全喂入谷子联合收获机脱出物含水率对其悬浮特性的影响

侯华铭,崔清亮,郭玉明

全喂入谷子联合收获机脱出物含水率对其悬浮特性的影响

侯华铭,崔清亮※,郭玉明

(山西农业大学工学院,太谷 030801)

谷子脱出物的悬浮特性是研究谷子收获清选参数优化及装备改进设计的基础特性。该文采用气吹式粮油作物脱出物悬浮速度测量装置,根据悬浮速度测定方法国家标准要求,设计分段悬浮试验测量了谷子经联合收获时的待清选脱出物各组分的悬浮速度及其在不同含水率下的悬浮速度,探究了谷子脱出物悬浮速度与其含水率的关系,预估了适宜的清选风速范围,并通过清选试验进行了验证。试验结果表明:收获的谷子脱出物籽粒、穗瓣、茎秆和叶子的悬浮速度分别是4.29~8.88、1.03~5.48、1.71~5.33、1.03~3.09 m/s,籽粒的悬浮速度大于叶子的悬浮速度,但与穗瓣、茎秆的悬浮速度数值区间有极小部分重叠。随着谷子作物含水率的降低,谷子籽粒悬浮速度与穗瓣、茎秆、叶子悬浮速度的差距在增大。含水率均显著影响谷子脱出物各组分的悬浮速度(≤ 0.05),谷子籽粒、穗瓣、茎秆和叶子的悬浮速度均随其含水率的增高而增大,且均与其含水率呈二次函数关系(2≥ 0.95)。清选试验结果证明预估是合理的,谷子脱出物的适宜清选风速范围为4.29~5.48 m/s,最佳清选风速为4.47 m/s,此时籽粒损失率为4.68%,籽粒清洁度为98.83%。该研究可为谷子适时收获时期和最优清选工作参数的确定提供参考。

机械化;收获;农作物;谷子;脱出物;悬浮速度;清选试验

0 引 言

物料悬浮速度是使物料悬浮的气流速度,研究农作物的悬浮特性将为农作物清选工作参数的选择提供参考依据,缩小清选工作参数的寻优范围,有助于快速获得清选最优工作参数,提高清选质量。国内学者对农业物料悬浮特性的研究主要从两方面入手:理论计算与仿真分析、试验测量与分析。在理论计算与仿真分析方面,国内学者的研究内容主要包括:物料在气流中的受力与运动情况、受力运动仿真模型的建立、物料悬浮速度计算公式的演算、悬浮速度计算数学模型的建立及应用等四方面内容。具体包括:利用阻力系数和升力系数分析小麦短茎秆在气流中的受力与运动情况[1],利用MATLAB软件的SIMULINK组件建立球形颗粒受垂直气流作用的仿真模型[2]。以不同粒径范围分区分析演算出球形颗粒、不规则颗粒及颗粒群的悬浮速度计算公式[3],采用分区粒径判断法建立球形颗粒悬浮速度计算数学模型,利用VC++开发工具创建悬浮速度计算软件[4]。

在试验测量与分析方面,国内学者通常采用2种方式研究农业物料的悬浮特性,一种是先设计试制一种物料悬浮速度测量装置,再测量农业物料的悬浮速度。悬浮速度测量装置按其工作原理可分为吸气式和吹气式两大类,基本由风机、管道、风速调节装置和测量装置四部分组成[5-8]。此外国内学者还将一些新技术应用到测量装置中。塔娜等应用图像处理技术判别稳定悬浮状态[9-10],李保谦等[11-13]应用自动控制技术研究物料悬浮速度测试系统。另一种是利用现有的物料悬浮速度测量装置,通过试验探究影响物料悬浮速度的因素。目前国内学者已经对小麦脱出物[1]、水稻脱出物[14]、油菜脱出物[15-16]、大豆脱出物[17]、花生脱壳机脱出物[18]、秧草收割物[19]、三七种子[20]、树木种子[21]、苜蓿段[22]等农业物料的悬浮速度进行了一定的研究,旨在为作物清选质量的提高进行有益探索。

