Influence of Change Law of Blade Leading-Edge Ellipse Ratio on Inception Cavitation Performance of Centrifugal Pump*

Fang-fang Zhang Ran Tao* Ruo-fu Xiao

(1.College of Water Resources and Civil Engineering,China Agricultural University;2.Beijing Engineering Research Center of Safety and Energy Saving Technology for Water Supply Network System,China Agricultural University)

Abstract:In this research,a parametric control method of blade leading-edge geometry is proposed for a centrifugal pump based on previous study.Based on reasonable blade deconstruction scheme,the method adopts the change rate of leadingedge ellipse ratio from impeller shroud to hub(RaLE),the initial blade thickness(Y0)and thickness diffusion rate(Rt)as three control parameters for the blade leadingedge.The research method of combining theoretical analysis,experimental data and numerical simulation is adopted.The research indicated that according to the operating condition of centrifugal pump,the reasonable design of blade leading-edge ellipse ratio can improve its cavitation performance.This research not only proposed an effective and feasible parameter control method,but also laid a the oretical foundation for improving the inception cavitation performance of centrifugal pump through effective design.

Keywords:Centrifugal Pump;Leading-edge Ellipse Ratio;Inception Cavitation

0 Introduction

Centrifugal pumps play an important role in national production as a common turbomachine used to convey liquid[1].They are commonly used in aerospace,petrochemical,municipal construction,agricultural production and many other fields[2].

The kinetic energy and pressure of the fluid are increased by impeller blades of centrifugal pump acting [3].But the blade leading-edge is the lowest pressure area of the entire blade where cavitation is easy to occur[4].Cavity will block the flow channel and affect the energy performance of the pump.Also,cavity bubble will cause irreversible damage to pump body material and increase the risk of impeller blade fracture[5].At the same time,with the development of the pump industry,it is a key point to research how to realize real cavitation free operation of pump units[6].

In the process of all kinds of engineering optimization projects,critical cavitation is usually used as the criterion of whether cavitation occurs or not [7].However,through numerical simulation,it is found that when critical cavitation occurs,largescale cavitation has occurred in the pump [8].Hence,inception cavitation is used as the criterion for judging the occurrence of cavitation which makes the occurrence of cavitation have a stronger strict criterion [9].Conclusively,the optimization of inception cavitation performance of centrifugal pump is an effective way to realize cavitation free operation of centrifugal pump units[10-13].

This study is mainly based on previous work basics of improving the cavitation performance of centrifugal pump by optimizing leading-edge geometry of impeller blade,the influence of the change rate of leading-edge ellipse ratio from hub surface to shroud surface on inception cavitation performance of pump will be investigated.

1 Research Object

1.1 Pump Model

The centrifugal pump is a unit with open data [14].The model of objective pump is shown in Fig.1.In this centrifugal pump,the fluid flows through the inflow domain,impeller,volute and finally flow out from outflow pipes.The rated speedndis 600r/min,design flow rateQdis 13.2kg/s,design pump headHdis 3.2m,design impeller headHdimpis 4.3m,the blade outlet radiusRTEis 139mm.Besides,the specific speednsis calculated by formula(1).Thensvalue is 23.

Fig.1 Geometry of objective pump and impeller

1.2 Parametric Method

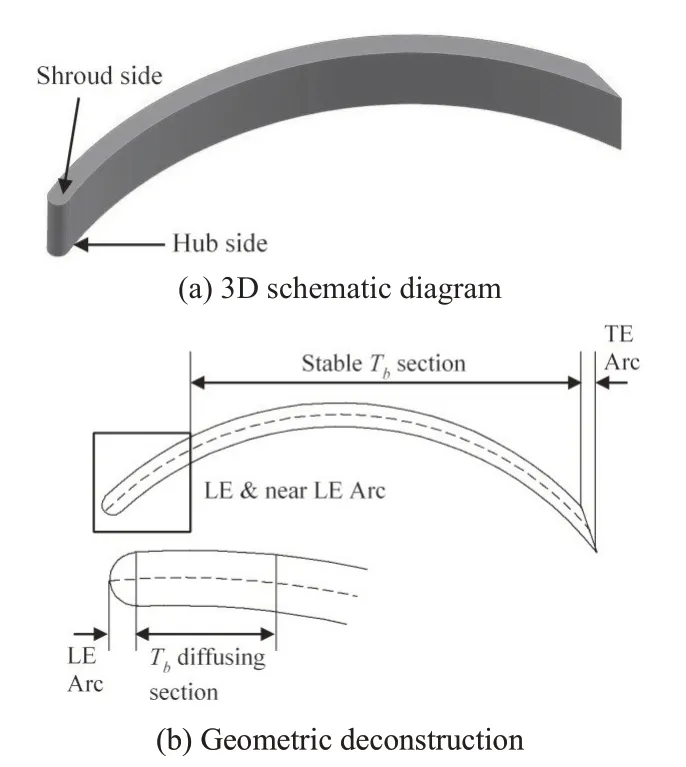

To facilitate the expression of blade geometry,the blade is geometrically structured.As shown in Fig.2,the ways of geometric deconstruction and parametric is the same as previous work[15].However,for the change rate of the leadingedge ellipse ratio from hub surface to shroud surface,this paper will discuss how different value of ellipse ratio of hub surface and shroud surface influence pump cavitation performance in detail.

