薄膜类柔性微型机器人研究进展

庞文博 徐世威 张一慧

摘要 近年来,随着三维微电子器件及微系统技术的迅速发展,微小型化逐渐成为机器人领域最重要的发展趋势之一。薄膜类微型机器人具有体积小、重量轻、鲁棒性高、柔韧性好、与平面制备工艺兼容等优点,因而是一类极具潜力的微型机器人,具有重要的研究价值。本文首先综述了薄膜类柔性微型机器人的代表性制备方法,随后,较为全面地回顾了基于不同驱动机制的薄膜类机器人,并对该领域所面临的机遇与挑战进行了展望与讨论。

关 键 词 薄膜类机器人;微型机器人;三维微组装;柔性机器人

中图分类号 TP242 文献标志码 A

Abstract With rapid development of three-dimensional (3D) microelectronics and microsystems technologies in recent years, the miniaturization of robots has received increasingly growing attention. Thin-film-based miniaturized robots represents a very promising research direction, since these robots combine versatile features of small size, lightweight, good robustness, high flexibility and excellent compatibility with modern planar technologies. This article reviews the fabrication methods of thin-film-based flexible miniaturized robots, followed by discussions on the various actuation mechanisms exploited by flexible miniaturized robots. Finally, more opportunities and challenges in this research area are discussed.

Key words Thin-film-based robots; miniaturized robots; microscale 3D assembly; flexible robots

0 引言

微型机器人通常指身躯长度小于15 cm、质量小于20 g的机器人[1]。这类机器人通常具有体积小、重量轻、灵活性高等优点,能够顺利进入一些特殊的非结构化环境中执行任务[2-4]。目前,微型机器人已在众多领域中展现出其巨大的应用潜力,如生物医疗领域的靶向药物输送[4-5]和微创外科手术[6]、救援领域用于搜救的飞行器和危险环境中的任务执行等[7-9]。另一方面,软体机器人由于其柔软的身躯、灵活的自由度、良好的环境适应性和鲁棒性以及友好的人机交互等特点,也越来越受到研究者的关注。目前,软体机器人通常由一些弹性模量较低的软材料构成,然而,较低的身躯弹性模量也会带来一些额外的挑战[10]。例如,与刚性机器人相比,其控制性较弱;将控制电路、传感元件、电源和其他功能模块有效集成到软材料中也是一个不小的挑战;微纳米尺度下软材料结构的制备无法很好地兼容传统微纳制备工艺[11]。因此,如何將微型机器人与软体机器人有效结合,一直是研究者努力的方向之一。

当前,细微观尺度下的三维成型工艺正在蓬勃发展,其在生物医疗器件、微尺度机器人等功能器件[12]的制备中发挥着重要的作用。现有的相关三维成型工艺大致有两类:直接三维成型法和间接三维组装法。其中,间接三维组装法是在传统的平面图案化工艺基础上,利用“二维到三维”的组装过程来实现。相比于直接三维成型法(如3D打印技术、三维激光直写等方法),三维组装技术的主要优点在于可以制备复杂的三维高性能材料(如半导体、石墨烯等)骨架,且制备过程往往是并行的,这将使其在制备速度和材料兼容性方面具有更大的优势[13]。基于三维组装成型技术,以薄膜类机器人为代表的微型机器人也受到越来越多的关注,其特点是身躯或关键驱动单元由薄膜型结构组成[14]。以薄膜为主要骨架的微型机器人具有更低的弯曲刚度,即使结构本身采用较刚硬的材料制备,也可以获得很好的柔韧性[15]。

本文分3个部分详细阐述薄膜类柔性微型机器人的研究进展。首先,介绍薄膜类柔性微型机器人的主要制备方法,包括二维图案化工艺和相关三维组装技术;随后,较为全面地回顾了基于不同驱动机制的薄膜类柔性微型机器人;最后,对该领域所面临的机遇与挑战进行展望与讨论,并对全文进行总结。

1 薄膜类柔性微型机器人的制备方法

传统刚性机器人的制备主要依赖于数控机床等加工设备。与之不同的是,薄膜类柔性微型机器人的制备通常分为两步:薄膜的二维图案化制备和二维到三维的组装。下面将依次对这两部分进行详细介绍。

1.1 用于薄膜类柔性微型机器人的平面图案化工艺

在薄膜类机器人领域,常见的平面图案化工艺包括:

1)直写技术。根据直写原理的不同一般可以将其分为减成法和加成法两类,该技术无需掩模板,周期短、材料利用率较高。其中,减成法主要指的是激光刻蚀直写技术(也称激光切割),该技术利用激光使材料气化或融化燃烧,从而对平面材料进行图案化切割。加成法可以根据不同的需求在基底表面沉积不同成分的膜层,灵活度高,节约原料。其中加成法主要包括喷墨打印、微流动沉积直写、激光直写等。目前,常用于薄膜类机器人二维图案化的直写技术是激光切割[28-29]和喷墨打印技术[30]。

2)光刻工艺。光刻工艺是微尺度薄膜机器人图案化成型最常用的手段,该工艺利用光刻胶敏感度的不同,在光照下发生物理化学反应,从而将图案从光掩模板转移到基板上。该方法具有对准和套刻精度高、掩模板制作简单、工艺条件成熟等优点。微尺度下薄膜机器人的结构和电路的图案化制备大多离不开光刻工艺[14,31-33]。

3)软刻蚀工艺。软刻蚀工艺也称软光刻,最早由美国哈佛大学Whitesides等[34]于1993年提出。通过弹性图章、模具和光掩模进行图形复制和转移,利用表面特性实现图案化。软刻蚀工艺是建立在光刻的基础上发展而来的,具备传统光刻工艺的诸多优点。同时,软刻蚀工艺的制备成本更加低廉、操作更加简便、材料兼容性更好,且适用于柔性和刚性基板上的非平面、大面积图案化。一些利用压力等驱动方式的薄膜类机器人常利用软刻蚀工艺[25,35-36]来制备。

4)电离印刷工艺。电离印刷工艺(Ionoprinting)[37-38]常被用于制备一些特殊凝胶类薄膜机器人,该工艺利用图案化金属印章将金属离子通过电离的方式,图案化地精确渗透到凝胶材料内部,进而改变凝胶的局部交联网络,该局部区域的密度、刚度和热响应等性质都会随之产生变化。利用该工艺可以进一步实现凝胶材料的可编程变形。

5)浇注成型。对于一些利用软材料(凝胶等)制备的薄膜机器人[39-41]来说,平面浇注成型技术是较为常见的图案化手段。该方法通过将液体状态下的软材料倒入硬质模具表面来实现软材料的图案化。

6)3D打印技术。3D打印技术是一种常用的直接三维成型工艺,适用于各种构型的二维/三维结构制备。在过去的数年中,利用3D 打印技术制造的软体机器人受到广泛关注[42-49]。 3D打印技术可以制备由凝胶、流体、功能聚合物等软/硬质材料构成的薄膜类机器人。

1.2 用于薄膜类柔性微型机器人的三维组装技术

我们将图案化的二维前驱体结构组装成复杂三维构型的过程称为三维结构的组装。对于一部分宏观尺度的薄膜机器人来说,其制备方法往往采用手工装配的方式[17]。这类方法具有方便、快捷、成本低等优势。但对于一些组装精度要求高、组装规模大、构型复杂且尺寸小于1 cm的微型机器人来说,手工装配无法满足要求。本节将主要讨论微尺度下用于制备薄膜类机器人的三维组装技术。

近年来,三维器件的微小型化越来越成为电子系统、机器人等领域重要的发展趋势之一。当前,细微观尺度下的三维组装技术是一类间接的三维组装方法,该技术基于较为成熟的平面图案化工艺,经历“二维到三维”的组装过程,克服了直接三维成型法中的一些技术局限性[50]。三维组装技术不仅可以用于复杂的三维高性能材料(如金属、半导体、聚合物、压电薄膜、石墨烯、二硫化钼等)的制备,还可以与许多智能柔性材料(如功能性凝胶等)兼容[12],这一特点为三维组装技术在薄膜机器人的制备奠定了基础。在众多三维组装技术中,根据其加载或变形的特点,我们可以将其分为屈曲组装、卷曲组装、折叠组装和共形组装4类,如图1所示。其中,屈曲组装方法[51]主要依赖于可变性的弹性基底,通过弹性基底的机械变形来诱导基底表面二维前驱体的组装;卷曲组装方法[52]一般通过引入内部应力梯度或外力来驱动二维前驱体结构的整体弯曲变形,用于制备管状或螺旋状等三维构型;折叠组装方法与卷曲组装类似,不同之处在于应力梯度布置的位置,折叠组装[53]一般只在局部区域引入应力梯度,使二维前驱体发生有折角的弯曲变形,类似于带铰链机构的折叠变形;共形组装方法[54]侧重于通过高效的转移印刷技术将二维前驱体与曲面弹性基底共形贴附,进而形成与弹性基底形貌相同的三维结构。下面的小节将依次对上述几种方法进行介绍。

1.2.1 屈曲组装方法

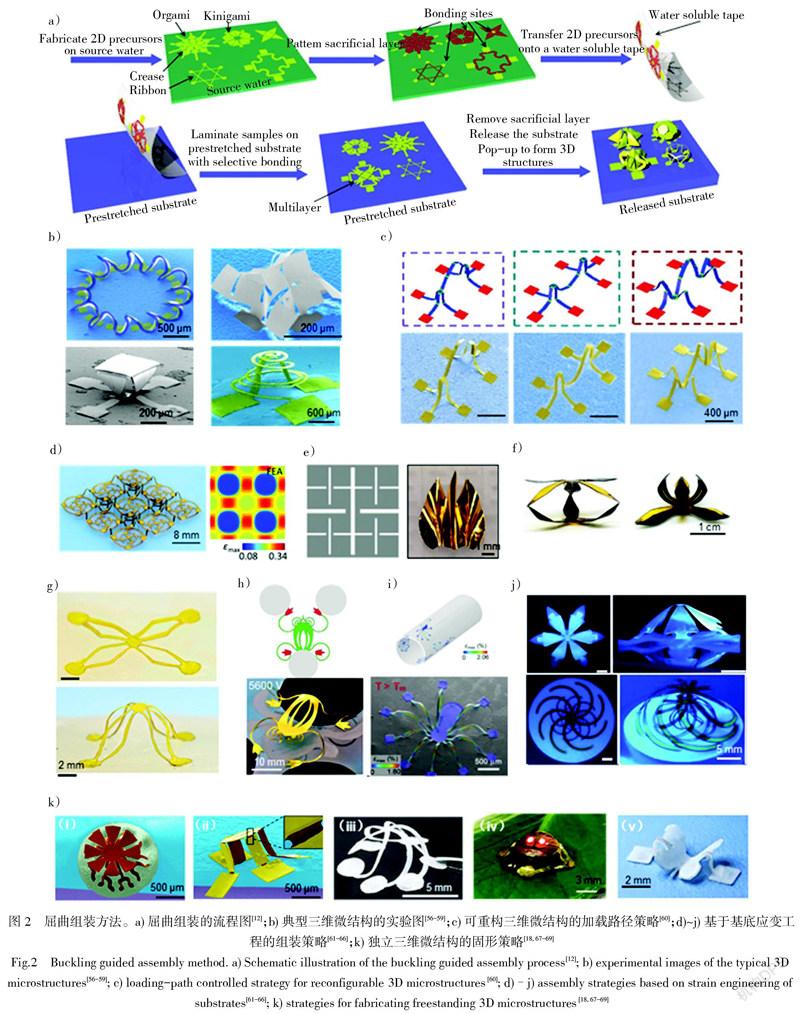

屈曲组装方法主要利用可拉伸弹性基底作為组装平台,该组装平台可以为二维前驱体的组装提供必要的驱动力[51,55]。图2a)展示了屈曲组装的过程,其中包括3个关键步骤,即二维前驱体的制备、转印和力学引导的三维结构屈曲成型。首先,利用平面图案化工艺制备所需的二维前驱体结构,在宏观尺度下,我们可以采用激光刻蚀等图案化工艺制备二维前驱体,而在微纳米尺度下,往往采用光刻等更高精度的平面加工工艺来完成。随后,采用离子溅射或蒸发镀膜的方法制备牺牲层和黏结点层,其中的黏结点层主要用于二维前驱体与后述弹性基底的黏结。此时,需要依靠弹性印章或水溶性胶带将二维前驱体转印到预拉伸后的弹性基底表面,然后对黏结层进行激活,使二维前驱体与预拉伸弹性基底实现选择性强黏接。最后,释放弹性基底的预应变,由于弹性基底的牵拉作用,二维前驱体会在黏接部位受到压缩力作用,发生屈曲失稳而变形为三维结构。在屈曲组装过程中,有几个关键的控制因素:二维前驱体的图案、弹性基底的应变场分布和应变释放的路径。同时,使组装完成的三维结构顺利脱离弹性基底并保持三维构型,对薄膜类柔性微型机器人的制备具有重要意义。在这一小节中,将介绍上述几个关键控制因素及其相应的设计策略,最后展示几种常见的三维结构固形方法。