谷子以其丰富的营养价值和良好的食用口感为人们所喜爱,几乎中国各地都有种植[23]。谷子收获多采用改进后的谷物联合收获机[24-25],专用的谷子联合收获机仍处于研制改进阶段[26-27],清选分离难,采用风筛式清选装置[28],风速大会使谷粒吹出,清选损失大[26];风速小又致使筛子堵塞,脱出物堆积,含杂率高、清洁度差[25]。如果提前研究谷子脱出物各组分的形状尺寸及其在气流中的悬浮特性,测量其的悬浮速度,则可根据其悬浮速度的差异设置合适的风机转速,有利于清选时脱出物中籽粒与轻杂物的分离,消除清选参数选择的盲目性,提供适宜的清选风速范围,简化清选参数的寻优过程。国内学者对小麦、水稻、油菜等作物脱出物的悬浮特性进行了研究,而鲜有对谷子脱出物的悬浮特性进行研究。

参考水稻、油菜等作物脱出物悬浮特性的研究方法,根据种子悬浮速度测定方法[29]国家标准要求,本文设计分段悬浮试验,利用气吹式粮油作物脱出物悬浮速度测量装置[30]测量了谷子经联合收获机收获时的待清选脱出物各组分的悬浮速度及其在不同含水率下的悬浮速度,探究谷子脱出物悬浮速度与其含水率的关系,获得谷子脱出物适宜的清选风速范围,并进行清选试验验证。

1 试验材料与方法

1.1 试验材料

试验谷子品种为晋谷21号,取自山西谷子全程机械化产业技术开发繁峙基地,收集改进的4LZ-2.5(PRO688Q)全喂入联合收割机收获成熟期谷子时所得的待清选脱出物作为试验材料。迅速对脱出物进行分拣,得到籽粒、穗瓣、茎秆和叶子4种物料,穗瓣、茎秆和叶子又被称为轻杂物,如图1所示。采用烘干法测得4种物料的成熟期含水率。拟取5个水平研究含水率对谷子脱出物各组分悬浮速度的影响,已具备成熟期含水率水平的试验物料,采用先复水后烘干的方法获取其他含水率水平的试验物料。对每种脱出物取5组样本,每组样本包含6个试样,每个试样取料10 g,分别包入尼龙网中并编号。从5组样本中取出1组作为成熟期含水率水平的试验样本,将其余4组样本置于水中浸泡6 h,使物料含水率趋于饱和后取出晾置,用滤纸吸去物料表面浮水。将4组样本置于干燥箱中干燥不同时间后取出,装入保鲜袋中封存,干燥时间分别取10、20、30和40 min,干燥温度为100 ℃。

图1 谷子脱出物各组分

1.2 试验原理与方法

1.离心风机 2.风力及其调控部件 3.盛料网 4.测试部件 5.流场结构部件 6.锥形观察管 7.悬浮高度标尺 8.L型毕托管 9.智能压力风速风量仪 10.变频器

依次测量不同含水率下谷子脱出物各组分的悬浮速度,统计分析不同含水率下谷子籽粒与其他脱出物悬浮速度的差异及脱出物各组分悬浮速度与其含水率的关系。

2 试验结果与分析

2.1 不同含水率下谷子脱出物的悬浮速度

试验前测量了收获期谷子脱出物各组分的含水率、形状尺寸等基本物性参数,测量结果如表1所示。

表1 谷子脱出物基本物性

由表1可知,谷子脱出物中籽粒形状与其他3种轻杂物形状不同。籽粒个体间尺寸差异极小,穗瓣、茎秆和叶子个体间尺寸差异较大。籽粒尺寸远小于穗瓣尺寸。籽粒长度远小于茎秆和叶子长度;籽粒宽度范围与茎秆和叶子的宽度范围有极小部分重叠;籽粒厚度范围与茎秆厚度范围有极小部分重叠,籽粒厚度远大于叶子厚度。总体而言,籽粒尺寸与其他3种轻杂物的尺寸有明显差异但又有极小部分的重叠。脱出物的形状尺寸决定了其的迎风面积和体积,在不考虑密度的情况下,籽粒与其他3种轻杂物尺寸上的重叠预示其在悬浮速度上会有所重叠。此外脱出物各组分尺寸参数的测定也为清选筛网的选型提供参考依据。

收获的谷子脱出物经复水烘干处理后的4组样本及原始样本的含水率如表2所示。

表2 谷子脱出物含水率

由表2可知随烘干时间增加,谷子脱出物中穗瓣、茎秆、叶子的含水率均高于其收获时的含水率,籽粒含水率在烘干时间达到30 min后降低到其收获时含水率以下。

试验测得5组不同含水率样本中谷子脱出物各组分的悬浮速度如表3所示。收获的籽粒、穗瓣、茎秆和叶子的悬浮速度分别是4.29~8.88、1.03~5.48、1.71~5.33、1.03~3.09 m/s。

