植物脲酶诱导碳酸盐沉淀改良土体研究进展

李明东 张诗艾 杨远江 徐浩峰 陶雪晴 何稼

摘要: 酶诱导碳酸盐沉淀(EICP)改良土体是岩土工程领域的新兴热点技术,全面总结梳理EICP改良土体的研究现状,优选关键技术参数,并对EICP的未来发展提出了展望。建议制定植物脲酶促沉碳酸钙改良土体方法标准,对植物脲酶的保存方法、EICP改良土体在特殊环境条件下的长期性能开展研究。研究结果表明:EICP能够显著提高土体的性能,无侧限抗压强度最高可达3 MPa,抗风蚀能力可达29.1 m·s-1,表面贯入强度可达1.065 MPa,渗透系数降低率可达98.2%,重金属离子质量分数降低率可达99.96%。

关键词:植物脲酶; 酶诱导碳酸盐沉淀(EICP); 土体改良; 固化; 重金属

中图分类号: TU 44文献标志码: A 文章编号: 1000-5013(2024)01-0001-09

Research Progress of Soil Improvement by Plant Urease Induced Carbonate Precipitation

LI Mingdong, ZHANG Shiai, YANG Yuanjiang,XU Haofeng, TAO Xueqing, HE Jia

(School of Civil Engineering and Architecture, East China University of Technology, Nanchang 330013, China)

Abstract: Soil improvement by enzyme induced carbonate precipitation (EICP) is an emerging hot technologie in the field of geotechnical engineering. The research status of soil improvement by EICP are summarized comprehensively, the key technical parameters are optimized, and the prospects of future development of EICP are pointed out. The standard method of soil improvement by plant urease promoting sinking of calcium carbonate is suggested. The preservation methods of plant urease and the longterm performance of soil improvement by EICP under special environmental conditions are conducted. The research results show that EICP can significantly improve the performance of soil, the maximal unconfined compressive strength reaches 3 MPa, the ability of wind erosion resistance reaches 29.1 m·s-1, the surface penetration strength reaches 1.065 MPa, the rate of permeability coefficient reduction reaches 98.2%, the rate of heavy metal ion mass content reduction reaches 99.96%.

Keywords: plant urease; enzyme induced carbonate precipitation (EICP); soil improvement; solidification; heavy metal

許多植物的种子或根部富含脲酶,脲酶能够将土体中的尿素催化水解为氨气和二氧化碳,它们与土体中的水反应,转化为碳酸根和铵根离子。当土体中存在难溶碳酸盐的阳离子(钙离子、铅离子等)时,碳酸盐达到过饱和状态,形成沉淀,其自然反应为

利用该自然反应,人为地从植物中提取脲酶,将足量脲酶和尿素引入土体中,它们能在短时间内诱导生成大量碳酸盐沉淀,称为植物脲酶诱导碳酸盐(EICP),相应的处理过程称为EICP改良土体[1-6]过程。EICP在岩土工程领域具有广阔的应用前景[7-9],主要有3个方面。1) 土体加固和防渗处理。将脲酶、尿素和可溶性钙盐同时引入土体,生成强胶结力的碳酸钙[10],碳酸钙粘结松散的土颗粒,填充土内孔隙,起到提高土体强度、降低土体渗透性的作用,具体可用于路基加固、防风固沙、湿陷性土治理和膨胀土治理等[11-14]。2) 岩石、混凝土裂隙堵漏。将脲酶、尿素和可溶性钙盐配制成堵漏液,当堵漏液流经过渗漏裂隙时,碳酸钙在裂缝侧壁上逐渐沉积,直至裂隙闭合[15]。3) 重金属污染土修复。将脲酶和尿素引入重金属污染土,重金属离子与碳酸根结合成稳定的碳酸盐结合态。

植物脲酶诱导碳酸盐技术具有3个优势。1) EICP与微生物诱导碳酸钙(MICP)相比,整个反应过程不需要空气(氧气),因此,也适用于细粒土[16-17]。2) 堵漏液中的游离脲酶只有12 nm,能够修复极细小的裂隙。3) 全过程环保来源为植物,处理过程不需要水泥,处理后的剩余脲酶可以自然降解[18]。

为了总结EICP改良土体的现状,优选技术参数,研讨前进方向,本文从EICP的影响因素、改良土体的效果和改良土体的机理3个方面进行了全面梳理,希望能为这一新兴领域的发展提供借鉴。

