聚乳酸改性及其在包装材料中的应用

吕培 马丕明 东为富 王如寅

(1.江南大学化学与材料工程学院;2.道达尔科比恩聚乳酸有限公司)

聚乳酸改性及其在包装材料中的应用

吕培1马丕明1东为富1王如寅2

(1.江南大学化学与材料工程学院;2.道达尔科比恩聚乳酸有限公司)

聚乳酸(PLA)是一种具有高强度、高模量、透明性、生物降解性和生物相容性的生物基热塑性聚酯,已发展成为具有一定竞争力的商业化材料,并有望在包装领域逐步替代传统的石油基聚合物。然而,PLA的应用却受其本身固有的结晶速率慢、结晶度低和脆性大等缺点的限制。近年来,研究人员做了大量工作以解决PLA的上述技术瓶颈。本文综述了PLA在成核结晶与增韧改性领域的研究进展以及PLA在包装材料中的应用。

聚乳酸 成核结晶 增韧 包装

1.前言

目前,世界塑料年产量已超过3亿吨[1],塑料在许多方面使人类受益,推动了社会和科技的发展。然而,大量源于化石资源的使用加剧了全球变暖、环境污染和资源不可持续等诸多社会问题。因此,学术界和产业界正大力发展可再生聚合物[2]。在几种商用生物基热塑性聚合物中,聚乳酸(PLA)受到了广泛关注。

PLA是来自可再生资源的可生物降解和生物相容性的聚合物[3-6],可以通过丙交酯开环聚合或乳酸单体缩聚合成[7-9]。2014年,PLA在全球市场的使用量达12万吨,并且每年以20%-30%的速度增长,预计到2020年将达到30-50万吨。PLA作为一种环境友好型聚合物,由于其高模量、高强度和良好的透明度,在包装领域展现出良好的应用前景。另一方面,PLA的发展在一定程度上受其结晶速率慢、结晶度低和脆性大等固有缺陷的制约[10,11]。例如,由于结晶速率慢和结晶度低导致PLA的热变形温度只有大约55℃,这严重限制了其应用,尤其是在热包装或耐热制品领域的应用[12]。研究表明,添加成核剂可以加速PLA的结晶速率,增加其结晶度,进而提高热变形温度,这是目前提高PLA耐热性最为有效的手段之一。其次,为了克服聚乳酸固有的脆性,研究者对其进行了增塑、共聚和共混改性以制备柔韧的PLA材料[13]。本文综述了PLA在成核结晶与增韧改性领域的研究进展以及PLA在包装材料领域的应用,并对聚乳酸的发展前景提出了展望。

2.聚乳酸的结晶改性

如上所述,PLA结晶速率和结晶度低,影响了其耐热性。目前,提高PLA结晶速率和结晶度的方法主要包括提高PLA的光学纯度、退火处理和添加成核剂[14-18]。其中,添加成核剂方法简单,而且可有效降低PLA的成核诱导期、提高晶核密度,最终提高PLA的结晶速率和结晶度。

2.1 无机成核剂对PLA结晶行为的影响

实用且成本较低的无机成核剂被广泛应用于PLA。滑石粉是PLA的一种有效成核剂,常作为参照用于衡量其他成核剂的成核能力[17-22]。An等人[17]发现滑石粉在PLA中分散均匀并具有异相成核的作用,添加3wt%滑石粉,PLA的结晶度从2.7%增加到36.2%。Shakoor等人[23]在PLA复合材料中采用滑石粉作为成核剂和补强剂,发现PLA冷结晶温度从127℃降低到96℃,结晶度从2%提高至25%。Petchwattana等人[24]发现滑石粉颗粒尺寸对其成核效果有显著影响,1wt%的滑石粉使PLA的冷结晶温度从128℃降低到107℃,并且滑石粉颗粒越小,PLA的结晶度越高。粘土(clay)也被广泛用来改善PLA的热性能、机械性能和阻隔性能。研究发现粘土使PLA的冷结晶峰变窄[25]。

As'habi等人[26]研究了PLA/LLDPE/clay纳米复合材料的非等温结晶行为,发现纳米粘土具有良好的成核效果,而LLDPE则表现出一定的塑化效果,这两者的协同效应显著提高了PLA结晶速率。在另一项研究中[27],5wt%的有机改性蒙脱石则使PLA结晶速率提高了3倍。

2.2 有机成核剂对PLA结晶行为的影响

无机填料可以改善PLA的结晶性能,但对于降低PLA的半结晶时间(t1/2)却效果有限,在快速降温过程中诱导PLA结晶效果也不理想[18]。相比之下,有机化合物在PLA熔体中分散均匀、尺度容易控制能提供更为有效的成核位点,从而有效地促进PLA成核。已有文献报道,脂肪族酰胺[15,28,29]、N,N′-二苯甲酰肼衍生物[30-33]、三苯甲酰胺衍生物[34-36]、有机磷[22,37,38]和乙二酰胺化合物[39]皆可作为PLA的有效有机成核剂。

