,从而降低断尾轮对甘蔗的打击频率,造成断尾率降低。

3.4.3 伤皮率互作效应分析

X1X2、X2X3在ɑ=0.1水平达到显著水平。其中,X1X2互作效应情况如图6c所示。分析可知,随着碎叶轮转速X1和剥叶轮转速X2的降低,伤皮率逐渐下降,这是由于转速的降低减少了碎叶轮和剥叶轮对甘蔗打击疏刷的频率和作用力,伤皮率的最小值理论上可降至0%。X2X3互作效应情况如图6d所示,分析可知,剥叶轮转速X2和断尾轮转速X3的互作效应对伤皮率的表现和X1X2的表现类似,这说明降低剥叶轮和断尾轮转速也可有效减少作业过程中对甘蔗的破坏。

3.4.4 未折断率互作效应分析

由未折断率方差分析可知,X1X2、X1X3互作效应在ɑ= 0.1水平均不显著,但X2X3达到极显著水平,对其作图如图6e所示。分析可知,随着剥叶轮转速X2和断尾轮转速X3的增加,未折断率表现出先降低后增加的趋势,但均维持在较高水平。剥叶轮和断尾轮转速相差越大则未折断率越低,当剥叶轮转速过高而断尾轮转速过低时,容易造成甘蔗的挤压和堵塞,当剥叶轮转速过低而断尾轮转速过高时则又会导致断尾轮对甘蔗的打击频率增大,并伴随两者对甘蔗的撕扯作用,这两种情况均会增大甘蔗折断的几率。

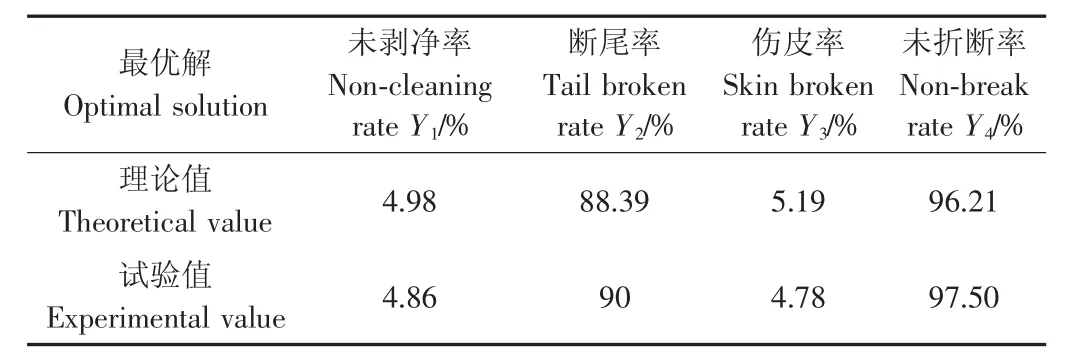

4 参数优化与验证试验

4.1 试验台参数优化

在实际生产过程中,未剥净率和断尾率对榨糖用甘蔗出糖品质的影响要远远大于伤皮率和未折断率的影响,机械化收获的甘蔗一般要求在收获后20 h内进厂加工,以保证足够的新鲜度[26],因此可适当降低对伤皮率和未折断率的要求。采用综合平衡法来分析最优参数组合,在保证较优的未剥净率和断尾率水平下,尽量降低伤皮率,利用MATLAB在-1.682≤Xi≤1.682(i=1,2,3)范围内寻找试验台作业过程中的综合最优工作参数为:X1=0.218,X2=-0.582,X3=0.118,即试验台碎叶轮转速为512.9 r/min,剥叶轮转速为418.8 r/min,断尾轮转速为307.0 r/min时,未剥净率达到4.98%,断尾率为88.39%,伤皮率为5.19%,未折断率为96.21%。

4.2 试验验证

为了验证最优工作参数的有效性,选用40根甘蔗进行验证试验,试验过程如图7所示,试验后分析计算各试验指标,结果如表6所示。

图6 因子交互作用图Fig.6 Interaction effects of factors

图7 试验台验证试验Fig.7 Verification experiments of test bench

表6 验证试验结果Table 6 Results of verification experiments

对比综合最优解的理论值和试验值,试验结果和理论值基本相符。因此,由本试验台试验分析得出的综合最优结果正确可信,可有效提高甘蔗碎叶、剥叶和断尾质量。

4.3 讨 论

1)碎叶轮的主要作用是在剥叶工序前将蔗叶划碎并且不损伤蔗皮,保证后续的剥叶作业顺利进行,两级碎叶轮和剥叶轮的协同作用有利于降低未剥净率。

2)过低或过高的转速会导致未剥净率升高,这是由于较低的转速会削弱各作业部件的作用力和作用频率,而较高的转速则又会导致作业不彻底。

3)碎叶轮和剥叶轮、剥叶轮和断尾轮之间转速的相对值对试验指标均会造成影响,各滚筒转速差太大会增大对甘蔗的挤压或撕扯作用并最终导致试验指标不理想。因此,协调好两者之间的速度关系对改善试验指标十分重要。

