基于改进TOPSIS法的供应商选择模型研究

高倩 李国栋

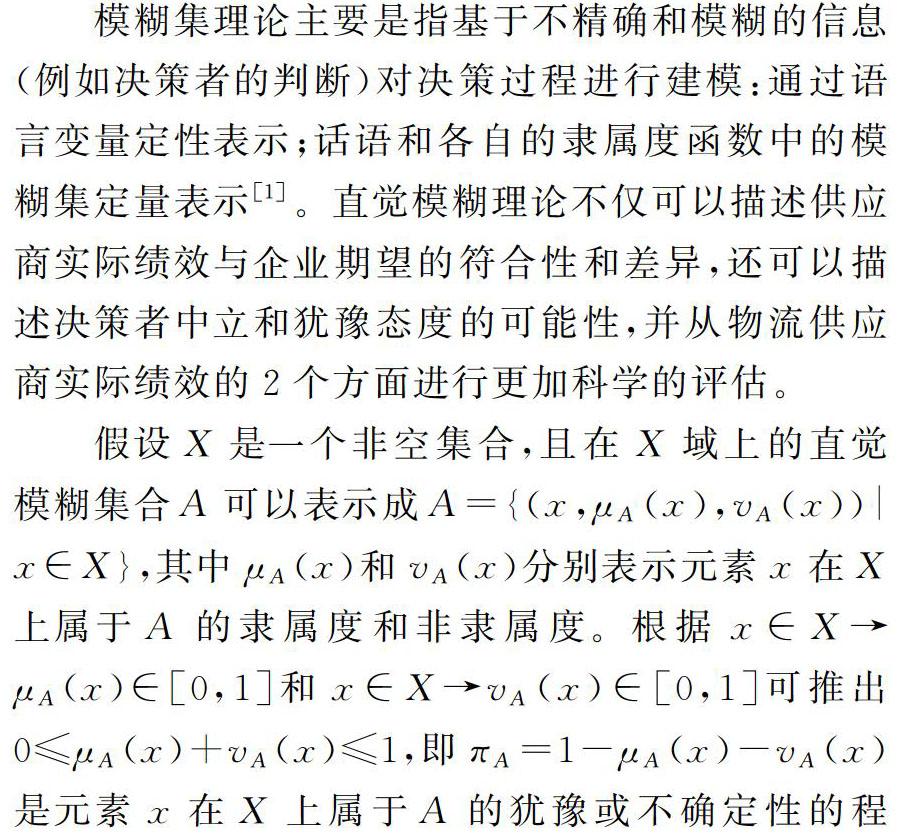

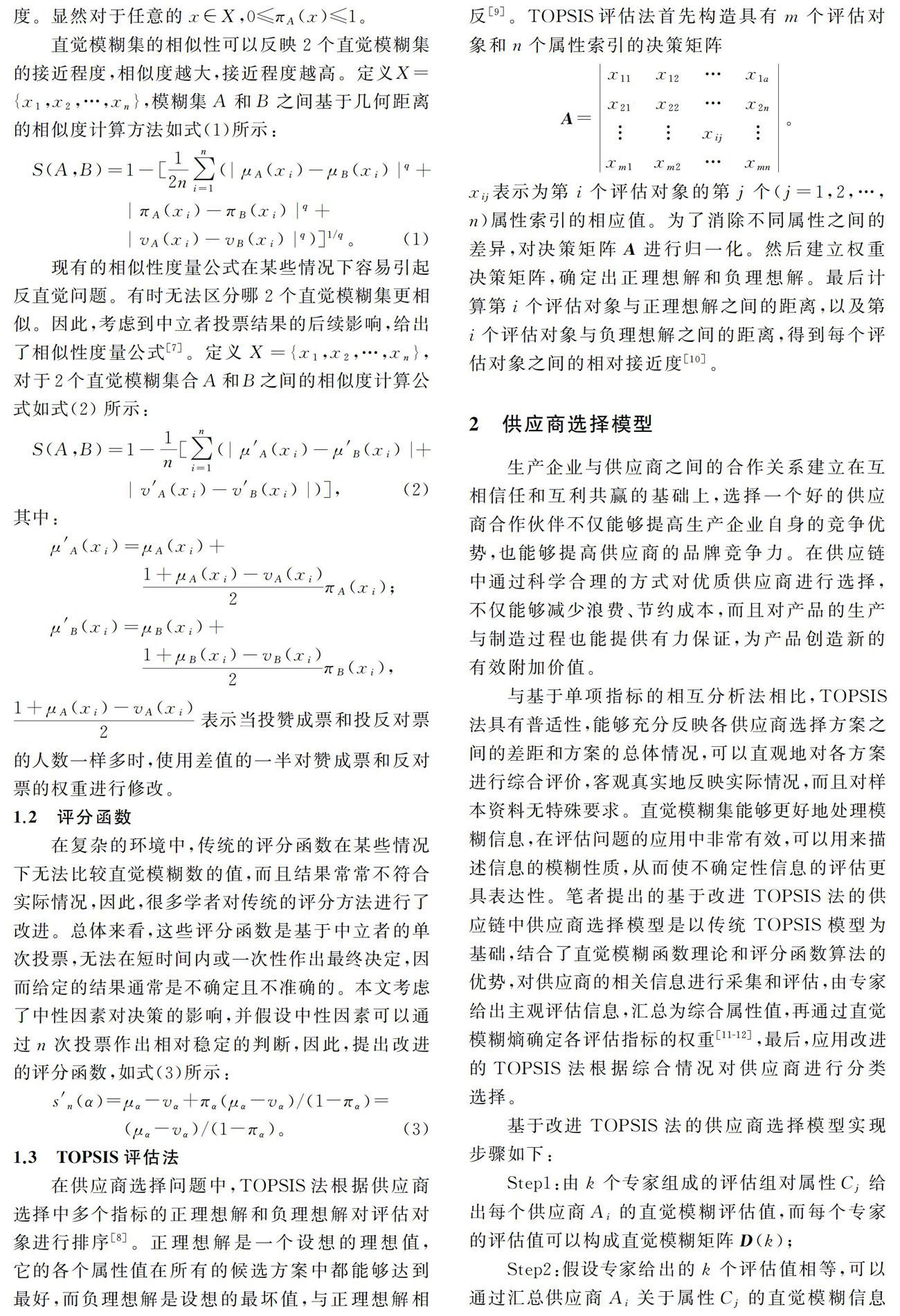

摘 要: 为有效地帮助企业快速找到合适的供应商合作伙伴,采用直觉模糊集、评分函数等方法对TOPSIS评估法进行优化,并以此为基础建立了一种供应商选择模型。

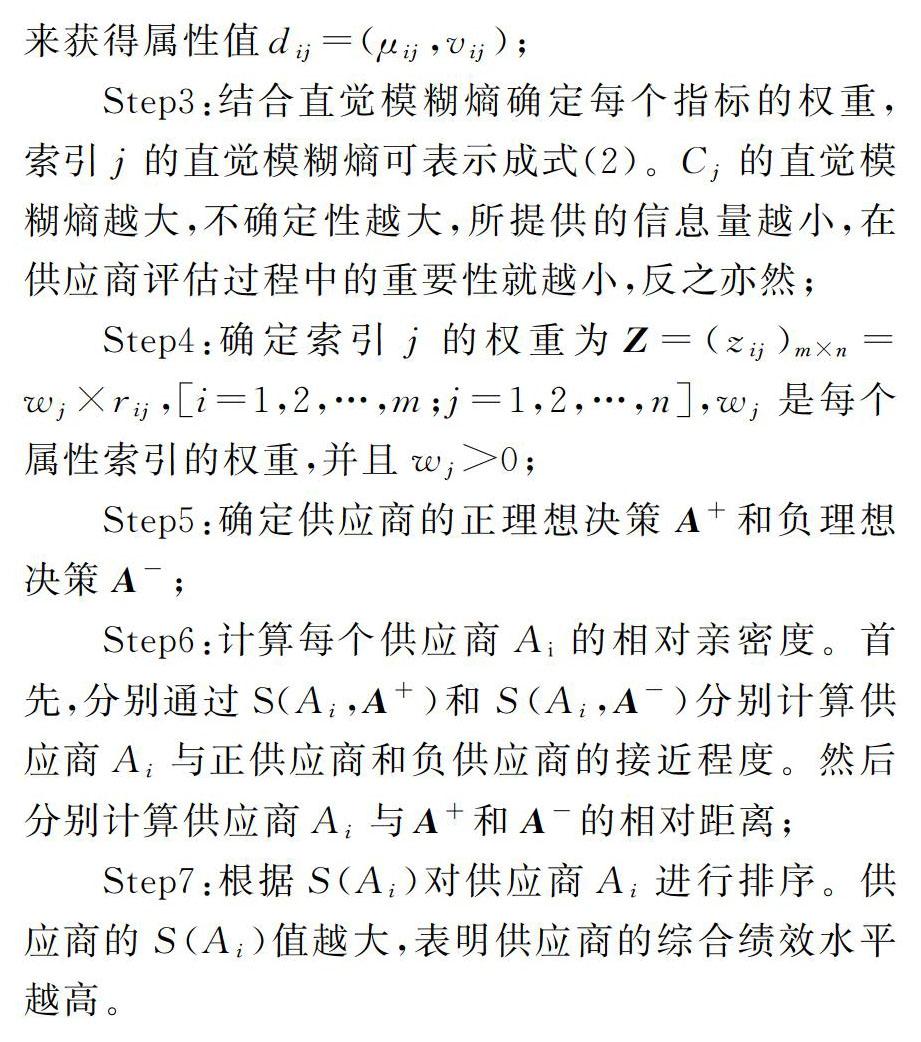

首先,采集和评估供应商的产品质量、产品价格、产品交货的可靠性、供应位置、财务情况、库存水平、劳资关系、发展能力和技术能力等相关信息,由专家给出主观评估信息,汇总为综合属性值;然后,通过直觉模糊熵确定各评估指标的权重;最后,综合考虑供应商选择决策过程中的多个目标和标准,应用改进TOPSIS法的对供应商进行分类选择。结果显示,基于改进TOPSIS法的供应商选择模型能够较准确地反映出各供应商的真实水平和对企业的潜在价值,可以有效地解决不确定条件下对供应商的选择问题,提高了供应商选择结果的可靠性。改进后的模型简便易行,具有良好的稳定性,对于合理制定企业供应商选择标准以及进一步优化决策模型具有一定的借鉴意义。

关键词: 决策理论;TOPSIS法;选择;供应链;供应商

中图分类号: F202 文献标识码: A

doi: 10.7535/hbgykj.2020yx06005

Research on supplier selection model based on

improved TOPSIS method

GAO Qian, LI Guodong

(School of Chinese Law and Economic Management, Shengli College China University of Petroleum, Dongying,Shandong 257000, China)

Abstract:

In order to help enterprises find suitable supplier partners effectively in a short time, the TOPSIS evaluation method was optimized by utilizing intuitionistic fuzzy sets and scoring functions, based on this, a supplier selection model was established. Firstly, the product information of suppliers such as quality, product price, delivery reliability, supply location, financial situation, inventory level, labor relation, development ability and technical ability of suppliers was collected and evaluated. After that, the subjective evaluation information was given by experts, and comprehensive attribute values were obtained. Then, the weight of each evaluation index was determined by intuitionistic fuzzy entropy. Finally, taking multiple objectives and criteria into consideration in the process of supplier selection, the improved TOPSIS method was applied to classify and select suppliers. The results show that the supplier selection model based on improved TOPSIS method can accurately reflect the true level and potential value of each supplier for enterprises. It can effectively solve the problem of supplier selection under uncertain conditions, and improve the reliability of supplier selection results. With merits of easier operation and better stability, the improved model provides significant reference for making reasonable supplier selection standards and further optimizing the decision-making model.

