基于烟度限值的柴油机怠速瞬态过程性能评价方法与试验

楼狄明,孙瑜泽,于华洋,谭丕强,胡志远

基于烟度限值的柴油机怠速瞬态过程性能评价方法与试验

楼狄明1,孙瑜泽1,于华洋2,谭丕强1,胡志远1

(1. 同济大学汽车学院,上海 201804; 2. 上汽大众汽车有限公司,上海 201805)

以一台增压中冷高压共轨柴油机为研究对象,对怠速瞬态过程进行台架试验研究。首先采用了滞后系数、劣变系数和瞬态均值3个指标来定量评价怠速瞬态过程性能,然后从时间、峰值和均值3个维度上研究了怠速瞬态过程过渡时间和烟度限值对最大缸压、燃油流量和排放性的影响规律。试验结果表明:通过采用滞后系数、劣变系数和瞬态均值能较准确地评价柴油机怠速瞬态过程中性能的变化情况,为进一步的优化提供参考。柴油机在怠速瞬态过程中缸压,油耗及排放性能较稳态有所恶化。通过调整过渡时间和烟度限值,可以降低柴油机在怠速瞬态过程中的恶化程度。

柴油机;试验;排放控制;怠速瞬态过程;烟度限值;性能评价

0 引 言

在正常工作状态下,发动机工作工况经常发生改变,即经常处于瞬态工况[1-3]。根据调查统计[4],在怠速、加速、减速和匀速4种行驶过程中,瞬态工况行驶时间占54.8%,而匀速行驶时间的比例不超过30%。因此解决瞬态工况性能劣化问题日益成为实现发动机节能减排的关键。瞬态工况下柴油机的循环进气量和喷油量不断变化[5],由于增压器迟滞效应[6-11],引起进气量不足,空燃比下降,燃油燃烧不完全,导致柴油机瞬态工况特性偏离其稳态工况,某些尾气有害成分及工作噪声均高于稳态工况,燃油经济性也出现明显恶化。重型柴油机在起动时有毒气体(CO、苯、萘等)的排放比稳态工况高15倍,此外冷起动时的黑烟和白烟排放也比稳态工况高[12];车用发动机在欧洲驾驶循环中50%的NOx排放来自于加速工况期间[13];而加载工况期间的瞬时PM和NOx的排放则高出与之对应的准稳态工况1到2个数量级[14]。随着排放法规日益严格,欧洲及美国相应采用欧洲瞬态循环及美国瞬态循环测试[15]。柴油机瞬态工况的研究逐渐受到国内外众多研究人员重视[16-22]。

本文所用试验样机为一台串联式混合动力工程机械用柴油机,考虑怠速瞬态过程为典型瞬态过程[23],本文选取怠速点到1 500 r/min、85%负荷工况点的变转速变转矩这一典型瞬态过程进行试验研究。采用了“滞后系数”、“劣变系数”、“瞬态均值”3个指标[24]。对柴油机怠速瞬态过程中烟度限值与过渡时间对柴油机经济性与排放性能进行了分析,以期为怠速瞬态过程的优化提供参考。

1 瞬态性能评价指标

对发动机瞬态研究大多是进行定性分析,难以对瞬态过程性能进行清晰的量化。本文采用滞后系数、劣变系数以及瞬态均值3个指标,对发动机怠速瞬态过程性能做出定量的评价及分析。

1.1 滞后系数

滞后系数是某性能参数的响应时间与供油响应时间的比值

式中为某性能参数的滞后系数,为某性能参数的响应时间,s;0为供油的响应时间,s。以该性能参数瞬态取值与终点稳态值偏差在10%以内作为瞬态过程的结束。

当滞后系数小于1时,表示该性能参数的响应速度比供油响应速度快;当滞后系数为1时,表示该性能参数与供油的响应速率一致;当滞后系数大于1时,表示该性能参数的响应速度慢于供油响应速率,且值越大,表示该性能参数的响应越慢。

1.2 劣变系数

劣变系数是某性能参数的瞬态峰值与瞬态终点稳态值的比值

式中为某性能参数的劣变系数;为该性能参数在瞬态工况下的峰值,0为该性能参数瞬态终点在稳态工况下的值。

当劣变系数小于1时,表示该性能参数在瞬变过程中有所改善;当劣变系数等于1时,表示该性能参数在瞬变过程中没有发生劣变;当劣变系数大于1时,表示该性能参数在瞬变过程中发生劣变,且值越大,表示发动机瞬变性能恶化越严重。