首先介绍二维前驱体结构的设计策略。我们可以将二维前驱体图案大致分为以下4种类型:条带形结构[58]、剪纸形结构[57]、折纸形结构[56]和多级结构[59]。条带形结构通常由细长的薄条带组成,其厚度远小于宽度,宽度远小于弧长,如图2b)左上角实验图所示[58]。图2b)右上角展示的是基于剪纸概念制备的三维结构[57],该策略充分利用了剪纸结构的特点,显著降低了屈曲过程中结构内部的应力集中,可以有效避免一些脆性(半导体材料等)结构的破坏。进一步地,通过对剪纸刻痕图案的设计,可以进一步增加三维几何构型的丰富性[57]。受折纸艺术的启发,通过对二维前驱体局部刚度的非均匀设计,可以在三维结构中引入折痕,如图2b)左下角所示[56]。图2b)右下角则展示了一种多级结构,通过对多层二维前驱体进行多次转印并组装,可以得到如图2b)右下角中的几何构型,这类结构往往具有更高的空间密度[59]。

随后介绍基于基底应变工程的组装策略,包括:基于机械加载的基底调控策略和基于智能材料的基底调控策略。在第一种调控策略中[61,70],研究者提出利用基底厚度[70]或弹性模量[61]的非均匀分布来实现基底的应变场非均匀分布。非均匀厚度的弹性基底通常采用浇注成型或软光刻等方式制备,弹性基底在较厚区域的拉伸应变较小,因此对应区域的二维前驱体在组装过程中的变形也更小。进一步,通过对基底弹性模量的非均匀设计,可以实现更大的应变梯度分布。图2d)展示了基于该策略的一种棋盘式应变场分布和对应的非均匀三维结构阵列[61]。此外,将剪纸设计概念引入弹性基底,可以使基底在变形过程中产生局部旋转位移[64],如图2e)所示。利用该策略可以得到一些具有手性特征的三维结构。在基于智能材料的基底调控策略中,研究者分别将介电弹性体[63]、形状记忆聚合物[71]、水凝胶[65]和激光诱导石墨烯复合材料[62]用于弹性组装平台。图2h)展示的是利用介电弹性体组装平台制备的三维“类青蛙”结构,该组装策略的特点是组装速度快(1 s内完成组装)、基底应变场可设计性强等。通过将机械加载(释放预拉伸弹性基底)与电驱动加载(介电弹性体电致变形)结合,可以使已成型的三维构型发生再变形,即重构。图2f)展示的是基于激光诱导石墨烯复合材料的组装策略。利用激光实现在聚酰亚胺薄膜表面改性以产生多孔石墨烯材料,并利用石墨烯电热效应使结构产生弯曲变形[62]。将这类复合材料作为组装平台或二维前驱体,可以得到如图2f)所示的可重构结构。图2g)展示了将液晶弹性体(LCE)作为基底的例子[66],LCE具有拉伸应变较大、可逆远程热响应等特点。类似地,可以利用形状记忆聚合物(SMP)作为弹性基底[71],如图2i)所示。该策略可以将基底与结构作为整体,方便按需组装与重构。图2j)则展示了利用热敏水凝胶制备的弹性基底[65],该基底在热刺激下会发生面内变形,进而诱导二维前驱体的组装。

在弹性基底的应变释放路径方面,研究者于2018年提出将传统的压缩屈曲变形模式转换为拉伸屈曲模式[72],实现了一些特殊结构(蛇形线结构、蜿蜒条带结构等)的高效组装。此外,通过改变预拉伸基底的预应变释放顺序,研究者首次提出基于加载路径调控的微尺度屈曲组装策略[60,73],极大地丰富了可重构三维结构的几何构型。图2c)展示了基于该策略实现的具有3个稳态的可重构三维结构。

弹性基底在一定程度上限制了所组装结构的应用领域,因此将屈曲组装得到的三维构型有效固定并脱离基底具有重要意义。图2k)中展示了几种不同的固形策略[18,67-69],其中图2k)(i)中,研究者利用界面光聚合[18],将光刻胶滴到三维结构表面,利用紫外光对光刻胶的固化作用制备硬质衬底,用于三维结构的固定,该方法具有广泛的适用性。图2k)(ii)展示了一种有效利用金属塑性变形的固形策略[18]。在二维前驱体结构中引入金属材料,当结构组装完成并与基底脱离后,由于金属层的塑性作用,三维结构会在小范围回弹的基础上保持较好的三维构型。图2k)(iii)中研究者将SMP用于二维前驱体结构的制备[67],屈曲后的三维结构经历一次温度循环后便可有效保持三维构型。类似地,将LCE作为二维前驱体结构,利用LCE在紫外光作用下的固形能力也可以较好地实现三维结构的固形,如图2k)(v)。此外,通过巧妙的结构设计,可以实现基于“钩子、凸耳”基本单元的“自锁”三维结构[68],如图2k)(iv)所示。

1.2.2 卷曲组装方法

卷曲组装的过程中二维前驱体会发生整体性弯曲变形,这类组装方法可以较好地实现微尺度下卷筒状/螺旋状三维微结构的制备。本小节将介绍两种实现卷曲组装的策略,即由残余应力诱导的卷曲策略[52,74-76]和基于活性材料的卷曲策略[2, 77-79]。图3a)展示了利用非外延沉积技术引入残余应力的策略[76]。该策略首先需要在低温下将有预应力的无机纳米薄膜沉积到犧牲层表面,然后利用溶剂去除牺牲层,最后纳米薄膜在内部应力释放后形成微/纳米管(图3a)左)。图3a)右侧分别展示了利用该策略制备的Pt和TiO2管状结构。对于活性材料的卷曲组装策略,Gladman等[79]通过控制水凝胶复合材料内的局部纤维方向,打印了具有局部各向异性膨胀特性的二维前驱体,在浸入水中时二维结构会发生复杂的溶胀变形,进而形成三维构型。

1.2.3 折叠组装方法

折叠组装方法通常利用二维前驱体在局部区域的弯曲实现结构的折叠变形,类似于刚性板在铰链处的弯折。其驱动力包括毛细力、智能材料响应变形、残余应力等。我们以毛细力为例来介绍折叠组装策略[82-84]。Py等[84]利用聚二甲基硅氧烷(PDMS)制备了四面体、长方体和六棱锥等三维结构。在该组装过程中,随着水分的蒸发,折叠角度会由于毛细力的作用而逐渐增大,最终导致结构完全闭合。从能量角度来看,该过程中的表面能(γA)转化为弹性应变能,最终导致结构的折叠变形。另外,通过采用智能材料,同样可以形成有折角的三维结构[80,85-86]。图3b)为室温在水性缓冲液中组装得到的微型“类鸟”结构[80]。随着温度在22~55 °C之间变化,由聚(N-异丙基丙烯酰胺-共聚-丙烯酸钠)(PNIPAM)共聚物制成的水凝胶层会在局部区域发生膨胀与收缩,进而实现结构在平面与折叠“鸟”构型之间的可逆变换。

1.2.4 共形组装方法

共形组装方法[81,87-89]是基于转移印刷技术发展起来的一类三维共形贴合的组装方法。在薄膜机器人的制备中,这类组装方法通常用于制备类球形、环状等较为规则的三维身躯结构[90]。本小节以图3c)为例介绍一种典型的三维转移印刷技术。如图3c)所示的水转印技术,首先,在水溶性基底上布置导电图案,然后将基底放入热的去离子水表面,待薄膜溶解后,将曲面基板浸入水中,图案会共形贴附到三维基板表面[81]。该策略可以在具有复杂弯曲形状的一般物体上制备三维图案化结构。

2 基于不同驱动机制的薄膜类柔性微型机器人

薄膜类柔性微型机器人的驱动单元主要由薄膜驱动器组成。本节根据薄膜驱动器的激励类型对其进行分类和介绍,其中涉及聚合物、复合材料、功能性软材料等不同类型的材料。薄膜驱动器的激励类型主要包括电响应[15,29-32,37,90-99]、磁响应[2,27,44-48,78,100-115]、热响应[22-23,62,66,69,116-131]、光响应[20-21,39,41,124,132-170]、化学响应[14,18,40,71,139,171-200]和压力响应[24,36,201-207]。其中,电、光、磁这样的驱动方式可以实现对控制信号幅值、相位、频率等参数的精确、快速调控,同时实现对机器人的无线控制,这对微尺度机器人的控制具有重要意义[11]。电场可以通过有线方式对机器人进行控制,也可以通过电场发生装置产生复杂电场分布;磁场可以穿透大多物体,因此,磁驱动薄膜机器人往往是无线控制;光驱动也可以用于无线控制,但驱动效率较低。除此之外,热驱动也是薄膜机器人常用的驱动方式之一,通过内部热应力失配或智能材料的热响应变形,机器人可以实现高效运动。化学驱动一般利用内部化学成分、湿度或pH值的变化来实现结构的變形,但这类驱动器往往需要在某些特殊环境(如液体、密封环境等)中操作,且响应速度较慢。

2.1 电响应驱动

目前,能够将电能转换为机械能的薄膜型驱动器有很多,包括压电薄膜驱动器、离子型电致活性聚合物驱动器、功能性凝胶等智能材料驱动器,也包括利用外加物理场实现的电致变形驱动器(即静电力驱动的薄膜结构和介电弹性体驱动器)。电响应驱动的主要优势是能够实现信号相位、幅值和频率的高效控制与调制,可以与传统的电子设备兼容,是机器人标准化控制的首选驱动方式之一。

2.1.1 压电功能材料驱动

材料的压电效应通常指某些无对称中心的晶体材料在受到外力时,物体内部产生异号电荷或电势差的现象。相反地,当该材料两端存在电场时,材料会产生电致变形,这一过程被称作逆压电效应[208]。目前,应用于薄膜型微型机器人的压电材料主要是锆钛酸铅压电陶瓷(PZT)和聚偏氟乙烯压电薄膜(PVDF)。在压电机器人的低频驱动方面[28,93,95,209-211],Xiao等[91]于2016年制备了水面运动的仿生机器鱼,其中用到了石墨烯/PVDF复合材料。Qu等[95]和Wood 课题组[209,211]分别利用PZT复合材料制备了毫米/厘米尺度薄膜机器人,实现了机器人的精确控制以及爬行、爬墙、飞行等多种运动模式。在压电机器人的高频驱动方面[15,91,212-213],Wu等[15]于2019年设计了一款基于PVDF多层复合材料的薄膜机器人,研究者分析了昆虫的快速爬行机制,并利用PVDF复合材料的逆压电效应实现了机器人在高频电压驱动下的快速运动(20身长/s)。该机器人充分体现出薄膜类机器人轻质和鲁棒性高的特点。

