Dynamic changes in physicochemical property,biogenic amines content and microbial diversity during the fermentation of Sanchuan ham

Zhongi Chen,Hong Chen,Hun Du,Cong Chen,Kixing Lu,Qioli Xue*,Yongjin Hu,*

a College of Food Science and Technology,Yunnan Agricultural University,Kunming 650000,China

b Institute of Food Processing,Guizhou Academy of Agricultural Sciences,Guiyang 550006,China

c Editorial Department of Journal of Yunnan Agricultural University,Yunnan Agricultural University,Kunming 650000,China

Keywords:Sanchuan ham Nitrite cont ent Free amino acids Cadaverine Staphylococcus

ABSTRACT Sanchuan ham is appreciated in Yunnan Province,China,for its characteristic flavor and taste,while the microbial community structure and biogenic amines content remain unclear during fermentation processes.In this study,we explored the physicochemical property,biogenic amines concentration and microbial diversity of external and internal Sanchuan ham by high-throughput sequencing during the processing of Sanchuan ham.Results showed that the nitrite remained at a stable level of 0.15 mg/kg which was significantly lower than the national health standard safety level of 20 mg/kg.In addition,compared with fresh hams,the content of total free amino acids in ripe Sanchuan ham has grown 14 folds; sour and bitter were the main tastes of Sanchuan ham.Notably,the concentration of cadaverine was the highest of all biogenic amines during the entire fermentation period. At the bacterial phyla level,Firmicutes and Actinobacteria were the two main phyla,while at the genus level, Staphylococcus was a significant strain throughout the whole fermentation.Moreover,the dry stage has a great impact on the succession change of microbial community structure.Simultaneously,the change trends and composition of bacteria in the interior have slight discrepancies with those of the exterior of Sanchuan ham.

1. Introduction

Dry-cured ham,a traditional fermented meat product,is widely consumed around the world for its unique aroma,attractive color and high nutritional value.The famous dry-cured ham in China includes Xuanwei ham,Rugao ham,Jinhua ham,Nuodeng ham[1-3].Sanchuan ham,a representative product of dry-cured ham in Yunnan province,is appreciated in southwest China for its characteristic flavor and taste.Compared with the well-known Xuanwei ham produced in Yunnan province,the Sanchuan ham had the highest total watersoluble low molecular weight compounds,such as amino acids,amino acids derivatives,nucleic acids,organic acids,sugars,alcohols,vitamins,small peptides,and free fatty acid contents,which together determined the unique flavor and chewy texture of Sanchuan ham[4].

Sanchuan ham is produced in Lijiang of Yunnan province with a long history of 600 years,where the altitude is about 1 570 m and the average temperature is 7–19 °C.The cold and humid climate of Lijiang County provides a favorable environment for natural fermentation of Sanchuan ham,which is also called “the sole softness ham” by food experts in China (https://baike.so.com/doc/1077240-1139976.html).It is generally prepared by a local conventional technology that mainly includes raw selection,salting,drying and overlaying fermentation[4-5].To be specific,Sanchuan ham is prepared by selecting the black fur pig of local breeding as material,which is well known for its distinguished meat quality and it is the superior raw material for producing dry-cured ham.Firstly,the strong hind leg of a black fur pig was selected,and salt and liquor were mixed thoroughly on the surface of the ham,rubbing them into muscle,repeating 6–7 times.Subsequently,put them into a fermentation tank,stack them in layers,turn them over about 15 days for about 30 days,and then take them out from the tank,hanging for 60 to 90 days to dry.For the following dry technology,to our knowledge,some details are different from other ham[6].Notably,the semi-dried ham must be covered with a layer of white cotton paper,putting it on the shelf for air drying for 1–2 months[7].Afterward,the dried ham was enclosed in a cloth bag,put into a bamboo basket,covered completely with plant (pine tree) ash and fermented for 6–8 months[4].The purposes of being covered with plant ash are to absorb the moisture remaining in the ham and prevent erosion by insects.However,covering with plant ash to ferment is the most important characteristic that distinguished Sanchuan ham from other famous Jinhua ham,Xuanwei ham,which has been its exclusive technology.