1 EICP的影响因素

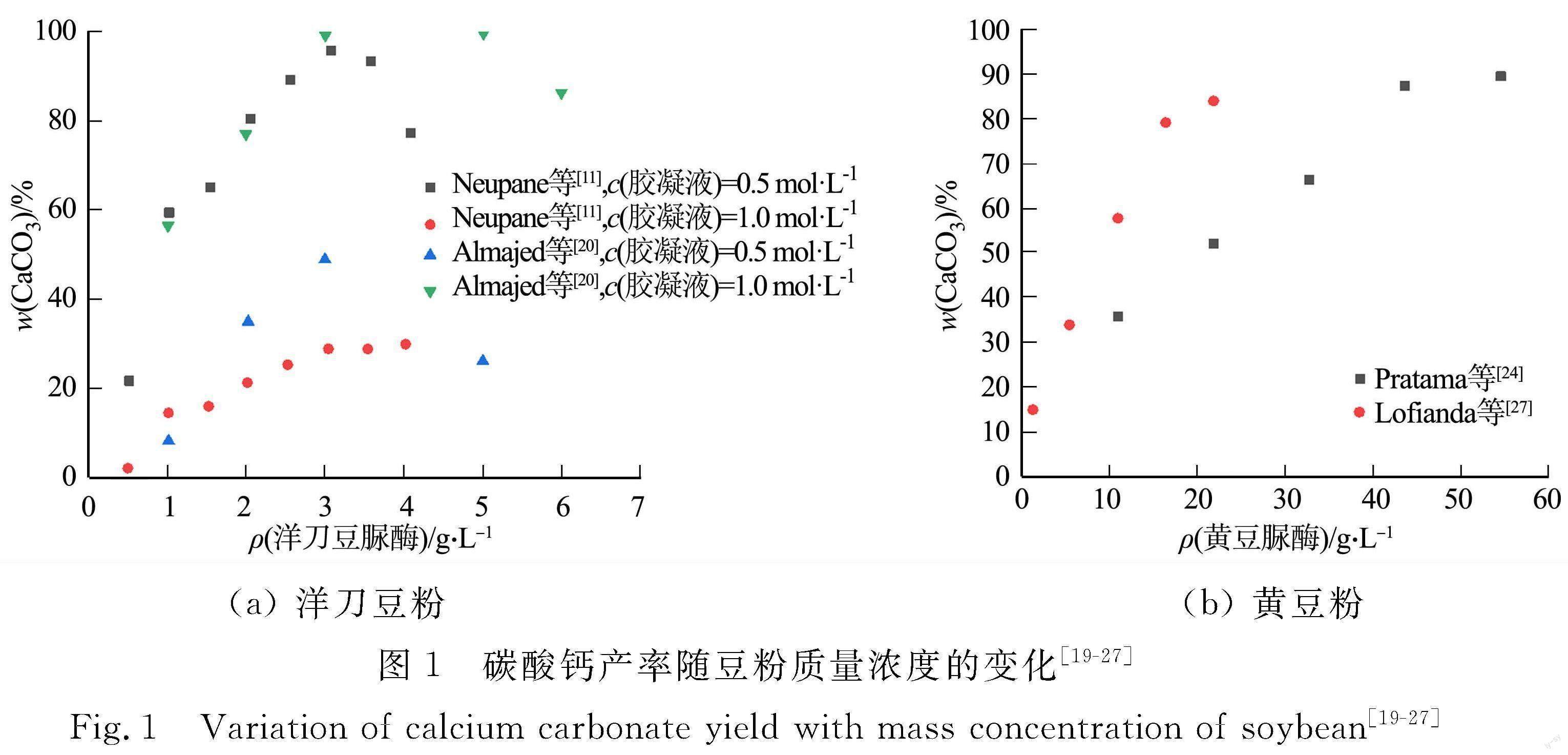

EICP的反应效率(实际碳酸钙沉淀量与理论最大值的比率)用碳酸钙产率进行表达,其影响因素包括脲酶的来源、质量浓度、钙离子质量浓度、pH值和温度等。碳酸钙产率随豆粉质量浓度的变化[19-27],如图1所示。图1中:ρ为质量浓度;w为质量分数;c为浓度。由图1可知:碳酸钙产率随洋刀豆脲酶质量浓度的增加先增加后减小,当洋刀豆脲酶质量浓度为3 g·L-1时,碳酸钙产率最大,可达90%以上[19-23];当黄豆脲酶质量浓度低于15 g·L-1时,碳酸钙产率随黄豆脲酶质量浓度增加而快速增加,当黄豆脲酶质量浓度超过15 g·L-1时,碳酸钙产率增长缓慢[24],当黄豆脲酶质量浓度为15 g·L-1時,碳酸钙产率为55%[25],当黄豆脲酶质量浓度为40~50 g·L-1时,碳酸钙产率为80%~90%[26],当黄豆脲酶质量浓度为50 g·L-1时,碳酸钙产率达到99.4%[27]。Javadi等[28]使用西瓜籽脲酶,碳酸钙产率可达64%。