表3 谷子脱出物悬浮速度

由表3可知,收获的谷子脱出物中籽粒的悬浮速度数值区间与穗瓣和茎秆的悬浮速度数值区间有极小部分重叠,籽粒的悬浮速度大于叶子的悬浮速度。籽粒悬浮速度的最小值为4.29 m/s,穗瓣和叶子悬浮速度的最大值分别为5.48、5.33 m/s。清选的目的在于分离掉轻杂物,留下干净的籽粒,同时控制籽粒损失率,则由谷子籽粒与各轻杂物的悬浮速度值可估得适宜的清选风速范围为4.29~5.48 m/s。随着谷子脱出物含水率的降低,籽粒悬浮速度与穗瓣、茎秆、叶子悬浮速度值的重叠数值区间在减小,说明籽粒悬浮速度与穗瓣、茎秆、叶子悬浮速度的差距在增大,表明谷子作物含水率越低,越有利于脱出物清选时籽粒与轻杂物的分离。籽粒与轻杂物悬浮速度值的重叠数值区间的存在表明清选时不能单靠风选将籽粒与轻杂物彻底分离,需采用风选与筛选或与旋风分离器分离轻杂相结合的方式进行清选以获得干净的籽粒。

2.2 含水率对谷子脱出物各组分悬浮速度的影响

在同组样本同种物料最大悬浮速度值的气流的吹动下,该种物料将全部悬浮起来,故可以最大值max代表该种物料的悬浮速度进行统计分析。分别绘制籽粒、穗瓣、茎秆和叶子的悬浮速度随其含水率变化的散点图,并采用平滑曲线连接散点,如图3所示。

由图3可知,谷子脱出物籽粒、穗瓣、茎秆和叶子的悬浮速度随其含水率变化而变化的规律相似,均随含水率的降低而减小。随含水率降低,悬浮速度一开始减小的较快,当含水率下降到某一值后,悬浮速度减小的速率变得平缓。究其原因:悬浮速度与物料质量密切相关,谷子脱出物为植物物料,物料含水率较高;含水率降低时,物料减少的主要是水分,干物质减少的较少,所以随含水率降低,物料质量减小的速率呈现由快到慢至平缓的变化过程,由此则解释了悬浮速度的变化规律。由于不同物料的饱和含水率、持水能力及干物质变化情况不同,所以其质量变化由快转慢的节点含水率不同,因此其悬浮速度变化由快转慢的节点含水率不同。观察图3中曲线可判断谷子脱出物各组分悬浮速度与其含水率成二次或三次函数关系,利用SAS统计软件分别对各组分在不同含水率下的悬浮速度数据作一元二次多项式和一元三次多项式回归分析[34-35]。根据回归模型值、拟合精度2和回归系数值判断出各组分较优的模型均为一元二次多项式模型,各组分的回归分析结果如表4所示。