On Sanchuan ham,recent studies have predominantly focused on the water-soluble low molecular weight compound profiles and the free fatty acid compositions[4],volatile compounds[6],synthesis mechanism of biogenic amine[7].They found that Sanchuan ham had the highest total low molecular weight compounds and free fatty acid contents among five kinds of dry-cured hams,and aldehydes and alkanes were the most abundant volatile compounds in Sanchuan ham.Biogenic amines,organic compounds containing nitrogen,are often detected in fermented food with relatively rich protein.The production of biogenic amines in fermented meat products has been attributed to the action of decarboxylating enzyme of several microorganisms which facilitate free amino acids to decarboxylate[8].The low amounts of biogenic amines may play an essential role in promoting cell growth division,but excessive intake of biogenic amines from food might lead to physiological symptoms such as headaches,nausea,respiratory distress,heart palpitation,and hypertension.Landeta et al.[8]found that tyramine and putrescine were the most abundant biogenic amines in Italian dry-cured ham.Alfaia et al.[9]evaluated the profile of biogenic Amines in Portuguese dry-cured hams and found that Spermine and cadaverine tended to be present in larger quantities,whereas histamine and spermidine contents were usually low.

Due to the long production cycle and the complex microbial flora of natural surroundings,the instability quality of Sanchuan ham among different batches has always been a serious problem for production enterprises of Sanchuan ham.As a result,it is necessary to explore the community’s structures of microbes in Sanchuan ham during the manufacturing process of it.It is reported that microbial flora in the ham is the key to regulating and improving the quality of ham products[3].To be specific,microorganisms participate in biochemical reactions in meat by secreting extracellular enzymes that lead to macromolecule materials in the raw material,such as protein,fat,and the carbohydrate hydrolyzed into short peptides,free amino acid,fatty acid and lactic acid to produce volatile flavor compounds and taste substances during the fermentation,thereby affecting the sensorial quality of traditional fermented meat products[10].The bacterial community and volatile profile of the Jinhua ham during different processing stages were researched[1],indicating thatStaphylococcuswas the dominant bacteria during the entire fermentation process.Mu et al.[11]have established the relationship between microorganisms and metabolites during the fermentation of Panxian ham,andStaphylococcus,Debaryomyces,andChromohalobacterpromoted the production of amino acids and fatty acids,with the most significant changes occurring in the initial stage of ripening. Nevertheless,different production technology leads to different product quality.To date,little information is available about the physicochemical property,biogenic amine content and microbial community succession on the surface and inside of Sanchuan ham during the whole processing period.

Hence,in this research,physicochemical properties including the content of moisture,NaCl,nitrite,and pH,biogenic amine,free amino acids were investigated and the bacterial communities’ structures of Sanchuan ham were revealed using high-throughput sequencing (HTS)technology during the manufacturing process.We hope our research findings will enhance our understanding of the effect of microbiota structure on comprehensive quality during the manufacturing of Sanchuan ham and provide a theoretical basis for industrial production.