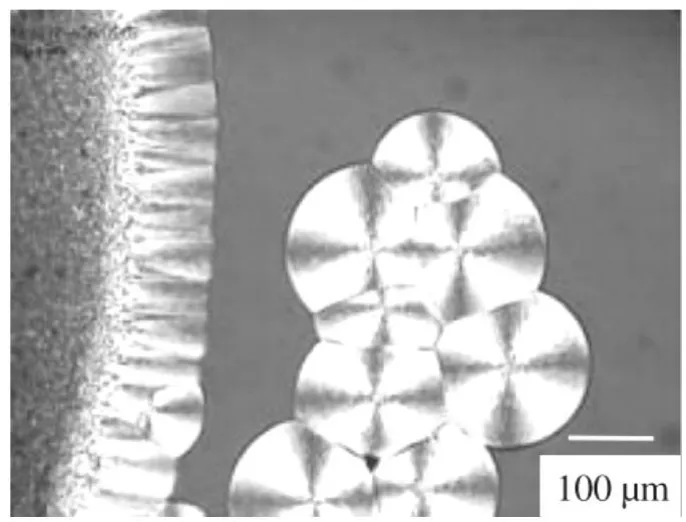

Nam等人[15]将N,N'-乙撑双硬脂酰胺(EBH)作为左旋聚乳酸(PLLA)的成核剂,使PLLA的冷结晶温度(Tcc)从100.7℃降到79.7℃(升温速率:5℃/min),并且通过偏光显微镜观察到聚乳酸球晶在EBH外延生长,出现了横结晶现象,表明EBH具有成核作用(如图1所示)。Nakajima等人[34]合成了系列三苯甲酰胺(BTA)衍生物,发现在PLA中添加1wt%的BTA,在100℃结晶5min,结晶度达到44%,而相同条件下纯PLA的结晶度只有17%。Tang等人[28]研究发现,成核剂EBH(1wt%)使聚乳酸在105℃等温结晶的半结晶时间t1/2从18.8min缩短到2.8min,在105℃退火5min,可使PLA结晶度达到35%。经过短时间退火后,PLA热变形温度升至93℃,同时提高了其模量和冲击强度。

图1 PLA/EBH共混物在130℃等温结晶30min的偏光显微镜图片Figure 1 a Polarizing optical micrograph at interface between PLA and EBH at Tc=130℃for 30 min[28]

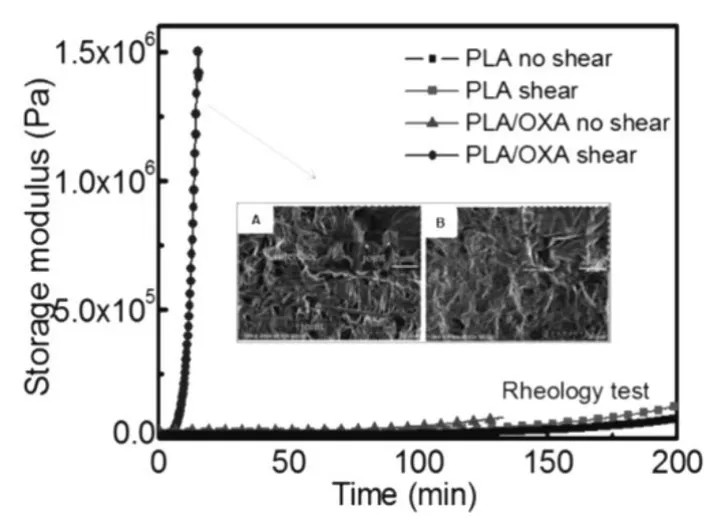

此外,本课题组设计并可控制备了系列乙二酰胺小分子化合物(OXA)[39,40,41],率先报道了OXA能够“溶解”于聚合物熔体,在一定条件下可组装成微纤并诱导聚合物分子链在其表面快速有序堆砌,为聚合物结晶过程和多尺度有序结构调控提供了新方法,进一步通过乙二酰胺化合物氢键重数、端基构型以及外场条件的设计与优化,使PLA的结晶周期缩短了95%以上。在此基础上,P.Ma等还将上述OXA成核剂与剪切共同作用于聚乳酸体系,在保证高结晶度与高结晶速率的前提下使PLA最高结晶温度比现有文献报道结果提高了14℃以上(如图2)[42,43,44],通过OXA微纤取向、拉伸流场、温度场的共同作用构筑了特殊串晶结构并获得了强度高(>120MPa)、伸长率适中(>25%)、耐热性能优异(>150℃)的全PLA复合材料[44]。

图2 PLLA和PLLA/OXA共混物在155℃剪切后的储能模量随结晶时间的变化Figure 2 Storage modulus(G′)variation of the PLLA and PLLA/OXA samples as a function of crystallization time(t) and shear at 155℃[42]

2.3 立构复合物对PLA结晶行为的影响

Ikada等人[45]率先报道了左旋聚乳酸(PLLA)和右旋聚乳酸(PDLA)按照1:1比例共混会产生一种立构复合(SC)晶体,其熔点比PLLA或PDLA匀质晶体高 50℃,因此在不对称PLLA/PDLA共混物中,SC微晶可以作为PLA的成核剂。之后,PLLA和PDLA分子量、混合比例、混合条件和光学纯度对SC微晶的形成和性质的影响得到了广泛的研究[46]。

Yamane等[47]研究了PLLA/PDLA(1-5wt%)的热性能和结晶行为,证明了SC微晶作为PLLA的成核位点显著改善了PLLA的结晶过程。事实上,只要添加少量PDLA就能显著增加PLLA的成核密度,加速PLLA结晶[48],例如,在PLLA中添加0.25wt%PDLA后,其成核密度提高了150倍。

Yang等人[48]研究了在不对称PLLA/PDLA共混物中SC微晶网络的形成、结构和对聚乳酸分子链扩散的约束效应,发现在等温和非等温结晶中保留SC微晶可以显著加快PLA的结晶速率。Jing等[49]通过丙交酯开环合成了线性PDLA和星型PDLA,发现PDLA显著促进了PLLA的结晶,不同结构PDLA促进结晶的能力排序为:4臂PDLA>PDLA>6臂PDLA>3臂PDLA。Hiroki等人[50]制备了立构复合聚乳酸纳米颗粒,并将其与PLLA溶液共混,发现共混物结晶峰值温度比PLLA高15℃,在140℃等温结晶的半结晶时间(t1/2)缩短了50%。

2.4 生物基成核剂对PLA结晶行为的影响

除 PDLA外,淀粉[22,51,52]和纤维素[53-55]等生物质聚合物也可改善PLA的结晶行为。Ke等[22]通过对PLA/淀粉复合材料熔融行为和结晶动力学的研究发现,添加1wt%的淀粉能有效地提高PLA的结晶速率,但效果不如滑石粉。