2.1.2 静电力驱动

薄膜类静电驱动器是一类利用电荷间相互作用实现的驱动元件,由于其执行效率高、响应时间短、功耗低等优点,常被用于高频电压下的驱动。但这类驱动器也有明显的缺点,包括:驱动力较小、驱动电压较高、工作量程较小、易发生介质电击穿等。2006年,Donald等[31]基于MEMS微加工工艺和静电吸附原理,研发了一款微米尺度的薄膜机器人,通过施加周期性静电力使机器人身躯发生不对称变形,进而实现机器人的沿轨迹爬行。这类机器人虽然实现了无线控制,但依然被束缚在特殊基底表面,且运动速度较慢。2017年,Shigemune等[30]利用喷墨打印工艺和卷曲组装技术,制备了一款宏观尺度的三维薄膜机器人。2018年,Taghavi等[99]将单极型静电驱动器应用于机器人的重物抬升,借助折纸设计并引入液体介质,实现了静电驱动下人造肌肉较大的驱动力。2020年,Jin等[17]同样采用单极型电极设计,制备了运动速度较快的静电驱动机器人(0. 7身长/s),如图4a)所示。该机器人可以实现越障、爬坡等复杂环境下的爬行,且具有较高的鲁棒性。2021年,Wang等[29]开发了一款毫米尺度的仿肌肉柔性静电驱动机器人,采用双激励多相静电驱动(dual excitation multiphase electrostatic drive)的原理[214],通过在不同层之间施加不同相位的三相交流电,可以实现层间的位错运动。

2.1.3 电致活性聚合物驱动

电致活性聚合物(EAPs)指能在电刺激下改变大小和形状的聚合物,这类材料具有较大电致变形/电驱动力、低噪音、低模量、高断裂韧性等特点,并且制备工艺相对简便[215]。EAPs材料主要分类两大类:电场型EAPs和离子型EAPs。在这一小节,我们主要讨论两类常被用于薄膜机器人制备的材料:介电弹性体 (DE)和离子导电聚合物 (IEAP) 。其中,DE属于电场型EAPs,很早便受到了研究者的广泛关注[92, 216-217]。IEAP属于离子型EAPs,在电场作用下其内部离子或溶剂会重分布,进而发生形状改变[218]。IEAP具有工作电压低、生物兼容性好、蠕变少、单周期能量密度高、微纳米尺度下易制备等优势,但工作寿命较为有限,且大多需要在液体或液体封装环境中使用[219]。

目前,薄膜类DE驱动器主要以双层复合结构为主[96, 220-222]。图4b)展示了一种以机械能为动力源的新型摩擦电软机器人系统 (TESR)[16]。TESR是由柔性身躯(DE复合层结构)和2个静电脚掌构成,利用摩擦电效应驱动。图4c)展示了一种利用预拉伸DE薄膜与被动层相结合的薄膜型抓手[96]。将抓手表面柔性电极进行图案化的方法有很多,例如,石墨碳膏/石墨粉一般采用丝网印刷或直接涂抹、银浆或可拉伸金属薄膜采用选择性薄膜沉积或印刷等工艺[223]。

基于MEMS微加工工艺, Jager等[32]于2000年制备了基于聚吡咯-金双层复合材料的IEAP微米尺度机器人手臂,用于操纵细胞等微米大小的物体。Must等[224]在IEAP材料的表征及IEAP机器人方面做了很多研究工作[90, 225]。图4d)展示了其在2015年制备的一款基于IEAP復合层结构的厘米尺度机器人,驱动部分由活性炭基电极和离子液体作为电解质,利用共形贴附结合加热固形的工艺得到圆弧状三维构型,实现了IEAP机器人在干燥环境中的无线自供电运动。

2.1.4 电响应凝胶驱动

浸没于离子溶液中的电响应凝胶可以在电场作用下改变内外离子浓度,吸收或释放大量液体,进而实现凝胶本身体积的巨大变化。这种材料通常在低电压下便可被驱动,同时具有较好的生物相容性,但其响应速度慢,且依赖电解质溶液,在驱动过程中也容易产生热量或气体[226]。2008年, Kwon等[97]利用电响应凝胶制备了类章鱼、精子和多足水生物等仿生机器人(图4e)),该机器人是采用基于微流控平台的顺序原位光聚合方法,对凝胶材料进行图案化曝光得到的。2013年,Palleau等[37]提出电离印刷 (ionoprinting)工艺,利用图案化金属印章通过电离的方式,将金属离子快速转移到凝胶体系中,得到了“二维-三维”可逆变形的薄膜类凝胶机器人。2014年,Morales等[98]将两种变形方向相反的电响应凝胶集成在一个机器人身躯中,实现了机器人的地面双向爬行。

2.2 磁响应驱动

利用磁场力或洛伦兹力可以实现对薄膜机器人的有效驱动。这类磁响应驱动的特点包括:非接触远程控制、可精确操纵、较强可控性等。制备磁响应材料的方法有很多,例如,可以将磁性填料掺入到基体材料中得到组合方式丰富的磁响应材料,也可以利用蒸镀、溅射等方式将磁性材料直接沉积到基体材料表面。本节将按照材料种类将磁响应材料分为:磁响应聚合物[2,27,44-46,48,100,102-103,105,107-108,112-113,115,227-229]、磁响应水凝胶[22, 42, 101, 230]、磁响应形状记忆聚合物[104, 111, 114]和其他磁响应材料,并分别对其进行介绍。

2.2.1 磁响应聚合物驱动

磁响应聚合物通常指嵌有磁性颗粒的软/硬聚合物材料,这类材料可以通过3D打印、光刻等工艺制备二维图案化结构[107-108]。对于磁弹性软聚合物,在毫米尺度下,Sitti团队[2]于2018年制备了一款在磁场下具有滚动、行走和跳跃等多种运动模式的机器人,又于2019年设计了毫米尺度仿生游泳机器人[27],如图5a)所示。该机器人由外部振荡磁场驱动,可以完成物体捕获等功能。此外,有研究者在磁弹性体的微尺度制备方面做了很多工作。2016年, Huang等[100]基于光刻工艺制备出多模式运动的游泳机器人。Cui等[228]于2019年基于电子束光刻制造出纳米磁性驱动器,在不同磁场下具有不同的变形模式。2018年,Zhao团队[44]基于直接墨水书写(DIW)技术,打印了一系列具有任意图案和磁畴分布的薄膜机器人,其在磁场作用下可以快速完成形变。Xu等[48]于2019年利用数字光处理(DLP)技术对微米尺度平面结构中的磁性粒子进行磁化编码,得到兼具抓取、爬行、游泳等多种运动模式的薄膜机器人。

在基于硬质磁响应聚合物的薄膜类微型驱动器研究方面,研究者[102,105,115]利用电子束沉积实现聚合物表面软磁性薄膜的加工,基于力学引导的屈曲组装方法实现复杂三维结构的制备。在磁场力/洛伦兹力驱动下,实现了三维微电子器件的重构与精确控制。图5b)展示了利用该方法得到的类蝴蝶的可重构结构。

2.2.2 磁响应水凝胶驱动

磁响应水凝胶是一种具有亲水性聚合物链并表现出弹性行为的聚合物,这些聚合物网络可以包含质量超过 90%的水分。由于其低刚度和良好的生物相容性,水凝胶已在生物医学应用领域得到广泛的关注。磁性粒子的掺入赋予了水凝胶磁响应变形的能力[22, 42, 101, 230]。如图5c)所示,Breger等[22]于2015年基于光刻工艺制备出微型水凝胶抓手,该机器人通过磁场实现空间移动,同时可以在纤维细胞团中捕获和切除细胞。2020年,Li等[101]制备了一款磁/光耦合驱动的机器人,该机器人在磁场控制下可以沿着预定的路径运动。

2.2.3 磁响应形状记忆聚合物驱动

磁响应形状记忆聚合物(SMP)是基体材料中掺杂有磁性颗粒的SMP材料,其主要原理是在高频交变磁场下感应加热磁响应颗粒,进而触发SMP的相变和固形[104, 111, 114]。图5d)中,Ze等[114]报道了一种基于磁响应SMP的可逆变形抓手,实现了驱动磁场和加热磁场的独立控制。将可编程概念引入SMP中也可进一步增加机器人的自由度[111]。

2.2.4 其他磁响应材料驱动

一些纤维构成的材料(如纸张)能够吸收带有磁性颗粒的流体[231-232],进而实现磁场对纤维材料变形的控制。Ding等[231]使用纸张吸收铁磁流体,在磁场下实现了高达40°的偏转和0. 4 N的驱动力。另外,香港城市大学Shen团队[113]研发了一种磁性喷雾“M-spray”,该喷雾可附着于物体表面,在磁场控制下实现物体的变形与运动。这类磁性喷雾可以附着的材料种类很广泛。

2.3 热响应驱动

热响应薄膜驱动器包括基于红外 (IR)、近场红外 (NIR)、热辐射和焦耳加热等原理制备的驱动器。薄膜结构由于其几何上的特点,可以有效提高热驱动器的驱动效率和响应速度。下面的小节将按照材料类型对热响应薄膜机器人进行介绍。

2.3.1 形状记忆合金驱动

形状记忆合金(SMA)是一类可以在热循环下变形并恢复到原始“记忆”形状的材料。不同温度下,其晶体结构会在马氏体和奥氏体之间可逆切换。这类材料在薄膜机器人中应用广泛[120-121,123,126-127]。受蚱蜢运动启发, Wang等[127]制备了一款基于SMA的薄膜机器人,电热驱动下可实现曲线运动。Jin等[120]报道了一种具有爬行、游泳、抓取等多种功能的SMA机器人。为解决合金冷却速度慢的问题,Huang等[120]提出一种快速响应的SMA驱动器制备方法。该驱动器由U形SMA纤维组成,并介于双层导热弹性体之间。图6a)展示的是利用上述驱动器制备的可快速变形的跳跃机器人。

2.3.2 形状记忆聚合物驱动

SMP大多具有热响应特性,在热循环载荷下可逆地改变三维构型。图6b)展示了一种基于屈曲组装方法制备的双运动模式微型游泳机器人[71]。在不同环境温度下,该机器人具有不同的几何构型,可以实现水面直行和沿曲线运动两种模式的切换。

2.3.3 熱响应液晶弹性体驱动

当受到热刺激时,一些热响应液晶弹性体材料(LCE)会发生相变(液晶相与非晶各向同性相之间转换),基于这一特性,LCE广泛用于薄膜机器人中[23, 66, 69, 122, 129]。Kotikian等[122]报道了一种基于LCE 铰链的可逆折叠/展开机构,并利用该机构实现了机器人的滚动前行。图6c)中Xiao等[129]则利用LCE复合材料薄膜的电热驱动,实现了机器人推动物体、爬行等多运动模式。在小尺度下,研究者也将LCE薄膜应用于屈曲组装方法,将其作为二维前驱体[69]或弹性基底[66],实现了微尺度三维LCE驱动器的变形与重构。