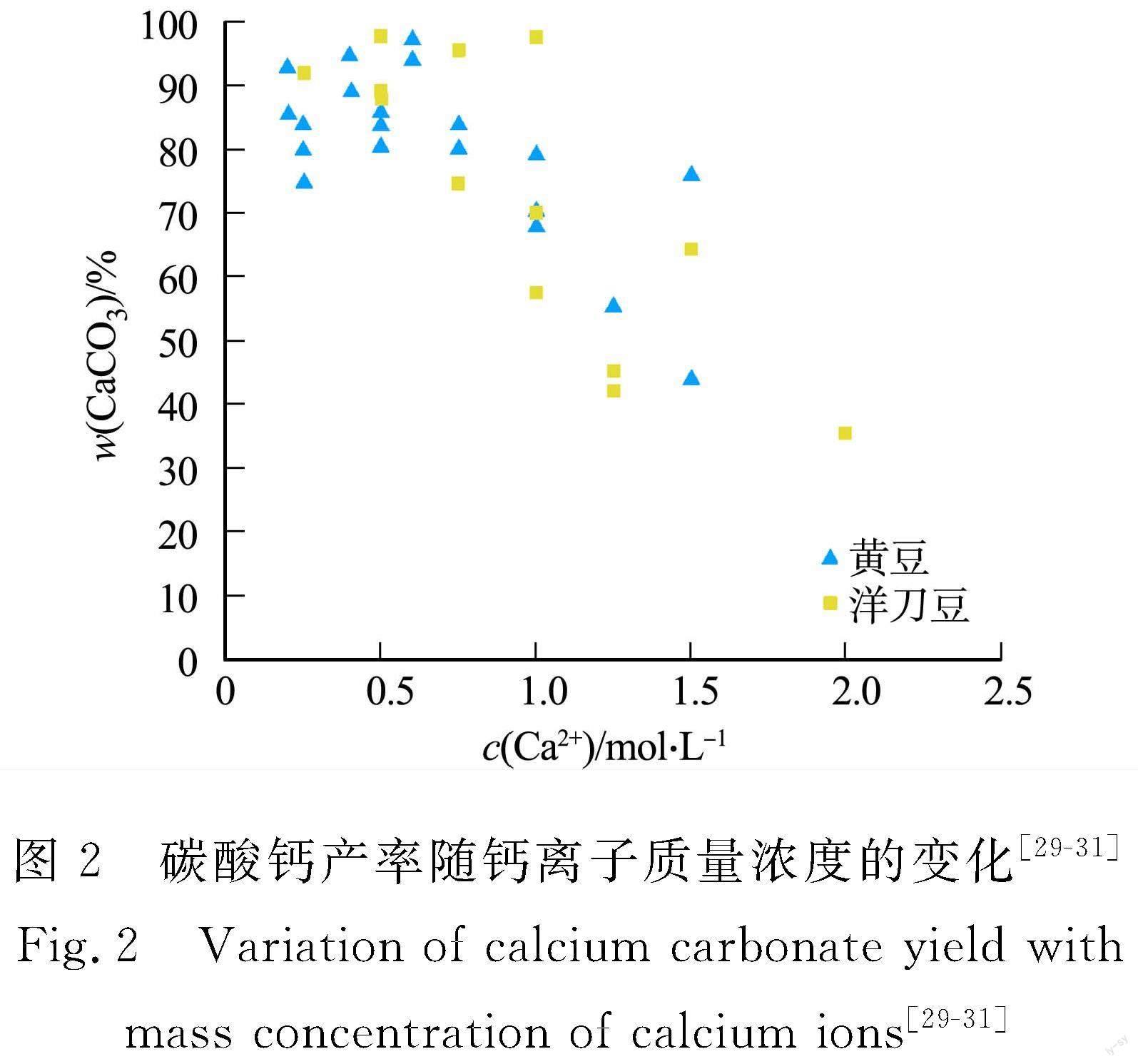

碳酸钙产率随钙离子质量浓度的变化[29-31],如图2所示。

文献[29-36]发现使用低Ca2+ 质量浓度的钙源时,碳酸钙产率较高,随着Ca2+ 质量浓度的增加,碳酸钙产率逐渐下降。氯化钙、醋酸钙、硝酸钙、乳酸钙的加固效果依次降低[32]。随着反应环境pH值的升高,碳酸钙产率先增高后降低,当反应环境pH值在8~9时,碳酸钙产率达到峰值[9,33-36],主要原因是偏酸性反应环境会抑制脲酶活性,强碱性反应环境不利于尿素水解[31]。Arab等[23]在10,25,40 ℃条件下,使用EICP改良土体,25,40 ℃土体中的碳酸钙质量分数接近,分别为4.3%和4.4%,而10 ℃土体中的碳酸钙质量分数只有3.4%。Krajewska等[37]发现温度从0 ℃上升至50 ℃时,碳酸钙沉淀速率从0.038 g·h·L-1提升至0.340 g·h·L-1,这是由于脲酶活性会随温度的升高而逐步增加[23,34,37],但不同种类的脲酶差异性较大,对温度的耐受程度不一致,存在不同的最适温度范围。黄豆脲酶在0~75 ℃范围内活性随温度上升快速升高,65 ℃以上酶活性的增长率变缓[34];西瓜籽脲酶在50 ℃左右达到最佳酶活性[2];黑眼豌豆的最佳酶活性在30~35 ℃之间[38]。

Ahenkorah等[39]发现植物脲酶诱导碳酸钙的晶型主要为方解石,少部分为球霰石、文石,晶型主要取决于植物脲酶来源、钙源和外加剂。不同酶源的方解石形态扫描电子显微镜(scanning electron microscope,SEM)图像[28,40-41],如图3所示。由图3可知:西瓜籽脲酶诱导碳酸钙晶型为斜方6面体方解石[28];洋刀豆脲酶诱导碳酸钙晶型大多为方块状方解石[40];黄豆脲酶诱导碳酸钙晶型多为类球型方解石[41],这是由于不同植物脲酶的氨基酸序列不同,其中,酸性氨基酸的数量和分布结构是决定碳酸钙晶型的重要因素之一[36]。氯化钙、硝酸钙等无机钙盐生成的碳酸钙晶型为更稳定的方解石[42-44],使用有机钙盐生成的晶型多为球霰石,少数为文石。Phua等[45]用乳酸钙制成了放射性增长的球形方解石。外加剂的引入有利于生成更稳定的方解石,并促进球霰石向方解石的转换[22,46-53]。

2 EICP改良土体的效果

2.1 加固效果

Cui等[46]用单相(低pH值)注入法处理砂土,砂土的无侧限抗压强度达到3.0 MPa(目前最好记录),大多数为0.2~2.0 MPa[2,17,20,23,29,34,47]。EICP的处理能将抗风蚀能力从加固前的8 m·s-1提高到加固后的25 m·s-1[48],最高可达29.1 m·s-1,将海藻酸钠加入EICP溶液抗风蚀能力还能再提升一倍[22],多次处理的效果更佳,循环4次后,砂粒的平均表面贯入强度由11 kPa增加到了1.065 MPa[49],这是因为风沙表面形成了坚硬致密的凝胶结皮层[22]。