此外,进一步增加淀粉含量至40wt%,PLA的结晶速率略有增加。Kang等[51]研究了化学改性热塑性淀粉(CMPS)对PLA热性能和等温结晶动力学的影响,发现添加CMPS可以提高聚乳酸的结晶速率和结晶度,但添加量对PLA的结晶影响不大。

上述研究表明,淀粉或改性淀粉对PLA具有一定的成核效果,但效果弱于滑石粉。Pei等人[53]使用纳米纤维素(CNC)和硅烷化的纤维素纳米晶(SCNC)作为PLLA的成核剂,结果发现1wt%的SCNC便可使PLA结晶速率显著加快,并且提高了材料的模量和强度,而CNC粒子对PLA结晶行为没有显著影响,这与另一项研究报道的结果一致[12]。

3.聚乳酸的增韧改性

PLA断裂伸长率低(~5%)、冲击韧性差(~3kJ/m2),阻碍了其在许多领域的应用。近年来,聚乳酸增韧改性已成为PLA研究的热点之一,增韧改性的方法包括增塑、共聚和与柔性聚合物共混等。

3.1 增塑改性

加入增塑剂是改善PLA柔韧性的一个有效方法[56]。PLA理想的增塑剂应能与基体相容、可降解、环境友好。

到目前为止,大量的低分子量化合物已经被用作聚乳酸的增塑剂,如聚乙二醇(PEG)[57,58]、聚丙二醇[59,60]、聚己二酸[61]、环氧大豆油[62,63]、柠檬酸酯[64,65]和聚丙烯酸丁酯[66,67]。其中,PEG和柠檬酸酯最为常用。

研究证实,PEG的增塑效果随PEG分子量的减小和含量增加而提高。Sungsanit等人[57]证实PEG(5wt%,10wt%)显著降低了PLA的玻璃化转变温度(Tg),添加PEG的PLA与纯PLA相比具有不同机械和流变性能,且更加柔韧。柠檬酸酯是美国食品和药物管理局(FDA)批准的食品添加剂,是一种“绿色”增塑剂。Labrecque等人[64]用柠檬酸酯增塑PLA发现,当柠檬酸酯添加量超过10wt%时,PLA的伸长率提高显著;当柠檬酸酯含量为20wt%时,PLA的屈服强度下降了76%;当柠檬酸酯含量达到20-30wt%时,屈服强度降至10MPa以下。在另一项研究中,Ljungberg等人[65]报道了三乙酸甘油酯和柠檬酸三丁酯(TBC)对聚乳酸也有良好的增塑效果。

虽然上述增塑剂改善了PLA的脆性,扩大了其应用领域,但大多数增塑剂与聚乳酸的相容性不佳,当增塑剂含量超过20wt%时,共混物易发生相分离,且使PLA的强度下降显著,这限制了该类材料在食品包装中的应用[68]。Yang等人[69]合成了一种生物基增塑剂二辛酸异山梨酯(SDO),并研究其与聚乳酸共混物的塑化行为,证实了PLA的Tg随着SDO含量的增加而降低。当SDO的增加达到20wt%,PLA的Tg从60.7℃降到32.5℃,同时,PLA的断裂伸长率从3.5%提高到281.1%。

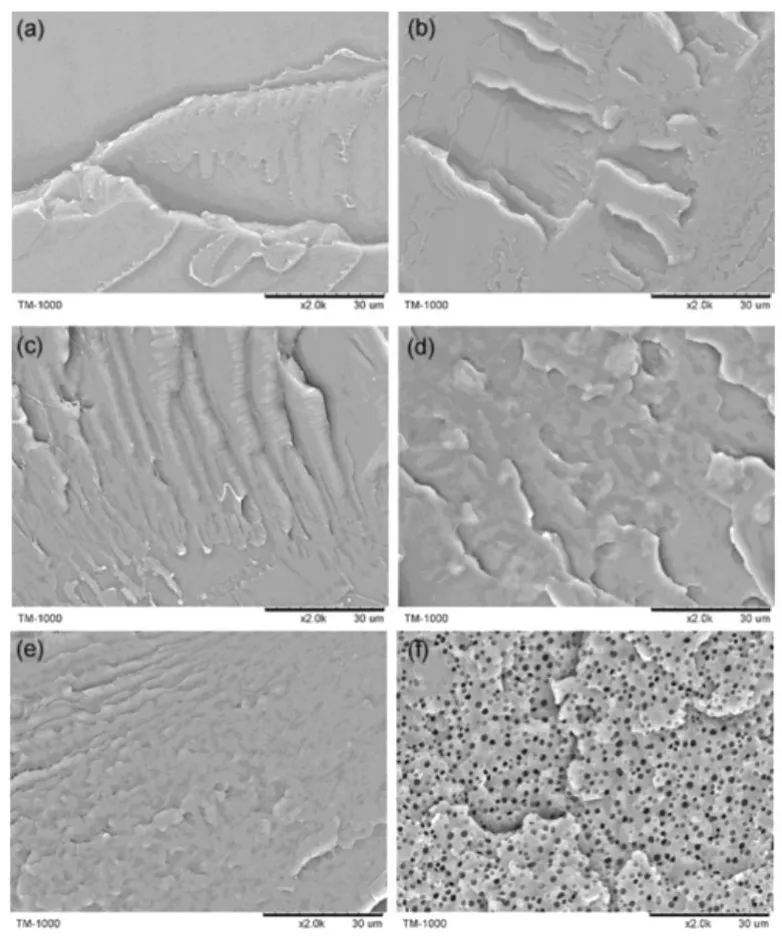

此外,引入市售增塑剂对苯二甲酸二辛酯(DOTP)作对比,从图3可以看出,PLA与SDO相容性良好,PLA/DOTP20共混物则出现明显的相分离。

图3 PLA,PLA/SDO和 PLA/DOTP共混物放大2000倍的扫描电镜照片(a)Neat PLA;(b)PLA/SDO5;(c)PLA/SDO10; (d)PLA/SDO20;(e)PLA/DOTP10;(f)PLA/DOTP20Figure 3 SEM micrographs of neat PLA,PLA/SDO and PLA/DOTP blends at 2000×magnification.(a)neat PLA;(b) PLA/SDO5;(c)PLA/SDO10;(d)PLA/SDO20;(e)PLA/DOTP10; (f)PLA/DOTP20[69]