图3 不同含水率下谷子脱出物各组分悬浮速度散点连线

表4 谷子脱出物悬浮速度与含水率的拟合关系

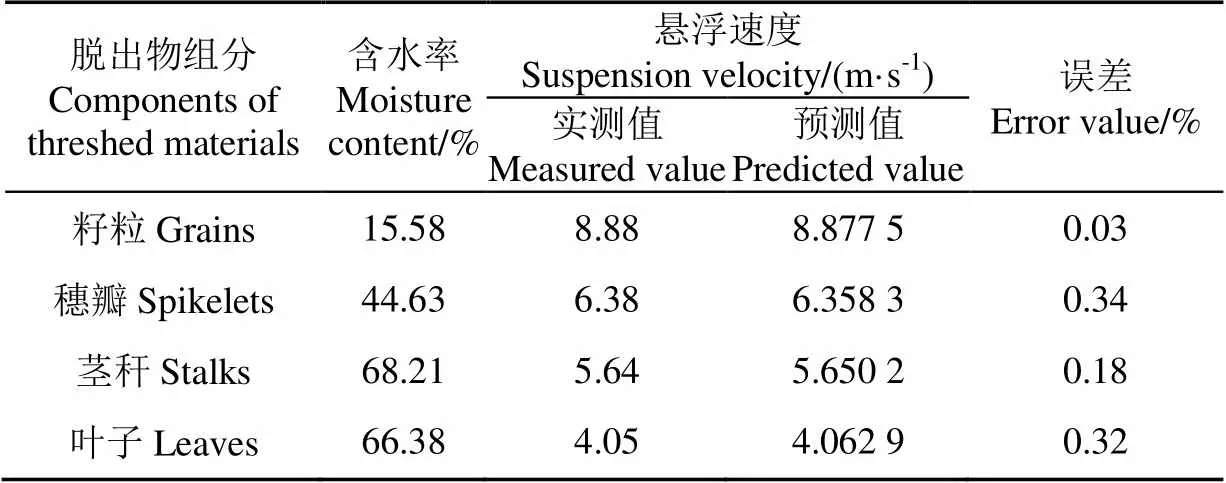

由表4可知,各组分的回归模型均很显著,拟合精度均较高。重复前述试验操作验证拟合关系,测量谷子脱出物各组分经复水烘干25 min后的悬浮速度,与预测值进行比较,试验结果如表5所示。

表5 拟合关系验证试验结果

由表5可知,根据拟合关系预测的谷子脱出物的悬浮速度值与实测值之间的误差较小,拟合关系可信。收获时测得谷子各组分的含水率后,可按表4中各函数关系估得各组分的悬浮速度,根据各组分的悬浮速度差异设置合适的清选风机转速,可得到较好的清选效果。

2.3 清选试验验证

清选试验在山西农业大学自行研制的清选试验装置上进行,如图4所示,测量不同清选风速下的籽粒损失率和清洁度,清选后观察籽粒与轻杂物的分布情况,并将清选效果最佳的风速值与估得的适宜风速范围相比较,以验证通过悬浮试验预估适宜清选风速范围的合理性。试验前采用人工挑拣的方法预先测得谷子脱出物中籽粒、穗瓣、茎秆和叶子的比例分别是45.61%、8.57%、10.82%和35%。

1.风机 2.振动筛 3.谷物收集区域 4.风速测量装置

清选试验装置结构类型为风筛式,根据收获的谷子脱出物各组分悬浮速度值的差异,选取4、4.5、5、5.5、6 m/s 5个风速水平进行清选试验,风机倾角为25°,在每个风速水平下重复5次试验,每次试验清选脱出物3 kg左右,清选喂入量为0.5 kg/s,对测得的籽粒损失率与清洁度取平均值。试验时,分别调节风机风速至选取的各风速水平,清选后观察籽粒与轻杂物的分布情况,收集清选后的物料,从中挑拣出轻杂物,分别称量籽粒与轻杂物的质量,计算籽粒损失率与清洁度。试验结果如表6所示。

由表6可知,当清选风速小于谷子籽粒悬浮速度时,籽粒损失率随风速增大而减小;当风速大于籽粒悬浮速度时,损失率随风速增大而增大。籽粒清洁度均较高,随风速增大整体呈增高趋势。当风速小于籽粒悬浮速度时,籽粒随风运动距离较短,极小部分籽粒没能落入指定收集区域而造成损失,随风速增大,籽粒随风运动距离增长,绝大部分籽粒落入收集区域,损失率降低;当风速大于籽粒悬浮速度时,风速越大,被吹走的籽粒越多,损失率增大;轻杂物几乎全被吹走,所以籽粒清洁度高。当出风口风速为4.47 m/s时,籽粒损失率最低,为4.68%;籽粒清洁度较高,为98.83%;此时清选效果最佳,此时的风速值在预估的适宜清选风速范围内,证明通过悬浮速度测量试验来预估谷子脱出物的适宜清选风速范围是合理的。

表6 不同风速下谷子脱出物清选损失率与清洁度

3 结 论

1)试验测量了谷子脱出物籽粒、穗瓣、茎秆和叶子在不同含水率下的悬浮速度。收获的籽粒、穗瓣、茎秆和叶子的悬浮速度分别是4.29~8.88、1.03~5.48、1.71~5.33、1.03~3.09 m/s,籽粒的悬浮速度大于叶子的悬浮速度,但与穗瓣和茎秆的悬浮速度数值区间有极小部分重叠。随着谷子作物含水率的降低,谷子籽粒悬浮速度与穗瓣、茎秆、叶子悬浮速度的差距在增大,有利于脱出物清选时籽粒与轻杂物的分离,因此选择收获期内谷子作物含水率较低的时刻进行收获,有利于清选干净。