2. Materials and methods

2.1 Sample preparation

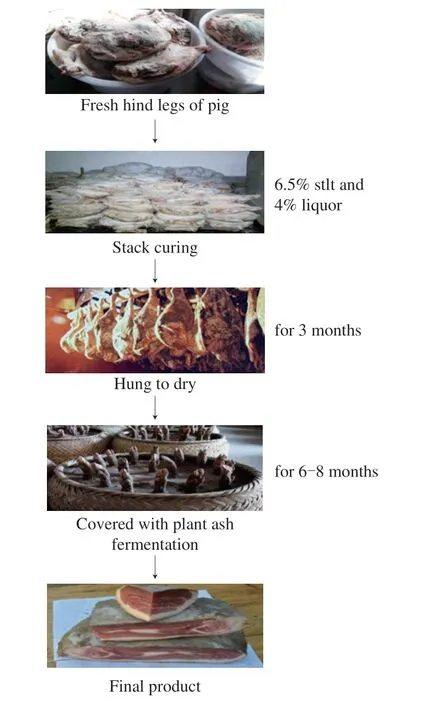

Sanchuan hams were prepared and collected at Sanchuan Food Co.,Ltd.,Lijiang,Yunnan,China.The manufacturing of Sanchuan ham was according to local traditional techniques.As shown in the flow chart (Fig.1).Simply,after having been slaughtered,48 hind legs of black fur pig were selected,salted with 6.5% salt as well as 4% liquor in total,repeated 2–3 times for 30 d,then wrapped with tissue paper,hung to dry for 3 months,and covered with plant ash to stack to ferment for 6–8 months.Three Sanchuan hams were randomly selected for each sampling,and three different points from the surface and inside of theBicepsfemorismuscle of dry-cured hams were sampled respectively and cut into 3 cm3cubes.The samples were immediately put into sterilized ziplocked bags and stored in a refrigerator at -80 °C until further use.

Fig.1 A process diagram for Sanchuan ham fermentation

Sanchuan ham samples were collected periodically at 16 different fermentation stages.In curing period,samples were taken on days 0 (HS-0,HI-0),4 (HS-4,HI-4),8 (HS-8,S HI-8),12 (HS-12,HI-12),16 (HS-16,HI-16),30 (HS-30,HI-30),a total of 6 times.In the dry period,samples were collected on days 60 (HS-60,HI-60),90 (HS-90,HI-90),120 (HS-120,HI-120) a total of 3 times.In the ripening period,samples were taken on days,150 (HS-150,HI-150),180 (HS-180,HI-180),210 (HS-210,HI-210),240 (HS-240,HI-240),270 (HS-270,HI-270),300 (HS-300,HI-300),330 (HS-330,HI-330),a total of 7 times.HS represents the surface samples and HI represents the interior samples of Sanchuan.The determination of physicochemical property,biogenic amines content used the mixture of surface and interior samples,while microbial diversity employed the surface and interior samples,respectively.A total of 96 samples were transported into the lab on ice and stored at -80 °C until further use.

2.2 Determination of moisture content and pH

The moisture content of Sanchuan ham was analyzed using the dry method,while its pH was measured using a pH meter (Jingke Leici Instruments,Shanghai,China)[12].In brief,10 g of Sanchuan hams were mixed with 100 mL of distilled water to be heated to a boil,cooled to room temperature,and then centrifuged at 6 000 ×gfor 10 min.The supernatant was directly measured with a pH meter.

2.3 Determination of sodium chloride concentration

The sodium chloride concentration was determined according to the method reported by previous study[1].In brief,Sanchuan hams samples (20 g) were boiled with distilled water (80 mL) and then the mixture was diluted to 200 mL with distilled water.Subsequently,the mixture solution was filtered with filter paper,then the filtrate was collected to measure the sodium chloride concentration.At last,2 mL filtrate and 50 mL distilled water were mixed thoroughly and titrated with 0.10 mol/L AgNO3,5% (m/V) K2CrO4solution (1 mL) as an indicator.The titration was terminated when the solution appeared orange.

2.4 Determination of nitrite content

The nitrite contents of Sanchuan hams during the fermentation were performed according to previously reported methods[13].In brief,5 grams of Sanchuan ham samples were collected and put into a conical flask with 80 mL of distilled water,then 1 mL of 1 mol/L KOH was added.After ultrasonication (800 W,10 s of work,and 5 s of interval) for 30 min,the mixture was incubated at 80 °C for 6 min.After cooling and filtration,40 mL filtrate was reacted with 2 mL of 4 g/L of sulfanilamide for 3–5 min,before 1 mL of 2 g/L ofN-(1-Naphthyl) ethylenediamine dihydrochloride was added.The formation of amaranth indicates the level of nitrite.The absorbance was detected at 538 nm using distilled water without the sample as the blank.At last,the nitrite content in Sanchuan ham samples was calculated based on the standard curve of nitrite.