Fig.2 Geometric expression of impeller blade

The change rate of leading-edge ellipse ratio from hub surface to shroud surface is defined as following formula:

WhereHaLErepresents the value of leading-edge ellipse ratio of blade hub surface,SaLErepresents the value of leadingedge ellipse ratio of blade shroud surface.The value range ofHaLEandSaLEis (0,16].To facilitate the law discussion,HaLEandSaLEboth take integers within the (0,16] interval,andHaLE≠SaLE,that is,HaLE≠0.

1.3 CFD Setup

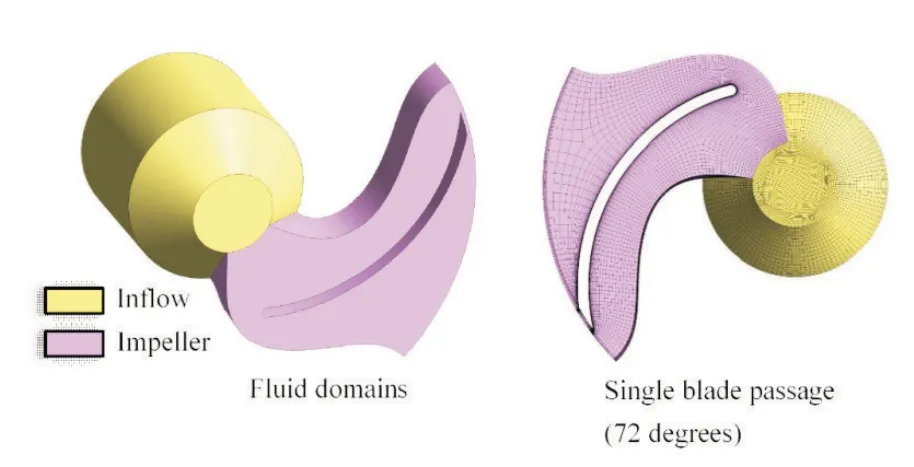

In order to facilitate the summary of the laws in this study as well as save computational resources,the inflow domain and one-fifth impeller passage model are used as the fluid domain for calculation.In this study,the numerical calculations are based on CFX software and Computational Fluid Dynamics (CFD) theory.Compared with other turbulence models,SSTk-ωmodel has more accurate prediction for nearby wall grids,which makes the turbulence model more accurate and has good convergence[16].Therefore,SSTk-ωmodel is selected as turbulence prediction model for the whole simulation process.

Fig.3 shows mesh condition of objective fluid domain.ICEM is used to mesh each component of fluid domain.All meshes are hexahedral structure meshes.Mesh independent check is proceed based on Richardson Extrapolation Method(GCI) [17].And the convergence details of three mesh schemes are shown in Fig.4.The GCI value of coarse grid is 0.75%,and that of fine grid is 0.13%,which all meets the convergence requirements.

Fig.3 Object fluid domain and final mesh

Fig.4 GCI check for three mesh schemes

For the turbulence calculation,the fluid medium is water of 25 centigrade.All walls are set as non-slip walls.All simulations are steady state,the maximum number of iteration steps in the calculation process is 500,and the convergence standard of continuity equation and momentum equation is 1×10-5.

2 Laws Exploration

2.1 Energy Performance Comparison

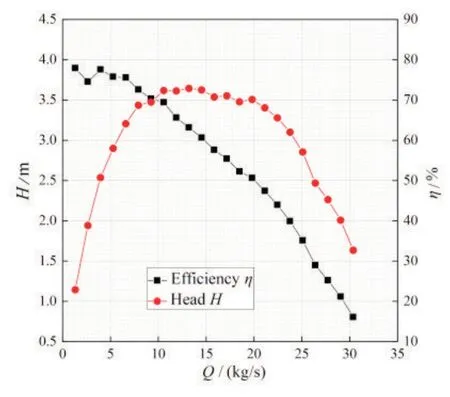

For the objective centrifugal pump,its Q-HandQ-ηperformance curves are shown in Fig.5.It can be seen from performance curves that the studied centrifugal pump has the characteristics of wide high efficiency zone.In this research,same as previous research work[15],none-zero incidence angle working condition (1.0Qd=13.19kg/s) and zero incidence angle working condition (1.7Qd=22.44kg/s) are selected as the characteristic working conditions to explore the influence of change rate of leading-edge ellipse ratio from hub surface to shroud surface on inception cavitation performance for the centrifugal pump.The pump head and efficiency are calculated by the following formulas:

Fig.5 Energy performance of objective pump

Wherep1represents the static pressure of inlet;p2represents the static pressure of outlet;ρis water density,gis gravitational acceleration.