2)试验分析表明,含水率均显著影响谷子脱出物各组分的悬浮速度,谷子籽粒、穗瓣、茎秆和叶子的悬浮速度均随其含水率的增高而增大,谷子籽粒、穗瓣、茎秆和叶子的悬浮速度均与其含水率呈二次函数关系。收获时可预先测量谷子各组分的含水率,利用含水率与悬浮速度的关系估得各组分的悬浮速度,根据各组分悬浮速度的差异设置合适的清选风机转速,可得到较好的清选效果。

3)清选试验证明,通过悬浮速度测量试验来预估谷子脱出物的适宜清选风速范围是合理的。收获期谷子脱出物的适宜清选风速范围为4.29~5.48 m/s。最佳清选风速为4.47 m/s,此时籽粒损失率为4.68%,籽粒清洁度为98.83%。

[1] 赵学笃,张魁学,张振京. 短茎秆的气动特性及其在气流中的运动[J]. 农业机械学报,1982,13(2):55-65. Zhao Xuedu, Zhang Kuixue, Zhang Zhenjing. The aerodynamic properties of short stems and their behavior in the air flow[J]. Transactions of the Chinese Society for Agricultural Machinery, 1982, 13(2): 55-65. (in Chinese with English abstract)

[2] 刘娟,贾磊. 基于SIMULINK的物料悬浮速度仿真研究[J].微计算机信息,2007(1):266-268.Liu Juan, Jia Lei. Study owing to that the SIMULINK material suspension speed simulates[J]. Microcomputer Information, 2007(1): 266-268. (in Chinese with English abstract)

[3] 吕子剑,曹文仲,刘今,等. 不同粒径固体颗粒的悬浮速度计算及测试[J]. 化学工程,1997,25(5):42-46,4. Lü Zijian, Cao Wenzhong, Liu Jin, et al. Research of suspension of particle in reactor[J]. Chemical Engineering (China), 1997, 25(5): 42-46, 4. (in Chinese with English abstract)

[4] 李骥,李英. 基于VC++的物料悬浮速度的可视化快速计算[J]. 干燥技术与设备,2005(2):89-92. Li Ji, Li Ying. A fast visual calculation of suspended velocity based on VC++[J]. Drying Technology & Equipment, 2005(2): 89-92. (in Chinese with English abstract)

[5] 盛江源,田宏炜,于津寿,等. 物料空气动力学特性测试装置的设计和试制[J]. 吉林农业大学学报,1980(2):45-52. Sheng Jiangyuan, Tian Hongwei, Yu Jinshou, et al. Design and trial-manufacture of the testing device for the aerodynamics characteristic of materials[J]. Journal of Jilin Agricultural University, 1980(2): 45-52. (in Chinese with English abstract)

[6] 姬江涛,蔺公振. 农业物料飘浮速度测试仪的设计与试验[J]. 洛阳工学院学报,1994,15(4):27-31. Ji Jiangtao, Lin Gongzhen. Design and experiment of measure on floating velocity of agricultural materials[J]. Journal of Luoyang Institute of Technology, 1994, 15(4): 27-31. (in Chinese with English abstract)

[7] 张佳,庄卫东,陈彬. 农业物料悬浮速度试验台的研制[J].黑龙江八一农垦大学学报,1998(3):57-60. Zhang Jia, Zhuang Weidong, Chen Bin. The development of the test-bed for stuff of agriculture in suspension speed[J]. Journal of Heilongjiang Bayi Agricultural University, 1998(3): 57-60. (in Chinese with English abstract)

[8] 王维,王亚妮,田智辉,等. 物料悬浮速度测试台的设计与试验研究[J]. 中国农机化学报,2016,37(6):44-46,78. Wang Wei, Wang Yani, Tian Zhihui, et al. Research on design and experimental of material suspension velocity bench[J]. Journal of Chinese Agricultural Mechanization, 2016, 37(6): 44-46, 78. (in Chinese with English abstract)

[9] 塔娜,张志耀,秀荣. 基于图像法的粮食物料悬浮速度研究[J]. 粮食与饲料工业,2008(7):8-10.Ta Na, Zhang Zhiyao, Xiu Rong. Research of grain suspension velocity based on image processing method[J]. Cereal & Feed Industry, 2008(7): 8-10. (in Chinese with English abstract)