2.3.4 热响应凝胶驱动

热响应凝胶可在热刺激下脱水发生变形。这类材料生物相容性好,在微型药物输送/抓取[22, 125]和其他领域[65, 157, 180]中具有重要的应用价值。Malachowski等[125]基于微尺度下残余应力诱导的卷曲技术制备了一款微型抓手,可以深入细胞组织,抓取并输送药物,如图6d)所示。图6e)则展示了利用屈曲组装方法得到的三维结构,利用水凝胶弹性基底的热响应变形诱导二维前驱体的组装,实现了微尺度下丰富的可重构三维构型[65]。

2.3.5 复合材料热失配驱动

复合材料薄膜在温度变化下,其各层间热应变的差别引起的应变失配会导致结构的弯曲变形[62, 117, 128, 131]。图6f)中,Chen等[117]利用碳纳米管/聚合物复合材料制备了一种低电压下快速爬行的薄膜机器人。图6g)中,研究者则制备得到聚合物/石墨烯/硅胶复合材料体系(LIG),系统研究了LIG电热薄膜驱动器的驱动性能,并探索了其在薄膜型人工肌肉、可重构三维微结构及人机交互中的应用[62]。

2.4 光响应驱动

光响应驱动具有远程可控、快速调制等特点,并且光斑可以轻松聚焦在纳米或微米级区域。这里将按照材料种类来介绍光驱动薄膜机器人。

2.4.1 光响应凝胶驱动

光反应基团可以结合到凝胶网络中,使凝胶材料在光刺激下发生膨胀或收缩。目前已有研究人员利用光驱动水凝胶制备具有爬行[39,145,155]、游泳[157,170]等多种运动模式的机器人。2020年,Li等[145]将螺吡喃基聚合物水凝胶制成薄膜,并用于四足机器人的直线与转向运动。在此基础上,利用双层结构驱动器设计,该团队制备了一款折纸型爬行机器人[39]。Zhao等[170]则设计了一种在恒定光刺激下持续振荡运动的水凝胶驱动器,能够在液体表面运动。

2.4.2 光响应液晶弹性体驱动

光响应液晶弹性体驱动器具有易加工、耐腐蚀、低成本等优点,在光驱动薄膜机器人中具有较为广泛的应用[20-21,133,140-141,147-148,150,154,162-164,174,233],其中也不乏复杂的运动模式,如爬行[21, 133, 149, 164, 233]、行走[140-141]、跳跃[133, 144]、游泳[148,153-154]、滚动[20]等。利用该材料在三种波长光源刺激下的复杂变形模式,研究者分别制备出多方向运动[233]和可搬运货物的微型四足机器人[149],如图7a)和b)所示。当光线以一定角度入射时,通过合理设计可以实现机器人的变形和运动,进而实现机器人的前进与后退[141]。同时,也有研究者将碳纳米管掺杂到液晶弹性体材料中,制备出具有光热效应的薄膜机器人,实现了爬行、跳跃等运动模式[133],如图7c)所示。

2.4.3 光响应形状记忆聚合物驱动

光化学响应SMP(如含有肉桂基团的聚合物)可以被预先处理为一种特定形状,并在光照下会恢复到原始形状[135, 143, 152],常用于医疗等领域。然而,在薄膜机器人中,掺杂光热填料的光热驱动SMP具有更加广泛的应用[132, 135, 143, 151, 156, 167, 169],尤其是薄膜类爬行机器人[156, 167, 169]。

2.4.4 其他光响应材料及结构驱动

通过光响应层与被动层集成得到的复合材料驱动器可以在光照下发生变形,具有灵敏度高、可编程性强、兼容性好、鲁棒性好等优点,且易于制备[132, 136-138, 142-144, 147, 158, 159]。研究人员利用不同复合片层实现了许多有趣的机器人设计。图7d)展示的是一种由石墨烯(SGA)/聚乙烯(PE)双层薄膜制备的机器人,可以在红外照射下实现滚动[158]。也有研究者利用碳纳米管/PDMS双层驱动器得到人造肌肉驱动部件[165]。

还有一些特殊的驱动机制,例如,Park等[41]受黄貂鱼的启发制造了一种生物混合驱动机器人,可以在光刺激下于水中波动前行。Andrén等[134]利用光机械效应构造的光学超表面载体,实现了微观粒子的长距离可控运动。Miskin等[234]基于光-电-化学驱动原理,实现了尺寸小于0. 1 mm的薄膜机器人的制备和运动。

2.5 化学响应驱动

化学响应驱动器在施加液体或蒸汽形式的刺激后会发生变形,其包含多种物理化学机制。我们按照其驱动方式可以分为:湿度驱动、pH驱动、表面张力驱动以及其他类型驱动。

2.5.1 湿度响应驱动

湿度响应驱动器可以在环境湿度改变时发生构型变化,这类驱动器适用于很多材料,且有不少有趣的湿度驱动薄膜机器人被报道[139, 172-173, 175, 180, 182, 185, 187-190, 194, 196-197, 200]。2017年, Liu等[188]设计了基于还原氧化石墨烯/氧化石墨烯(GO)的双层驱动器,利用其对水分子吸收能力的差异,制作了湿度驱动爬行机器人。Zhang等[19]利用氧化石墨烯纳米薄片制备机器人,这类材料可以显著促进水分的吸收,如图8a)所示。基于该材料的类蜈蚣薄膜机器人,具有反应速度快、变形程度大、变形复杂、可预测等特点。Shin等[194]于2018年利用静电纺丝技术制备了纳米纤维复合薄膜,通过复合薄膜不同层对湿度响应的差异,制备得到由环境湿度驱动的自主爬行机器人。

2.5.2 pH响应驱动

pH响应驱动器是由材料官能团的 pH 依赖性电离和电荷之间的静电排斥引起,常用于“芯片实验室”和微流体等环境[171, 174, 177, 179, 184, 186, 191, 198-199],有望应用于药物特异性输送和肿瘤治疗等领域[186, 199]。Meng等[191]设计的一款水凝胶微型机器人在磁场作用下移动到目标位置后,利用pH变化将包裹在内部的珠子状物体释放,且该机器人对人体细胞没有毒性,具有较好的生物相容性。

2.5.3 表面张力驱动

在基于液体表面张力驱动的薄膜机器人中,有代表性的工作包括梅永丰教授团队于2021年报道的一种类水黾的水面运动薄膜机器人[40],可以持续运动长达3.5 h。该机器人由具有疏水和亲水基团的活性水凝胶制备而成,在水表面的润湿过程中,利用亲水和疏水部分表面张力的差别来实现机器人的运动。

2.5.4 化学反应驱动

一些化学反应会产生气泡,进而为机器人带来推进力,典型的反应为过氧化氢的分解。利用这一原理可以制备很多水面运动的薄膜机器人[14, 18, 71]。其中,Schmidt教授团队[14]于2020年制备了微米尺度的多功能水面运动机器人,基于光刻工艺集成控制电路和无线功能模块,利用催化反应可以实现机器人的可控运动,同时利用局部加热的方式也可以实现微小物体的抓取。另外,也有研究者利用三维结构的屈曲组装方法,得到了图8b)和c)中的液体表面运动机器人[18, 71]。这类机器人利用屈曲组装的方法实现微尺度下机器人结构的制备,并利用铂电极的图案化布置和可变形基底的调控,实现在过氧化氢液体表面的运动。其中,机器人的几何重构为运动模式的切换带来了可能(直线和曲线运动)。

另外,有些特殊材料会在有机化学物质的刺激下产生响应。Lin课题组[176]于2017年的一个工作中,利用激光直写方法对PVDF晶相进行了调控,并利用PVDF制备了多层复合材料薄膜。该薄膜在丙酮蒸汽的作用下会发生不对称膨胀。利用这一原理,研究者得到了具有较快驱动速度的大变形薄膜机器人[176, 200]。

2.6 压力驱动

压力驱动在软体机器人中较为常见。一些微型薄膜类软材料制备的机器人,同样可以采用压力驱动的方式[202, 207, 235-237]。这类薄膜压力驅动器具有重量轻、效率高、无污染、环境适应性强等优点[25, 201, 238-241],在生物医疗等领域展现出巨大的应用前景[36, 202, 205, 207, 242]。这里将按照气压驱动与液压驱动分别进行介绍。

气压驱动方面,OK等[242]于2006年基于光刻技术制造出适用于各种环境的气动微型笼。同年,Lu等[205]制备了一款微型抓手,如图9a)所示。该抓手可以精确抓取微型生物体和生物组织。除了微尺度下制备的薄膜机器人外,宏观尺度气动机器人应用更加广泛[201]。图9b)展示的是Kumar等[25]于2021年基于软光刻工艺开发的机器人,在气压驱动下可以实现机器人在水面的快速运动。同时该机器人具有温度感知、酸度感知等功能。

液压驱动的研究相对较少,主要集中在利用封装液体实现薄膜类柔性关节的驱动。Kellaris等[203]、Wood课题组[204]在这方面都进行了相关研究。

3 总结与展望

平面图案化微加工工艺与三维微电子系统组装技术的蓬勃发展催生出众多薄膜类的柔性微型机器人。这类微型机器人已在生物医疗、救援等多个领域展现出巨大的应用潜力。从本文中展示的薄膜类机器人可以发现,该类机器人可以采用电、热、磁、光、压力、化学等多种激励方式来驱动,在鲁棒性、小型化、器件集成度、功能多样化等多个方面具有独特的优势。但目前,薄膜类机器人构型的复杂度与传统刚性机器人或软体机器人相比,仍较为单一,多以单层薄膜或较为简单的可变形结构组成,这在一定程度上限制了薄膜类机器人在多运动模式、多功能器件集成等方面的发展。以屈曲组装为代表的三维微结构组装技术可以制备几何构型复杂的三维功能性电子系统,且适用于半导体、聚合物、金属、二维材料、功能性软材料等多种材料的组装。利用微尺度组装技术来制备薄膜类柔性微型机器人,可以使薄膜机器人具有更丰富的几何构型、更高的器件集成度和更多样的运动模式。

参考文献:

[1] CHEN Y F,DOSHI N,GOLDBERG B,et al. Controllable water surface to underwater transition through electrowetting in a hybrid terrestrial-aquatic microrobot[J]. Nature Communications,2018,9:2495.

[2] HU W Q,LUM G Z,MASTRANGELI M,et al. Small-scale soft-bodied robot with multimodal locomotion[J]. Nature,2018,554(7690):81-85.

[3] SITTI M. Voyage of the microrobots[J]. Nature,2009,458(7242):1121-1122.

[4] SITTI M,CEYLAN H,HU W Q,et al. Biomedical applications of untethered mobile milli/microrobots[J]. Proceedings of the IEEE,2015,103(2):205-224.

[5] ALAPAN Y,YASA O,SCHAUER O,et al. Soft erythrocyte-based bacterial microswimmers for cargo delivery[J]. Science Robotics,2018,3(17):eaar4423.

[6] NELSON B J,KALIAKATSOS I K,ABBOTT J J. Microrobots for minimally invasive medicine[J]. Annual Review of Biomedical Engineering,2010,12:55-85.

[7] FLOREANO D,WOOD R J. Science,technology and the future of small autonomous drones[J]. Nature,2015,521(7553):460-466.

[8] GRAULE M A,CHIRARATTANANON P,FULLER S B,et al. Perching and takeoff of a robotic insect on overhangs using switchable electrostatic adhesion[J]. Science,2016,352(6288):978-982.

[9] JAFFERIS N T,HELBLING E F,KARPELSON M,et al. Untethered flight of an insect-sized flapping-wing microscale aerial vehicle[J]. Nature,2019,570(7762):491-495.

