Comparative evaluation of commercial Douchi by different molds:biogenic amines,non-volatile and volatile compounds

Aijun Li,Gng Yng,b,Zhirong Wng,b,Shngln Lio,Muying Du,b,c,d,Jun Song,Jinqun Kn,b,c,d,*

a College of Food Science,Southwest University,Beibei,Chongqing 400715,China

b Chinese-Hungarian Cooperative Research Centre for Food Science,Chongqing 400715,China

c Laboratory of Quality &Safety Risk Assessment for Agri-products on Storage and Preservation (Chongqing),Ministry of Agriculture and Rural Affairs of the People’s Republic of China,Chongqing 400715,China

d Chongqing Key Laboratory of Speciality Food Co-Built by Sichuan and Chongqing,Chongqing 400715,China

e Shu Xiang Douchi Food Research Institute Limited Company,Chongqing 402160,China

Keywords:Douchi Starting strains Non-volatile compounds Volatile compounds Sensory evaluation

ABSTRACT To provide new insights into the development and utilization of Douchi artificial starters,three common strains(Aspergillus oryzae,Mucor racemosus,and Rhizopus oligosporus) were used to study their influence on the fermentation of Douchi.The results showed that the biogenic amine contents of the three types of Douchi were all within the safe range and far lower than those of traditional fermented Douchi.Aspergillus-type Douchi produced more free amino acids than the other two types of Douchi,and its umami taste was more prominent in sensory evaluation (P <0.01),while Mucor-type and Rhizopus-type Douchi produced more esters and pyrazines,making the aroma,sauce,and Douchi flavor more abundant.According to the Pearson and PLS analyses results,sweetness was significantly negatively correlated with phenylalanine,cysteine,and acetic acid (P <0.05),bitterness was significantly negatively correlated with malic acid (P <0.05),the sour taste was significantly positively correlated with citric acid and most free amino acids (P <0.05),while astringency was significantly negatively correlated with glucose (P <0.001).Thirteen volatile compounds such as furfuryl alcohol,phenethyl alcohol,and benzaldehyde caused the f lavor difference of three types of Douchi.This study provides theoretical basis for the selection of starting strains for commercial Douchi production.

1. Introduction

Douchi is a traditional soybean product produced via fermentation by various groups of microorganisms and is widely favored by consumers due to its enriched flavor,unique taste,and high nutrient levels[1].Based on the type of microorganism used,Douchi can be divided into four types,Aspergillus-type (e.g.,Liuyang Douchi,Yangjiang Douchi,etc.),Mucor-type (e.g.,Yongchuan Douchi),Rhizopus-type (e.g.,tempeh),andBacterial-type (e.g.,natto)[2].Mold can secrete abundant hydrolases,which can remarkably change the nutritional structure of soybean products and are extensively employed in the industry to decomposes,flatulence factors in soybean products,such as raffinose and stachyose,reduce levels of antinutrients,including phytic acid and trypsin inhibitor,increase soybean digestibility,inhibit bacterial spoilage,and promote product quality[3,4].Koji-making and post-fermentation are the two most important stages of Douchi production.The principal function of koji fermentation is the induction and supply of hydrolytic enzymes,which play important roles in the post-fermentation process,degrading soybean proteins,starches,fibers,and other macromolecules into free amino acids,organic acids,soluble sugars,and other molecules to endow Douchi with abundant flavor and high nutrition value[5].

Although Douchi produced by traditional fermentation using natural starter in the koji-making process is typically richer in flavor than that produced by commercial fermentation[5],the post-fermentation period is quite long,often up to 10 months[6],Furthermore,for traditional fermentation,the fungal community is determined by the production environment,making product quality uneven[2].According to a three-year study (2018-2020)[7],traditional fermentation methods are susceptible to contamination with harmful microorganisms likeAspergillusflavusandAspergillusparasiticus,both of which produce a highly toxic secondary metabolism,aflatoxin,which can cause food safety issues and threaten human health.Therefore,commercial fermentation has been widely suggested for Douchi production due to its safety,stability,and minimal-time consumption (usually only one month)[8].