[10] 塔娜,秀荣,张志耀. 粮食颗粒悬浮速度的测试分析[J].农机化研究,2009,31(8):147-149,190. Ta Na, Xiu Rong, Zhang Zhiyao. Experimental study on suspension velocity of grain in vertical pipe[J]. Journal of Agricultural Mechanization Research, 2009, 31(8): 147-149, 190. (in Chinese with English abstract)

[11] 李保谦,王威立,栗文雁,等. 物料悬浮速度测试方法研 究[J]. 农机化研究,2009,31(1):123-125.Li Baoqian, Wang Weili, Li Wenyan, et al. Research on methods of grain suspension velocity test[J]. Journal of Agricultural Mechanization Research, 2009, 31(1): 123-125. (in Chinese with English abstract)

[12] 王威立. 单片机控制的物料悬浮速度测试系统研究[D]. 郑州:河南农业大学,2009. Wang Weili. Study and Design of Grain Suspending Speed Detecting System Based on the Single-chip Control[D]. Zhengzhou: Henan Agricultural University, 2009. (in Chinese with English abstract)

[13] 付娅琦. 物料悬浮速度智能测试系统的设计研究[D]. 郑州:河南农业大学,2011. Fu Yaqi. Research on Design of Intelligent Testing System of Grain Suspension Velocity[D]. Zhengzhou: Henan Agricultural University, 2011. (in Chinese with English abstract)

[14] 刘艳艳,李耀明,徐立章,等. 水稻悬浮速度试验研究[J].农机化研究,2010,32(2):149-151,155. Liu Yanyan, Li Yaoming, Xu Lizhang, et al. Experimental study on rice floating velocity[J]. Journal of Agricultural Mechanization Research, 2010, 32(2): 149-151, 155. (in Chinese with English abstract)

[15] 陈立,廖庆喜,宗望远,等. 油菜联合收获机脱出物空气动力学特性测定[J].农业机械学报,2012,43(增刊1):125-130. Chen Li, Liao Qingxi, Zong Wangyuan, et al. Aerodynamic characteristics measurement of extraction components for rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(Supp.1): 125-130. (in Chinese with English abstract)

[16] 马征,李耀明,徐立章. 油菜脱出物漂浮速度及摩擦与浸润特性的测定与分析[J]. 农业工程学报,2011,27(9):13-17. Ma Zheng, Li Yaoming, Xu Lizhang. Testing and analysis on rape excursion components characteristics in floating, friction and wettability[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(9): 13-17. (in Chinese with English abstract)

[17] 张继成,陈海涛,纪文艺,等. 大豆脱出物悬浮速度试验研究[J].农机化研究,2013,35(4):127-131. Zhang Jicheng, Chen Haitao, Ji Wenyi, et al. Experimental study on floating velocity of soybean extraction[J]. Journal of Agricultural Mechanization Research, 2013, 35(4): 127-131. (in Chinese with English abstract)

[18] 高连兴,张文,杜鑫,等. 花生脱壳机脱出物的漂浮系数试验[J]. 农业工程学报,2012,28(2):289-292. Gao Lianxing, Zhang Wen, Du Xin, et al. Experiment on aerodynamic characteristics of threshed mixtures of peanut shelling machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(2): 289-292. (in Chinese with English abstract)

[19] 吴明聪,陈树人,卞丽娜,等. 不同刈割期秧草收割物悬浮速度的测定与分析[J]. 安徽农业大学学报,2014,41(3):507-512.

[20] 苏微,高筱钧,任闯,等. 种子颗粒群的悬浮速度模拟预测方法[J]. 华南农业大学学报,2016,37(1):110-116. Su Wei, Gao Xiaojun, Ren Chuang, et al. A simulation prediction method of suspension speed of seed particle swarm[J]. Journal of South China Agricultural University, 2016, 37(1): 110-116. (in Chinese with English abstract)

[21] 裴克,刘伟. 树木种子悬浮速度的实验研究[J]. 东北林业大学学报,1986(1):51-58. Pei Ke, Liu Wei. Study on the critical speed of the seeds through experiment[J]. Journal of Northeast Forestry University, 1986(1): 51-58. (in Chinese with English abstract)