[10] EL-ATAB N,MISHRA R B,AL-MODAF F,et al. Soft actuators for soft robotic applications:a review[J]. Advanced Intelligent Systems,2020,2(10):2070102.

[11] YANG J,ZHANG C,WANG X D,et al. Development of micro- and nanorobotics:a review[J]. Science China Technological Sciences,2019,62(1):1-20.

[12] CHENG X,ZHANG Y H. Micro/nanoscale 3D assembly by rolling,folding,curving,and buckling approaches[J]. Advanced Materials,2019,31(36):1901895.

[13] HUANG G S,MEI Y F. Assembly and self-assembly of nanomembrane materials—from 2D to 3D[J]. Small,2018,14(14):1703665.

[14] BANDARI V K,NAN Y,KARNAUSHENKO D,et al. A flexible microsystem capable of controlled motion and actuation by wireless power transfer[J]. Nature Electronics,2020,3(3):172-180.

[15] WU Y C,YIM J K,LIANG J M,et al. Insect-scale fast moving and ultrarobust soft robot[J]. Science Robotics,2019,4(32):eaax1594.

[16] LIU Y,CHEN B D,LI W,et al. Bioinspired triboelectric soft robot driven by mechanical energy[J]. Advanced Functional Materials,2021:2104770.

[17] JIN C R,ZHANG J H,XU Z,et al. Tunable,flexible,and resilient robots driven by an electrostatic actuator[J]. Advanced Intelligent Systems,2020,2(3):2070030.

[18] YAN Z,HAN M D,SHI Y,et al. Three-dimensional mesostructures as high-temperature growth templates,electronic cellular scaffolds,and self-propelled microrobots[J]. PNAS,2017,114(45):E9455-E9464.

[19] ZHANG Y L,LIU Y Q,HAN D D,et al. Actuators:quantum-confined-superfluidics-enabled moisture actuation based on unilaterally structured graphene oxide papers [J]. Advanced Materials,2019,31(32):1970231.

[20] CHENG Y C,LU H C,LEE X,et al. Kirigami-based light-induced shape-morphing and locomotion[J]. Advanced Materials,2020,32(7):1906233.

[21] ZENG H,WANI O M,WASYLCZYK P,et al. Light-driven,caterpillar-inspired miniature inching robot[J]. Macromolecular Rapid Communications,2018,39(1):1700224.

[22] BREGER J C,YOON C,XIAO R,et al. Self-folding thermo-magnetically responsive soft microgrippers[J]. ACS Applied Materials & Interfaces,2015,7(5):3398-3405.

[23] WANG C J,SIM K,CHEN J,et al. Adaptive soft robots:soft ultrathin electronics innervated adaptive fully soft robots [J]. Advanced Materials,2018,30(13):1870087.

[24] RANZANI T,RUSSO S,BARTLETT N W,et al. Increasing the dimensionality of soft microstructures through injection-induced self-folding[J]. Advanced Materials,2018,30(38):1802739.

[25] KUMAR V,KO U H,ZHOU Y L,et al. Microengineered materials with self-healing features for soft robotics[J]. Advanced Intelligent Systems,2021,3(7):2100005.

[26] LU H J,HONG Y,YANG Y Y,et al. Battery-less soft millirobot that can move,sense,and communicate remotely by coupling the magnetic and piezoelectric effects[J]. Advanced Science,2020,7(13):2000069.

[27] REN Z Y,HU W Q,DONG X G,et al. Multi-functional soft-bodied jellyfish-like swimming[J]. Nature Communications,2019,10:2703.

[28] GOLDBERG B,ZUFFEREY R,DOSHI N,et al. Power and control autonomy for high-speed locomotion with an insect-scale legged robot[J]. IEEE Robotics and Automation Letters,2018,3(2):987-993.

[29] WANG H Q,YORK P,CHEN Y F,et al. Biologically inspired electrostatic artificial muscles for insect-sized robots[J]. The International Journal of Robotics Research,2021,40(6/7):895-922.

[30] SHIGEMUNE H,MAEDA S,CACUCCIOLO V,et al. Printed paper robot driven by electrostatic actuator[J]. IEEE Robotics and Automation Letters,2017,2(2):1001-1007.

[31] DONALD B R,LEVEY C G,MCGRAY C D,et al. An untethered,electrostatic,globally controllable MEMS micro-robot[J]. Journal of Microelectromechanical Systems,2006,15(1):1-15.

[32] JAGER E W,INGANÄS O,LUNDSTRÖM I. Microrobots for micrometer-size objects in aqueous media:potential tools for single-cell manipulation[J]. Science,2000,288(5475):2335-2338.

[33] 尹周平,黃永安. 柔性电子制造:材料、器件与工艺[M]. 北京:科学出版社,2016:1.

[34] KUMAR A,WHITESIDES G M. Features of gold having micrometer to centimeter dimensions can be formed through a combination of stamping with an elastomeric stamp and an alkanethiol ‘ink’ followed by chemical etching[J]. Applied Physics Letters,1993,63(14):2002-2004.

[35] MORAES C,SUN Y,SIMMONS C A. Solving the shrinkage-induced PDMS alignment registration issue in multilayer soft lithography[J]. Journal of Micromechanics and Microengineering,2009,19(6):065015.

[36] RUSSO S,RANZANI T,WALSH C J,et al. An additive millimeter-scale fabrication method for soft biocompatible actuators and sensors[J]. Advanced Materials Technologies,2017,2(10):1700135.

[37] PALLEAU E,MORALES D,DICKEY M D,et al. Reversible patterning and actuation of hydrogels by electrically assisted ionoprinting[J]. Nature Communications,2013,4:2257.

[38] MORALES D,PODOLSKY I,MAILEN R,et al. Ionoprinted multi-responsive hydrogel actuators[J]. Micromachines,2016,7(6):98.

[39] LI C,XUE Y G,HAN M D,et al. Synergistic photoactuation of bilayered spiropyran hydrogels for predictable origami-like shape change[J]. Matter,2021,4(4):1377-1390.

[40] ZHU H,XU B R,WANG Y,et al. Self-powered locomotion of a hydrogel water strider[J]. Science Robotics,2021,6(53):eabe7925.

[41] PARK S J,GAZZOLA M,PARK K S,et al. Phototactic guidance of a tissue-engineered soft-robotic ray[J]. Science,2016,353(6295):158-162.

[42] CHEN Z,ZHAO D H,LIU B H,et al. 3D printing of multifunctional hydrogels[J]. Advanced Functional Materials,2019,29(20):1900971.

[43] GUL J Z,SAJID M,REHMAN M M,et al. 3D printing for soft robotics – a review[J]. Science and Technology of Advanced Materials,2018,19(1):243-262.

[44] KIM Y,YUK H,ZHAO R K,et al. Printing ferromagnetic domains for untethered fast-transforming soft materials[J]. Nature,2018,558(7709):274-279.

[45] LANTEAN S,BARRERA G,PIRRI C F,et al. 3D printing of magnetoresponsive polymeric materials with tunable mechanical and magnetic properties by digital light processing[J]. Advanced Materials Technologies,2019,4(11):1900505.

[46] ROH S,OKELLO L B,GOLBASI N,et al. 3D-printed silicone soft architectures with programmed magneto-capillary reconfiguration[J]. Advanced Materials Technologies,2019,4(4):1800528.

[47] WU S,HU W Q,ZE Q J,et al. Multifunctional magnetic soft composites:a review[J]. Multifunctional Materials,2020,3(4):042003.

[48] XU T Q,ZHANG J C,SALEHIZADEH M,et al. Millimeter-scale flexible robots with programmable three-dimensional magnetization and motions[J]. Science Robotics,2019,4(29):eaav4494.

[49] ZHAO R K,KIM Y,CHESTER S A,et al. Mechanics of hard-magnetic soft materials[J]. Journal of the Mechanics and Physics of Solids,2019,124:244-263.

[50] ZHANG Y H,ZHANG F,YAN Z,et al. Printing,folding and assembly methods for forming 3D mesostructures in advanced materials[J]. Nature Reviews Materials,2017,2(4):1-17.

[51] XU S,YAN Z,JANG K I,et al. Assembly of micro/nanomaterials into complex,three-dimensional architectures by compressive buckling[J]. Science,2015,347(6218):154-159.

[52] PRINZ V Y. A new concept in fabricating building blocks for nanoelectronic and nanomechanic devices[J]. Microelectronic Engineering,2003,69(2/3/4):466-475.

[53] CHO J H,AZAM A,GRACIAS D H. Three dimensional nanofabrication using surface forces[J]. Langmuir,2010,26(21):16534-16539.

[54] KIM J B,ZAEHRES H,WU G M,et al. Pluripotent stem cells induced from adult neural stem cells by reprogramming with two factors[J]. Nature,2008,454(7204):646-650.

[55] YAN Z,HAN M D,YANG Y Y,et al. Deterministic assembly of 3D mesostructures in advanced materials via compressive buckling:a short review of recent progress[J]. Extreme Mechanics Letters,2017,11:96-104.

[56] YAN Z,ZHANG F,WANG J C,et al. 3D assembly:controlled mechanical buckling for origami-inspired construction of 3D microstructures in advanced materials (adv. funct. mater. 16/2016)[J]. Advanced Functional Materials,2016,26(16):2586.

[57] ZHANG Y H,YAN Z,NAN K W,et al. A mechanically driven form of Kirigami as a route to 3D mesostructures in micro/nanomembranes[J]. Proceeding National Academy of Sciences of the United States of America,2015,112(38):11757-11764.

[58] XU B X,MUELLER R,KLASSEN M,et al. On electromechanical stability analysis of dielectric elastomer actuators[J]. Applied Physics Letters,2010,97(16):162908.

[59] YAN Z,ZHANG F,LIU F,et al. Mechanical assembly of complex,3D mesostructures from releasable multilayers of advanced materials[J]. Science Advances,2016,2(9):e1601014.

[60] FU H R,NAN K W,BAI W B,et al. Morphable 3D mesostructures and microelectronic devices by multistable buckling mechanics[J]. Nature Materials,2018,17(3):268-276.

[61] LUAN H W,CHENG X,WANG A,et al. Design and fabrication of heterogeneous,deformable substrates for the mechanically guided 3D assembly[J]. ACS Applied Materials & Interfaces,2019,11(3):3482-3492.

[62] LING Y,PANG W B,LI X P,et al. Laser-induced graphene for electrothermally controlled,mechanically guided,3D assembly and human–soft actuators interaction[J]. Advanced Materials,2020,32(17):1908475.

[63] PANG W B,CHENG X,ZHAO H J,et al. Electro-mechanically controlled assembly of reconfigurable 3D mesostructures and electronic devices based on dielectric elastomer platforms[J]. National Science Review,2020,7(2):342-354.

[64] ZHAO H B,LI K,HAN M D,et al. Buckling and twisting of advanced materials into morphable 3D mesostructures[J]. PNAS,2019,116(27):13239-13248.

[65] ZHANG C,DENG H,XIE Y C,et al. Stimulus responsive 3D assembly for spatially resolved bifunctional sensors[J]. Small,2019,15(51):1904224.

[66] LI Y,LUO C Q,YU K,et al. Remotely controlled,reversible,on-demand assembly and reconfiguration of 3D mesostructures via liquid crystal elastomer platforms[J]. ACS Applied Materials & Interfaces,2021,13(7):8929-8939.

[67] WANG X J,GUO X G,YE J L,et al. Freestanding 3D mesostructures,functional devices,and shape-programmable systems based on mechanically induced assembly with shape memory polymers[J]. Advanced Materials,2019,31(2):1805615.