1.3 瞬态均值

瞬态均值是某性能参数在整个瞬变过程的积分值与过渡时间的比值

式中为某性能参数的瞬态均值;1为瞬态过程起始时刻,2为瞬态过程终了时刻。同样,以该性能参数瞬态取值与终点稳态值偏差在10%以内作为瞬态过程的结束。

2 试验装置与试验方法

2.1 试验发动机

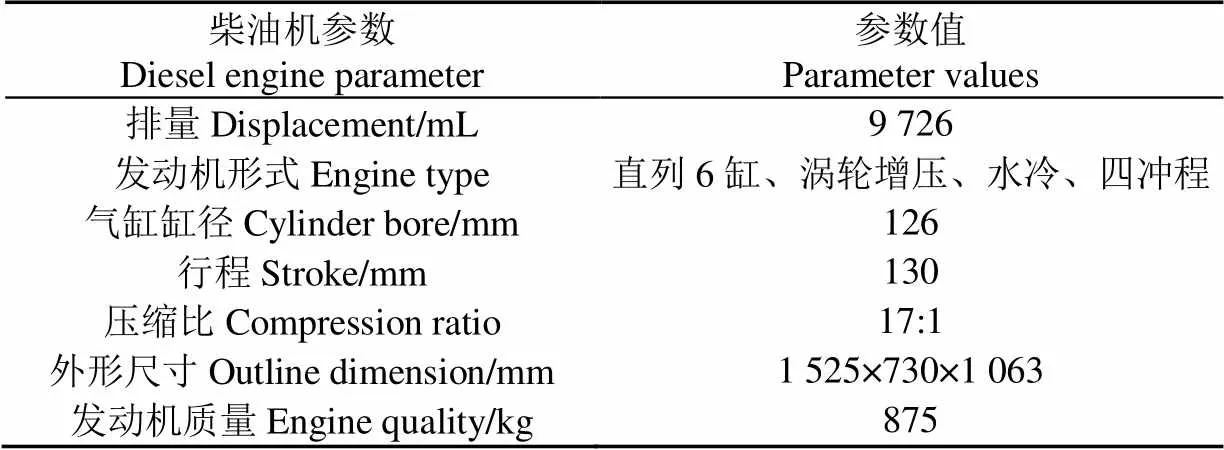

本文选用了一台潍柴动力股份有限公司的WP10工程机械用柴油机作为试验柴油机,其主要参数如表1。

表1 试验柴油机主要参数

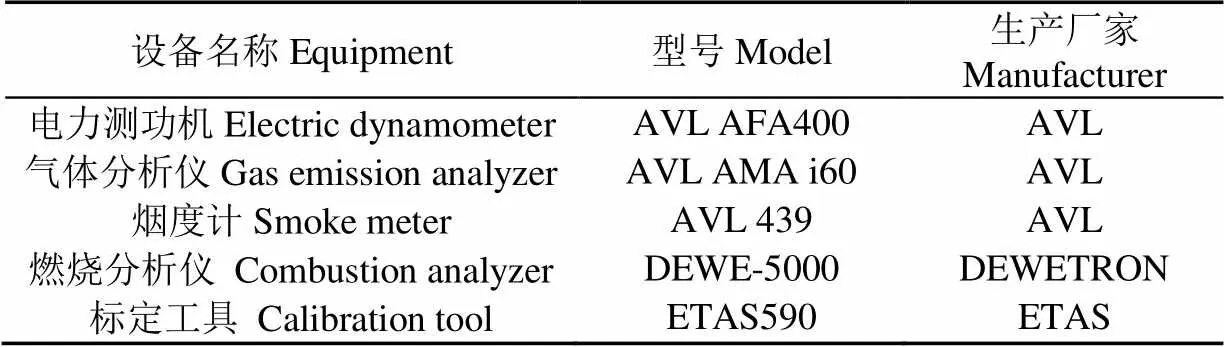

2.2 试验系统及试验设备

发动机台架测控系统测点的总体布置如图1所示,试验采用的主要仪器和设备见表2。

表2 试验用仪器和设备

2.3 烟度限值控制策略

发动机烟度需要根据相关法规进行限制[25],冒烟限制喷油量是排放法规允许的烟度限值下获得的最大喷油量,通过(过量空气系数)的MAP图的2个输入参数发动机转速和进气量决定。

图2所示为冒烟限制喷油量的控制策略。从图2可知热膜传感器输入信号经“热膜传感器处理模块”处理后,获得冒烟限制的每缸进气量;再与“冒烟限制的最小进气量参数”比较取最大值,得到冒烟限制的每缸实际进气量。然后叠加3个修正MAP:1)关于发动机进气量与转速的烟度限值修正MAP;2)关于发动机温度和转速的全负荷修正MAP;3)关于大气压力与发动机转速的不同海拔下修正MAP。最后按式(4)的过量空气系数转换公式得到冒烟限制喷油量[26]。

2.4 试验方案

研究发动机从怠速点到1 500 r/min、85%负荷工况点的变转速变转矩瞬态过程,台架转速-转矩控制模式下,从怠速点以不同过渡时间和不同烟度限值加速至目标工况点,分别选取过渡时间为3、5、10 s,烟度限值变化为减小10%、不变、增大10%。