Keywords:

decision theory; TOPSIS method; selection; supply chain; supplier

國内外学者对供应商选择的研究主要集中在2个方面:一方面是供应商选择决策过程的方式和模型;另一方面是供应商的选择标准。针对决策过程的方式和模型角度,曹一哲等 [1] 指出,供应商的选择本质上是一个决策过程,其目的是将潜在供应商的初始集合尽可能缩减,以便在最后决策时能够从极少的几个备选单位中挑选出最佳供应商。先从现有的供应商库中选择或者寻找新的供应商,再根据当前情况对供应商的多个定量和定性指标进行评估,从而确定最终供应商。赵国军 [2] 认为由于部分无相关数据作为参考,大多数情况下的决策过程都存在不确定性,同时,多位决策者对定性和定量指标的评估具有主观性,一定程度上影响了评估结果的准确性。

1) 稳定性 使用改进模型对供应商进行排序,不断微调,观察模型数据在多次指标权重不同情境下的变化情况,发现改进TOPSIS模型对指标权重的调整是相对稳定的。因此,生产企业可以依据改进模型对供应商进行筛选。

2) 真实性 利用改进TOPSIS模型对企业的产品质量、产品采购价格、产品交货的可靠性、供应位置、财务情况、库存水平、劳资关系、发展能力和技术能力等方面进行评估,能够反映出供应商的实际水平和潜在价值。

3) 高效性 改进模型基于选择决策的多角度指标,将直觉模糊集和评分函数融入传统的TOPSIS决策评价方法,对供应商的产品质量等9项指标进行测算,并对供应商进行分类选择,最终筛选出能够真正体现实际潜力及客观水平的供应商。因此,改进模型能够帮助企业准确、迅速地挑选出合适的供应商。

改进的供应商选择模型的评价指标采用的是单一的评估类型值(即直觉模糊集数据类型),具有一定的局限性。为了提高模型的适用性,建议今后应尝试采用多种评估类型值(例如语言形式评估值、主观评估值、客观评估值等)对评价对象作出多维度评价,进一步提高模型的准确性。

参考文献/References:

[1] 曹一哲,杨玉中.基于熵值修正BWM的煤炭企业绿色供应商选择评价模型及应用[J].河南理工大学学报(社会科学版), 2020, 21 (4): 34-40.

CAO Yizhe, YANG Yuzhong. An entropy modification BWM-based evaluation model of green supplier selection for coal enterprises and its application[J]. Journal of Henan Polytechnic University (Social Sciences), 2020, 21 (4): 34-40.

[2] 赵国军.基于三角模糊集和MCDM的企业供应链管理绩效评估[J]. 财会月刊, 2016(30):80-83.

[3] 刘丽霞. 建设材料分类及供应商选择研究[D]. 大连: 大连理工大学, 2016.

LIU Lixia. Research on Construction Material Segmentation and Supplier Selection [D].Dalian: Dalian University of Technology, 2016.

[4] 史金朋. 改进TOPSIS法的装备可靠性评估方法[J].计算机测量与控制,2017,25(8):300-303.

SHI Jinpeng. A reliability evaluation method of equipment on improved TOPSIS[J]. Computer Measurement and Control, 2017,25 (8): 300-303.

[5] GOVINDAN K, RAJENDRAN S, SARKIS J, et al. Multi-criteria decision making approaches for green supplier evaluation and selection: A literature review[J].Journal of Cleaner Production, 2015, 98(1):66-83.

[6] KAR A K. A hybrid group decision support system for supplier selection using analytic hierarchy process fuzzy set theory and neural network[J].Journal of Computational Science, 2015,6:23-33.

[7] 趙婷婷.应急物流发展的现状与战略[J].辽宁工业大学学报(社会科学版),2020,22(2):38-40.

[8] 傅少川,黄亚卿.考虑风险规避的生鲜混合双渠道供应链协调研究[J].武汉理工大学学报(信息与管理工程版),2020,42(2):115-122.

FU Shaochuan, HUANG Yaqing. Coordination of fresh and mixed dual-channel supply chain with risk aversion[J]. Journal of Wuhan University of Technology (Information and Management Engineering), 2020, 42(2): 115-122.

[9] 白杨敏,李炎.生态系统视角下的物流产业集群创新体系研究——以天津市为例[J].物流技术,2020,39(3):48-54.

BAI Yangmin, LI Yan. Research on innovation system of logistics industrial cluster from ecosystem perspective: Taking Tianjin as example [J]. Logistics Technology, 2020,39 (3): 48-54.

[10] 李雷,杨怀珍,冯中伟. 供应链上游段VMI&TPL模式的利益分配机制——基于最大熵值法与正交投影法的整合视角[J].系统管理学报,2020,29(2):400-408.