4)各作业部件在作业过程中对甘蔗还具有辅助输送的作用。

5)试验台的工作效率取决于各工作部件之间的协同作用。

5 结论

1)各因素对未剥净率的影响贡献率依次为:碎叶轮转速、剥叶轮转速、断尾轮转速;对断尾率的影响贡献率依次为:断尾轮转速、碎叶轮转速、剥叶轮转速;对伤皮率的影响贡献率依次为:断尾轮转速、剥叶轮转速、碎叶轮转速;对未折断率的影响贡献率依次为:断尾轮转速、剥叶轮转速、碎叶轮转速。

2)未剥净率与碎叶轮转速、剥叶轮转速和断尾轮转速的因子效应曲线均为开口向上的抛物线;断尾率与碎叶轮转速和剥叶轮转速的单因子效应关系为斜率为负的直线,与断尾轮的单因子效应曲线为开口向下的抛物线;伤皮率与碎叶轮转速和剥叶轮转速的单因子效应关系为斜率为正的直线,与断尾轮的单因子效应曲线为开口向下的抛物线;碎叶轮转速和剥叶轮转速对未折断率的影响不显著,而断尾轮转速对未折断率有显著影响,其单因子效应曲线为开口向下的抛物线。

3)最优参数组合为:碎叶轮转速为512.9 r/min、剥叶轮转速为418.8 r/min、断尾轮转速为307.0 r/min,此时未剥净率达到4.98%,断尾率为88.39%,伤皮率为5.19%,未折断率为96.21%;试验验证结果与理论分析一致。

[1]韦巧,杨宝玲,高振江,等.我国甘蔗产业化现状浅析[J].农机化研究,2015,4(4):247-254.Wei Qiao,Yang Baoling,Gao Zhenjiang,et al.Analysis of current situation of sugar cane industry[J].Journal of Agricultural Mechanization Research,2015,4(4):247-254.(in Chinese with English abstract)

[2]Michael E S,Lonnie P C.A spreadsheet-based cost model for sugarcane harvesting systems[J].Computers and Electronics in Agriculture,1998,20(3):215-227.

[3]肖宏儒,王明友,宋卫东,等.整秆式甘蔗联合收获机降低含杂率的技术改进与试验[J].农业工程学报,2011,27(11):42-45.Xiao Hongru,Wang Mingyou,Song Weidong,et al.Experiments and technology improvement on reducing trash content of whole stalk sugarcane harvest[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2011,27 (11):42-45.(in Chinese with English abstract)

[4]程绍明,王俊,王水维.我国整杆式甘蔗联合收割机的现状和问题[J].现代农业科技,2013(20):193-194.Cheng Shaoming,Wang Jun,Wang Yongwei.Study on status and problems of whole stalk sugarcane combine harvest in China [J].Modern Agricultural Science and Technology,2013(20): 193-194.(in Chinese with English abstract)

[5]刘芳建,狄明利,米义,等.各级转速受控式甘蔗剥叶装置的设计与试验[J].农机化研究,2014,(11):168-171.Liu Fangjian,Di Mingli,Miyi,et al.Design and experimental study of sugarcane leaf-stripping device which the rotate speed of every roller was in control[J].JournalofAgricultural Mechanization Research,2014(11):168-171.(in Chinese with English abstract)

[6]沈中华,李尚平,麻芳兰,等.小型甘蔗收获机喂入能力仿真与试验[J].农业机械学报,2014,45(11):117-123.Shen Zhonghua,Li Shangping,Ma Fanglan,et al.Simulation and experiment on feed ability of small sugarcane harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010,41(12):48-53.(in Chinese with English abstract)

[7]陈超平,阳慈香,杨丹彤,等.甘蔗机械化收获系统的试验与分析[J].华南农业大学学报,2009,30(3):107-109.Chen Chaoping,Yang Cixiang,Yang Dantong,et al.Experiments and analysis on mechanized harvesting system of sugarcane[J]. Journal of South China Agricultural University,2009,30(3): 107-109.(in Chinese with English abstract)

[8]刘志华,林茂.甘蔗收割机剥叶元件的优化研究[J].机械设计与制造,2015,(2):253-256.Liu Zhihua,Lin Mao.Optimization of sugarcane harvester detrashing elements[J].Machinery Design&Manufacture,2015, (2):253-256.(in Chinese with English abstract)