3 试验结果与分析

3.1 对缸内压力的影响

图3所示为烟度限值不变时,不同过渡时间对怠速瞬态过程最大缸压的影响规律。由图3可知,怠速瞬态过程中最大缸压短暂波动后急剧上升,达到峰值稍稍下降,再缓慢上升达到稳态。随着过渡时间的增加,最大缸压上升时刻延后,峰值增高,过渡时间为3、5、10 s时的峰值分别为9.07、9.87和10.88 MPa。

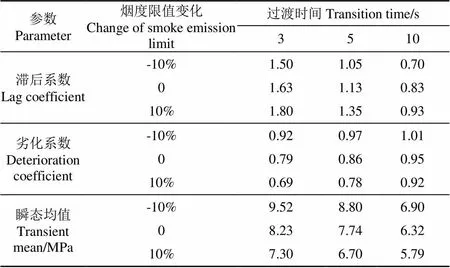

表3所示分别为不同烟度限值下,怠速瞬态过程最大缸压的滞后系数、劣变系数和瞬态均值的变化情况。由表2可见,随着过渡时间的增加,最大缸压的滞后系数减小,过渡时间为10 s时滞后系数已小于1,说明此时最大缸压先于油门接近稳态。过渡时间的增加为进气系统和缸壁热力状态的改变提供了更充裕的时间,瞬态滞后现象有所缓解[27-28]。随着过渡时间的增加,最大缸压的劣变系数小幅增大;而随着烟度限值的增加,最大缸压的劣变系数小幅减小。另外,最大缸压的劣变系数始终小于1,说明怠速瞬态过程最大缸压的峰值未达到稳态水平。随着过渡时间的增加,最大缸压的瞬态均值减小;烟度限值不变、过渡时间为3、5、10 s时,最大缸压的瞬态均值分别为8.23、7.74和6.32 MPa。此外,随着烟度限值的增加,最大缸压的瞬态均值减小。过渡时间为3 s、烟度限值减小10%时,最大缸压瞬态均值达到最大值9.52 MPa;过渡时间为10 s、烟度限值增大10%时,最大缸压瞬态均值取最小值5.79 MPa。

表3 最大缸压滞后系数、劣变系数和瞬态均值变化情况

3.2 对燃油流量的影响

图4所示为烟度限值不变时不同过渡时间对怠速瞬态过程中燃油流量的影响规律。由图4可知,怠速瞬态过程燃油流量匀速上升,达到峰值稍稍下降达到稳态;随着过渡时间的增加,燃油量增速放缓,达到稳态的时间延后。过渡时间为3、5、10 s时的峰值分别为33.3、34.2和31.3 kg/h。

