欧盟馆3D打印立面,阿姆斯特丹,荷兰

建筑设计:DUS建筑事务所

Architect: DUS Architects

欧盟馆3D打印立面,阿姆斯特丹,荷兰

3D Printed Façade for the EU Building, Amsterdam, the Netherlands, 2016

建筑设计:DUS建筑事务所

Architect: DUS Architects

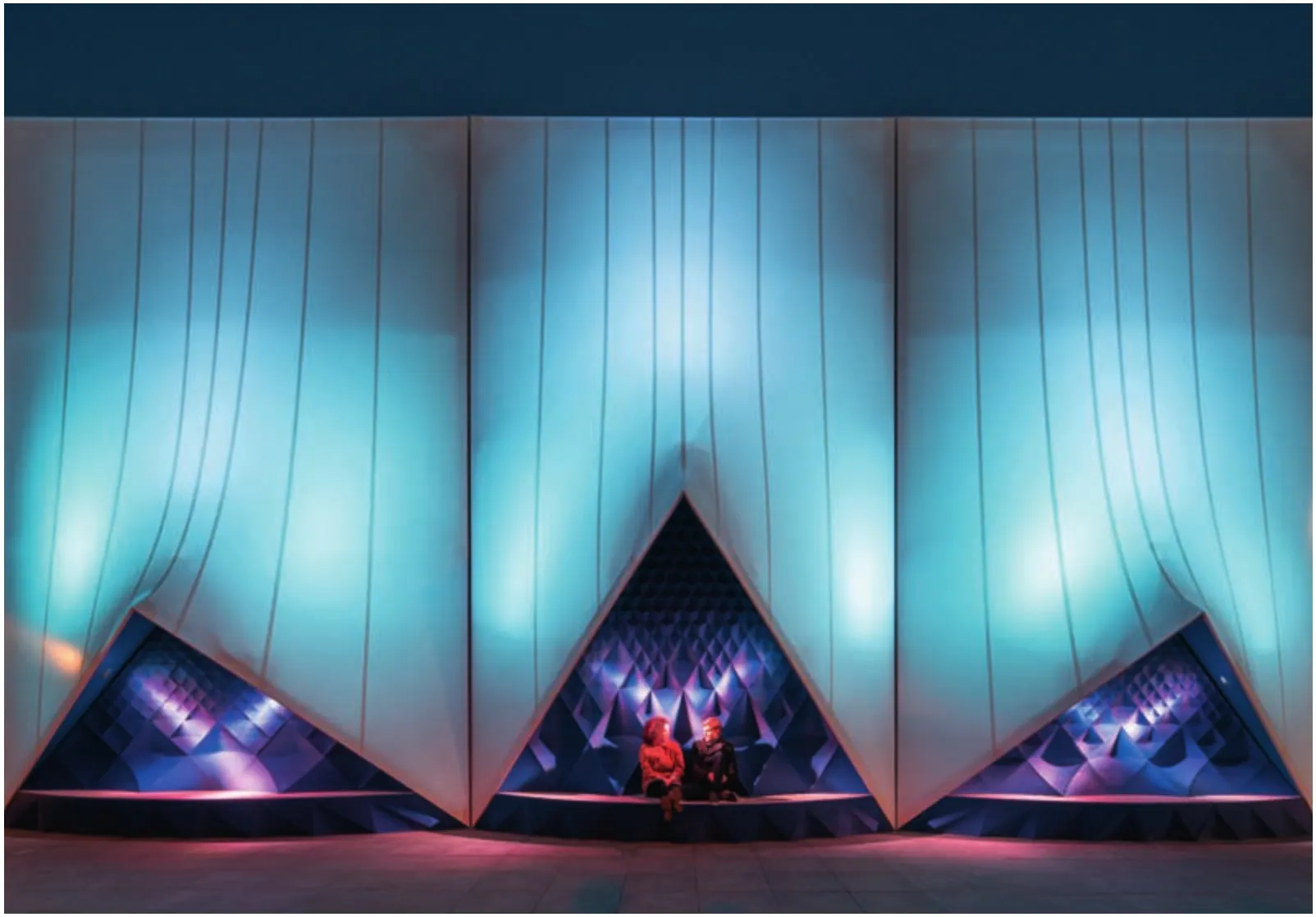

1 外景/Exterior view

DUS建筑事务所利用大尺度的生物塑料3D打印技术,实现了荷兰2016年欧盟轮值主席国展馆的立面设计。

2016年1月开始的半年内,荷兰出任欧盟轮值主席国,欧盟馆位于阿姆斯特丹运河河畔(海运区)。欧洲的政治家相聚在这座为该活动特殊制造的临时性“欧洲建筑”当中。DUS建筑事务所设计的入口立面夺人眼球,该立面由一种生物塑料制成的独特3D打印构件组装而成,轮值工作结束后可以全部回收利用。