[22] 李爱平,汪春. 苜蓿段长度对干燥速度与悬浮速度影响的试验[J]. 农业机械学报,2006,37(8):168-170. Li Aiping, Wang Chun. Experimental study on the effect of alfalfa's length on drying rate and floating velocity[J]. Transactions of the Chinese Society for Agricultural Machinery, 2006, 37(8): 168-170. (in Chinese with English abstract)

[23] 李顺国,刘斐,刘猛,等. 中国谷子产业现状、发展趋势及对策建议[J]. 农业现代化研究,2014,35(5):531-535. Li Shunguo, Liu Fei, Liu Meng, et al. The current industry situation, development trend and suggestions for the future of foxtail millet in China[J]. Research of Agricultural Modernization, 2014, 35(5): 531-535. (in Chinese with English abstract)

[24] 郝丰园. 站在农机农艺融合的高度企望谷子生产机械化的春天:全国谷子生产机械化技术研讨会纪要[J]. 农业技术与装备,2012(20):26-31. Hao Fengyuan. The summary of technical seminar for foxtail millet production mechanization: Looking forward to spring of foxtail millet production mechanization in the perspective of fusion of agricultural machinery and agronomy[J]. Agricultural Technology & Equipment, 2012(20): 26-31. (in Chinese with English abstract)

[25] 高海涛,郭永杰,曹军,等. 4LZG-2型谷子收获机的试验与改进[J]. 农业技术与装备,2013(17):76-77. Gao Haitao, Guo Yongjie, Cao Jun, et al. Test and improvement of 4LZG-2 type millet combine harvester[J]. Agricultural Technology & Equipment, 2013(17): 76-77. (in Chinese with English abstract)

[26] 梁苏宁,金诚谦,张奋飞,等. 4LZG-3.0型谷子联合收获机的设计与试验[J]. 农业工程学报,2015,31(12):31-38. Liang Suning, Jin Chengqian, Zhang Fenfei, et al. Design and experiment of 4LZG-3.0 millet combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(12): 31-38. (in Chinese with English abstract)

[27] 钱菊平,朱云飞,张奋飞,等. 谷子联合收获机脱粒清选装置试验与探讨[J]. 农机质量与监督,2017(9):25-28. Qian Jüping, Zhu Yunfei, Zhang Fenfei, et al. Test and discussion of threshing and cleaning device of millet combine harvester[J]. Agricultural Machinery Quality & Supervision, 2017(9): 25-28. (in Chinese with English abstract)

[28] 中国农业机械化科学研究院. 农业机械设计手册(上册)[M]. 北京:机械工业出版社,1988:971-979.

[29] 中华人民共和国国家发展和改革委员会. 牧草种子悬浮速度测定方法:JB/T7290-2007[S]. 北京:中国标准出版社,2007.

[30] 侯华铭,崔清亮,郭玉明,等. 气吹式粮油作物脱出物清选悬浮速度测量装置设计与试验[J]. 农业工程学报,2018,34(16):43-49. Hou Huaming, Cui Qingliang, Guo Yuming, et al. Design and test of air-sweeping suspension velocity testing device for cleaning threshed materials of grain and oil crops[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(16): 43-49. (in Chinese with English abstract)

[31] 郭维东. 流体力学[M]. 北京:中国农业出版社,2009:103-106.

[32] 续魁昌. 风机手册[M]. 北京:机械工业出版社,1999:14-26.

[33] 安连锁,吕玉坤. 泵与风机[M]. 北京:中国电力出版社,2008:3-7.

[34] 盛骤,谢式千,潘承毅. 概率论与数理统计[M]. 北京:高等教育出版社,2008:224-257.

[35] 王玉顺. 试验设计与统计分析SAS实践教程[M]. 西安:西安电子科技大学出版社,2012:195-201.