2.5 Determination of free amino acids

Free amino acids (FAA) were measured as described by Tan et al.[14]The concentrations of FAA in Sanchuan ham were detected by the ultra-HPLC-tandem MS method (UPLC-MS/MS;model 1290/6460;Agilent Ltd.).Briefly,both 20 mg Sanchuan ham sample and 1 000 μL extraction solution (volume ratio of acetonitrile: methanol:water=2:2:1) were transferred into a 50 mL tube to be stirred for 30 s.The contents of the tube were treated with steel ball at 40 Hz for 4 min,then processed with ultrasonic waves in an ice-water bath for 5 min.Then,the prepared sample was centrifuged at 12 000 ×gfor 10 min at 4 °C to be used for UHPLC-MS/MS analysis.An ACQUITY UPLC BEH HILIC (2.1 × 100 mm,1.7 μm;Waters Corp.) liquid chromatographic column was used to separate FAA at temperature 35 °C with liquid chromatography phase A (1%formic acid aqueous solution) as well as phase B (1% formic acid acetonitrile);injection volume1 μL.MS measurements were conducted using positive (ESI+) and negative (ESI-) electrospray ionization with an external standard.

2.6 Biogenic amine analysis

2.6.1 Preparation of standard biogenic amine solutions

Biogenic amines analysis was performed according to the method described by Roseiro et al.[15]with a minor modification.Standard substances of biogenic amines,tryptamine,phenethylamine,putrescine,cadaverine,histamine,tyramine,spermidine,spermine,were purchased from Sigma-Aldrich Sigma Chemical Co.(St.Louis,MO,USA).The stock solution of standard biogenic amines was prepared by dissolving 10 mg of each standard biogenic amines in 0.1 mol/L HCl and diluted to 10 mL.The final concentration of the solution was 1 000 mg/L.Subsequently,1.0 mL stock solution of each standard biogenic amines was taken to the same volumetric flask of 10 mL and diluted to 10 mL with 0.1 mol/L HCl.The final concentration of the mixture solution was adjusted to 100 mg/L.The mixture solutions of different concentration (1–50 mg/L) were prepared by doing a serial dilution (1.0,2.5,5.0,10.0,15.0,20.0,25.0,50.0 mg/mL) of the mixture solutions with 0.1 mol/L HCl to a final volume of 10 mL.These solutions were stored at -20 °C till used for HPLC analysis.1,7-diaminoheptane was used as the internal standard,which was diluted with 0.1 mol/L HCl to a final concentration of 100 mg/L.

2.6.2 Preparation of sample extracts

Five grams of previously homogenized Sanchuan ham sample were extracted with 0.4 mol/L of 40 mL perchloric acid aqueous solution.Then the extract was frozen centrifuged at 3 000 ×gfor 10 min and collected the sediment to centrifuge again.At last,the two times supernatant was combined,using perchloric acid (0.4 mol/L) to dilute the supernatant to 50 mL until further use.

2.6.3 Derivatization of standard substances

One mL standard serial mixture solution was transferred into a 5 mL volumetric flask,respectively.Then,250 μL (100 mg/L) internal standard solution,200 μL (2 mol/L) NaOH solution,300 μL saturated NaHCO3solution,2 mL dansyl chloride solution (10 mg/mL)were added into the volumetric flask.Subsequently,after the mixture solution has been performed in a dark environment to react for 45 min,100 μL NH4OH (0.4 mol/L) was added to it to remove the excess dansyl chloride.The final volume of solution was adjusted to 5 mL with acetonitrile and filtered through an 0.22 μm Millex HV filter (Millipore Corp.,Bedford,MA).Sample derivatization was performed according to the same procedure.