EICP加固土体的效果除了受到EICP反应影响外,还受到土体的影响和外加剂的影响。吴林玉等[34]用EICP处理砂土后,发现随着砂土粒径的增大,砂土试样的无侧限抗压强度先增大后减小,粒径为0.25~0.50 mm的砂土的无侧限抗压强度最高(1.21 MPa);粒径为0.50~1.00 mm的砂土和粒径小于0.25 mm的砂土的无侧限抗压强度分别为0.62,0.40 MPa。

外加剂的影响也十分显著,不同成核剂作用效果[19,21-22,50-54],如图4所示。图4中:p为无侧限抗压强度.由图4可知:木素的无侧限抗压强度由298 kPa提高到419 kPa[50],脱脂奶粉由0.12~0.16 MPa提高到1.65 MPa~1.82 MPa[22],山梨醇提高2.2倍[51],黄原胶提高约8倍,Mg2+提高16.6%[52-53],海藻酸钠最多提高3倍[54]。提高的主要原因是外加剂为碳酸钙提供了成核位点[20,50,53,55-60]。综上,当前研究主要基于无侧限抗压强度判定加固效果,遴选最佳技术参数。

在不同环境条件(降雨引发干湿循环、冻融循环、酸雨)下,需要进一步研究加固土体的耐久性及动力特性。

2.2 防渗效果

EICP具有较好的防渗效果,Yasuhara等 [29]用EICP处理一次后,土体渗透系数降低60%~70%,4次处理后土体渗透系数从初始的0.040 0 cm·s-1降低至0.001 5 cm·s-1,总体降低了96%。 Handley-Sidhu等[57]用达西方程式进行了计算,多孔介质的渗透率从9.990 m3·s-1降至0.175 m3·s-1,渗透系数降低了98.2%。Hoang等[17]使用EICP对砂土进行8,12和16次处理,发现增加处理次数会降低土体渗透率,16次处理后,渗透系数最大降低90%。综上,EICP技术在降低土体渗透性方面效果明显,主要原因是碳酸钙沉淀充填于土颗粒之间,占据土体孔隙,土体孔隙体积减小[58]。截止目前,尚未见利用EICP进行混凝土裂隙或岩石裂隙堵漏的相关研究,有必要开展专题研究。

2.3 修复重金属污染土的效果

重金属污染对环境和生物的危害极大,且易通过食物链富集危害人类的健康。Nam等[40]应用EICP修复矿山废渣中的重金属,发现处理后的可溶性As,Mn,Zn,Pb,Cr和Cu的质量浓度分别降低了31.7%,65.8%,50.6%,51.6%,45.1%和49.7%。Moghal等[59]探究了EICP对不同重金属组合污染土的修复效果,发现重金属吸附从大到小顺序为Cd,Ni,Pb。在EICP反应液中添加脱脂奶粉,养护40 d后,可溶性铅离子下降率最高可达99.96%[59]。边汉亮等[60]用黄豆粗提取脲酶对锌离子污染土进行修复,经过3次修复后,土体中可溶性锌离子减少83.75%,碳酸鹽结合态增加68.51%。重金属污染土的修复是千年工程,但目前尚未见到EICP修复重金属污染土在不同环境(酸碱度、温度及湿度)条件下的长期稳定性相关研究,有必要开展专题研究。

3 EICP改良土体的机理

3.1 加固机理

EICP加固土体的机理,如图5所示。

过饱和的碳酸钙沉积在土体内,起到桥接、黏结和覆膜作用。桥接作用是碳酸钙晶体在两个相邻但不接触的土颗粒之间沉淀、生长,通过“搭桥”连接两个土颗粒;黏结作用是碳酸钙晶体在土颗粒接触点附近沉积聚集,黏结土颗粒,提高土体强度;覆膜作用是碳酸钙晶体覆盖在土颗粒表面。

因此,桥接作用和黏结作用在土体颗粒之间产生胶结作用,能显著增强土体团块的强度,是EICP加固土体的主要机制,而覆膜作用未能给土颗粒之间建立联系,没有明显的加固作用[61-73]。

碳酸钙质量分数随无侧限抗压强度的变化[17,20,23,29,34,73],如图6所示。由于各试验使用的EICP溶液配比、加固土体类型、处理周期等不同,数据出现一定的离散性,整体呈现出碳酸钙质量分数越高,无侧限抗压强度越大的趋势[17,20,23,29,34,65]。

3.2 修复重金属污染土的机理

EICP主要是将污染土体中的可交换态重金属离子转化为固态碳酸盐,EICP修复重金属机理示意图,如图7所示。由图7可知:一些离子半径接近Ca2+的重金属离子(Pb2+,Cu2+和Zn2+等)直接替代Ca2+离子,并与CO2-3结合生成碳酸盐沉淀[66];在土壤中形成的CaCO3对环绕其表面的金属离子具有很强的化学吸附能力,将重金属离子包裹,有效减少重金属污染物淋滤浸出[67-68];部分重金属(As,Cr等)在溶液中形成络合阴离子(亚砷酸根等),络合阴离子替代CO2-3与Ca2+反应生成沉淀[69-71]。