3.2 共聚改性

共聚是获得具有独特性能的高分子材料的一种有效方法,通过调控分子结构、共聚单体的组合顺序可以定制共聚物的性能[2]。两种途径可以获得PLA共聚物。Grijpma等人[70]通过左旋乳酸与己内酯(50/50,mol/mol)共聚制备了嵌段共聚物。发现共聚物伸长率达到500%,然而,拉伸强度下降至34MPa。为了增加聚乳酸的韧性而不明显降低其拉伸强度和模量,Theryo等人[71]首先通过1,5-环辛二烯和5-降冰片烯-2-甲醇开环共聚得到PCN,然后合成了乳酸与PCN的接枝共聚物,结果发现,含5wt%PCN骨架的接枝共聚物不仅透明,而且伸长率增加了17倍,达到240%,同时,拉伸模量和屈服强度分别达到了1.86 GPa和64.8MPa,较纯PLA略有降低。

3.3 共混改性

熔融共混是获得聚合物新性能的一种经济方便的方法[2],因此通过与柔性聚合物熔融共混可以获得韧性PLA材料。据文献报道,较多柔性聚合物被用来增韧聚乳酸,包括乙烯-辛烯共聚物(POE)[72]、氢化苯乙烯-丁二烯嵌段共聚物(SEBS)[73]、聚丁烯己二酸-1,4-环己烷二羧酸共聚物(PBAC)[74]、乙烯基弹性体[75]、聚已内酯(PCL)[76,77]、聚丁二酸丁二醇酯(PBS)[78]和聚己二酸/对苯二甲酸丁二酯(PBAT)[79]等。Qiu等人[74]通过添加柔性聚酯 PBAC来增韧聚乳酸,当PBAC含量为30wt%时,PLA的断裂伸长率从4%增加到196%,同时显著提高了PLA的缺口冲击强度,其增韧机理如图6所示。

一方面,PBAC与PLA有较好的相容性;另一方面,PBAC主链含有“非刚性的”结构单元,分子链通过构型转换(船式-椅式)而表现出弹性,进而对PLA产生增韧效果。P.Ma等[75]通过系统改变乙烯基弹性体共聚单体的比例调控聚乳酸与乙烯基弹性体合金的相容性和相态结构,基于材料在冲击与拉伸形变过程中的空洞化行为实现了聚乳酸的超韧改性,使聚乳酸的缺口冲击强度由3kJ/m2提高到70kJ/m2。

P.Ma等[79]在PLA/PBAT、PDLLA/PHB等全降解体系引入自由基,通过原位交联与支化补偿热降解引发的相对分子质量降低,改善了相界面的粘合强度和合金的流变特性,细化并稳定了相结构,进而实现了聚乳酸合金的强韧化改性,较为有效的解决了生物高分子成型加工中易降解、韧性差的技术问题。

PCL是另一种可生物降解聚酯,具有出色的柔性和延展性,可用来增韧聚乳酸。然而,PLA/PCL(70/30)共混物仅为15%,这是由于PCL与PLA的相容性较差,导致对PLA的增韧效果有限。Semba等人[76]在PLA/PCL共混过程中引入0.1-0.2wt%过氧化二异丙苯(DCP)使共混物在混合过程发生反应增容,从而使PLA/PCL(70/30)共混物的断裂伸长率达到130%,但进一步增加DCP含量对共混物的断裂伸长率有负面影响;当DCP含量为0.3wt%时,PLA/PCL(70/30)共混物的冲击强度是纯PLA的2.5倍。

4.聚乳酸在包装材料中的应用

虽然近年来PLA在包装领域的使用大幅增加,其固有的缺点使其应用仍面临众多挑战,因此PLA需通过调整加工工艺、与其他聚合物并用、添加助剂(例如成核剂、抗氧化剂和增塑剂)来改善其性能,以满足市场需求[79]。

早在2010年,Frito Lay为Sunchips®品牌引入了可降解的PLA包装袋,但PLA包装袋脆性和噪音大而使其却饱受诟病,以至于在2015年这种PLA包装袋撤出了市场[80]。通过调整PLA加工方法与工艺可得到不同取向度的PLA,取向PLA比无取向PLA拥有更好耐热性和强度,适合用于烘焙包装和礼品卡[79],而无取向聚乳酸薄膜更倾向用于包装生鲜和其他保质期短的产品[81]。有研究表明,采用PLA包装容器可以使水果的保质期延长10%-15%[82]。然而,PLA膜材料对水分和气体的阻隔性较差,限制了在高阻隔包装领域的使用。

欧洲市场较早的推出了PLA产品。Danone®在德国市场推出了聚乳酸酸奶杯,占碧悠产品线总量的80%[83],但是无取向PLA包装材料仅限于常温应用。为了满足其他一些PLA商业包装应用(如收缩塑料薄膜和收缩标签),PLA需要具有收缩性。康尼格拉食品公司推出使用可回收的取向PLA收缩薄膜作为标签(由EarthFirst®生产和提供)[84],但因PLA在70℃的收缩率低和结晶白化而使其使用受到限制。鉴于上述技术问题,无定形PLA与其他聚酯薄膜层压或与其他聚合物共混被用于提高 PLA的收缩特性[79]。S&B Foods,Nisshin Oilio和Asahi制造的软饮料产品便使用了改性PLA收缩标签[79]。