As has been established,the choice of artificial starter contributes considerably to the quality of commercial fermented soybean products.For example,in terms of flavor formation,He et al.[9]found that the levels of organic acids and fatty acids inMucor-type Douchi were significantly higher than those inAspergillus-type Douchi during the koji-making stage,meaning thatMucor-type Douchi may be sourer.Meanwhile,umami taste,a characteristic of fermented soybean products,was shown to be highly associated with glutamine levels inPenicillium-type soybean paste,but with aspartic acid and asparagine levels inAspergillus-type soybean paste[10].In addition,previous studies have demonstrated a close relationship between the choice of artificial starters and the presence of harmful factors in many fermented products.In particular,the excessive intake of biogenic amines (BAs),a class of nitrogen-containing organic compounds has been linked to potential toxic effects,such as nausea,vomiting,and dizziness[11].Our previous study[12]demonstrated that bothMucor-type andAspergillus-type Douchi contains ornithine and tyrosine decarboxylase,and the BA levels ofMucor-type Douchi were lower than those ofAspergillus-type Douchi.Therefore,the choice of starting strains is crucial to Douchi.However,previous research,including our earlier study,focused solely on the one-sided influence of different starting strains on fermented soybean products,with little information available regarding the comprehensive evaluation of Douchi metabolites,taste,flavor,and sensory characteristics by starting strain.The results of one-sided information can not provide reliable starting strain selection for commercial Douchi,and it is also insufficient for the development of artificial starters.

Therefore,this study aimed to comprehensively explore the effects of different molds (Aspergillus oryzae,Mucorracemosus,andRhizopus oryzae) on the safety,non-volatile compounds,volatile compounds,and sensory of Douchi.Four critical control points(mixing and cooling,koji-making,mixing,post-fermentation) in the fermentation process were selected for comparison.Pearson and PLS analyses were used to explore the contribution components of flavor and taste.The insights provided by this work provide a basis for the selection of starting strains for the production of safe and high-quality commercial Douchi,thus giving a new idea for the development of mixed commercial starter.

2. Material and methods

2.1 Material and chemicals

Soybean and flour were purchased from the Yonghui supermarket(Chongqing,China).All reference standards were at least 98% purity.BAs (putrescine,cadaverine,tryptamine,phenylethylamine,spermine,spermine,tyramine,and histamine) were purchased from Sigma-Aldrich (St.Louis,USA).Soluble sugars (fructose,glucose,maltose,and sucrose) and organic acids (oxalic,tartaric,malic,lactic,acetic,citric,and succinic acids) were purchased from Solarbio (Shanghai,China).Food-grade of sensory reagents (citric acid,sucrose,quinine hydrochloride,sodium chloride,sodium glutamate,and alum),gas chromatography (GC)-grade reagents (2-methyl-butanal,ethyl caproate,γ-nonyl lactone,2-phenyl ethanol,and p-Methoxybenzaldehyde),highperformance liquid chromatography (HPLC)-grade reagents (acetonitrile and methanol),analytical reagent (AR)-grade reagents (diammonium hydrogen phosphate,phosphoric acid,and sulfosalicylic acid) were purchased from Macklin (Shanghai,China).

2.2 Preparation of raw materials

2.2.1 Preparation of starting culture strains

The pure culture strains used in this study,includingA.oryzae2339,M.racemosus40714,andR.oligosporus3152,were purchased from the China Center of Industrial Culture Collection (Beijing,China).Each strain was grown in potato dextrose agar (PDA) at 30 °C for 3 days.Then,spore suspension was generated by addition of 1 mL sterile water after which samples were incubated in a bran medium at 30 °C for 3 days.

2.2.2 Preparation of Douchi

The process of Douchi preparation was performed in detail as described in our previous research,with further optimization[12](Supplementary Fig.A.1).5% (m/m) steamed flour and soybeans were mixed evenly to make koji,and then 8% salt,and 10% rice wine were added.The duration of koji-making is determined by protease activity,as represented by the ability of a sample to convert soybean proteins into small molecules with active ingredients or taste contributions[13],the important factors affecting the quality of koji.Therefore,the time of koji-making ofAspergillus-type andRhizopustype were 64 h,while that ofMucor-type was 120 h.The three types of Douchi were cultured until amino acid nitrogen reached stability in the post-fermentation (Supplementary Fig.A.2),soAspergillustype,Mucor-type,andRhizopus-type Douchi were cultured for 22,27 and 32 days,respectively.The mixtures were then packed into sealed bags and cultured in an incubator at 45 °C[14].During the koji-making stage,samples were collected regularly at 8 h.During the rapid postfermentation stage,the degree of change in amino acid nitrogen gradually decreased,so samples were collected at the following time points: 0,2,4,7,10,14,18,22,27,and 32 days.Among them,four critical control points (after mixing and cooling,S1;after kojimaking,S2;after mixing,S3;after post-fermentation,S4) in the fermentation process were selected to determine the level of biogenic amines,soluble sugars,and organic acid in the three types of Douchi.All samples were stored at -20 °C until further testing.

2.3 Determination of biogenic amines (BAs)

Qualitative and quantitative analyses of BAs were performed using HPLC (1260,Agilent,USA).The determination was performed as described by Tan et al.[12]using a Zorbax Eclipse XDB C18(250 mm × 4.6 mm,5 μm) with a UV detector.