[68] PARK Y,LUAN H W,KWON K,et al. 4D electronic systems:transformable,freestanding 3D mesostructures based on transient materials and mechanical interlocking (adv. funct. mater. 40/2019)[J]. Advanced Functional Materials,2019,29(40):1970277.

[69] ; LI Y,YU H B,YU K,et al. Reconfigurable three-dimensional mesotructures of spatially programmed liquid crystal elastomers and their ferromagnetic composites[J]. Advanced Functional Materials,2021,31(23):2100338.

[70] NAN K W,LUAN H W,YAN Z,et al. Engineered elastomer substrates for guided assembly of complex 3D mesostructures by spatially nonuniform compressive buckling[J]. Advanced Functional Materials,2017,27(1):1604281.

[71] PARK J K,NAN K W,LUAN H W,et al. Remotely triggered assembly of 3D mesostructures through shape-memory effects[J]. Advanced Materials,2019,31(52):1905715.

[72] GUO X G,WANG X J,OU D P,et al. Controlled mechanical assembly of complex 3D mesostructures and strain sensors by tensile buckling[J]. Npj Flexible Electronics,2018,2(1):1-7.

[73] BAI K,CHENG X,XUE Z G,et al. Geometrically reconfigurable 3D mesostructures and electromagnetic devices through a rational bottom-up design strategy[J]. Science Advances,2020,6(30):eabb7417.

[74] BELL D J,DONG L,NELSON B J,et al. Fabrication and characterization of three-dimensional InGaAs/GaAs nanosprings[J]. Nano Letters,2006,6(4):725-729.

[75] SCHMIDT O G,EBERL K. Thin solid films roll up into nanotubes[J]. Nature,2001,410(6825):168.

[76] MEI Y F,HUANG G S,SOLOVEV A A,et al. Versatile approach for integrative and functionalized tubes by strain engineering of nanomembranes on polymers[J]. Advanced Materials,2008,20(21):4085-4090.

[77] SAWA Y,URAYAMA K,TAKIGAWA T,et al. Shape and chirality transitions in off-axis twist nematic elastomer ribbons[J]. Physical Review E,2013,88(2):022502.

[78] WEI H,ZHANG Q,YAO Y,et al. Direct-write fabrication of 4D active shape-changing structures based on a shape memory polymer and its nanocomposite[J]. ACS Applied Materials & Interfaces,2017,9(1):876-883.

[79] GLADMAN A S,MATSUMOTO E A,NUZZO R G,et al. Biomimetic 4D printing[J]. Nature Materials,2016,15(4):413-418.

[80] NA J H,EVANS A A,BAE J,et al. Programming reversibly self-folding origami with micropatterned photo-crosslinkable polymer trilayers[J]. Advanced Materials,2015,27(1):79-85.

[81] SAADA G,LAYANI M,CHERNEVOUSKY A,et al. Hydroprinting conductive patterns onto 3D structures[J]. Advanced Materials Technologies,2017,2(5):1600289.

[82] BASSIK N,STERN G M,GRACIAS D H. Microassembly based on hands free origami with bidirectional curvature[J]. Applied Physics Letters,2009,95(9):091901.

[83] VACCARO P O,KUBOTA K,FLEISCHMANN T,et al. Valley-fold and mountain-fold in the micro-origami technique[J]. Microelectronics Journal,2003,34(5/6/7/8):447-449.

[84] PY C,REVERDY P,DOPPLER L,et al. Capillary origami[J]. Physics of Fluids,2007,19(9):091104.

[85] KOBAYASHI K,OH S H,YOON C,et al. Multitemperature responsive self-folding soft biomimetic structures[J]. Macromolecular Rapid Communications,2018,39(4):1700692.

[86] JAMAL M,ZARAFSHAR A M,GRACIAS D H. Differentially photo-crosslinked polymers enable self-assembling microfluidics[J]. Nature Communications,2011,2:527.

[87] LE BORGNE B,DE SAGAZAN O,CRAND S,et al. Conformal electronics wrapped around daily life objects using an original method:water transfer printing[J]. ACS Applied Materials & Interfaces,2017,9(35):29424-29429.

[88] PARK H,CHO H,KIM J,et al. Multiscale transfer printing into recessed microwells and on curved surfaces via hierarchical perfluoropolyether stamps[J]. Small,2014,10(1):52-59.

[89] XU X,DAVANCO M,QI X F,et al. Direct transfer patterning on three dimensionally deformed surfaces at micrometer resolutions and its application to hemispherical focal plane detector arrays[J]. Organic Electronics,2008,9(6):1122-1127.

[90] MUST I,KAASIK F,PÕLDSALU I,et al. Ionic and capacitive artificial muscle for biomimetic soft robotics[J]. Advanced Engineering Materials,2015,17(1):84-94.

[91] XIAO P S,YI N B,ZHANG T F,et al. Construction of a fish-like robot based on high performance graphene/PVDF bimorph actuation materials[J]. Advanced Science,2016,3(6):1500438.

[92] ANDERSON I A,GISBY T A,MCKAY T G,et al. Multi-functional dielectric elastomer artificial muscles for soft and smart machines[J]. Journal of Applied Physics,2012,112(4):041101.

[93] BAISCH A T,OZCAN O,GOLDBERG B,et al. High speed locomotion for a quadrupedal microrobot[J]. The International Journal of Robotics Research,2014,33(8):1063-1082.

[94] CHANG Y C,KIM W J. Aquatic ionic-polymer-metal-composite insectile robot with multi-DOF legs[J]. IEEE/ASME Transactions on Mechatronics,2013,18(2):547-555.

[95] QU J H,CHOI J,OLDHAM K R. Dynamic structural and contact modeling for a silicon hexapod microrobot[J]. Journal of Mechanisms and Robotics,2017,9(6):061006.

[96] KOFOD G,WIRGES W,PAAJANEN M,et al. Energy minimization for self-organized structure formation and actuation[J]. Applied Physics Letters,2007,90(8):081916.

[97] KWON G H,PARK J Y,KIM J Y,et al. Biomimetic soft multifunctional miniature aquabots[J]. Small,2008,4(12):2148-2153.

[98] MORALES D,PALLEAU E,DICKEY M D,et al. Electro-actuated hydrogel walkers with dual responsive legs[J]. Soft Matter,2014,10(9):1337-1348.

[99] TAGHAVI M,HELPS T,ROSSITER J. Electro-ribbon actuators and electro-origami robots[J]. Science Robotics,2018,3(25):eaau9795.

[100]HUANG H W,SAKAR M S,PETRUSKA A J,et al. Soft micromachines with programmable motility and morphology[J]. Nature Communications,2016,7:12263.

[101]LI C,LAU G C,YUAN H,et al. Fast and programmable locomotion of hydrogel-metal hybrids under light and magnetic fields[J]. Science Robotics,2020,5(49):eabb9822. .

[102]LI Y,AVIS S J,CHEN J B,et al. Reconfiguration of multistable 3D ferromagnetic mesostructures guided by energy landscape surveys[J]. Extreme Mechanics Letters,2021,48:101428.

[103]LUM G Z,YE Z,DONG X G,et al. Shape-programmable magnetic soft matter[J]. PNAS,2016,113(41):E6007-E6015. DOI:10. 1073/pnas. 1608193113.

[104]MA C P,WU S,ZE Q J,et al. Magnetic multimaterial printing for multimodal shape transformation with tunable properties and shiftable mechanical behaviors[J]. ACS Applied Materials & Interfaces,2021,13(11):12639-12648.

[105]MIAO L M,SONG Y,REN Z Y,et al. 3D temporary-magnetized soft robotic structures for enhanced energy harvesting[J]. Advanced Materials,2021:2102691.

[106]MITSUMATA T,OHORI S. Magnetic polyurethane elastomers with wide range modulation of elasticity[J]. Polymer Chemistry,2011,2(5):1063-1067.

[107]MIYASHITA S,GUITRON S,LI S G,et al. Robotic metamorphosis by origami exoskeletons[J]. Science Robotics,2017,2(10):eaao4369.

[108]MIYASHITA S,GUITRON S,LUDERSDORFER M,et al. An untethered miniature origami robot that self-folds,walks,swims,and degrades[C]//2015 IEEE International Conference on Robotics and Automation (ICRA). May 26-30,2015,Seattle,WA,USA. IEEE,2015:1490-1496.

[109]PETERS C,HOOP M,PANÉ S,et al. Degradable magnetic composites for minimally invasive interventions:device fabrication,targeted drug delivery,and cytotoxicity tests[J]. Advanced Materials,2016,28(3):533-538.

[110]TOTTORI S,ZHANG L,QIU F M,et al. Magnetic helical micromachines:fabrication,controlled swimming,and cargo transport[J]. Advanced Materials,2012,24(6):811-816.

[111]WANG L,RAZZAQ M Y,RUDOLPH T,et al. Reprogrammable,magnetically controlled polymeric nanocomposite actuators[J]. Materials Horizons,2018,5(5):861-867.

[112]WU S,ZE Q J,ZHANG R D,et al. Symmetry-breaking actuation mechanism for soft robotics and active metamaterials[J]. ACS Applied Materials & Interfaces,2019,11(44):41649-41658.

[113]YANG X,SHANG W F,LU H J,et al. An agglutinate magnetic spray transforms inanimate objects into millirobots for biomedical applications[J]. Science Robotics,2020,5(48):eabc8191.

[114]ZE Q J,KUANG X,WU S,et al. Shape memory polymers:magnetic shape memory polymers with integrated multifunctional shape manipulation [J]. Advanced Materials,2020,32(4):2070025.

[115]ZHANG F,LI S P,SHEN Z M,et al. Rapidly deployable and morphable 3D mesostructures with applications in multimodal biomedical devices[J]. Proceeding National Academy of Sciences of the United States of America,2021,118(11):e2026414118.

[116]YAN D J,CHANG J H,ZHANG H,et al. Soft three-dimensional network materials with rational bio-mimetic designs[J]. Nature Communications,2020,11(1):1-11.

[117]CHEN L Z,WENG M C,ZHOU Z W,et al. Large-deformation curling actuators based on carbon nanotube composite:advanced-structure design and biomimetic application[J]. ACS Nano,2015,9(12):12189-12196.

[118]CHEN T,BILAL O R,SHEA K,et al. Harnessing bistability for directional propulsion of soft,untethered robots[J]. PNAS,2018,115(22):5698-5702.

[119]FELTON S M,TOLLEY M T,SHIN B,et al. Self-folding with shape memory composites[J]. Soft Matter,2013,9(32):7688.

[120]HUANG X N,KUMAR K,JAWED M K,et al. Highly dynamic shape memory alloy actuator for fast moving soft robots[J]. Advanced Materials Technologies,2019,4(4):1800540.

[121]JIN H,DONG E B,XU M,et al. Soft and smart modular structures actuated by shape memory alloy (SMA) wires as tentacles of soft robots[J]. Smart Materials and Structures,2016,25(8):085026.

[122]KOTIKIAN A,MCMAHAN C,DAVIDSON E C,et al. Untethered soft robotic matter with passive control of shape morphing and propulsion[J]. Science Robotics,2019,4(33):eaax7044.

[123]LEE J H,CHUNG Y S,RODRIGUE H. Long shape memory alloy tendon-based soft robotic actuators and implementation as a soft gripper[J]. Scientific Reports,2019,9(1):11251.

[124]LIU Y,BOYLES J K,GENZER J,et al. Self-folding of polymer sheets using local light absorption[J]. Soft Matter,2012,8(6):1764-1769.

[125]MALACHOWSKI K,BREGER J,KWAG H R,et al. Stimuli-responsive theragrippers for chemomechanical controlled release[J]. Angewandte Chemie International Edition,2014,53(31):8045-8049.