PLA也被用于生产水和果汁瓶,但该市场有限。注射-拉伸-吹塑是PLA瓶子典型的生产方式。由于PLA的蠕变行为不足和对二氧化碳的低阻隔性,PLA瓶子的应用只限于非碳酸饮料。据报道,Vitamore®PLA碳酸饮料瓶对二氧化碳有大约6个月的保质期[85]。尽管制造商努力向市场推广PLA瓶子,但PLA产品的阻隔性能还需要进一步改善来扩大商业应用。

PLA的热变形温度只有55至65℃[86],容易受热变形,在热包装领域应用具有一定挑战性,如微波容器和一次性咖啡杯。有研究通过添加成核剂,如亚烷基双酰胺[79]、Ecopromote®(日产化学的一种可生物降解成核剂)[87]、滑石粉、PDLA,更快的诱导聚乳酸结晶,提高其热变形温度。例如,Corbion Purac®生产的PURALACT®聚乳酸餐具,其抗冲击性能与丙烯腈丁二烯苯乙烯共聚物(ABS)相近,而且可用于微波加热;此外,通过PLLA和PDLA的立构复合可以得到具有耐高温等特殊性能的产品[88]。Teknor Apex开发了一种PLA产品(Terraloy BP-34001),其冲击强度和热变形温度分别达到135 J/m和112℃,Teknor Apex声称这种新产品中PLA含量约为80wt%,并且加工周期短[85]。在未来几年,PLA耐热餐具将变得更加实用。

5.结语

聚乳酸具有高强度、高模量、透明性、生物降解性和生物相容性等优点,国内外众多工公司正努力开发并不断推出聚乳酸新产品以(部分)替代石油基与不可降解聚合物在包装材料领域的应用,减少塑料废弃物对生态环境的破坏。随着结晶、增韧与耐热改性技术的发展,聚乳酸塑料将保持强劲的发展势头,大规模地进入市场,在包装、耐热餐具等领域得到广泛应用。

[1]Jenck J F,Agterberg F,Droescher M J.Products and processes for a sustainable chemical industry:a review of achievements and prospects[J].Green Chemistry,2004, 6:544-556.

[2]Liu H,Zhang J.Research progress in toughening modification of poly(lactic acid)[J].Journal of polymer science part B:Polymer Physics,2011,49:1051-1083.

[3]Rasal R M,Hirt D E.Micropatterning of covalently attached biotin on poly(lactic acid)film surfaces[J]. Macromolecular bioscience,2009,9:989-996.

[4]Ray S S,Okamoto M.Biodegradable polylactide and its nanocomposites:opening a new dimension for plastics and composites [J]. Macromolecular Rapid Communications,2003,24:815-840.

[5]Zhu K J,Xiangzhou L,Shilin Y.Preparation, characterization,and properties of polylactide(PLA)-poly (ethylene glycol)(PEG)copolymers:a potential drug carrier [J].Journal of Applied Polymer Science,1990,39:1-9.

[6]Schugens C H,Grandfils C H,Jérôme R,Teyssie P. Preparation of a macroporous biodegradable polylactide implant for neuronal transplantation [J]. Journal of Biomedical Materials Research Part A,1995,29:1349-1362.

[7]Okada M.Chemical syntheses of biodegradable polymers[J].Progress in Polymer Science,2002,27:87-133.

[8]Kremer A B,Andrews R J,Milner M J,Zhang X R, Ebrahimi T,Patrick B O,Diaconescu,Mehrkhodavandi P.A comparison of gallium and indium alkoxide complexes as catalysts for ring-opening polymerization of lactide[J]. Inorganic Chemistry,2017,56:1375-1385

[9]Rasal R M,Janorkar A V,Hirt D E.Poly(lactic acid)modifications[J].Progress in Polymer Science,2010,35:338-356.

[10]Xiong Z,Ma SQ,Fan LB,Tang ZB,Zhang RY, Na HN,Zhu J.Surface hydrophobic modification of starch with bio-based epoxy resins to fabricate high-performance polylactide composite materials[J].Composites Science and Technology,2014,94:16-22.

[11]Xiong Z,Yang Y,Feng JX,Zhang XM,Zhang CZ, Tang ZB,Zhu J.Preparation and characterization of poly (lactic acid)/starch composites toughened with epoxidized soybean oil[J].Carbohydrate Polymers,2013,92:810-816.

[12]Saeidlou S,Huneault MA,Li HB,Park CB.Poly (lactic acid)crystallization[J].Progress in Polymer Science, 2012,37:1657-1677.

[13]Xiong Z,Zhang LS,Ma SQ,Yang Y,Zhang CZ, Tang ZB,Zhu J.Effect of castor oil enrichment layer produced by reaction on the properties of PLA/HDI-g-starch blends[J].Carbohydrate Polymers,2013, 94:235-243.

[14]LegrasR,MercierJP,Nield E.Polymer crystallization by chemical nucleation[J].Nature,1983, 304:432-434.

[15]Nam JY,Okamoto M,Okamoto H,Nakano M, Usuki A,MatsudaM.Morphologyandcrystallization kinetics in a mixture of low-molecular weight aliphatic amide and polylactide[J].Polymer,2006,47:1340-1347.

[16]Harris A M,Lee E C.Improving mechanical performance ofinjection molded PLA by controlling crystallinity[J].Journal of Applied Polymer Science,2008, 107:2246-2255.

[17]Huang A,Yu P,Jing X,Mi HY,Geng LH,Chen BY,Peng XF.The effect of talc on the mechanical, crystallization and foaming properties of poly(lactic acid) [J].Journal of Macromolecular Science,Part B,2016,55: 908-924.

[18]Pivsa-Art W,Fujii K,Nomura K,Aso Y,Ohara H, Yamane H.Isothermal crystallization kinetics of talc-filled poly(lactic acid)and poly(butylene succinate)blends[J]. Journal of Polymer Research,2016,23:1-8.

[19] Battegazzore D, Bocchini S, Frache A. Crystallization kinetics of poly(lactic acid)-talc composites [J].Express Polymer Letters,2011,5:849-858.