2.4 Determination of non-volatile compounds

2.4.1 Neutral protease and amino acid nitrogen

Neutral protease was assessed using the standard method described by GB/T 23527-2009[15].For each sample,1 mL diluent was added to a test tube,preheated for 2 min in a water bath at 40 °C,and treated with 1 mL casein before being heated for precisely 10 min.Two mL 0.4 mol/L trichloroacetic acid was added to stop the reaction,after which samples were incubated for additional 20 min in a water bath.The samples were then filtered to remove residual protein,and 1 mL filtrate was transferred to a fresh test tube and combined with 5 mL 0.4 mol/L sodium carbonate.One mL diluted Folin reagent was added with shaking,and samples were incubated at 40 °C for 20 min,followed by measurement at 680 nm.For blank control,one test tube was processed as described above,but with the addition of 2 mL 0.4 mol/L trichloroacetic acid to inactivate the enzyme before addition of casein.Data were obtained by subtracting blank group value from test group values.The experiments were repeated five times,and average values were calculated.

Amino acid nitrogen levels were measured using the formalin titration method[16].Briefly,the mixed supernatant of the treated sample (10 mL) was added to 60 mL water and titrated to pH 8.2 with 0.05 mol/L NaOH.Then,10 mL 360 g/L formaldehyde was added to the solution and titrated to pH 9.2 with 0.05 mol/L NaOH.The level of amino nitrogen was obtained based on the consumed volume of 0.05 mol/L NaOH in increasing the pH value from 8.2 to 9.2.

2.4.2 Organic acids and soluble sugars

Organic acids were measured using HPLC (1260,Agilent,USA)with SB-Aq (250 mm × 4.6 mm,5 μm) and a DAD detector according to the method described in our previous study[17].Soluble sugars were determined using a Polaris NH2(250 mm × 4.6 mm,5 μm) with a RID detector;about 20 μL of each sample was injected,separation was carried out using a mobile phase of 70% acetonitrile-water,a flow rate of 0.4 mL/min,and column and detector temperatures of 35 °C.

2.4.3 Free amino acid

The free amino acid composition of Douchi samples was measured as described by Suo et al.[18]with slight modifications.For each sample,ground Douchi (200 mg) was weighed,put into a 10 mL plastic tube and vortex-mixed with 2 mL of 4% sulfosalicylic acid solution.After an incubation at 4 °C for 15 h,the mixture was centrifuged at 8 000 r/min for 10 min.The supernatant was filtered through a 0.22-μm aqueous filter,and the filtrate was analyzed using an automatic amino acid analyzer (L-8900,Hitachi,Japan).

2.5 Determination of volatile compounds

The extraction of volatile compounds was manually performed using a headspace-solid phase microextraction (HS-SPME) sampler equipped with 50/30 μm fused silica DVB/CAR/PDMS fiber (Supelco,Bellefonte,PA,USA).GC-mass spectrometry (GC-MS) was used to analyze volatile compounds in three types of Douchi as described by Lu et al.[19]with minor modifications.Each sample was sealed and balanced at 60 °C for 20 min,and then extracted by exposing the fiber to the headspace for 30 min.The extraction fiber was then placed into the GC-MS apparatus (GP201010200,Shimadzu Corporation,Japan) equipped with a DB-5MS column (30 m × 0.25 mm,0.25 μm,Agilent,USA) in splitless mode.The oven temperature was maintained at 40 °C for 5 min,increased at 5 °C/min to 100 °C,maintained for 5 min,increased at 8 °C/min to 180 °C,maintained for 5 min,increased at 10 °C/min to 250 °C,and maintained for 2 min.Helium served as the carrier gas (1 mL/min).The key MS operating parameters were as follows: the detector temperature was 230 °C;the ion source temperature was 250 °C;the ionization voltage was 70 eV(electron impact ionization),and the scan window during acquisition was 35-500m/z.In addition,a mixture of n-alkane standards (from C7to C40) was injected for external retention index calibration.Volatile compounds were identified by comparing their mass spectra to the NIST17 database.p-Methoxybenzaldehyde was used as an internal standard for the quantitative calculation of volatile compound levels in three types of Douchi.