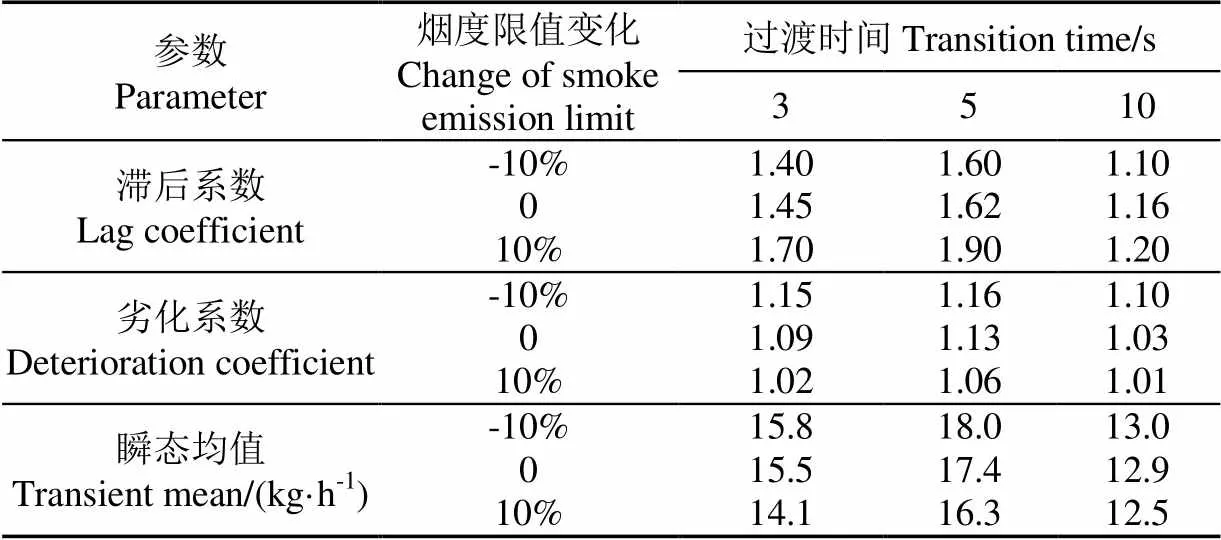

表4所示为不同过渡时间和烟度限值下,怠速瞬态过程燃油流量的滞后系数、劣变系数和瞬态均值。由表4可见,随着过渡时间的增加,燃油流量的滞后系数先增大后减小,但均大于1,说明燃油流量总是晚于油门接近稳态。且随着烟度限值的增加,燃油流量的滞后系数有所增大。随着过渡时间的增加,燃油流量的劣变系数先增大后减小,但均大于1,说明燃油流量瞬态过程峰值大于终点稳态值。此外,随着烟度限值的增加,燃油流量的劣变系数有所减小。随着过渡时间的增加,燃油流量的瞬态均值先增大后减小;而随着烟度限值的增加,燃油流量的瞬态均值则稍稍减小。烟度限值增大,限值了瞬态允许喷油量,导致燃油流量有所减小。过渡时间为10 s、烟度限值增大10%时,燃油流量瞬态均值取最小值12.5 kg/h,此时怠速瞬态过程经济性较好。

表4 燃油流量滞后系数、劣变系数和瞬态均值变化情况

3.3 对NOx排放的影响

图5所示为烟度限值不变时,不同过渡时间对怠速瞬态过程NOX排放的影响规律。由图5可知,怠速瞬态过程NOX排放先稳定不变再急剧上升,波峰后有所下降,再缓慢上升达到稳态。随着过渡时间增加,上升期延后,峰值有所升高;加速初期,喷油量突然增加造成过量空气系数急剧下降,此时缺少氧气占主要地位,NOx有减小趋势。放热量的相对增加使得缸内温度和压力升高,增压压力上升,氧气缺乏状况有所改善,致使加速中期 NOX浓度急剧上升。加速过程末期,增压压力持续上升,氧气量相对提高;缸内最高温度减小,同时发动机已达到较高转速,气体在缸内的滞留时间缩短:三方面因素的综合效果使NOX排放体积分数有所下降。过渡时间为3、5、10 s时的峰值分别为1.23×10-3、1.22×10-3和1.32×10-3。