[126]WANG W,KIM N G,RODRIGUE H,et al. Modular assembly of soft deployable structures and robots[J]. Materials Horizons,2017,4(3):367-376.

[127]WANG W,LEE J Y,RODRIGUE H,et al. Locomotion of inchworm-inspired robot made of smart soft composite (SSC)[J]. Bioinspiration & Biomimetics,2014,9(4):046006.

[128]WANG Y,LI K,LI X G,et al. Electro-thermally driven flexible robot arms based on stacking-controlled graphite nanocomposites[J]. Carbon,2019,152:873-881.

[129]XIAO Y Y,JIANG Z C,TONG X,et al. Biomimetic locomotion of electrically powered “Janus” soft robots using a liquid crystal polymer[J]. Advanced Materials,2019,31(36):1903452.

[130]ZHANG Y F,ZHANG N B,HINGORANI H,et al. Soft robots:fast-response,stiffness-tunable soft actuator by hybrid multimaterial 3D printing [J]. Advanced Functional Materials,2019,29(15):1970098.

[131]ZHU Y,BIRLA M,OLDHAM K R,et al. Elastically and plastically foldable electrothermal micro-origami for controllable and rapid shape morphing[J]. Advanced Functional Materials,2020,30(40):2003741.

[132]AHIR S V,TERENTJEV E M. Photomechanical actuation in polymer–nanotube composites[J]. Nature Materials,2005,4(6):491-495.

[133]AHN C,LIANG X D,CAI S Q. Bioinspired design of light-powered crawling,squeezing,and jumping untethered soft robot[J]. Advanced Materials Technologies,2019,4(7):1900185.

[134]ANDRÉN D,BARANOV D G,JONES S,et al. Microscopic metavehicles powered and steered by embedded optical metasurfaces[J]. Nature Nanotechnology,2021,16(9):970-974.

[135]BEHL M,LENDLEIN A. Shape-memory polymers[J]. Materials Today,2007,10(4):20-28.

[136]CHEN Y H,YANG J J,ZHANG X,et al. Light-driven bimorph soft actuators:design,fabrication,and properties[J]. Materials Horizons,2021,8(3):728-757.

[137]DENG H,ZHANG C,SU J W,et al. Bioinspired multi-responsive soft actuators controlled by laser tailored graphene structures[J]. Journal of Materials Chemistry B,2018,6(34):5415-5423.

[138]DONG X,XU J W,XU X Z,et al. Sunlight-driven continuous flapping-wing motion[J]. ACS Applied Materials & Interfaces,2020,12(5):6460-6470.

[139]GAO Y Y,ZHANG Y L,HAN B,et al. Gradient assembly of polymer nanospheres and graphene oxide sheets for dual-responsive soft actuators[J]. ACS Applied Materials & Interfaces,2019,11(40):37130-37138.

[140]GE F J,YANG R,TONG X,et al. A multifunctional dye-doped liquid crystal polymer actuator:light-guided transportation,turning in locomotion,and autonomous motion[J]. Angewandte Chemie,2018,130(36):11932-11937.

[141]GELEBART A H,JAN MULDER D,VARGA M,et al. Making waves in a photoactive polymer film[J]. Nature,2017,546(7660):632-636.

[142]HAN B,ZHANG Y L,ZHU L,et al. Soft robotics:plasmonic-assisted graphene oxide artificial muscles [J]. Advanced Materials,2019,31(5):1970029.

[143]HERATH M,EPAARACHCHI J,ISLAM M,et al. Light activated shape memory polymers and composites:a review[J]. European Polymer Journal,2020,136:109912.

[144]HU Y,LIU J Q,CHANG L F,et al. Electrically and sunlight-driven actuator with versatile biomimetic motions based on rolled carbon nanotube bilayer composite[J]. Advanced Functional Materials,2017,27(44):1704388.

[145]LI C,ISCEN A,SAI H,et al. Supramolecular-covalent hybrid polymers for light-activated mechanical actuation[J]. Nature Materials,2020,19(8):900-909.

[146]LIU Y,SHAW B,DICKEY M D,et al. Sequential self-folding of polymer sheets[J]. Science Advances,2017,3(3):e1602417.

[147]LV P,YANG X,BISOYI H K,et al. Stimulus-driven liquid metal and liquid crystal network actuators for programmable soft robotics[J]. Materials Horizons,2021,8(9):2475-2484.

[148]MA S D,LI X,HUANG S,et al. A light-activated polymer composite enables on-demand photocontrolled motion:transportation at the liquid/air interface[J]. Angewandte Chemie,2019,131(9):2681-2685.

[149]PILZ D A CUNHA M,AMBERGEN S,DEBIJE M G,et al. A soft transporter robot fueled by light[J]. Advanced Science,2020,7(5):1902842.

[150]PILZ D A CUNHA M,DEBIJE M G,SCHENNING A P H J. Bioinspired light-driven soft robots based on liquid crystal polymers[J]. Chemical Society Reviews,2020,49(18):6568-6578.

[151]QIAN W Q,SONG Y F,SHI D J,et al. Photothermal-triggered shape memory polymer prepared by cross-linking porphyrin-loaded micellar particles[J]. Materials,2019,12(3):496.

[152]ROSE A,ZHU Z G,MADIGAN C F,et al. Sensitivity gains in chemosensing by lasing action in organic polymers[J]. Nature,2005,434(7035):876-879.

[153]SHAHSAVAN H,AGHAKHANI A,ZENG H,et al. Bioinspired underwater locomotion of light-driven liquid crystal gels[J]. Proceeding National Academy of Sciences of the United States of America,2020,117(10):5125-5133.

[154]TIAN H,WANG Z,CHEN Y,et al. Polydopamine-coated main-chain liquid crystal elastomer as optically driven artificial muscle[J]. ACS Applied Materials & Interfaces,2018,10(9):8307-8316.

[155]WANG E,DESAI M S,LEE S W. Light-controlled graphene-elastin composite hydrogel actuators[J]. Nano Letters,2013,13(6):2826-2830.

[156]WANG K J,ZHU X X. Two-way reversible shape memory polymers containing polydopamine nanospheres:light actuation,robotic locomotion,and artificial muscles[J]. ACS Biomaterials Science & Engineering,2018,4(8):3099-3106.

[157]WANG L,LIU Y,CHENG Y,et al. A bioinspired swimming and walking hydrogel driven by light-controlled local density[J]. Advanced Science,2015,2(6):1500084.

[158]WANG S,GAO Y,WEI A R,et al. Asymmetric elastoplasticity of stacked graphene assembly actualizes programmable untethered soft robotics[J]. Nature Communications,2020,11(1):1-12.

[159]WANG X D,JIAO N D,TUNG S,et al. Photoresponsive graphene composite bilayer actuator for soft robots[J]. ACS Applied Materials & Interfaces,2019,11(33):30290-30299.

[160]WANG X,YANG B S,TAN D,et al. Bioinspired footed soft robot with unidirectional all-terrain mobility[J]. Materials Today,2020,35:42-49.

[161]WANG X Q,CHAN K H,CHENG Y,et al. Somatosensory,light-driven,thin-film robots capable of integrated perception and motility[J]. Advanced Materials,2020,32(21):2000351.

[162]WANI O M,ZENG H,PRIIMAGI A. A light-driven artificial flytrap[J]. Nature Communications,2017,8:15546.

[163]XIAO Y Y,JIANG Z C,ZHAO Y. Liquid crystal polymer-based soft robots[J]. Advanced Intelligent Systems,2020,2(12):2000148.

[164]YAMADA M,KONDO M,MIYASATO R,et al. Photomobile polymer materials—various three-dimensional movements[J]. J Mater Chem,2009,19(1):60-62.

[165]YANG L L,CHANG L F,HU Y,et al. Autonomous soft actuators:an autonomous soft actuator with light-driven self-sustained wavelike oscillation for phototactic self-locomotion and power generation (adv. funct. mater. 15/2020)[J]. Advanced Functional Materials,2020,30(15):2070095.

[166]YANG Y Y,ZHANG M,LI D F,et al. Graphene-based light-driven soft robot with snake-inspired concertina and serpentine locomotion[J]. Advanced Materials Technologies,2019,4(1):1800366.

[167]YENPECH N,INTASANTA V,CHIRACHANCHAI S. Laser-triggered shape memory based on thermoplastic and thermoset matrices with silver nanoparticles[J]. Polymer,2019,182:121792.

[168]ZENG H,WASYLCZYK P,WIERSMA D S,et al. Light robots:bridging the gap between microrobotics and photomechanics in soft materials[J]. Advanced Materials,2018,30(24):1703554.

[169]ZHANG H,ZHAO Y. Polymers with dual light-triggered functions of shape memory and healing using gold nanoparticles[J]. ACS Applied Materials & Interfaces,2013,5(24):13069-13075.

[170]ZHAO Y S,XUAN C,QIAN X S,et al. Soft phototactic swimmer based on self-sustained hydrogel oscillator[J]. Science Robotics,2019,4(33):eaax7112. .

[171]CHEN H M,LI Y,LIU Y,et al. Highly pH-sensitive polyurethane exhibiting shape memory and drug release[J]. Polym Chem,2014,5(17):5168-5174.

[172]CHEN X,GOODNIGHT D,GAO Z H,et al. Scaling up nanoscale water-driven energy conversion into evaporation-driven engines and generators[J]. Nature Communications,2015,6(1):1-7.

[173]DAI M,PICOT O T,VERJANS J M N,et al. Humidity-responsive bilayer actuators based on a liquid-crystalline polymer network[J]. ACS Applied Materials & Interfaces,2013,5(11):4945-4950.

[174]DE HAAN L T,GIMENEZ-PINTO V,KONYA A,et al. Accordion-like actuators of multiple 3D patterned liquid crystal polymer films[J]. Advanced Functional Materials,2014,24(9):1251-1258.

[175]DE HAAN L T,VERJANS J M,BROER D J,et al. Humidity-responsive liquid crystalline polymer actuators with an asymmetry in the molecular trigger that bend,fold,and curl[J]. Journal of the American Chemical Society,2014,136(30):10585-10588.

[176]DENG H,DONG Y,ZHANG C,et al. An instant responsive polymer driven by anisotropy of crystal phases[J]. Materials Horizons,2018,5(1):99-107.

[177]DONG L,AGARWAL A K,BEEBE D J,et al. Adaptive liquid microlenses activated by stimuli-responsive hydrogels[J]. Nature,2006,442(7102):551-554.

[178]DONG Y,WANG J,GUO X K,et al. Multi-stimuli-responsive programmable biomimetic actuator[J]. Nature Communications,2019,10:4087.

[179]HAN X J,DONG Z Q,FAN M M,et al. pH-induced shape-memory polymers[J]. Macromolecular Rapid Communications,2012,33(12):1055-1060.

[180]HAO X P,XU Z,LI C Y,et al. Kirigami-design-enabled hydrogel multimorphs with application as a multistate switch[J]. Advanced Materials,2020,32(22):2000781.

[181]IONOV L. Hydrogel-based actuators:possibilities and limitations[J]. Materials Today,2014,17(10):494-503.

[182]JI Z Y,YAN C Y,YU B,et al. 3D printing of hydrogel architectures with complex and controllable shape deformation[J]. Advanced Materials Technologies,2019,4(4):1800713.

[183]KHODAPARAST S,BOULOGNE F,POULARD C,et al. Water-based peeling of thin hydrophobic films[J]. Physical Review Letters,2017,119(15):154502.

[184]LEE B P,KONST S. Novel hydrogel actuator inspired by reversible mussel adhesive protein chemistry[J]. Advanced Materials,2014,26(21):3415-3419.