4 结论

总结梳理EICP改良土体现有研究,得到了以下3点主要结论。

1) 目前,已经开发出的植物脲酶包括洋刀豆、黄豆、黑豆、西瓜籽和南瓜子脲酶等,其中,洋刀豆脲酶效果最好,最佳质量浓度为3 g·L-1;黄豆脲酶经济性最好,质量浓度越大,效果越好;氯化钙、醋酸钙、硝酸钙、乳酸钙的加固效果依次降低。

2) EICP能够显著提高土体强度,土体强度随碳酸钙质量分数的增加而增加,最高可达3 MPa;EICP能够显著提高砂土的抗风蚀能力,由8 m·s-1提高到25 m·s-1;EICP能够显著降低土体的渗透系数,降低率可达98.2%;EICP能够显著降低重金属离子的质量分数,最高可达99.96%。EICP改良土体缺乏成核点位的问题可通过添加方解石种子、木质素、脱脂奶粉、蔗糖、山梨醇和海藻酸钠等成核剂进行解决。

3) EICP加固土体的内在机理是碳酸盐晶体的桥接作用和黏结作用,防渗的内在机理是碳酸钙晶体的孔隙填充作用和孔道堵塞作用,修复重金属污染土内在机理是成盐沉淀和络合作用。

当前,EICP改良土体研究存在以下3点不足。

1) 计算碳酸钙产率的反应时间、钙离子浓度、反应温度标准不统一,难以比较不同研究人员的结果,建议尽快建立统一的标准。

2) 植物脲酶溶液在常温下放置72 h后会大量失活,亟需对植物脲酶的保存方法开展对比研究,在实验室研究中可考虑0 ℃水溶液、-5 ℃软冻、-18 ℃冰冻、-80 ℃冰冻状态等,并给出植物脲酶溶液的合理保存方法。

3) 目前,EICP改良土体的研究主要集中于处理后即时性能评价,对于改良后土体长期性能的研究仍占少数[72],尚需进一步开展系统研究,包括干湿循环、冻融循环、酸雨影响和反复荷载下的性能演化规律和机制。

参考文献:

[1] 张海丽,徐品品,冷立健,等.微生物诱导碳酸钙沉积研究与应用[J].生物学杂志,2020,37(1):86-91.DOI:10.3969/j.issn.2095-1736.2020.01.086.

[2] DILRUKSHI R A N,NAKASHIMA K,KAWASAKI S.Soil improvement using plant-derived urease-induced calcium carbonate precipitation[J].Soils and Foundations,2018,58(4):894-910.DOI:10.1016/j.sandf.2018.04.003.

[3] ABDULLAH A,HAMED K T,EDWARD K,et al.Enzyme induced biocementated sand with high strength at low carbonate content[J].Scientific Reports,2019,9(1):1135.DOI:10.1038/s41598-018-38361-1.

[4] GAO Yufeng,HE Jia,TANG Xinyi,et al.Calcium carbonate precipitation catalyzed by soybean urease as an improvement method for fine-grained soil[J].Soils and Foundations,2019,59(5):1631-1637.DOI:10.1016/j.sandf.2019.03.014.

[5] 劉阳,高玉峰,何稼,等.大豆脲酶诱导碳酸钙沉积技术的防风固沙试验研究[J].河南科学,2019,37(11):1784-1789.DOI:10.3969/j.issn.1004-3918.2019.11.012.

[6] HE Jia,GAO Yufeng,GU Zhangxiang,et al.Characterization of crude bacterial urease for CaCO3 precipitation and cementation of silty sand[J].Journal of Materials in Civil Engineering,2020,32(5):04020071.DOI:10.1061/(ASCE)MT.1943-5533.0003100.

[7] KAVAZANJIAN E,HAMDAN N.Enzyme induced carbonate precipitation (EICP) columns for ground improvement[C]∥International Conference on Future Environment and Energy.Virginia:Geotechnical Special Publication,2015:2252-2261.DOI:10.1061/9780784479087.209.

[8] MUJAH D,CHENG L,SHAHIN M A.Microstructural and geomechanical study on biocemented sand for optimization of MICP process[J].Journal of Materials in Civil Engineering,2019,31(4):04019025.DOI:10.1061/(ASCE)MT.1943-5533.0002660.

[9] CHENG Liang,SHAHIN M A.Microbially induced calcite precipitation (MICP) for soil stabilization[J].Ecological Wisdom Inspired Restoration Engineering,2019(1):47-68.DOI:10.1007/978-981-13-0149-0_3.

[10] QIAN Chunxiang,REN Xinwei,RUI Yafeng.et al.Characteristics of bio-CaCO3 from microbial bio-mineralization with different bacteria species [J].Biochemical Engineering Journal,2021,176:108180.DOI:10.1016/j.bej.2021.108180.

[11] NEUPANE D,YASUHARA H,KINOSHITA N,et al.Applicability of enzymatic calcium carbonate precipitation as a soil-strengthening technique[J].Journal of Geotechnical and Geoenvironmental Engineering,2013,139(12):2201-2211.DOI:10.1061/(ASCE)GT.1943-5606.0000959.

[12] KAVAZANJIAN J E,ALMAJED A,HAMDAN N.Bio-inspired soil improvement using EICP soil columns and soil nails[C]∥Grouting 2017.Virginia:Geotechnical Special Publication,2017:13-22.DOI:10.1061/978078448079 3.002.