[20]Ouchiar S,Stoclet G,Cabaret C,Gloaguen V. Influence of the filler nature on the crystalline structure of polylactide-based nanocomposites:new insights into the nucleating effect[J].Macromolecules,2016,49:2782-2790.

[21]Tábi T,Kovács N K,Sajó I E,Czigány T,Hajba S, Kovács J G.Comparison of thermal,mechanicaland thermomechanical properties of poly (lactic acid) injection-molded into epoxy-based rapid prototyped (PolyJet)and conventionalsteelmold [J].Journalof Thermal Analysis and Calorimetry,2016,123:349-361.

[22]Ghassemi A,Moghaddamzadeh S,Duchesne C, Rodrigue D.Effect of annealing on gas permeability and mechanical properties of polylactic acid/talc composite films[J].JournalofPlasticFilm & Sheeting,2017: 8756087917694618.

[23]Shakoor A,Thomas N L.Talc as a nucleating agent and reinforcing filler in poly(lactic acid)composites [J].Polymer Engineering&Science,2014,54:64-70.

[24]PetchwattanaN,Covavisaruch S,PetthaiS. Influence of talc particle size and content on crystallization behavior,mechanical properties and morphology of poly (lactic acid)[J].Polymer bulletin,2014,71:1947-1959.

[25] Kelnar I, Kratochvíl J, Kaprálková L. Crystallization and thermalproperties of melt-drawn PCL/PLA microfibrillar composites[J].Journal of Thermal Analysis and Calorimetry,2016,124:799-805.

[26]As’habi L,Jafari S H,Khonakdar H A,Häussler L. Non-isothermal crystallization behavior of PLA/LLDPE/nanoclay hybrid:synergistic role of LLDPE and clay[J].Thermochimica Acta,2013,565:102-113.

[27]Zaldua N,Mugica A,Zubitur M,Iturrospe A, Arbe A,Lore G,Raquez J M,Dubois P,Müller A J.The role of PLLA-g-montmorillonite nanohybrids in the acceleration ofthe crystallization rate ofa commercialPLA [J]. CrystEngComm,2016,18:9334-9344.

[28]Tang Z,Zhang C,Liu X,Zhu J.The crystallization behavior and mechanical properties of polylactic acid in thepresence of a crystal nucleating agent[J].Journal of Applied Polymer Science,2012,125:1108-1115.

[29]Xing Q,Zhang XQ,Dong X,Liu GM,Wang DJ. Low-molecularweightaliphatic amides asnucleating agentsforpoly (l-lactic acid):conformation variation induced crystallization enhancement[J].Polymer,2012,53: 2306-2314.

[30]Morou E,LirakisM,PavlidiN,ZottiM, Nakagawa Y,Smagghe G,Vontas J,Swevers L.A new dibenzoylhydrazine with insecticidal activity against Anopheles mosquito larvae[J].Pest Management Science, 2013,69:827-833.

[31]Kawamoto N,Sakai A,Horikoshi T,Urushihara T, Tobita E.Physical and mechanical properties of poly (l-lactic acid)nucleated by dibenzoylhydrazide compound [J].Journal of Applied Polymer Science,2007,103:244-250.

[32]Cai YH,Yan SF,Fan YQ,Yu ZY,Chen XS,Yin JB. The nucleation effect of N,N′-bis(benzoyl)alkyl diacid dihydrazides on crystallization of biodegradable poly (l-lactic acid)[J].Iranian Polymer Journal,2012,21: 435-444.

[33]Cai YH,Yan SF,Yin JB,Fan YQ,Chen XS. Crystallization behavior of biodegradable poly(L-lactic acid)filled with a powerful nucleating agent:N,N′-bis (benzoyl)suberic acid dihydrazide[J].Journal of Applied Polymer Science,2011,121:1408-1416.

[34]Nakajima H,Takahashi M,Kimura Y.Induced crystallization of PLLA in the presence of 1, 3, 5-benzenetricarboxylamide derivatives as nucleators: preparation of haze-free crystalline PLLA materials [J].Macromolecular Materials and Engineering,2010,295: 460-468.

[35]Bai HW,Zhang WY,Deng H,Zhang Q,Fu QA. Control of crystal morphology in poly(L-lactide)by adding nucleating agent[J].Macromolecules,2011,44:1233-1237.

[36]Song P,Wei ZY,Liang JC,Chen GY,Zhang WX. Crystallization behavior and nucleation analysis of poly (l-lactic acid)with a multiamide nucleating agent[J]. Polymer Engineering&Science,2012,52:1058-1068.

[37]Suryanegara L,Okumura H,Nakagaito AN,Yano H.The synergetic effect of phenylphosphonic acid zinc and microfibrillated cellulose on the injection molding cycle time of PLA composites[J].Cellulose,2011,18:689-698.

[38]Wang SS,Han CY,Bian JJ,Han LJ,Wang XM. Morphology,crystallization and enzymatic hydrolysis of poly (L-lactide) nucleated using layered metal phosphonates[J].Polymer International,2011,60:284-295.

[39]Ma P,Xu Y,Wang D,Dong W,Chen M.Rapid crystallization of poly(lactic acid)by using tailor-made oxalamide derivativesasnovelsoluble-type nucleating agents[J].Industrial&Engineering Chemistry Research, 2014,53:12888-12892.

[40]Ma P,Xu Y,Shen T,Dong W,Chen M,Lemstra P J.Tailoring the crystallization behavior of poly(L-lactide) with self-assembly-type oxalamide compounds as nucleators:1.Effectofterminalconfiguration ofthe nucleators[J].European Polymer Journal,2015,70:400-411.

[41]Shen T,Xu Y,Cai X,Ma P,Dong W,Chen M. Enhanced crystallization kinetics of poly(lactide)with oxalamide compounds as nucleators:effect of spacer length between the oxalamide moieties[J].RSC Advances,2016,6: 48365-48374..