Effects of moisture contents of threshed materials from whole-feeding combine for foxtail millet on their suspension characteristics

Hou Huaming, Cui Qingliang※, Guo Yuming

(,,030801,)

The suspension characteristics of the threshed materials of foxtail millet are the basic characteristics for the research of cleaning working parameter optimization and improved design for the cleaning equipment, and the foxtail millet was harvested by the whole-feeding combine harvester. The threshed materials to be cleaned of foxtail millet include the grains, spikelets, stalks and leaves. Based on the requirements of the Chinese national standard test methods for forage seed suspension velocity, using the suspension velocity testing device for agricultural materials, we designed and conducted the staged suspension experiments to measure the suspension velocities of the 4 kinds of threshed materials of foxtail millet respectively, and we also measured the suspension velocities of the threshed materials with different moisture contents, and then we researched the relations between the suspension velocity of each part of threshed materials and its moisture content. Based on the differences among the measured suspension velocities of threshed materials, we estimated the suitable range of cleaning air velocity and conducted the cleaning experiment via cleaning experimental device to verify our estimation. We got the threshed materials with different moisture contents by means of rehydrating and drying. We immersed the threshed materials harvested into the water for 6 h to make their moisture contents saturate, and then we put the saturate threshed materials into the thermostatic drier box to dry for different times at 100 ℃. The drying times were 10, 20, 30 and 40 min respectively, and thus we got other 4 kinds of threshed materials with different moisture contents from the harvested threshed materials’, and so we totally measured 5 kinds of threshed materials with different moisture contents. The staged suspension experiments included 3 stages. When there were one third of the materials to be measured suspending in the tapered observed pipe at some height, one suspending stage was reached. We measured the suspension velocity of the suspended materials via DP2000-11 type intelligent pressure air-volume anemometer in every stage, and there were 6 measure points in every stage, and we calculated the average value of the 6 measured values. We used the suspended height ruler to measure the suspension height range of the suspended materials, and we used the average value and the suspension height range to calculate the suspension velocity range of the suspended materials based on the flow consistency principle. Synthesizing the 3 suspension velocity ranges, we got one suspension velocity range of this kind of material with a certain moisture content. There were 6 repeats of suspension velocity measurement for every kind of material with a certain moisture content. Synthesizing the 6 suspension velocity ranges of a kind of material with a certain moisture content, we finally got the suspension velocity ranges of this kind of material. The experimental results showed that the suspension velocities of grains, spikelets, stalks and leaves of threshed materials of foxtail millet harvested by combine harvester were respectively 4.29-8.88, 1.03-5.48, 1.71-5.33 and 1.03-3.09 m/s. There was no overlapping numerical interval between the grains’ suspension velocity range and the leaves’, while there were some overlapping numerical intervals between the grains’ suspension velocity range and the spikelets’ or the stalks’. With the decrease of moisture content of foxtail millet, the overlapping numerical intervals were all reducing between the grains’ suspension velocity range and the spikelets’ or the stalks’ or the leaves’. We used the maximum of the suspension velocity range of every kind of material with a certain moisture content to carry out a statistical analysis. The moisture content affected the suspension velocity of every component of the threshed materials significantly, and the significance levelvalues were all less than or equal to 0.048 8. With the decrease of moisture content, the suspension velocities of grains, spikelets, stalks and leaves were all decreasing, and there were quadratic function relations between the moisture content and the grains’ suspension velocity or the spikelets’ or the stalks’ or the leaves’, and the fitting precisions were all greater than or equal to 0.951 2. The results of cleaning experiment proved that the estimation was rational. The suitable range of cleaning air velocity for the threshed materials of foxtail millet was 4.29-5.48 m/s, and the optimal air velocity at air outlet was 4.47 m/s. Under the action of airflow with optimal air velocity, the loss ratio of grain was 4.68%, and the cleanliness of grain was 98.83%. The research results can provide reference for the determination of the timely harvest time and the optimal cleaning working parameters.

mechanization; harvesting; crops; foxtail millet; threshed material; suspension velocity; cleaning experiment

侯华铭,崔清亮,郭玉明. 全喂入谷子联合收获机脱出物含水率对其悬浮特性的影响[J]. 农业工程学报,2018,34(24):29-35. doi:10.11975/j.issn.1002-6819.2018.24.004 http://www.tcsae.org

Hou Huaming, Cui Qingliang, Guo Yuming. Effects of moisture contents of threshed materials from whole-feeding combine for foxtail millet on their suspension characteristics[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(24): 29-35. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.24.004 http://www.tcsae.org

2018-06-22

2018-12-10

国家重点研发计划课题(2016YFD0701801)

侯华铭,博士生,主要研究方向为旱作农业机械化关键技术与装备。Email:gxyhhm@163.com

崔清亮,教授,博导,主要从事旱作农业机械化关键技术与装备的研究。Email:qlcui@126.com

10.11975/j.issn.1002-6819.2018.24.004

S225.31

A

1002-6819(2018)-24-0029-07