历史上的帆船制造和数字制造

该区域曾是帆船制造基地,建筑船帆型的入口则来源于此。壁龛样的凹型空间将“欧盟蓝”的3D打印长椅笼罩。印制出的装饰图案从大到小,由圆至方,彰显了欧盟的联合与多样性。每到夜晚,船帆会被跳跃变化的灯光逐渐点亮。

特特大尺度的3D打印

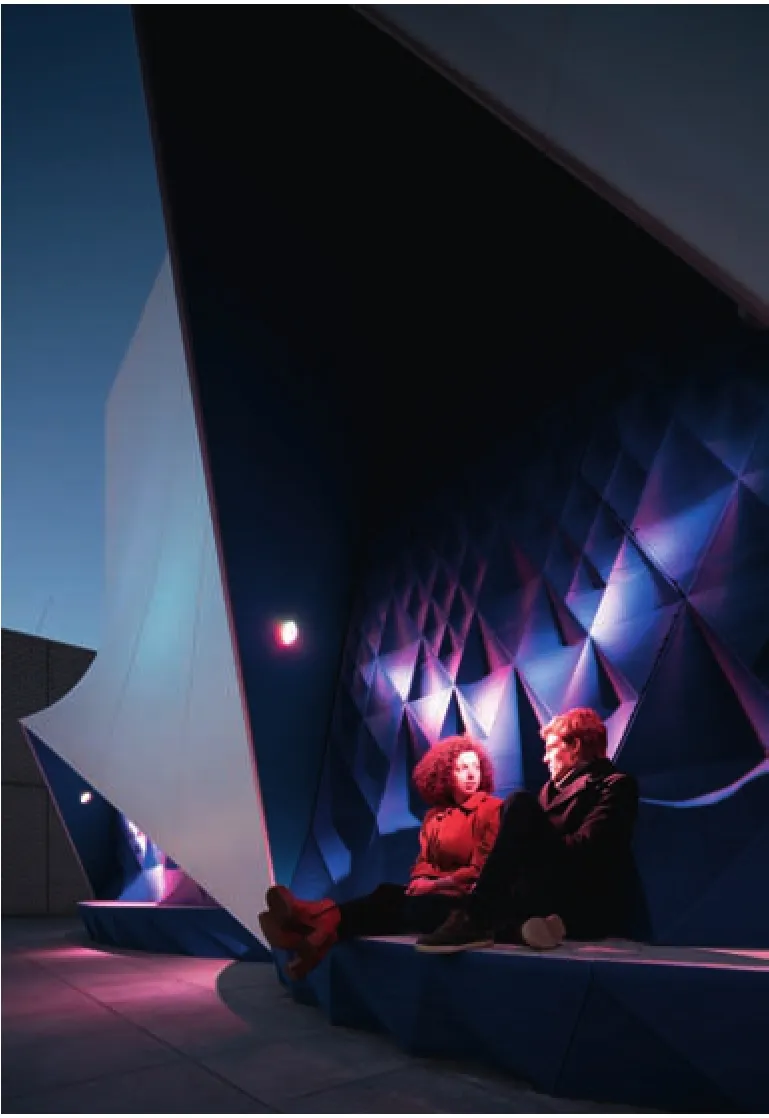

所有座位均为参数化设计并且与壁龛空间完美契合在一起。这个特意为轮值工作自主研发的示范性模型,在阿姆斯特丹运河畔运用特特大3D打印机打印。真人大小的打印机可以制造出尺寸为2m×2m×3.5m的建筑构件。构件由自主研发的特殊生物塑料制成,座位表面用浅色的混凝土填充。生物塑料在轮值工作结束后可以被粉碎并再次进行。这种3D打印技术在公共领域的应用在世界尚属打印首次。(天妮 译)

2 立面侧面/Elevation profile

项目信息/Credits

该项目是与3D打印技术协作产生的首例商业衍生品:由DUS建筑事务所及合伙人自主研发。项目的3D打印构件由Actual有限公司生产完成。Actual有限公司位于阿姆斯特丹,致力于将大尺度3D打印与建筑构件相链接及线上定制软件的研发。立面在极短的时间跨度内研发完成,要感谢以下各方之间的紧密合作:DUS事务所(设计)、Actual(参数化研发和3D打印)、海王集团(临时结构)、TenTech(工程)、德国汉高(材料研发)、飞利浦(照明)以及曼斯(施工和装配)。以创新为导向的曼斯建筑公司是该项目的特约合作者。

Te project is the first commercial by-product caused by the collaborations on the 3D Print Canal House: an initiative of DUS architects and partners. The production of the 3D prints has been done by Actual, an Amsterdam-based start-up that develops online customizing software for building elements linked to XL 3D printing. Te facade has been developed in a very short time period thanks to the close collaboration between various parties: DUS (design), Actual (parametricdevelopment & 3D printing), Neptunus (temporary structures), TenTech (engineering), Henkel (material development), Philips (light), and Heijmans (construction and assembly). Heijmans, an innovationdriven building company, is a special partner of this project.摄影/Photos: Ossip van Duivenbode

3 日景/Day view

4 夜景/Night view

DUS architects produced façade design with large scale bio-plastic 3D prints for the Dutch EU Presidency 2016.