[13] SONG J Y,SIM Y,JANG J,et al.Near-surface soil stabilization by enzyme-induced carbonate precipitation for fugitive dust suppression[J].Acta Geotechnica,2020,15(7):1967-1980.DOI:10.1007/s11440-019-00881-z.

[14] PUTRA H,YASUHARA H,FAUZAN M.Review of enzyme-induced calcite precipitation as a ground-improvement technique[J].Infrastructures,2020,5(8):66.DOI:10.3390/infrastructures5080066.

[15] 李明东,李琳,田安国,等.一种混凝土坝缝隙的堵漏方法: CN 104480902A [P].2015-04-01.

[16] KHODADADI T H,KAVAZANJIAN E,BILSEL H.Mineralogy of calcium carbonate in MICP-treated soil using soaking and injection treatment methods[C]∥Geotechnical Frontiers 2017.Florida:American Society of Civil Engineers,2017:195-201.DOI:10.1061/9780784480441.021.

[17] HOANG T,ALLEMAN J,CETIN B,et al.Sand and silty-sand soil stabilization using bacterial enzyme-induced calcite precipitation (BEICP)[J].Canadian Geotechnical Journal,2019,56(6):808-822.DOI:10.1139/CGJ-2018-0191.

[18] 曹光輝,刘士雨,俞缙,等.酶诱导碳酸钙沉淀(EICP)技术及其在岩土工程中的应用[J].高校地质学报,2021,27(6):754-768.DOI:10.16108/j.issn1006-7493.2020200.

[19] ALMAJED A.Enzyme induced carbonate precipitation (EICP) for soil improvement[D].Arizona:Arizona State University,2017.

[20] ALMAJED A,KHODADADI T H,KAVAZANJIAN J E.Baseline investigation on enzyme-induced calcium carbonate precipitation[J].Journal of Geotechnical and Geoenvironmental Engineering,2018,144(11):04018081.DOI:10.1061/(ASCE)GT.1943-5606.0001973.

[21] ALMAJED A,ABBAS H,ARAB M,et al.Enzyme-induced carbonate precipitation (EICP)-based methods for ecofriendly stabilization of different types of natural sands[J].Journal of Cleaner Production,2020,274:122627.DOI:10.1016/j.jclepro.2020.122627.

[22] ALMAJED A,LEMBOYE K,ARAB M G,et al.Mitigating wind erosion of sand using biopolymer-assisted EICP technique[J].Soils and Foundations,2020,60(2):356-371.DOI:10.1016/j.sandf.2020.02.011.

[23] ARAB M G,ROHY H,ZEIADA W,et al.One-phase EICP biotreatment of sand exposed to various environmental conditions[J].Journal of Materials in Civil Engineering,2021,33(3):04020489.DOI:10.1061/(ASCE)MT.1943-5533.0003596.

[24] PRATAMA E M,PUTRA H,SYARIF F.Application of calcite precipitation method to increase the shear strength of peat soil[C]∥Conference Series: Earth and Environmental Science.San Francisco:IOP Publishing,2018:012058.DOI:10.1088/1755-1315/871/1/012058.

[25] BAIQ H S,YASUHARA H,KINOSHITA N,et al.Examination of calcite precipitation using plantderived urease enzyme for soil improvement[J].Geomate Journal,2020,19(72):231-237.DOI:10.21660/2020.72.9481.

[26] LEE S,KIM J.An experimental study on enzymatic-induced carbonate precipitation using yellow soybeans for soil stabilization[J].KSCE Journal of Civil Engineering,2020,24(7):2026-2037.DOI:10.1007/s12205-020-1659-9.

[27] LOFIANDA L,PUTRA H,ERIZAL S,et al.Potentially of soybean as bio-catalyst in calcite precipitation methods for improving the strength of sandy soil[J].Architecture,2021,9(7):2317-2325.DOI:10.13189/cea.2021.090719.

[28] JAVADI N,KHODADADI H,HAMDAN N,et al.EICP treatment of soil by using urease enzyme extracted from watermelon seeds[C]∥International Conference on Future Environment and Energy.Virginia:Geotechnical Special Publication,2018:115-124.

[29] YASUHARA H,NEUPANE D,HAYASHI K,et al.Experiments and predictions of physical properties of sand cemented by enzymatically-induced carbonate precipitation[J].Soils and Foundations,2012,52(3):539-549.DOI:10.1016/j.sandf.2012.05.011.

[30] CARMONA J P S F,OLIVEIRA P J V,LEMOS L J L.Biostabilization of a sandy soil using enzymatic calcium carbonate precipitation[J].Procedia Engineering,2016,143:1301-1308.DOI:10.1016/j.proeng.2016.06.144.

[31] CHANDRA A,RAVI K.Application of enzyme-induced carbonate precipitation (EICP) to improve the shear strength of different type of soils[C]∥Problematic Soils and Geoenvironmental Concerns.Singapore:Springer,2021:617-632.DOI:10.1007/978-981-15-6237-2_52.

[32] 朱磊.颗粒级配对酶诱导碳酸钙沉淀加固遗址土的影响研究[D].兰州:兰州大学,2022.DOI:10.27204/d.cnki.glzhu.2022.000774.

[33] OLIVEIRA P J V,FREITAS L D,CARMONA J P S F.Effect of soil type on the enzymatic calcium carbonate precipitation process used for soil improvement[J].Journal of Materials in Civil Engineering,2017,29(4):04016263.DOI:10.1061/(ASCE)MT.1943-5533.0001804.