[42]Ma P,Yu Q,Shen T,Dong W,Chen M.Strong synergetic effect of fibril-like nucleator and shear flow on the melt crystallization of poly(L-lactide)[J].European Polymer Journal,2017:221-230

[43]Shen T,Ma P,Yu Q,Dong W,Chen M.The effect of thermalhistory on the fastcrystallization of poly (L-Lactide)with soluble-type nucleators and shear flow[J]. Polymers,2016,8:431.

[44]Shen T,Xu Y,Ma P,Wang L,Dong W,Chen M. High-performance poly (lactide) composites by construction of network-like shish-kebab crystals[J].RSC Advances,2016,6:71046-71051.

[45]Ikada Y,JamshidiK,TsujiH,HyonS H. Stereocomplex formation between enantiomeric poly (lactides)[J].Macromolecules,1987,20:904-906.

[46]Sun JR,Yu HY,Zhuang XL,Chen XS,Jing XB.Crystallization behavior of asymmetric PLLA/PDLA blends [J].The Journal of Physical Chemistry B,2011,115: 2864-2869.

[47]Wei XF,Bao RY,Cao ZQ,Yang W,Xie BH,Yang MB.Stereocomplex crystallite network in asymmetric PLLA/PDLA blends:Formation,structure,and confining effect on the crystallization rate of homocrystallites[J]. Macromolecules,2014,47:1439-1448.

[48]Jing Z,Shi X,Zhang G,Li J,Zhou L,Zhang H. Formation,structure and promoting crystallization capacity of stereocomplex crystallite network in the poly(lactide) blends based on linear PLLA and PDLA with different structures[J].Polymer,2016,92:210-221.

[49]Uehara H,Ishizuka M,Tanaka H,Kano,M, Yamanobe T.Stereocomplex poly(lactic acid)nanoparticles crystallized through nanoporous membranes and application as nucleating agent [J]. RSC Advances, 2016, 6: 13971-13980.

[50]Yamane H,Sasai K.Effect of the addition of poly (D-lactic acid)on the thermal property of poly(L-lactic acid)[J].Polymer,2003,44:2569-2575.

[51]Kang KS,Lee SI,Lee TJ,Narayan R,Shin BY. Effect of biobased and biodegradable nucleating agent on the isothermal crystallization of poly(lactic acid)[J]. Korean JournalofChemicalEngineering,2008,25: 599-608.

[52]Cai J,Liu M,Wang L,Yao KH,Li S,Xiong HG. Isothermal crystallization kinetics of thermoplastic starch/poly (lactic acid) composites [J].Carbohydrate Polymers,2011,86:941-947.

[53]Pei AH,Zhou Q,Berglund LA.Functionalized cellulose nanocrystals as biobased nucleation agents in poly (l-lactide)(PLLA)–Crystallization and mechanical property effects[J].Composites Science and Technology,2010,70: 815-821.

[54]Frone AN,Berlioz S,Chailan JF,Panaitescu DM. Morphology and thermalproperties ofPLA–cellulose nanofibers composites[J].Carbohydrate Polymers,2013, 91:377-384.

[55]Fortnati E,Peltze M,Armentano I,Torre L, Jimenez A,Kenny JM.Effectsofmodified cellulose nanocrystals on the barrier and migration properties of PLA nano-biocomposites[J].Carbohydrate Polymers,2012,90: 948-956.

[56]Wang Y,Qin YY,Zhang YJ,Yuan MW,Li HL, Yuan ML.Effects of N-octyl lactate as plasticizer on the thermal and functional properties of extruded PLA-based films [J]. International Journal of Biological Macromolecules,2014,67:58-63.

[57]Sungsanit K,Kao N,Bhattacharya SN.Properties of linear poly(lactic acid)/polyethylene glycol blends[J]. Polymer Engineering&Science,2012,52:108-116.

[58]Toncheva A,Mincheva R,Kancheva M,Manolova N,Rashkov I,Dubois P,Markova N.Antibacterial PLA/PEG electrospun fibers:Comparative study between grafting and blending PEG[J].European Polymer Journal, 2016,75:223-233.

[59]Mascia L,Su R,Clark J,Lou Y,Mele E.Fibres from blends of epoxidized natural rubber and polylactic acid by the electrospinning process:Compatibilization and surface texture [J].European Polymer Journal, 2017: 241–254.

[60]Piorkowska E,Kulinski Z,Galeski A,Masirek R. Plasticization of semicrystalline poly(L-lactide)with poly (propylene glycol)[J].Polymer,2006,47:7178-7188.

[61]MartinoV P,Jiménez A,RuseckaiteR A. Processing and characterization of poly(lactic acid)films plasticized with commercial adipates[J].Journal of Applied Polymer Science,2009,112:2010-2018.

[62] Vijayarajan S,Selke SEM,Matuana LM. Continuousblending approach in the manufacture of epoxidized soybean-plasticized poly(lactic acid)sheets and films[J].Macromolecular Materials and Engineering, 2014,299:622-630.

[63]Mauck S C,Wang S,Ding W,Rohde BJ,Fortune CK,Yang G,Ahn SK,Robertson ML.Biorenewable tough blends of polylactide and acrylated epoxidized soybean oil compatibilized by a polylactide star polymer [J].Macromolecules,2016,49:1605-1615.

[64]Labrecque L V,Kumar R A,Dave V,Gross R A, McCarthy S P.Citrate esters as plasticizers for poly(lactic acid)[J].Journal of Applied Polymer Science,1997,66: 1507-1513.

[65]Shirai M A,Müller C M O,Grossmann M V E, Yamashita F.Adipate and citrate esters as plasticizers for poly(lactic acid)/thermoplastic starch sheets[J].Journal of Polymers and the Environment,2015,23:54-61.