2.6 Sensory evaluation

Descriptive sensory analysis (DA) was used to characterize the flavor and taste attributes of Douchi.The panelists (5 men and 7 women,aged 20-28) assessed the sensory characteristics,and then,12 training sessions were performed within four weeks.The sensory characteristics measured for Douchi included sour,sweet,bitter,salty,umami,astringent,aftertaste,soy sauce aroma,Douchi aroma,fermentation,ester,sweet aroma,and aromatic.As previously reported[20],the reference materials were as follows: sour (0.2 g/L citric acid),sweet (10.0 g/L sucrose),bitter (0.1 g/L quinine hydrochloride),salty (2.5 g/L sodium chloride),umami (2.5 g/L sodium glutamate),astringent (1.0 g/L of alum),aftertaste,soy sauce aroma (commercial soy sauce),Douchi aroma (commercial Douchi),fermentation(10.5 g/L 2-methyl-butanal),ester (15.0 g/L ethyl caproate),sweet aroma (15.0 g/Lγ-nonyl lactone) and aromatic (12.5 g/L 2-phenyl ethanol).The samples of three types of Douchi were weighed and placed into a clean opaque plastic cup at room temperature.The samples were presented using three-digit random coding.Each sensory analyst selected one grain with toothpick and held it in their mouth for 30 s to perform taste sensory evaluation.For flavor sensory analysis,sensory personnel first sniffed the reference material and memorized its flavor,and then sniffed the samples with their eyes closed.Each sample was sniffed no more than three times,and the sniffing time was no more than 5 s.A scale of 0-10 with 0.5 increments,where 0 represented none and 10 represented extremely high,was applied to each flavor and taste to provide a measure of intensity.

2.7 Statistical analysis

All measurements were performed at least in triplicate,and data are expressed as mean ± SD.Statistical analyses were carried out with SPSS 24.0 (SPSS Inc,Chicago,IL,USA),using one-way analysis of variance (ANOVA) and the least significant difference (LSD) test withP<0.05 indicating significance.Partial least squares (PLS)and partial least squares discrimination analysis (PLS-DA) were performed using SIMCA 14.1 (Airsense Analytics GmbH).

3. Results and discussion

3.1 Analysis of species and content changes of BAs during fermentation

BAs are primarily formed by enzymatic decarboxylation of amino acids and reductive amination of ketones and aldehydes[21],and have attracted wide concern as a potential hazard factor in fermented soybean products[22].To evaluate the safety of three types of Douchi,four critical control points were selected to determine the composition and changes of BAs.Tryptamine,histamine,and tyramine were not detected in all groups,but putrescine,cadaverine,spermidine,and spermine were detected in the S1 stage,with total BA levels of 54.02 mg/kg (Table 1).During the fermentation process,the BA content ofMucor-type andRhizopus-type Douchi decreased continuously,and the total BA content was 6.28 and 22.57 mg/kg in the S4 stages,respectively (Fig.1A),which was significantly lower than that in S1 stage.However,the total BA content increased by 3.39-fold forAspergillus-type Douchi in the S2 stage,but decreased by 50.23% in the S4 stage,after which samples were dominated by phenylethylamine and putrescine.

In the S1 stage,a certain level of BAs was detected,mainly spermidine,indicating that the materials affected the BA content.Spermidine itself has no adverse effects on health,but it may react with nitrite to form carcinogenic nitrosamines,which are easily absorbed by the gastrointestinal tract and can inhibit the catabolism of toxic amines such as Tyramine and Tryptamine to increase toxicity[23].Interestingly,the spermidine content in the S4 stage was detected as 0.33-5.99 mg/kg,potentially due to the degradation of spermidine by microbial metabolism during the fermentation process[24].In previous reports[25],it was shown that the BA content of traditional fermented Douchi was 43.0-2 067.56 mg/kg,while the BA content of the final product in this study was 6.28-94.65 mg/kg,which was much lower than that of traditional fermented Douchi.Therefore,commercial fermentation can effectively reduce BA content.In this study,pure strain was used to make koji,which reduced the pollution of exotic microorganisms,thus reduced the levels of BA compared with traditional fermentation.In addition,according to the study of Benkerroum[26],BAs were controlled by reducing ripening times,thus reducing the amount of proteolytic activity to limit the availability of precursor amino acids.Commercial fermentation adopted in this study has achieved the effect of limiting BAs levels by obtaining products with the shortest fermentation time.The BA content ofAspergillus-type Douchi was higher than those of the other two types of Douchi due to the differences in the free amino acid content of the BA precursor,consistent with our previous research results[12].This study detected the presence of phenethylamine,which may be related to the different process conditions,as the addition of wheat flour may provide more synthetic BA precursors[27].Previous reports[28]showed that a total food amine content of more than 1 000 mg/kg may be harmful to health.The United States Food and Drug Administration (USFDA) guidelines suggest a threshold of 50 mg/kg for histamine in seafood[29].This study did not detect histamine,and the total BA content was far below the recommended limit,indicating that the three types of Douchi are relatively safe.