[9]牟向伟,区颖刚,吴昊,等.甘蔗叶鞘在弹性剥叶元件作用下破坏高速摄影分析[J].农业机械学报,2012,43(2):85-89.Mou Xiang wei,Ou Ying gang,Wu Hao,et al.Damage of sugarcane leaf sheath under action of elastic leaf-stripping elements based on high-speed photography[J].Transactions of the Chinese Society for Agricultural Machinery,2012,43(2): 85-89.(in Chinese with English abstract)

[10]麻芳兰,韦荣发,王海波,等.小型整杆式甘蔗收割机剥叶系统功耗试验研究[J].农机化研究,2015(4):163-167.Ma Fanglan,Wei Rongfa,Wang Haibo,et al.Experimental study on power consumption of the leaf-stripping system of small whole-stalk sugarcane harvester[J].Journal of Agricultural Mechanization Research,2015(4):163-167.(in Chinese with English abstract)

[11]孔林,周德俭,谌炎辉,等.新型小型甘蔗剥叶机剥叶机构设计与优化[J].中国农机化学报,2015,36(2):124-127.Kong Lin,Zhou Dejian,Chen Yanhui,et al.Design and optimization of the leaf cleaning element for new small-scale sugarcane leafcleaner[J].Journal of Chinese Agricultural Mechanization,2015,36(2):124-127.(in Chinese with English abstract)

[12]罗春周,李尚平,麻芳兰,等.整杆式小型甘蔗收割机蔗叶分离的试验研究[J].农机化研究,2015,37(2):181-185.Luo Chunzhou,Li Shangping,Ma Fanglan,et al.The whole small sugarcane harvester sugarcane leaf separation mechanism of the experimental Research[J].Journal of Agricultural Mechanization Research,2015,37(2):181-185.(in Chinese with English abstract)

[13]胡金冰.甘蔗收割后集成作业系统结构设计与作业速度仿真优化[D].杭州:浙江大学,2015.Hu Jinbing.Design and Simulation Optimization on Integrated Operating System AfterSugarcane Harvest[D].Hangzhou: Zhejiang University,2015.

[14]牟向伟,区颖刚,刘庆庭,等.弹性齿滚筒式甘蔗剥叶装置[J].农业机械学报,2012,343(4):60-65.Mou Xiangwei,Ou Yinggang,Liu Qingting,et al.Elastic dentation rollertype sugarcane leaf-stripping device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012,343(4):60-65.(in Chinese with English abstract)

[15]麻芳兰,蒋红梅,李尚平,等.整秆式甘蔗收获机剥叶断尾机构设计与试验[J].农业机械学报,2012,43(6):73-78.Ma Fanglan,Jiang Hongmei,Li Shangping,et al.Design and experiment on cleaning leaves and breaking tails mechanism of whole-stalk sugarcane harvester[J].Transactions of the Chinese Society for Agricultural Machinery,2012,43(6):73-78.(in Chinese with English abstract)

[16]罗菊川,区颖刚,刘庆庭,等.整秆式甘蔗联合收获机断蔗尾机构[J].农业机械学报,2013,44(4):89-94.Luo Juchuan,Ou Yinggang,Liu Qingting,et al.Tail-breaking mechanism of whole stalk sugarcane combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013,44(4):89-94.(in Chinese with English abstract)

[17]刘芳建,耿明利,米义,等.甘蔗逆剥剥叶方式的试验研究[J].农机化研究,2015(1):174-176.Liu Fangjian,Di Mingli,Mi Yi,et al.Experimental study of inverse-stripping of sugarcane leaf-stripping Device[J].Journal of Agricultural Mechanization Research,2015(1):174-176.(in Chinese with English abstract)

[18]吴剑锋.整秆式甘蔗收割机断尾机构的虚拟仿真分析与设计[D].杭州:浙江大学,2014.Wu Jianfeng.Virtual Simulation Analysis and Design on Tailbreaking Mechanism of Whole-stalk Sugarcane Harvester[D].Hangzhou:Zhejiang University,2014.

[19]卢志乐.一种甘蔗碎叶装置[P].中国专利:201120110255.5,2011-12-14.

[20]程绍明,王俊,卢志乐,等.小型整秆式甘蔗收割机改进设计与试验[J].农业工程学报,2014,30(4):12-17.Cheng Shaoming,Wang Jun,Lu Zhile,et al.Revised design and experiment on small-sized whole-stalk sugarcane harvester[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2014,30(4):12-17.(in Chinese with English abstract)

[21]麻芳兰,李尚平,何玉林,等.基于神经网络的甘蔗收获机剥叶元件性能研究[J].农业机械学报,2006,37(7):69-73.Ma Fanglan,Li Shangping,He Yulin,et al.Performance analysis on cleaning element of sugarcane harvester based on neural network[J].Transactions of the Chinese Society for Agricultural Machinery,2006,37(7):69-73.(in Chinese with English abstract)

[22]吴剑锋,程绍明,王俊,等.整杆甘蔗各部位切割力和糖度的差异性及二者间相关性试验研究[J].中国农机化学报,2014,35(6):196-198,151.Wu Jianfeng,Cheng Shaoming,Wang Jun,et al.Cutting force and brix content differences in all parts of the whole stalk sugarcane and their correlation research[J].Journal of Chinese Agricultural Mechanization,2014,35(6):196-198,151.(in Chinese with English abstract)

[23]GB/T 10499-2014.糖料甘蔗试验方法[S].