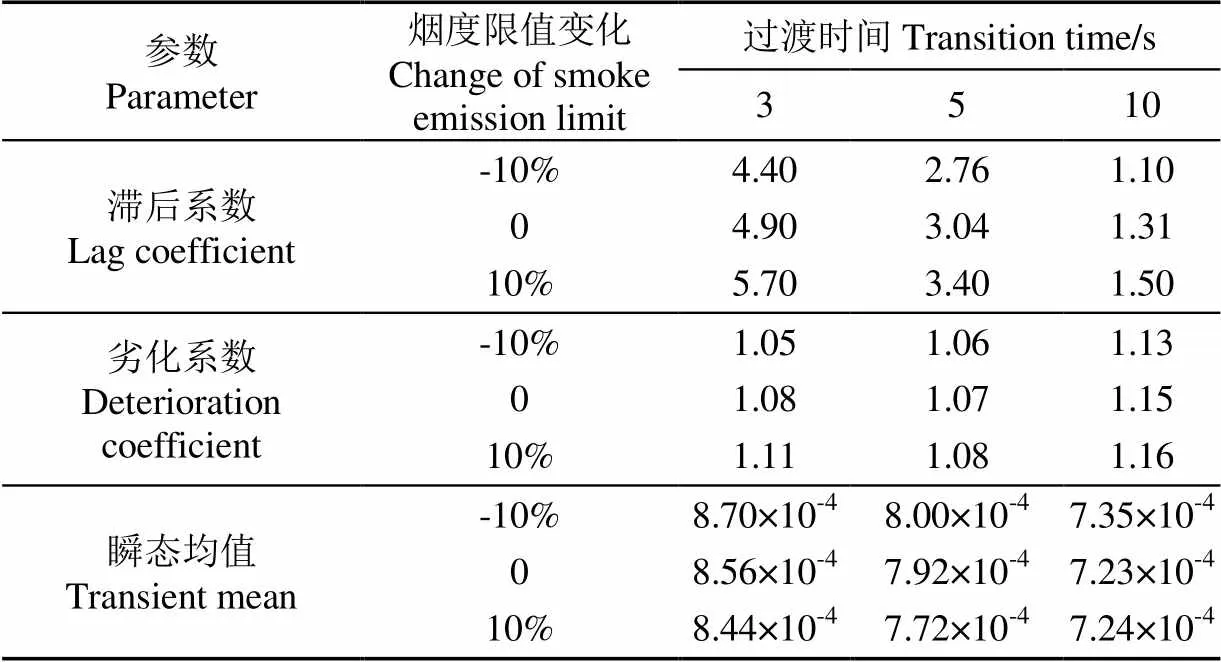

表5所示为不同过渡时间和烟度限值下,怠速瞬态过程NOX排放的滞后系数、劣变系数和瞬态均值。由表5可见,过渡时间较短时,NOX排放滞后严重。因为NOX排放需要在缸壁热力状态响应接近完成才能达到稳定[29]。随着过渡时间的增加,NOX排放的滞后系数大幅减小,过渡时间为10 s时基本与喷油同步达到稳态。过渡时间的增加为喷油系统和缸壁热力状态的改变提供了更充裕的时间,NOX瞬态排放滞后现象有所缓解。此外,随着烟度限值的增加,NOX排放的滞后系数有所增大。随着过渡时间的增加,NOX排放的劣变系数小幅减小后增大;而随着烟度限值的增加,NOX排放的劣变系数小幅增大。此外,NOX排放的劣变系数始终大于1,说明NOX排放瞬态过程峰值始终大于终点稳态值。随着过渡时间的增加,NOX排放的瞬态均值逐渐减小。而随着烟度限值的增加,NOX排放的瞬态均值稍稍增大;但与过渡时间的作用相比,影响较小。烟度限值增大,限值了瞬态允许喷油量,缸内温度和压力降低,导致NOX排放有所减少。过渡时间为10 s、烟度限值不变时,NOX排放体积分数瞬态均值取最小值7.23×10-4。

表5 NOx 排放滞后系数、劣变系数和瞬态均值变化情况

3.4 对烟度的影响

图6所示为烟度限值不变时,不同过渡时间对怠速瞬态过程烟度的影响规律。由图6可见,怠速瞬态过程烟度急剧增加,大大超过稳态值,达到峰值后逐渐下降回归稳态。随着过渡时间的增加,波峰时间延后,峰值不断提高。这是因为刚加速时单个循环的工作时间较长,柴油和空气在缸内混合均匀,燃烧情况良好,且排气时间较长也促进了碳烟氧化[30],整体烟度较低;中高转速时单个循环时间较短,突然喷入较多燃油,导致局部混合气过浓,缺氧情况加剧,缸内瞬时燃烧恶劣,烟度急剧增加,而后又逐渐趋于稳定。过渡时间为3、5、10 s时的峰值分别为0.063、0.085和0.106 m-1。

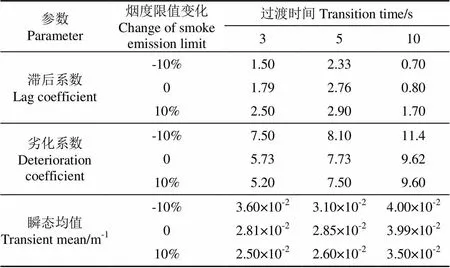

表6所示为不同过渡时间和烟度限值下,怠速瞬态过程烟度的滞后系数、劣变系数和瞬态均值。由表6可见,随着过渡时间的增加,烟度的滞后系数先增后减;而随着烟度限值的增加,烟度的滞后系数则不断增大。过渡时间为10 s、烟度限值不变和减小10%时,滞后系数小于1,说明此时烟度先于喷油接近稳态。

表6 烟度排放滞后系数、劣变系数和瞬态均值变化情况

随着过渡时间的增加,烟度的劣变系数增大;而随着烟度限值的增加,烟度的劣变系数有所减小;且均超过5,说明怠速瞬态过程中烟度恶化严重。随着过渡时间的增加,烟度的瞬态均值增大;而随着烟度限值的增大,烟度的瞬态均值减小。烟度限值增大,限制了瞬态允许喷油量,提高了空燃比,导致烟度有所降低。过渡时间为3 s、烟度限值增大10%时,烟度瞬态均值取最小值2.50×10-2m-1。

4 结 论

1)通过采用滞后系数、劣变系数和瞬态均值3个指标,可以对柴油机在怠速瞬态过程中性能的滞后程度、恶化程度进行定量的评价,为怠速瞬态性能的优化提供参考。

2)随着过渡时间的增加,最大缸压的滞后系数和瞬态均值减小,劣变系数增大;随着烟度限值的增加,最大缸压的滞后系数增大,劣变系数和瞬态均值减小。最大缸压滞后系数、劣化系数、瞬态均值最小值分别为0.70、0.69、5.79 MPa。

3)随着过渡时间的增加,燃油流量的滞后系数、劣变系数和瞬态均值均先增大后减小;随着烟度限值的增加,燃油流量的滞后系数和劣变系数增大,瞬态均值减小。燃油流量滞后系数、劣化系数、瞬态均值最小值分别为1.10、1.01、12.5 kg/h。

4)随着过渡时间的增加,NOX排放的滞后系数和瞬态均值减小,劣变系数增大;随着烟度限值的增加,NOX排放的滞后系数和劣变系数增大,瞬态均值减小。NOX排放体积分数滞后系数、劣化系数、瞬态均值最小值分别为1.1、1.05、7.23×10-4。

5)随着过渡时间的增加,烟度的滞后系数先增大后减小,劣变系数和瞬态均值增大;随着烟度限值的增加,烟度的滞后系数增大,劣变系数和瞬态均值减小。最大缸压滞后系数、劣化系数、瞬态均值最小值分别为0.70、5.20、0.025 m-1。

[1] Rakopoulos C D. Exhaust emissions estimation during transient turbocharged diesel engine operation using a two-zone combustion model[J]. International Journal of Vehicle Design, 2009, 49(1): 125-149.