WhereωMis shaft power.

2.2 Measurement Index

For the value of change rate of leading-edge ellipse ratio from hub surface to shroud surfaceRaLE,the inception cavitation coefficientCpminis used to characterize its cavitation performance,and its definition is shown as formula(5):

Wherepminis the minimum static pressure value on blade surface;pinis static pressure value of inlet;vinis velocity of inlet.

The larger the value ofCpmin,the better the inception cavitation performance,that is,the less cavity is likely to occur in pump.On the contrary,the smaller the value ofCpmin,the more likely cavity occurs in pump,and the worse the inception cavitation performance is.

2.3 Laws Analysis

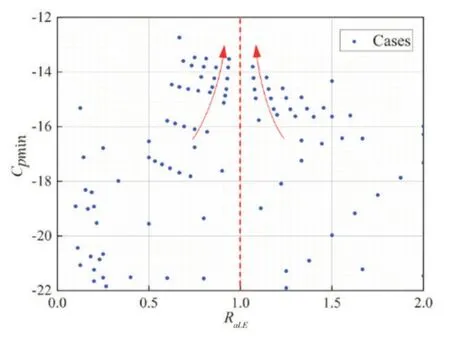

As shown in Fig.6,it shows the calculation result ofCpminunder the condition of 1.0Qdcorresponding to allRaLEvalues.It can be seen that the calculation cases with largerCpmintend to converge to the area with smallerRaLEvalue,that is,the smaller theRaLEvalue,the larger theCpminvalue,and the better the inception cavitation performance.

Fig.6 Calculation results for Cpmin under 1.0Qd

In order to further explore the exact range ofRaLEvalue with largerCpminvalue,as shown in Fig.7,which is a local enlarged figure with theRaLEvalue of 0~2.It can be seen that for the cases with largeCpminvalue,theRaLEvalue approachesRaLE=1 from both sides.This indicates that in non-zero incidence angle working condition,in order to obtain better inception cavitation performance of centrifugal pump during initial design,the value ofRaLEshould be close to 1,that is,the leading-edge ellipse ratio value of blade hub surface toshould be equal the leading-edge ellipse ratio value of blade of shroud surface.

Fig.7 Calculation results for Cpmin of local RaLE value under 1.0Qd

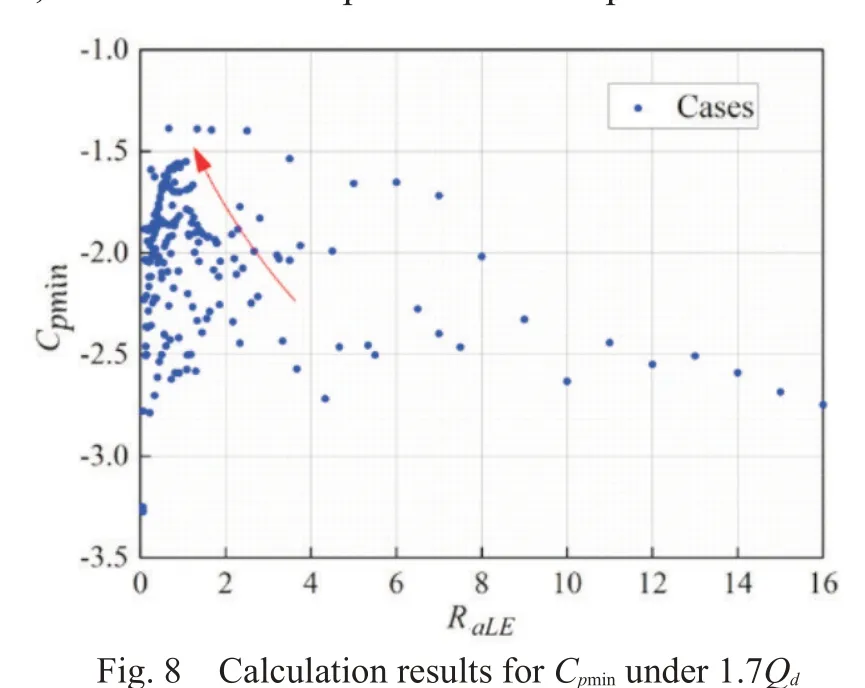

As shown in Fig.8,it is the calculation result ofCpminunder the condition of 1.7Qdcorresponding to allRaLEvalues.The results show that,similar to 1.0Qdworking condition,the calculation examples with largerCpmintend to converge to the area with smallerRaLEvalue,that is,the smaller theRaLEvalue,the better the inception cavitation performance.