The EU Presidency takes place in the Netherlands for half a year starting January 2016 at the Amsterdam Marineterrein (Marine Area). Here European politicians gather in the mobile 'Europe Building' constructed especially for this event. Eye catcher is the entrance façade designed by DUS architects, which consists of unique 3D printed elements made of bio-plastic that can be fully recycled after the presidency is over.

Historical sailing ships and digital fabrication

The entrance of the building is partially constructed with playfully shaped sails that refer to the historical sailing ships once built in this area. Tis creates alcoves, which house EU-blue coloured 3D-printed benches. Te printed patterns build up from large to small and round to square and depict the variety and community of the EU countries. At night the sails are lit gradually with a pulsing light.

XXL 3D printing

Every seating element is parametrically designed and fits perfectly within each alcove. Tey are prototypes developed especially for the EU presidency, and printed locally with the XXL 3D printer of the 3D Print Canal House in Amsterdam. This life-size printer can print component with size up to 2m × 2m × 3.5m. Te prints are made of a specially developed bio-plastic and the seating surfaces are filled with light-coloured concrete. Te bio-plastic can be shredded and reprinted after the presidency is over. Tis is the first time in the world that these kinds of XXL 3D prints are being shown in the public domain.

5 日景局部/Te detail during the day

6 夜景局部/Te detail at night

评论

龙灏:在当代技术条件下,建筑可以用“打印”的方式来建造,“临时建筑”的立面形象及其材料变得看上去不那么“临时”了,造型的精致与特别也变得非“手工建造”时代所能比拟。然而,这算是一种怎样的进步?生物塑料、3D打印、循环利用,这些看上去颇为炫目又体现可持续发展与“生物准则城市”目标的辞藻背后,对建筑学或建筑设计的本质意义是什么?是充实了内涵还是拓展了外延?用这些新材料和建造方式完成的建筑(立面)与用竹、木、天然材料纺织品、甚至石头等等天然或其他已有的生物可降解材料来完成有什么本质区别?这些追问,也许会有助于“建筑学”这个与人类历史一样长的古老学科更加冷静地面对可能会成为未来热点的“生物准则城市”、思考自己未来的路径。

林波荣:这一项目是环保理念、先进科技和地域性建筑美学完美结合的典范。建筑外立面饶有趣味,白色风帆、建筑材料的质地以及外立面的曲线令整座建筑看起来十分轻盈;入夜后,建筑与灯光效果相搭配,彰显出现代科技美。特别吸引人的是,外立面的许多构件是用一种高弹力、高强度的织物和3D打印的生物塑料作为主要材料、通过3D打印完成的。其3D打印图案,或大或小,或圆或方,彰显了世界领先科技、以及独特的建筑文化——即欧盟的联合与多样性。这种特殊的生物塑料,由亚麻籽油制成,具有易处理、循环利用等优势。个人认为,在建筑上使用3D打印,能耗低,运输成本相应减少,而且整个建筑可以轻易地拆除、回收,这将彻底改变我们建设城市的方式,对于展览性临时建筑有广阔应用前景。

Comments

L ONG Hao: In the environment of modern technology, architecture can be built by 'printing', the façades and materials of 'temporary buildings' don't seem so 'temporary', the delicacy and particularity of forms also reached a level that 'manual construction' era cannot reach. However, what kind of a progress is this? Bio-plastics, 3D printing, circulation, behind these seemingly dazzling terms that embody the goals of sustainable development and 'bioprincipled city', what's the essential meaning of this for architecture or architectural design? Enriching the intension or expanding the extension? What's the basic difference between architecture façades built by these new materials and methods, and the ones built with bamboos, woods, natural textiles, stones or other existing biodegradable materials? Tese questions may be helpful for 'architecture', an ancient subject as old as human history, to more calmly face the next possible hot spot 'bioprincipled city', and think about its own future path. (Translated by CHEN Yuxiao)

LIN Borong: This project is a paradigm for the comprehensive unification of environmental awareness, advance technology with regionalism architecture. The delightful façade with its white sail shape, selected building material and external curvature, contribute to a lightness of the building itself. At the fall of night, the building and its lighting effect compensate each other, expressing the beauty of modern technology prominently. Many of the façade components are especially attractive. They are 3D printed components made from a type of bioplastic reinforced tensile fabric. Its diversified 3D printed patterns and varies sizes represents not only the most advanced technological achievements but also the unique culture of diversity along unity within the Europe Union. This special material is entirely biobased, made from linseed oil with feasibility for treatment and recyclable. In my perspective, utilising 3D printing technology in architecture on one hand brings lower energy consumption as well we transportation cost, on the other hand, the entire architecture could be easily disassembled and recycled. This will ultimately transform our construction method for the city, and bears a broad scope of future application for temporary exhibition architecture. (Translated by LUO Dan)