[2] Nilsson T, Fröberg A, Åslund J. Optimal operation of a turbocharged diesel engine during transients[J]. SAE International Journal of Engines, 2012, 5(5): 571-578.

[3] Rakopoulos C D, Dimaratos A M, Giakoumis E G. Experimental assessment of turbocharged diesel engine transient emissions during acceleration, load change and starting[J]. SAE Paper 2010-01-1287, 2010.

[4] 田径,刘忠长,许允,等. 柴油机瞬变过程烟度排放的劣变分析[J]. 内燃机学报,2016, 34(2):125-134.

Tian Jing, Liu Zhongchang, Xu Yun, et al. Analysis of soot deterioration in diesel transient process[J]. Transactions of CSICE, 2016,34(2): 125-134. (in Chinese with English abstract)

[5] 杨蓉,楼狄明,谭丕强,等. 重型增压柴油机瞬变工况的燃烧阶段特性研究[J]. 内燃机工程,2015,36(4):41-45.

Yang Rong, Lou Diming, Tan Peiqiang, et al. Research on combustion phase characteristics of a turbocharged heavy duty diesel engine during transient process[J]. Chinese Internal Combustion Engine Engineering, 2015, 36(4): 41-45. (in Chinese with English abstract)

[6] Darlington A, Glover K, Collings N. A simple diesel engine air-path model to predict the cylinder charge during transients: Strategies for reducing transient emissions spikes[J]. SAE Technical Papers, 2006-01-3373, 2006.

[7] Rakopoulos C D, Dimaratos A M, Giakoumis E G, et al. Evaluation of the effect of engine, load and turbocharger parameters on transient emissions of diesel engine[J]. Energy Conversion & Management, 2009, 50(9): 2381-2393.

[8] Sabau A. transient regimes analysis for a diesel engine[J]. Advanced Materials Research, 2013, 837: 471-476.

[9] Giakoumis E G, Alafouzos A I. Study of diesel engine performance and emissions during a transient cycle applying an engine mapping-based methodology[J]. Applied Energy, 2010, 87(4): 1358-1365.

[10] 隋菱歌. 增压柴油机瞬态工况性能仿真及优化[D]. 长春:吉林大学,2012:93-109.

Sui Lingge. Simulation and Optimization of Turbo-Charged Diesel Engine Performance under Transient Operations[D]. Changchun: Jilin University, 2012: 93-109. (in Chinese with English abstract)

[11] 张龙平,刘忠长,田径,等. 车用柴油机瞬态工况试验及性能评价方法[J]. 哈尔滨工程大学学报,2014, 35(4):463-468.

Zhang Longping, Liu Zhongchang, Tian Jing, et al. Experiment and performance evaluation methods for automotive diesel engines under transient operation conditions[J]. Journal of Harbin Engineering University, 2014,35(4): 463-468. (in Chinese with English abstract)

[12] Gullett B K, Touati A, Oudejans L, et al. Real-time emission characterization of organic air toxic pollutants during steady state and transient operation of a medium duty diesel engine[J]. Atmospheric Environment, 2006, 40(22): 4037-4047.

[13] Hagena J R, Filipi Z S, Assanis D N. Transient diesel emissions: Analysis of engine operation during a tip-in[J]. SAE Technical Paper 2006-01-1151, 2006.

[14] Rakopoulos C D, Giakoumis E G. Review of thermodynamic diesel engine simulations under transient operating conditions [J]. SAE Technical Paper 2006-01-0884, 2006.

[15] 王忠恕,吴楠,许允,等. 增压直喷柴油机瞬态工况燃烧参数的变化规律[J]. 内燃机学报,2007,25(5):5-9.

Wang Zhongshu, Wu Nan, Xu Yun, et al. Study on combustion parameter from a turbocharged DI diesel engine under transient operating conditions[J]. Transactions of CSICE, 2007, 25(5): 5-9. (in Chinese with English abstract)

[16] 黄粉莲,纪威,周炜,等. 车用涡轮增压柴油机加速工况瞬态特性仿真[J]. 农业工程学报,2014,30(3):63-69.