[185]LEE H,XIA C G,FANG N X. First jump of microgel:actuation speed enhancement by elastic instability[J]. Soft Matter,2010,6(18):4342-4345.

[186]LI H,GO G,KO S Y,et al. Magnetic actuated pH-responsive hydrogel-based soft micro-robot for targeted drug delivery[J]. Smart Materials and Structures,2016,25(2):027001.

[187]LIU Y Q,CHEN Z D,HAN D D,et al. Bioinspired soft robots based on the moisture-responsive graphene oxide[J]. Advanced Science,2021,8(10):2002464.

[188]LIU Y Q,MA J N,LIU Y,et al. Facile fabrication of moisture responsive graphene actuators by moderate flash reduction of graphene oxides films[J]. Optical Materials Express,2017,7(7):2617-2625.

[189]LV C,XIA H,SHI Q,et al. Sensitively humidity-driven actuator based on photopolymerizable PEG-DA films[J]. Advanced Materials Interfaces,2017,4(9):1601002.

[190]MA Y,ZHANG Y Y,WU B S,et al. Polyelectrolyte multilayer films for building energetic walking devices[J]. Angewandte Chemie,2011,123(28):6378-6381.

[191]MENG H,ZHENG J,WEN X F,et al. pH- and sugar-induced shape memory hydrogel based on reversible phenylboronic acid-diol ester bonds[J]. Macromolecular Rapid Communications,2015,36(6):533-537.

[192]PY C,REVERDY P,DOPPLER L,et al. Capillary origami:spontaneous wrapping of a droplet with an elastic sheet[J]. Physical Review Letters,2007,98(15):156103.

[193]ROMAN B,BICO J. Elasto-capillarity:deforming an elastic structure with a liquid droplet[J]. Journal of Physics Condensed Matter,2010,22(49):493101.

[194]SHIN B,HA J,LEE M,et al. Hygrobot:a self-locomotive ratcheted actuator powered by environmental humidity[J]. Science Robotics,2018,3(14):eaar2629. .

[195]SONG S W,LEE S,CHOE J K,et al. Direct 2D-to-3D transformation of pen drawings[J]. Science Advances,2021,7(13):eabf3804. DOI:10. 1126/sciadv. abf3804.

[196]TACCOLA S,GRECO F,SINIBALDI E,et al. Toward a new generation of electrically controllable hygromorphic soft actuators[J]. Advanced Materials,2015,27(10):1668-1675.

[197]WU T F,FRYDRYCH M,O’KELLY K,et al. Poly(glycerol sebacate urethane)-cellulose nanocomposites with water-active shape-memory effects[J]. Biomacromolecules,2014,15(7):2663-2671.

[198]YE C H,NIKOLOV S V,CALABRESE R,et al. Self-(un)rolling biopolymer microstructures:rings,tubules,and helical tubules from the same material[J]. Angewandte Chemie International Edition,2015,54(29):8490-8493.

[199]YOON C,XIAO R,PARK J,et al. Functional stimuli responsive hydrogel devices by self-folding[J]. Smart Materials and Structures,2014,23(9):094008.

[200]ZHAO Q,DUNLOP J W C,QIU X L,et al. An instant multi-responsive porous polymer actuator driven by solvent molecule sorption[J]. Nature Communications,2014,5:4293.

[201]AMIRI MOGHADAM A A,ALAIE S,DEB NATH S,et al. Laser cutting as a rapid method for fabricating thin soft pneumatic actuators and robots[J]. Soft Robotics,2018,5(4):443-451.

[202]DE VOLDER M,REYNAERTS D. Pneumatic and hydraulic microactuators:a review[J]. Journal of Micromechanics and Microengineering,2010,20(4):043001.

[203]KELLARIS N,ROTHEMUND P,ZENG Y,et al. Spider-inspired electrohydraulic actuators for fast,soft-actuated joints[J]. Advanced Science,2021,8(14):2100916.

[204]LI S G,VOGT D M,RUS D,et al. Fluid-driven origami-inspired artificial muscles[J]. Proceeding National Academy of Sciences of the United States of America,2017,114(50):13132-13137.

[205]LU Y W,KIM C J. Microhand for biological applications[J]. Applied Physics Letters,2006,89(16):164101.

[206]TANG Y C,ZHANG Q T,LIN G J,et al. Switchable adhesion actuator for amphibious climbing soft robot[J]. Soft Robotics,2018,5(5):592-600.

[207]TSAI N C,SUE C Y. Review of MEMS-based drug delivery and dosing systems[J]. Sensors and Actuators A:Physical,2007,134(2):555-564.

[208]SOHN J W,CHOI S B. Various robots made from piezoelectric materials and electroactive polymers:a review[J]. International Journal of Mechanical Systems Engineering,2017,3(1):122.

[209]DE RIVAZ S D,GOLDBERG B,DOSHI N,et al. Inverted and vertical climbing of a quadrupedal microrobot using electroadhesion[J]. Science Robotics,2018,3(25):eaau3038.

[210]CHOI J,SHIN M,RUDY R Q,et al. Thin-film piezoelectric and high-aspect ratio polymer leg mechanisms for millimeter-scale robotics[J]. International Journal of Intelligent Robotics and Applications,2017,1(2):180-194.

[211]WOOD R J. The first takeoff of a biologically inspired at-scale robotic insect[J]. IEEE Transactions on Robotics,2008,24(2):341-347.

[212]WU Y C,HO K Y,KARIYA K,et al. PRE-curved PVDF/PI unimorph structures for biomimic soft crawling actuators[C]//2018 IEEE Micro Electro Mechanical Systems (MEMS). January 21-25,2018,Belfast,UK. IEEE,2018:581-584.

[213]PARK T,CHA Y. Soft mobile robot inspired by animal-like running motion[J]. Scientific Reports,2019,9(1):14700.

[214]NIINO T,HIGUCHI T,EGAWA S. Dual excitation multiphase electrostatic drive[C]//IAS '95. Conference Record of the 1995 IEEE Industry Applications Conference Thirtieth IAS Annual Meeting. October 8-12,1995,Orlando,FL,USA. IEEE,1995:1318-1325.

[215]KOSIDLO U,OMASTOVÁ M,MICUSÍK M,et al. Nanocarbon based ionic actuators—a review[J]. Smart Materials and Structures,2013,22(10):104022.

[216]BROCHU P,PEI Q B. Advances in dielectric elastomers for actuators and artificial muscles[J]. Macromolecular Rapid Communications,2010,31(1):10-36.

[217]ROSENTHAL M,BONWIT N,DUNCHEON C,et al. Applications of dielectric elastomer EPAM sensors[C]// Electroactive Polymer Actuators and Devices (EAPAD) 2007. San Diego,California. SPIE,2007:65241F.

[218]HINES L,PETERSEN K,LUM G Z,et al. Soft actuators for small-scale robotics[J]. Advanced Materials,2017,29(13):1603483.

[219]BAUGHMAN R H. Conducting polymer artificial muscles[J]. Synthetic Metals,1996,78(3):339-353.

[220]GU G Y,ZOU J,ZHAO R K,et al. Soft wall-climbing robots[J]. Science Robotics,2018,3(25):eaat2874.

[221]CHRISTIANSON C,BAYAG C,LI G R,et al. Jellyfish-inspired soft robot driven by fluid electrode dielectric organic robotic actuators[J]. Frontiers in Robotics and AI,2019,6:126.

[222]ZHAO J W,NIU J Y,MCCOUL D,et al. A rotary joint for a flapping wing actuated by dielectric elastomers:design and experiment[J]. Meccanica,2015,50(11):2815-2824.

[223]BIDDISS E,CHAU T. Dielectric elastomers as actuators for upper limb prosthetics:challenges and opportunities[J]. Medical Engineering & Physics,2008,30(4):403-418.

[224]MUST I,VUNDER V,KAASIK F,et al. Ionic liquid-based actuators working in air:the effect of ambient humidity[J]. Sensors and Actuators B:Chemical,2014,202:114-122.

[225]MUST I,KAASIK T,BARANOVA I,et al. A power-autonomous self-rolling wheel using ionic and capacitive actuators[C]// Electroactive Polymer Actuators and Devices (EAPAD) 2015. San Diego,California,USA. SPIE,2015:94300Q.

[226]KRUUSAMÄE K,SUGINO T,ASAKA K. Measuring blocking force to interpret ionic mechanisms within bucky-gel actuators[C]// Electroactive Polymer Actuators and Devices (EAPAD) 2015. San Diego,California,USA. SPIE,2015:94300P.

[227]ALAPAN Y,KARACAKOL A C,GUZELHAN S N,et al. Reprogrammable shape morphing of magnetic soft machines[J]. Science Advances,2020,6(38):eabc6414. .

[228]CUI J Z,HUANG T Y,LUO Z C,et al. Nanomagnetic encoding of shape-morphing micromachines[J]. Nature,2019,575(7781):164-168.

[229]DENG H,SATTARI K,XIE Y C,et al. Laser reprogramming magnetic anisotropy in soft composites for reconfigurable 3D shaping[J]. Nature Communications,2020,11:6325.

[230]ZHOU Y X,SHARMA N,DESHMUKH P,et al. Hierarchically structured free-standing hydrogels with liquid crystalline domains and magnetic nanoparticles as dual physical cross-linkers[J]. Journal of the American Chemical Society,2012,134(3):1630-1641.

[231]DING Z W,WEI P,CHITNIS G,et al. Ferrofluid-impregnated paper actuators[J]. Journal of Microelectromechanical Systems,2011,20(1):59-64.

[232]FRAGOULI D,BAYER I S,DI CORATO R,et al. Superparamagnetic cellulose fiber networks via nanocomposite functionalization[J]. J Mater Chem,2012,22(4):1662-1666.

[233]ZUO B,WANG M,LIN B P,et al. Visible and infrared three-wavelength modulated multi-directional actuators[J]. Nature Communications,2019,10:4539.

[234]MISKIN M Z,CORTESE A J,DORSEY K,et al. Electronically integrated,mass-manufactured,microscopic robots[J]. Nature,2020,584:557-61.

[235]JANG W I,CHOI C A,JUN C H,et al. Surface micromachined thermally driven micropump[J]. Sensors and Actuators A:Physical,2004,115(1):151-158.

[236]JEONG O C,YANG S S. Fabrication and test of a thermopneumatic micropump with a corrugated p+ diaphragm[J]. Sensors and Actuators A:Physical,2000,83(1/2/3):249-255.

[237]NGUYEN N T. Micro-optofluidic Lenses:a review[J]. Biomicrofluidics,2010,4(3):031501.

[238]CHI Y D,TANG Y C,LIU H J,et al. Leveraging monostable and bistable pre-curved bilayer actuators for high-performance multitask soft robots[J]. Advanced Materials Technologies,2020,5(9):2000370.

[239]LENG J S,SUN J,GUAN Q H,et al. Status of and trends in soft pneumatic robotics[J]. Scientia Sinica Technologica,2020,50(7):897-934.

[240]SHEPHERD R F,ILIEVSKI F,CHOI W,et al. Multigait soft robot[J]. Proceeding National Academy of Sciences of the United States of America,108(51):20400-20403.

[241]YAMAGUCHI T,KASHIWAGI T,ARIE T,et al. Human-like electronic skin-integrated soft robotic hand[J]. Advanced Intelligent Systems,2019,1(2):1900018.

[242]OK J,LU Y W,KIM C J C. Pneumatically driven microcage for microbe manipulation in a biological liquid environment[J]. Journal of Microelectromechanical Systems,2006,15(6):1499-1505.