Fig.8 Calculation results for Cpmin under 1.7Qd

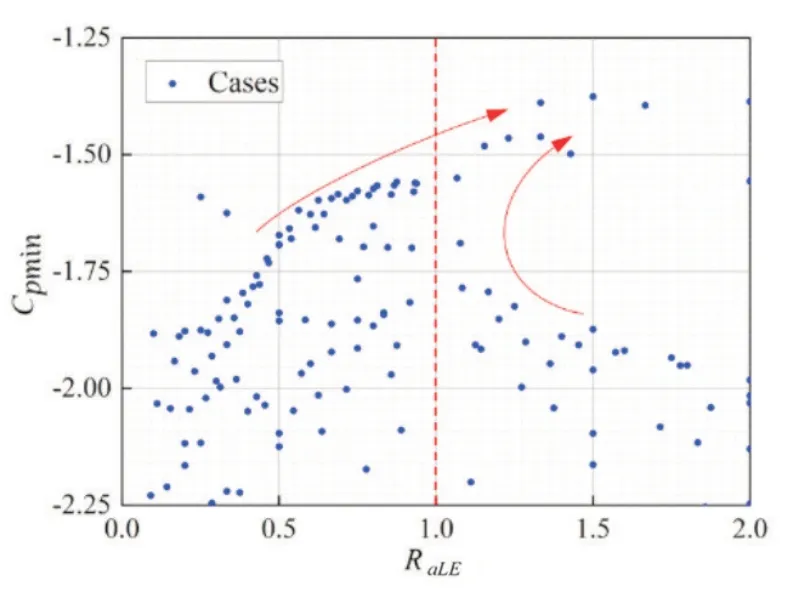

In order to further explore the influence ofRaLEvalue on the inception cavitation performance under zero incidence angle working condition as shown in Fig.9,it is a local enlarged figure withRaLEvalue of 0~2.It can be seen that theRaLEvalue of the cases with largerCpminvalue is within the range of 1~2,and closer toRaLE=2,which indicates that under zero incidence angle working condition,in order to obtain better inception cavitation performance of centrifugal pump during the initial design,theRaLEvalue should be close to 2,that is,The value of leading-edge ellipse ratio value of blade hub surface should be twice the value of the leading-edge ellipse ratio value of blade shroud surface.

Fig.9 Calculation results for Cpmin of local RaLE value under 1.7Qd

Based on the analysis of the influence of theRaLEvalue on inception cavitation performance under zero and non-zero incidence angle working condition,when during the process of designing the centrifugal pump,the operating conditions shall be comprehensively considered.If the centrifugal pump often operates near the non-zero incidence angle working conditions,in order to improve the inception cavitation performance of objective pump,it is recommended that the value of leading-edge ellipse ratio value of blade hub surface be the same as that of shroud surface.If the centrifugal pump often operates under zero incidence angle working condition,it is recommended that the value of leading-edge ellipse ratio value of blade hub surface be about twice that of shroud surface.

3 Discussion

This research only discusses and summarizes the size relationship between the leading-edge ellipse ratio of blade hub surface and shroud surface,but the influence of the continuous change law of the ellipse ratio from the blade hub surface to shroud surface on pump inception cavitation performance remains to be studied.

The values of the ellipse ratio of the blade hub face and shroud surface are all taken as an integer,which makes the calculated cases number insufficient for the summary of the universal law.Therefore,in the follow-up research,the improvement of cases number for the summary of the finer and more universal law remains to be studied.

4 Conclusions

In this research,the influence of different rate value of blade hub surface ellipse ratio and shroud surface ellipse ratio on the inception cavitation performance of centrifugal pump is explored,and the following suggestive conclusions are finally drawn:

At the beginning of centrifugal pump design,it is necessary to pay attention to the working conditions where the centrifugal pump often operates.If the centrifugal pump often operates under non-zero incidence working condition,it is recommended that the ellipse ratio value at hub surface is the same as that at shroud surface,that isRaLE=1;If the centrifugal pump often operates at zero incidence working condition,it is recommended that the ellipse ratio of hub surface is nearly twice that of shroud surface.

- 风机技术的其它文章

- 机匣处理在无喷嘴径流涡轮叶片抑振中的应用*

- Study on Loss Quantitative Analysis Methodology for Highly-loaded Transonic Fan*

- 带诱导轮的离心式航空燃油泵空化特性分析*

- Optimization Design of Air Conditioning Outdoor Unit Top Plate Based on Orthogonal Test

- 重燃透平叶片真实内部冷却通道的传热特性研究*

- Numerical Study of Film/Shock Interaction on Suction Surface of Transonic Turbine Cascade*