[66]Lee S,Lee K,Jang J,Choung J S,Choi W J,Kim G J, Kim Y W, Shin J. Sustainable poly (ε-decalactone)-poly (l-lactide)multiarm star copolymer architectures for thermoplastic elastomers with fixed molar mass and block ratio[J].Polymer,2017,112:306-317.

[67]Yang Y,Xiong Z,Zhang L,Tang Z,Zhang R,Zhu J.Isosorbide dioctoate as a“green”plasticizer for poly (lactic acid)[J].Materials&Design,2016,91:262-268.

[68]Burgos N,Tolaguera D,Fiori S,Jimenez A. Synthesis and characterization of lactic acid oligomers: evaluation of performance as poly(lactic acid)plasticizers [J].Journal of Polymers and the Environment,2014,22: 227-235.

[69]Yang Y,Xiong Z,Zhang L,Tang Z,Zhang R and Zhu J.Isosorbide dioctoate as a“green”plasticizer for poly (lactic acid)[J].Materials&Design,2016,91:262-268.

[70]Grijpma D W,Zondervan G J,Pennings A J. Synthesis and characterization of lactic acid oligomers: evaluation of performance as poly(lactic acid)plasticizers [J].Journal of Polymers and the Environment,2014,22: 227-235

[71]Theryo G,Jing F,Pitet L M,Hillmyer M A.Tough polylactide graft copolymers[J].Macromolecules,2010,43: 7394-7397.

[72]Li D,Shentu B,Weng Z.Preparation and Properties of Polylactide/Poly (ethylene-co-octene)/nano-SiO2 Ternary Composites[J].Journal of Macromolecular Science, Part B,2012,51:1766-1775.

[73] Hashima K, Nishitsuji S, Inoue T. Structure-properties of super-tough PLA alloy with excellent heat resistance[J].Polymer,2010,51:3934-3939.

[74]QiuJ,LiuF,ZhangJW,NaHN,ZhuJ. Non-planar ring contained polyester modifying polylactide to pursue high toughness[J].Composites Science and Technology,2016,128:41-48.

[75]Ma P,Hristova-Bogaerds D G,Goossens J G P, Spoelstra A B,Zhang Y,Lemstra P J.Toughening of poly (lactic acid)by ethylene-co-vinyl acetate copolymer with different vinyl acetate contents[J].European Polymer Journal,2012,48:146-154.

[76]Semba T,Kitagawa K,Ishiaku U S,Hamada H. The effect of crosslinking on the mechanical properties of polylactic acid/polycaprolactone blends [J].Journalof Applied Polymer Science,2006,101:1816-1825.

[77]Takayama T,Todo M.Improvement of impact fracture properties of PLA/PCL polymer blend due to LTI addition [J].JournalofMaterialsScience,2006,41: 4989-4992.

[78]Supthanyakul R,Kaabbuathong N,Chirachanchai S.Random poly(butylene succinate-co-lactic acid)as a multi-functional additive for miscibility,toughness,and clarity of PLA/PBS blends[J].Polymer,2016,105:1-9.

[79]Dong W,Ma P,Wang S,Chen M,Cai X,Zhang Y. Effect of partial crosslinking on morphology and properties ofthepoly (β-hydroxybutyrate)/poly (d,l-lactic acid) blends[J].Polymer Degradation and Stability,2013,98: 1549-1555.

[80]Basyamfar R A.Frito Lay Sunchips-packaging analysis[J].Jurnal Sagu,2015,13:19-26.

[81]Said P P,Pradhan R C,Sharma N,Naik B. Protective coatings for shelf life extension of fruits and vegetables[J].Journal of Bioresource Engineering and Technology|Year,2014,1:01-06.

[82]Jamshidian M,Tehrany E A,Imran M,Jacquot M, Desobry S.Poly-Lactic Acid:production,applications, nanocomposites,and release studies[J].Comprehensive Reviewsin Food Scienceand Food Safety,2010,9: 552-571.

【】【】

[83]Frederiksen C S,Haugaard V K,Poll L,Becker E M.Light-induced quality changes in plain yoghurt packed in polylactate and polystyrene[J].European Food Research and Technology,2003,217:61-69.

[84]Lorence J P,Rackovan M J,Potter C W,Pastor R D,Cone W L.Pressure sensitive shrink label:U.S.Patent Application 13/972,044[P].2013-8-21.

[85]Castro-Aguirre E,Iniguez-Franco F,Samsudin H, Fang X,Auras R.Poly (lactic acid)-Mass production, processing,industrial applications,and end of life[J]. Advanced Drug Delivery Reviews,2016,107:333-366.

[86]Mohanty A K,Misra M,Drzal L T.Sustainable bio-compositesfrom renewable resources:opportunities and challenges in the green materials world[J].Journal of Polymers and the Environment,2002,10:19-26.

[87]Gao Y,Picot O T,Bilotti E,Peijs T.Influence of filler size on the properties of poly (lactic acid) (PLA)/graphene nanoplatelet(GNP)nanocomposites[J]. European Polymer Journal,2017,86:117-131.

[88]Nampoothiri K M,Nair N R,John R P.An overview of the recent developments in polylactide(PLA) research [J]. Bioresource Technology, 2010, 101: 8493-8501.

Polylactic Acid Modification and Application in Packaging Materials

Pei Lv1Piming Ma1Weifu Dong1Ruyan Wang2

(1.School of Chemical and Material Engineering,Jiangnan University;2.Total Corbion PLA co.,LTD)

Poly(lactic acid)(PLA)is a bio-based thermoplastic polyester with high strength,high modulus, clarity,biodegradability and biocompatibility.It has evolved into a competitive commodity material with potentialto replace conventionalpetrochemical-based polymers.However,the wide applications of PLA have been hampered by its native drawbacks,such as low crystallization rate, crystallinity and inherent brittleness.In recent years,researchers have devoted to breaking above-mentioned bottleneck.The research progress of nucleation and toughening modification of PLA and its application in the packaging area are reviewed in this paper.

Poly(lactic acid) Crystallization Toughen Package