[34] 吳林玉,缪林昌,孙潇昊,等.植物源脲酶诱导碳酸钙固化砂土试验研究[J].岩土工程学报,2020,42(4):714-720.DOI:10.11779/CJGE202004014.

[35] 张宽,唐朝生,刘博,等.基于新型单相MICP技术改性黏性土力学特性的试验研究[J].工程地质学报,2020,28(2):306-316.DOI:10.13544/j.cnki.jeg.2019-528.

[36] SONDI I,SALOPEK B.Influence of the primary structure of enzymes on the formation of CaCO3 polymorphs: A comparison of plant (Canavalia ensiformis) and bacterial (Bacillus pasteurii) ureases[J].Langmuir: The ACS Journal of Surfaces and Colloids,2005,21(19):8876-8882.DOI:10.1021/la051129v.

[37] KRAJEWSKA B,VAN ELDIK R,BRINDELL M.Temperature-and pressure-dependent stopped-flow kinetic studies of jack bean urease implications for the catalytic mechanism[J].Journal of Biological Inorganic Chemistry,2012,17(7):1123-1134.DOI:10.1007/s00775-012-0926-8.

[38] ZUSFAHAIR Z,DIAN R N,DANIA P,et al.Partial purification and characterization of urease from black-eyed pea (Vigna unguiculata ssp. unguiculata L.) [J].Journal of Fundamental and Applied Sciences,2018,14(1):20-24.DOI:10.11113/MJFAS.V14N1.749.

[39] AHENKORAH I,RAHMAN M M,KARIM M R,et al.A review of enzyme induced carbonate precipitation (EICP): The role of enzyme kinetics[J].Sustainable Chemistry,2021,2(1):92-114.DOI:10.3390/suschem2010007.

[40] NAM I H,ROH S B,PARK M J,et al.Immobilization of heavy metal contaminated mine wastes using Canavalia ensiformis extract[J].Catena,2016,136:53-58.DOI:10.1016/j.catena.2015.07.019.

[41] 郎钞棚,马明,邱立冬,等.大豆脲酶促沉碳酸钙改良砂土地基承载特性模型试验研究: 基于静力触探试验[J].高校地质学报,2021,27(6):784-788.DOI:10.16108/j.issn1006-7493.2020212.

[42] GOROSPE C M,HAN S H,KIM S G,et al.Effects of different calcium salts on calcium carbonate crystal formation by Sporosarcina pasteurii KCTC 3558[J].Biotechnology and Bioprocess Engineering,2013,18(5):903-908.DOI:10.1007/s12257-013-0030-0.

[43] ZHANG Yie,GUO Hongxian,CHENG Xiaohui.Influences of calcium sources on microbially induced carbonate precipitation in porous media[J].Materials Research Innovations,2014,18(S2):79-84.DOI:10.1179/1432891714Z.000000000384.

[44] LIU Dagang,CHENG Huihuang,CHANG P R,et al.Biomimetic soyprotein nanocomposites with calcium carbonate crystalline arrays for use as wood adhesive[J].Bioresource Technology,2010,101(15):6235-6241.DOI:10.1016/j.biortech.2010.02.107.

[45] PHUA Y J,ROYNE A.Bio-cementation through controlled dissolution and recrystallization of calcium carbonate [J].Construction and Building Materials,2018,167(10):657-668.DOI:10.1016/j.conbuildmat.2018.02.059.

[46] CUI Mingjuan,LAI Hanjiang,HOANG T,et al.One-phase-low-pH enzyme induced carbonate precipitation (EICP) method for soil improvement[J].Acta Geotechnica,2020,16(8):1-9.DOI:10.1007/s11440-020-01043-2.

[47] NAFISI A,SAFAVIZADEH S,MONTOYA B M.Influence of microbe and enzyme-induced treatments on cemented sand shear response[J].Journal of Geotechnical and Geoenvironmental Engineering,2019,145(9):06019008.DOI:10.1061/(ASCE)GT.1943-5606.0002111.

[48] KNORR B.Enzyme-induced carbonate precipitation for the mitigation of fugitive dust[D].Arizona:Arizona State University,2014.

[49] GAO Yaqing,HUA Chen,KE Tong.Field test on soybean-urease induced calcite precipitation (SICP) for desert sand stabilization against the wind-induced erosion[J].Sustainability,2022,14(22):15474.DOI:10.3390/su142215474.

[50] 張建伟,王小锯,李贝贝,等.EICP-木质素联合固化粉土的试验研究[J].土木与环境工程学报(中英文),2021,43(2):201-202.DOI:10.11835/j.issn.2096-6717.2020.155.

[51] YANG Yuanjiang,LI Mingdong,TAO Xueqing,et al.The effect of nucleating agents on enzyme-induced carbonate precipitation and corresponding microscopic mechanisms[J].Materials,2022,15(17):5814.DOI:10.3390/ma151 75814.

[52] DAVIS K J,DOVE P M,DE YOREO J J.The role of Mg2+ as an impurity in calcite growth[J].Science,2000,290(5494):1134-1137.DOI:10.1126/science.290.5494.1134.

[53] CHANDRA A,RAVI K.Effect of magnesium incorporation in enzyme-induced carbonate precipitation (EICP) to improve shear strength of soil[J].Advances in Computer Methods and Geomechanics,2020(56):333-346.DOI:10.1007/978-981-15-0890-5_28.