3.2 Analysis of non-volatile compounds

3.2.1 Soluble sugars

The presence of soluble sugars makes Douchi have a kind of eating back to sweet taste.During the fermentation process,starch is hydrolyzed to produce glucose and fructose,resulting in a decrease insucrose and an increase in glucose[5].No maltose was detected during the fermentation process (Supplementary Table A.1).Three kinds of soluble sugars,sucrose,fructose,and glucose,were detected in the S1 stage,with a total soluble sugar content of 51.69 mg/g,and the sucrose content was (32.23 ± 0.15) mg/g due to the flour and soybean starch.In the S2 stage,starch was hydrolyzed into glucose by the action of glycosidase,leading to a decrease in sucrose content and a rapid increase in glucose content (Fig.1B).Sucrose was not detected inAspergillus-type andMucor-type Douchi in the S2 stage,at the same time,the glucose content in the three types of Douchi increased from(8.82 ± 2.52) mg/g in the S1 stage to (124.39 ± 6.61)−(153.15 ± 3.67) mg/g in the S4 stage,at least partially due to the addition of rice wine in the S3 stage.In addition,in the post-fermentation stage,soluble sugar is consumed by the Maillard reaction and microorganism metabolism,resulting in the decrease of glucose inAspergillus-type Douchi[30].In the finish products,the soluble sugar contents of three types of Douchi were all found to be dominated by glucose,with total soluble sugar levels ofAspergillus-type,Mucor-type,andRhizopus-type Douchi were 126.11,166.19,and 131.42 mg/g,respectively,which were significantly different (P<0.05).Based on the study of Han[31],both glucose and fructose were detected in the doenjang fermentation,and the final product was dominated by fructose,which was inconsistent with the results in this study and this may be due to the difference in fermentation process,resulting in higher glucose content in the final product.

3.2.2 Organic acid

Furthermore,organic acids not only provide a sour taste,which gives a mellow taste to the Douchi,but also are the main factors inhibiting the growth of pathogens and microorganisms that cause spoilage,helping prolong the shelf life of fermented products[32].During the fermentation process,organic acids are continuously produced,and ester formation was consumed to a certain extent during the post-fermentation stage.In the S1 stage,tartaric,acetic,and citric acid were detected,and the total organic acid content was 3.30 mg/g (Supplementary file Table A.2).As shown in Fig.1C,the organic acid content of three types of Douchi first increased,and then decreased,primarily driven by changes in citric,lactic,and acetic acid.The addition of rice wine in the S3 stage increased the contents of lactic acid,malic acid,and succinic acid.Lactic acid was the main organic acid present in the final products of three types of Douchi,and there was no significant difference (P>0.05) between its content in the three types of Douchi,with levels falling between (16.17 ±0.41)−(17.38 ± 0.28) mg/g.In the S2 stage,the acetic acid content ofMucor-type andRhizopus-type Douchi increased rapidly by 2.50-and 6.65-fold,respectively,while the acetic acid content ofAspergillustype Douchi had no significant (P>0.05) change.However,in the S4 stage,the acetic acid levels ofMucor-type andRhizopus-type Douchi decreased significantly (P<0.05),while the acetic acid content ofAspergillus-type Douchi increased.In the final product,the levels of acetic and succinic acids were significantly different (P<0.05)between the three types of Douchi.Aspergillus-type Douchi had a higher acetic acid content ((9.18 ± 0.25) mg/g),while succinic acid((8.44 ± 0.04) mg/g) was most abundant inRhizopus-type Douchi.From the study of Liu[30],acetic acid and lactic acid were common organic acids in fermented soybean products,showing consistency with this study,suggesting that heterolactic acid fermentation is the major process during fermentation.According to previous studies[30,31],the acetic acid content is related to the presence of bacterial communities such asTetragenococcus,Pediococcus,Weissella,andEnterococcus,while succinic acid content is positively correlated withLactobacillus.Due to the different environments associated with molds,different bacterial communities were present in the three types of Douchi,leading to differences in organic acid distribution.Aspergillus-type Douchi contained more acetic acid,making it sourer,simultaneously,the presence of succinic acid provides an umami taste forRhizopus-type Douchi[33].