Huang Fenlian, Ji Wei, Zhou Wei, et al. Simulation of transient performance of vehicle turbocharged diesel engine during acceleration process[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(3): 63-69. (in Chinese with English abstract)

[17] Tan P Q, Ruan S S, Hu Z Y, et al. Particle number emissions from a light-duty diesel engine with biodiesel fuels under transient-state operating conditions[J]. Applied Energy, 2014, 113(113): 22-31.

[18] 谭丕强,冯谦,胡志远,等. 车用柴油机瞬变工况的排放特性[J]. 工程热物理学报,2012,33(10):1819-1822.

Tan Piqiang, Feng Qian, Hu Zhiyuan et al .Emissions from a vehicle diesel engine during transient operating conditions[J]. Journal of Engineering Thermophysics, 2012, 33(10): 1819-1822. (in Chinese with English abstract)

[19] Kang H, Farrell P V. Experimental investigation of transient emissions (HC and NOx) in a high speed direct injection (HSDI) diesel engine[J]. SAE Technical Paper 2005-01-3883, 2005.

[20] Winkler N, Ångström H E. Simulations and measurements of a two-stage turbocharged heavy-duty diesel engine including egr in transient operation [J]. SAE Technical Paper 2008-01-0539, 2008.

[21] Glewen W, Heuwetter D, Foster D E, et al. Analysis of deviations from steady state performance during transient operation of a light duty diesel engine[J]. Cryogenics, 2012, 5(3): 909-922.

[22] 谭丕强,邹乐华,胡志远,等. 重型柴油机起动工况的颗粒数量排放特性[J]. 内燃机学报,2016, 34(5):431-437.

Tan Piqiang, Zou Lehua, Hu Zhiyuan, et al. Particle number emissions from a heavy-duty diesel engine during start-up operating conditions[J]. Transactions of CSICE, 2016, 34(5): 431-437. (in Chinese with English abstract)

[23] 于华洋. 基于喷油参数的串联式混合动力柴油机瞬态过程的优化[D]. 上海:同济大学,2015:20-28.

Yu Huayang. Optimization of Transient Operating Conditions for Series Hybrid Diesel Engine Based on Fuel Injection Parameters[D]. Shanghai: Tongji University, 2015: 20-28. (in Chinese with English abstract)

[24] 刘忠长,张龙平,田径,等. 一种内燃机瞬态工况性能评价方法:CN103528825A[P]. 2014-01-22.

[25] 王海宁,牛彦雷,范青海. 柴油车自由加速烟度控制方法研究[J]. 内燃机与动力装置,2015,32(5):5-7.

Wang Haining, Niu Yanlei, Fan Qinghai, et al. Study on the exhaust control to diesel vehicles under free acceleration[J]. Internal Combustion Engine & Power Plant, 2015, 32(5): 5-7. (in Chinese with English abstract)

[26] 刘俊明,徐劲松,张学文,等. 高压共轨柴油机的保护策略研究[J]. 内燃机工程,2009,30(5):36-40.

Liu Junming, Xu Jinsong, Zhang Xuewen, et al. Research on protection strategy of high pressure common rail diesel engine[J]. Chinese Internal Combustion Engine Engineering, 2009, 30(5): 36-40. (in Chinese with English abstract)

[27] 丁云龙,刘忠长,张龙平,等. 加载停滞时间对柴油机瞬态性能的影响[J]. 车用发动机,2015(3):22-26.

Ding Yunlong, Liu Zhongchang, Zhang Longping, et al. Effects of loading stagnation time on diesel engine performance under transient operations[J]. Vehicle Engine, 2015(3): 22-26. (in Chinese with English abstract)

[28] 刘忠长,丁云龙,田径,等. 多段加载策略对柴油机瞬态性能影响的试验[J]. 内燃机学报,2015, 33(3):193-200.

Liu Zhongchang, Ding Yunlong, Tian Jing, et al. Experiment of multistage loading strategies on diesel engine under transient operations[J]. Transactions of CSICE, 2015,33(3): 193-200. (in Chinese with English abstract)

[29] 张龙平,刘忠长,田径,等. 柴油机瞬变工况的动态响应及燃烧劣变分析[J]. 内燃机学报,2014,32(2):104-110.

Zhang Longping, Liu Zhongchang, Tian Jing, et al. Dynamic response and combustion deterioration analysis of a diesel engine under transient operations[J]. Transactions of CSICE, 2014, 32(2): 104-110. (in Chinese with English abstract)

[30] 王忠,孙波,赵洋,等. 小型非道路柴油机排气管内颗粒的粒径分布与氧化特性[J]. 农业工程学报,2016,32(10):41-46.