[24]JB/T 6275-2007.甘蔗收获机械试验方法[S].

[25]徐中儒.回归分析与试验设计 [M].北京:中国农业出版社,1998:140-156.

[26]林红辉,赖荣光,曾志强,等.甘蔗机械化收获技术规范[J].中国热带农业,2012(3):74-76.

Design and speed optimization of leaf-crushing and tail-breaking system of sugarcane harvester

Xie Luxin,Wang Jun※,Cheng Shaoming,Hu Jinbing

(College of Biosystems Engineering and Food Science,Zhejiang University,Hangzhou 310058,China)

As the most important procedures during sugarcane harvesting,leaves cleaning and tails severing are influenced by different growth height and lodging status,and the operating speeds of the rollers not only affect the operating efficiency of the sugarcane harvester,but also influence the quality of harvesting.In order to investigate the effect laws on the quality of peeling leaves and breaking tails of leaf-crushing impeller,leaf-cleaning impeller and tail wheel,the leaf-crushing and tail-breaking system was designed and manufactured for sugarcane harvester test bench after sugarcane harvesting.In the system,elastic wire springs were arranged uniformly on the leaf-crushing impellers,the outer edge of the leaf-cleaning impeller were installed with rubber plates,and the severing tail components on the tail wheels were elastic rib.As the test bench works,the rolling leaf-crushing impeller,leaf-cleaning impeller and tail wheel lacerated and peeled leaves attached tightly on the canes by producing centrifugal and frictional force.According to the mechanical properties that antideformation and impact resistance of the tails were significantly lower than other parts,the anti-float mechanism was designed for breaking tails,the groove of the circular arc can prevent the lateral movement and ensure the smooth transportation of the sugarcane.The experiments of peeling leaves and breaking tails of sugarcanes were conducted in Zhejiang University,2015.A quadratic general rotary unitized design was carried out with leaf-crushing impeller speed, leaf-cleaning speed and tail wheel speed as experimental factors,and with non-cleaning rate,tail broken rate,skin broken rate and non-break rate as experiment indices.By using SAS 9.3 regression analysis method,response surface method and combined with nonlinear optimization calculation method,the working parameters were calculated optimally,and the optimal factor combination was established.The results indicated that,the tail-broken rate and skin broken rate were influenced by the speeds of the three impellers significantly,however,the non-break rate was influenced by the speed of tail wheel only,but it had no effect on the non-cleaning rate.The contribution rate order of non-cleaning rate was leaf-crushing impeller speed,leaf-cleaning speed and tail wheel speed.The contribution rate order of tail broken rate was tail wheel speed,leaf-crushing impeller speed and leaf-cleaning speed.The contribution rate order of skin broken rate was tail wheel speed,leaf-cleaning speed and leaf-crushing impeller speed.The contribution rate order of non-break rate was tail wheel speed,leaf-cleaning speed and leaf-crushing impeller speed.The optimum parameter combination of the test bench after optimization was 512.9 r/min of leaf-crushing impeller speed,418.8 r/min of leaf-cleaning speed and 307.0 r/min of tail wheel speed.At this level,non-cleaning rate achieved theoretical optimum value of 4.98%,tail broken rate was 88.39%, skin broken rate was 5.19%and non-break rate was 96.21%.Verification experiment showed that the experimental value of non-cleaning rate was 4.86%,tail broken rate was 90%,skin broken rate was 4.78%and non-break rate was 97.5%,which indicated that the experimental values were consistent with predicted results,and regression models established by the experiment were appropriate,which can provide references to design whole-stalk sugarcane harvester and improve the harvesting quality.

mechanization;optimization;models;sugarcane;non-cleaning rate;tail broken rate;skin broken rate;nonbreak rate

10.11975/j.issn.1002-6819.2016.06.007

S225.5+3

A

1002-6819(2016)-06-0050-08

2015-10-12

2016-01-27

公益性行业(农业)科研专项经费项目(201003009-8)

谢卢鑫,男,云南曲靖人,博士生,主要从事经济作物收获机械研究。杭州 浙江大学生物系统工程与食品科学学院,310058。

Email:xlx123@zju.edu.cn

※通信作者:王俊,男,浙江东阳人,教授,博士生导师,主要从事经济作物种植与收获机械研究。杭州 浙江大学生物系统工程与食品科学学院,310058。Email:jwang@zju.edu.cn

中国农业工程学会会员:王俊(10 013)