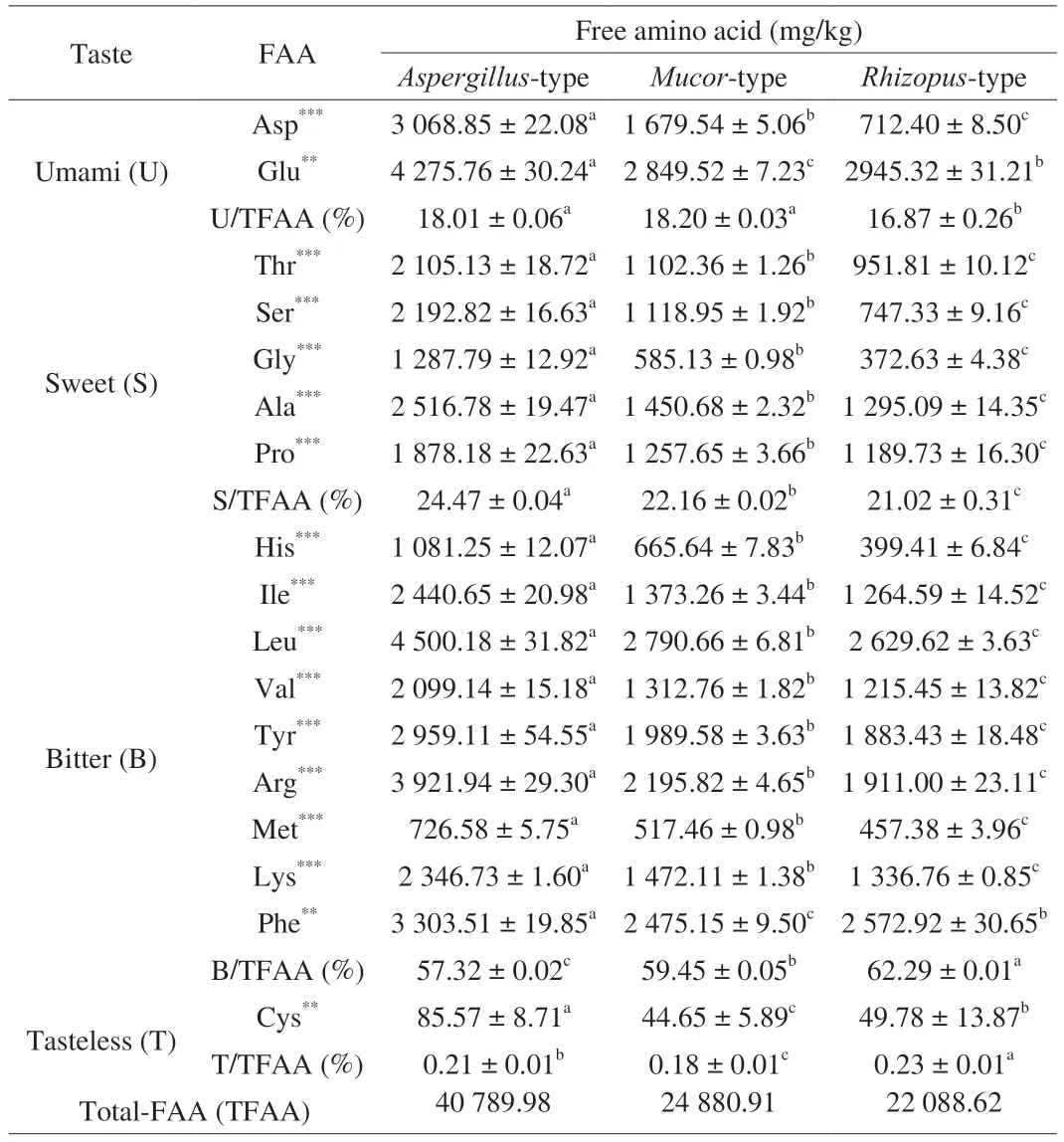

3.2.3 Free amino acid content

Free amino acids and their nitrogen-containing degradation products are important flavor compounds and precursors in fermented foods and are an important index to assess the flavor of a fermented product[34].According to the contribution of free amino acid to the taste,it can be divided by taste into umami,sweet,bitter,sour,and tasteless categories[35].Glutamic acid,leucine,and arginine were the most abundant free amino acids in the three types of Douchi.There were extremely significant differences (P<0.001) in free amino acid levels among them (Table 2).The content of free amino acids inAspergillus-type Douchi was significantly higher than those of the other two types of Douchi (P<0.01) (Table 2),consistent with the results of our previous study[12],related to the higher protein activity ofAspergillus-type Douchi in the S2 stage (Supplementary Fig.A.2).Comparing the proportion of different taste amino acids in total free amino acids,umami amino acids ofAspergillus-type andMucortype Douchi represented 18.01% and 18.20% of the total free amino acids,respectively,which were significantly higher than that ofRhizopus-type Douchi (P<0.05),at the same time,the percentage of sweet amino acids ofAspergillus-type Douchi was 24.47%,which was significantly higher than those of the other two types of Douchi,implying more prominent umami and sweet taste.Notably,bitter amino acids ofRhizopus-type Douchi represented 62.29% of the total free amino acids,indicating a more bitter taste.The higher protease capacity ofAspergillus-type Douchi did not increase the proportion of bitter free amino acids in total free amino acids,in contrast,Aspergillus-type Douchi accumulated more umami and sweet free amino acids in the fermentation process,therefore,the consumption of bitter free amino acids may be related to the formation of melanoid in Maillard reaction[36].