Wang Zhong, Sun Bo, Zhao Yang, et al. Characteristics of particle coagulation and oxidation in exhaust pipe of diesel engine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016. 32(10): 41-46. (in Chinese with English abstract)

Performance evaluation method and experiment for diesel engine under idle transient operation condition based on smoke emission limit

Lou Diming1, Sun Yuze1, Yu Huayang2, Tan Piqiang1, Hu Zhiyuan1

(1.,,201804,; 2.,, 201805,)

Nowadays, the performances of diesel engines under transient conditions become the research focus. Because of the frequent start and stop of the series hybrid diesel engine, the diesel engine is always in the steady state or idle speed switching state. In order to study the transient performance of diesel engine during the idle transient conditions, 3 indices are firstly adopted: The lag coefficient, which is an evaluation index for performance of diesel engine transient lag, the deterioration coefficient, which is an evaluation index for performance of diesel engine transient deterioration, and the transient mean, which is an evaluation index for comprehensive performance of diesel engine transient process. And then an analysis is carried out from the 3 dimensions of time, peak and mean value, and the influences of idle transient transition time and injection parameters on the maximum cylinder pressure, fuel flow and emissions are investigated. The test results show that the cylinder pressure, fuel consumption and emission performance of the diesel engine are worse than the steady state during the transient conditions. The deterioration of the engine can be reduced in the idle speed transient process by adjusting the transition time and smoke emission limit. With the increase of the transition time, the transient mean and lag coefficient of the maximum cylinder pressure decrease, and the deterioration coefficient increases; with the smoke limit increasing, the lag coefficient of the maximum cylinder pressure increases, and the deterioration coefficient and transient mean decrease. When the transition time is 10 s and the smoke emission limit is reduced by 10%, the lag coefficient of the maximum cylinder pressure gets the minimum value of 0.7. When the transition time is 3 s, and the smoke emission limit increases by 10%, the deterioration coefficient obtains the minimum value of 0.69. When the transition time is 10 s, and the smoke emission limit increases by 10%, the transient mean of the maximum cylinder pressure takes the minimum value of 5.79 MPa. With the increase of the transition time, the lag coefficient, deterioration coefficient and transient mean of fuel flow first increase and then decrease; with the increase of smoke emission limit, the lag coefficient and deterioration coefficient of fuel flow increase, and the transient mean decreases. When the transition time is 10 s, and the smoke emission limit is reduced by 10%, the lag coefficient of fuel flow gets the minimum value of 1.1. When the transition time is 3 s, and the smoke emission limit increases by 10%, the deterioration coefficient obtains the minimum value of 1.01. When the transition time is 10 s, and the smoke emission limit is increased by 10%, the fuel flow gets the minimum value of 12.49 kg/h. With the increase of the transition time, the lag coefficient and the transient mean of NOx emission decrease, and the deterioration coefficient increases; with the smoke emission limit increasing, the lag coefficient and the deterioration coefficient of NOx emission increase, and the transient mean decreases. When the transition time is 10 s, and the smoke emission limit is reduced by 10%, the lag coefficient of NOx emission gets the minimum value of 1.1. When the transition time is 5 s, and the smoke emission limit is reduced by 10%, the deterioration coefficient obtains the minimum value of 1.046. When the transition time is 10 s, and the smoke emission limit is invariable, the transient mean of NOx emission takes the minimum value of 7.23×10-4. With the increase of the transition time, the lag coefficient of smoke emission first increases and then decreases, and the deterioration coefficient and transient mean increase; with the smoke emission limit increasing, the lag coefficient of smoke emission increases, and the deterioration coefficient and transient mean decrease. When the transit time is 10 s, and the smoke emission limit is reduced by 10%, the lag factor of smoke emission obtains the minimum value of 0.7. When the transition time is 3 s, and the smoke emission limit increases by 10%, the deterioration coefficient obtains the minimum value of 5.2. When the transition time is 3 s, and the smoke emission limit is increased by 10%, the transient mean of smoke emission takes the minimum value of 0.025 m-1. These 3 indices can be used to evaluate the performance of the diesel engine in the transient process, which can provide the basis for further optimization.

diesel engine; experiments; emission control; idle transient process; smoke emission limit; performance evaluation

10.11975/j.issn.1002-6819.2017.04.016

TK421+.5

A

1002-6819(2017)-04-0111-06

2016-05-19

2017-02-05

“十二五”国家科技支撑计划项目(2011BAG04B02)

楼狄明,男,教授,主要研究方向为汽车发动机替代燃料应用技术和发动机排放控制后处理技术。上海 同济大学汽车学院,201804。 Email:loudiming@tongji.edu.cn

楼狄明,孙瑜泽,于华洋,谭丕强,胡志远. 基于烟度限值的柴油机怠速瞬态过程性能评价方法与试验[J]. 农业工程学报,2017,33(4):111-116. doi:10.11975/j.issn.1002-6819.2017.04.016 http://www.tcsae.org

Lou Diming, Sun Yuze, Yu Huayang, Tan Piqiang, Hu Zhiyuan. Performance evaluation method and experiment for diesel engine under idle transient operation condition based on smoke emission limit[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(4): 111-116. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.04.016 http://www.tcsae.org