[54] REFAEI M,ARAB M G,OMAR M.Sandy soil improvement through biopolymer assisted EICP[C]∥Geo-Congress 2020: Foundations, Soil Improvement and Erosion.Virginia:American Society of Civil Engineers,2020:612-619.DOI:10.1061/9780784482780.060.

[55] CHEN Tao,SHI Peiheng,LI Yi,et al.Biomineralization of varied calcium carbonate crystals by the synergistic effect of silk fibroin/magnesium ions in a microbial system[J].Cryst Eng Comm,2018,20(17):2366-2373.DOI:10.1039/C8CE00099A.

[56] ZHU Liping,LANG Chaopeng,LI Bingyan,et al.Characteristics of soybean urease induced CaCO3 precipitation[J].Geomechanics and Engineering,2022,31(3):281.DOI:10.12989/gae.2022.31.3.281.

[57] HANDLEY-SIDHU S,SHAM E,CUTHBERT M O,et al.Kinetics of urease mediated calcite precipitation and permeability reduction of porous media evidenced by magnetic resonance imaging[J].International Journal of Environmental Science and Technology,2013,10(5):881-890.DOI:10.1007/s13762-013-0241-0.

[58] CHO G C,DODDS J ,SANTAMARINA J C.Particle shape effects on packing density, stiffness, and strength: Natural and drushed sands[J].Journal of Geotechnical and Geoenvironmental Engineering,2006,133(5):591-602.DOI:10.1061/(ASCE)1090-0241(2006)132:5(591).

[59] MOGHAL A A B,LATEEF M A,MOHAMMED S A S,et al.Efficacy of enzymatically induced calcium carbonate precipitation in the retention of heavy metal ions[J].Sustainability,2020,12(17):7019.DOI:10.3390/su12177019.

[60] 邊汉亮,张旭钢,韩一,等.大豆脲酶对Zn2+污染土的修复试验研究[J].工业建筑,2022,52(11):67-70.DOI:10.13204/j.gyjzG20110216.

[61] MIAO Linchang,WU Linyu,SUN Xiaohao.Enzyme-catalysed mineralisation experiment study to solidify desert sands[J].Scientific Reports,2020,10(1):10611.DOI:10.1038/s41598-020-67566-6.

[62] SUN Xiaohan,MIAO Linchang,WANG Hengxing,et al.Enzymatic calcification to solidify desert sands for sandstorm control[J].Climate Risk Management,2021,33:100323.DOI:/10.1016/j.crm.2021.100323.

[63] LIN Hai,SULEIMAN M T,BROWN D G.Investigation of pore-scale CaCO3 distributions and their effects on stiffness and permeability of sands treated by microbially induced carbonate precipitation (MICP)[J].Soils and Foundations,2020,60(4):944-961.DOI:10.1016/j.sandf.2020.07.003.

[64] 张茜,叶为民,刘樟荣,等.基于生物诱导碳酸钙沉淀的土体固化研究进展[J].岩土力学,2022(2):1-13.DOI:10.16285/j.rsm.2021.1249.

[65] ALIOTTA L,CINELLI P,COLTELLI M.B,et al.Rigid filler toughening in PLA-calcium carbonate composites: Effect of particle surface treatment and matrix plasticization[J].European Polymer Journal,2019,113:78-88.DOI:10.1016/j.eurpolymj.2018.12.042.

[66] DILRUKSHI R A N,KAWASAKI S.Effective use of plant-derived urease in the field of geoenvironmental[J].Journal of Civil and Environmental Engineering,2016,6(1):2.DOI:10.4172/2165-784X.1000207.

[67] CHEN Minjie,LI Yafei,JIANG Xiaoru,et al.Study on soil physical structure after the bioremediation of Pb pollution using microbial-induced carbonate precipitation methodology[J].Journal of Hazardous Materials,2021,411:125103.DOI:10.1016/j.jhazmat.2021.125103.

[68] ZHU Xuejiao,KUMARI D,HUANG M S,et al.Biosynthesis of CdS nanoparticles through microbial induced calcite precipitation[J].Materials and Design,2016,98:209-214.DOI:10.1016/j.matdes.2016.03.008.

[69] TRIPTI K.pH modulates arsenic toxicity in Bacilluslicheniformis DAS-2[J].Ecotoxicology and Environmental Safety,2016,130:240-247.DOI:10.1016/j.ecoenv.2016.04.029.

[70] CATELANI T,PERITO B,BELLUCCI F,et al.Arsenic uptake in bacterial calcite[J].Geochimica et Cosmochimica Acta,2017,222:642-654.DOI:10.1016/j.gca.2017.11.013.

[71] QIAN Xinyi,FANG Chaolin,HUANG Minsheng,et al.Characterization of fungal-mediated carbonate precipitation in the biomineralization of chromate and lead from an aqueoussolution and soil[J].Journal of Cleaner Production,2017,164:198-208.DOI:10.1016/j.jclepro.2017.06.195.

[72] XU Kai,HUANG Ming,ZHEN Jiajie,et al.Field implementation of enzyme-induced carbonate precipitation technology for reinforcing a bedding layer beneath an underground cable duct[J].Journal of Rock Mechanics and Geotechnical Engineering,2023,15(4):1011-1022.DOI:10.1016/j.jrmge.2022.06.012.

[73] WHIFFIN V S,VAN PAASSEN L A,HARKES M P.Microbial carbonate precipitation as a soil improvement technique[J].Geomicrobiology Journal,2007,24(5):417-423.DOI:10.1080/01490450701436505.