Table 2 Free amino acid content of Douchi with different molds.

Table 3 Volatile compound content of Douchi with different molds.

3.3 Analysis of volatile compounds

Volatile compounds are believed to be produced by the Maillard reaction,Strecker degradation,oxidative thermal degradation of fatty acids and microbial catabolism[34].Volatile compound content of Douchi with different molds were shown in Tables 3.In this study,a total of 67 volatile substances were detected (Fig.2A),including 11 alcohols,5 acids,11 aldehydes,9 alkenes,14 esters,4 pyrazines,and 13 other substances.Of these,26 volatile compounds were common among all three types of Douchi,and 9,7,and 9 volatile compounds were unique toAspergillus-type,Mucor-type,andRhizopus-type,respectively.Generally,alcohols are formed during fermentation,and their synthesis is linked to amino acid metabolism and sugar metabolism of yeast.1-octen-3-ol,maltol,and phenethyl alcohol were detected in the three types of Douchi,described as mushroomlike,flower,and caramel-like aroma,respectively[37,38].2,3-Butanediol and 3-methyl-1-butanol are the characteristic flavors substances of the fermented product,to endow Douchi fruit with sweet aroma[39].The contents of ethanol and 3-methyl-1-butanol inMucor-type Douchi were (13.51 ± 1.29) and (10.78 ± 0.29) μg/g,respectively,and the content of 2,3-butanediol inRhizopus-type Douchi was (4.70 ± 0.34) μg/g,but they were not detected inAspergillus-type Douchi.

Aldehydes are mainly produced by lipid oxidation and amino acid degradation,and exhibit lower thresholds,so they exert more impact on the flavor[40].Benzaldehyde exhibits the smell of bitter almonds,which is not desired.There was a significant difference (P<0.05) in its content among the three types of Douchi,and the content ofMucortype Douchi was the highest ((3.65 ± 0.16) μg/g).Aspergillus-type Douchi contains more 2-methyl butyraldehyde ((9.17 ± 0.61) μg/g),which gives a malty flavor[38].Aldehydes can be converted into acid by aldehyde dehydrogenase.The content of acetic acid inAspergillustype Douchi was up to (5.43 ± 0.13) μg/g,while it was not detected inMucor-type andRhizopus-type Douchi.

As a typical source of aroma in fermented products,the variety and content of esters have a major impact on the flavor of Douchi[41].Among the esters detected,the types and contents of esters inMucortype Douchi were more abundant.The content of ethyl acetate inMucor-type Douchi was up to (9.92 ± 0.52) μg/g,similar to that of cheese and yogurt.In addition,as the unique pyrazines ofRhizopus-type Douchi,2,3-dimethyl pyrazine,2,3,5-trimethyl pyrazine,and tetramethyl pyrazine have been reported to contribute to nutty flavor[37].

To assess the differences in flavor between the three types of Douchi,volatile profiles were analyzed using partial least squares discrimination analysis (PLS-DA).The Score Plot (Fig.2B) showed that the three types of Douchi exhibited good parallelism,and the variance explanation rate of this model wasR2X=0.736 (R2X(1)=0.4,R2X(2)=0.336).PLS-DA can be used to successfully separate three types of Douchi based on GC-MS analysis data.Mucor-type Douchi had the highest score on P1,indicating thatMucor-type Douchi contributed substantially to P1.WhileRhizopus-type Douchi exhibited a positive load on P2,Aspergillus-type Douchi exhibited a negative load,indicating a major difference betweenRhizopus-type Douchi andAspergillus-type Douchi on P2.

3.4 Analysis of sensory evaluation

The descriptive sensory analysis results indicated that all threetypes of Douchi were rich in umami,saltiness,and aftertaste.The taste intensity ofAspergillus-type was the highest,and there was a significant difference in umami intensity (P<0.01),and sour intensity(P<0.05) (Fig.2C).It can be explained by the fact thatAspergillustype Douchi is rich in acetic acid and umami amino acids (glutamic acid and aspartic acid) (Fig.1C and Table 2).In terms of flavor,soy sauce aroma,Douchi aroma,and aromatic flavor were noted for three types of Douchi.there were no significant differences in flavor between the three types of Douchi (P>0.05) (Fig.2D),but it can be seen that the evaluation scores ofMucor-type andRhizopustype Douchi were higher than those ofAspergillus-type Douchi in the aromatic and sweet aroma.Mucor-type Douchi contains more esters and alcohols,endowing it with aromatic and fruity flavors.2,3,5-trimethyl pyrazine and tetramethyl pyrazine were present inRhizopus-type Douchi and were considered to be the main sources of soy sauce and Douchi aroma[33].Conversely,the excessive fermentation ofAspergillus-type Douchi increased the levels of acetic acid and aldehydes,which are associated with beany and unpleasant flavors[39],