LI Lei, YANG Huaizhen, FENG Zhongwei. Profit distribution mechanism of VMI & TPL model at upstream section of supply chain based on the perspective of integration of the maximum entropy method and vertical projection method[J]. Journal of Systems and Management, 2020,29(2):400-408.

[11] 吴倩,曹光四.基于层次分析法的供应环节选择研究策略[J].广西质量监督导报,2020(1):160-161.

[12] 王凯成,廖吉林.基于AHP和TOPSIS的Y药品集团物流配送中心选址研究[J].物流工程与管理,2020,42(1):67-69.

WANG Kaicheng, LIAO Jilin. Research on location of logistics distribution center of Y pharmaceutical group based on AHP and TOPSIS[J]. Logistics Engineering and Management, 2020,42 (1): 67-69.

[13] 王佳蓉. 基于跨阶段级联失效的集团型企业供应链网络稳定性研究[D].杭州:浙江工商大学,2020.

WANG Jiarong. Research on Supply Chain Network the Stability of Group-type Enterprises Based on Cross -stage Cascading Failure[D].Hangzhou: Zhejiang Gongshang University, 2020.

[14] 苏子豪. 供应链网络级联故障与脆弱性研究[D].南京:南京邮电大学,2019.

SU Zihao. Research on Cascading Failures and Vulnerabilities of Supply Chain Networks[D]. Nanjing: Nanjing University of Posts and Telecommunications, 2019.

[15] 张亮星,王少华,张明尧.串联可修复供应链运行可靠性研究[J].机械设计与制造,2019(11):25-28.

ZHANG Liangxing, WANG Shaohua, ZHANG Mingyao. Research on operation reliability of repairable series supply chain[J]. Machinery Design and Manufacture, 2019 (11): 25-28.

[16] 范露华. 基于熵权TOPSIS模型的建筑物料供应商评价与管理研究[J].重庆理工大学学报(自然科学),2019,33(12): 240-248.

FAN Luhua. Research on the construction material supplier evaluation and management based on entropy weight TOPSIS model[J]. Journal of Chongqing University of Technology (Natural Science), 2019,33 (12): 240-248.

[17] 趙军阳,张志利.基于模糊粗糙集信息熵的蚁群特征选择方法[J].计算机应用, 2009,29(1):109-111.

ZHAO Junyang, ZHANG Zhili. Ant colony feature selection based on fuzzy rough set information theory[J]. Journal of Computer Applications, 2009,29(1):109-111.

[18] 胡劲松,陈怡宁.多目标问题的逼近于理想解的排序方法研究[J]. 青岛大学学报(自然科学版), 2013(1):72-76.

HU Jinsong, CHEN Yining. Techique for multiple objective system order preference by similarity to ideal solution[J]. Journal of Qingdao University(Natural Science), 2013(1): 72-76.

[19] YILDIZ A, YAYLA Y A. Application of fuzzy TOPSIS and generalized Choquet integral methods to select the best supplier[J]. Decision Science Letters, 2017, 6(2):137-150.

[20] 孙希彤,刘秋生,王乐军.基于改进权值和TOPSIS质量评估方法[J].计算机测量与控制,2017,25(1):228-231.

SUN Xitong, LIU Qiusheng, WANG Lejun. Method of quality assessment based on improved weight and TOPSIS [J]. Computer Measurement and Control, 2017,25 (1): 228-231.

[21] 韩二东,徐国东.基于直觉模糊交叉熵及灰色关联的混合评价信息供应商选择决策[J].科学技术与工程,2017,17(7):1-9.

HAN Erdong, XU Guodong. Supplier selection decision making method based on intuitionistic fuzzy cross entropy and grey relational[J]. Science Technology and Engineering, 2017,17(7):1-9.

[22] 赵萌, 邱菀华. 基于混合信息的供应商选择熵决策模型[C]//统筹优选与经济转型——中国管理科学学术年会. 杭州: [s.n.] , 2011:511-517.

[23] 李晓英. 大型餐饮企业绿色供应链管理的供应商选择与契约协调模型研究[D]. 大连:大连理工大学,2018.

LI Xiaoying. Research on Models of Supplier Selection and Contract Coordination for Green Supply Chain Management of Large-scale Restaurants[D]. Dalian: Dalian University of technology, 2018.