leading to flavor deficiencies.From the study of Allwood[42],A.oryzaeproduced an enzyme called glutaminase that converts glutamine into glutamic acid during koji-making,which was particularly important for providing the unique umami taste of Douchi,soA.oryzaewas considered very suitable for fermentation.However,there were many aromatic substances were metabolized due to overexpression of hydrolase byA.oryzae,which produced some unpleasant flavors.Therefore,althoughMucor-type andRhizopustype Douchi have relatively low protease activity so that the taste is not prominent,they retain more aromatic substances and have attractive flavor.In conclusion,in order to enrich the taste and flavor of Douchi,it is not enough to pursue high protease activity,and mutistrain fermentation mode dominated by starting strains may be a potential means of improvement.

3.5 Correlation analysis between non-volatile compounds,volatile compounds,and sensory evaluation

To explore the contribution of flavor and taste,Pearson and PLS were used to analyze the correlation between non-volatile compounds,volatile compounds,and sensory evaluation (Fig.3).The results showed that sweetness was significantly negatively correlated with phenylalanine,cysteine,and acetic acid (P<0.05),bitterness was significantly negatively correlated with oxalic acid and malic acid,and sour taste was significantly positively correlated with citric acid,threonine,alanine,lysine,arginine,valine,proline,tyrosine,glycine,and methionine (P<0.001).The salty taste was significantly positively correlated with glycine and methionine,and extremely significantly positively correlated with serine (P<0.01),and the astringent taste was significantly positively correlated with lactic acid (P<0.01),and significantly negatively correlated with glucose(P<0.05).The PLS-DA analysis method was used to analyze correlations between flavor sensory evaluation results and volatile compound levels (Fig.3B).First,a total of 13 VIP >1 species were screened out as substances with large contribution rates to sample classification in the principal component region[43].Furfuryl alcohol,phenethyl alcohol,benzaldehyde,ethyl caproate,3-hydroxy-2-butanone,1,2-bis (1-methyl phenyl)-(1R,2R)-rel-cyclobutane,and guaiacol were associated with aromatic,estery,and sweet flavors,indicating strong correlations with flavor presentation.

Fig.3 Correlation between non-volatile and volatile compounds and sensory evaluation (A): Heatmap obtained by Pearson analysis combining taste evaluation and non-volatile compounds;(B): The Loading Scatter Plot obtained by PLS analysis combined with flavor sensory evaluation and volatile compounds (x: volatile components;y: flavor characteristics);*P <0.05;**P <0.01;***P <0.001.

4. Conclusion

This study showed that commercial fermented Douchi has a significantly low level of BA in Douchi,and the BA content of three types of Douchi is within the safe level.A.oryzaehas a strong protein decomposition ability,which makes its free amino acid content higher and its umami taste more prominent,but this excessive fermentation produces unpleasant flavor substances such as acids and aldehydes.On the contrary,althoughMucor-type Douchi andRhizopus-type Douchi are insufficient in taste,their moderate fermentation makes them produce more ester and pyrazine aromatic substances.The selection of starting strain determines the microbial composition of artificially mixed starter,by revealing the advantages and disadvantages of different molds,more targeted addition of flavor or taste promoting strains was performed to make up for the defects of single strain fermentation.It is worth exploring to make up for the disadvantage of single strain fermentation by adding exogenous microorganisms,which will be the focus of our future.

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This study was financially supported by Special key project of technological innovation and application development in Yongchuan District,Chongqing (2021yc-cxfz20002) and the special funds of central government for guiding local science and technology development,and the funds for the platform projects of professional technology innovation (CSTC2018ZYCXPT0006).

Appendix A.Supplementary data

Supplementary data associated with this article can be found,in the online version,at http://doi.org/10.26599/FSHW.2022.9250037.

- 食品科学与人类健康(英文)的其它文章

- GUIDE FOR AUTHORS

- Targeting gut microbiota in osteoporosis: impact of the microbial based functional food ingredients

- Weizmannia coagulans: an ideal probiotic for gut health

- Natural sources,refined extraction,biosynthesis,metabolism,and bioactivities of dietary polymethoxyflavones (PMFs)

- A review of salivary composition changes induced by fasting and its impact on health

- Minerals in edible insects: a review of content and potential for sustainable sourcing