2.6.4 HPLC analysis

An aliquot of 20 μL of sample solution was injected into an HPLC system.Chromatographic separation was carried out with a ZOR biogenic amines×Eclipse×DB-C18(4.6 mm × 250 mm × 5 μm) column(Waters,Germany).The mobile phases of the gradient elution system were a mixture of water (solvent A) and acetonitrile (solvent B).The gradient elution program was set with a flow rate of 1.0 mL/min and the temperature was set at 30 °C.All extractions were performed in duplicate.Biogenic amines detection was performed at 254 nm using a Dual λUV/Vis Detector 2487 (Waters,Milford,MA).Biogenic amines final results were expressed in mg/kg on a fresh matter basis.

2.7 Total genomic DNA extraction

The total genomic DNA from 2.0 g of each Sanchuan ham sample was extracted by E.Z.N.A Soil DNA kit (Omega Bio-tek,Norcross,GA,USA) and the extraction method was carried out by following the experimental operating guidelines provided by the manufacturer(QIAamp DNA Microbiome Kit,QIAGEN Inc.).Spectrophotometry and 1% agarose gel electrophoresis were used to detect the quality of extracted microbial DNA[16].After having been qualified,database construction and sequencing were carried out.

2.8 Illumina MiSeq sequencing analysis

The bacterial V3-V4 region of 16S rRNA gene was amplified with primers 338F (5’-ACT CCT ACG GGA GGC AGC A-3’) and 806R (5’-GGA CTA CHV GGG TWT CTA AT-3’).PCR procedure was implemented as follows: predegeneration at 95 °C for 3 min,followed by 27 cycles at 95 °C for 30 s,55 °C for 30 s and 72 °C for 45 s,and extension at 72 °C for 10 min.The PCR mixtures contain 4 μL of 5 × TransStart FastPfu buffer,2 μL of 2.5 mmol/L dNTPs mix,0.8 μL forward primer (5 μmol/L),0.8 μL reverse primer(5 μmol/L),0.4 μL TransStart FastPfu DNA Polymerase,10 ng template DNA,and finally dd H2O up to 20 μL[17].PCR reactions were performed in triplicate.After being eluted by Tris-HCl and detected via electrophoresis on a 1% agarose gel,amplicons were quantified using QuantiFluor™-ST (Promega,USA) and applied to construct library PE 2 × 300 according to the standard of Illumina MiSeq(Illumina,San Diego,USA).The gene amplicons were sequenced by Illumina Miseq PE300 (Majorbio Biopharm Technology Co.,Ltd,Shanghai,China).The calculations of the alpha and beta diversity statistics were conducted after sequence rarefication using the free online platform of Majorbio Cloud Platform (www.majorbio.com).After having been merged by FLASH and quality filtered,the sequences were clustered into operational taxonomic units (OTUs)at 97% similarity threshold by UPARSE,and the UCHIME was employed to identify chimaeras.

2.9 Statistics analysis

Statistics analysis of all results was implemented using SPSS 19 software (SPSS Inc.,Chicago,IL,USA).Values were presented as the mean and standard deviation (SD).The statistical difference was determined by analysis of variance (ANOVA).Each experiment was implemented in triplicate.The significant differences were evaluated by Duncan’s multiple range test (P<0.05).In addition,figures were painted with Origin 2021 pro software (OrginLab,Northampton,MA,USA).

3. Results

3.1 Changes in physicochemical properties during Sanchuan ham fermentation

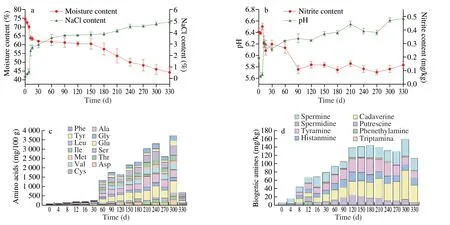

As shown in Fig.2a,the moisture content exhibits a gradual decrease trend during the entire fermentation period.At the fermentation of 330 d,the moisture content accounted for the initial 40.54% and our results were higher than the findings of other authors[18].For sodium chloride concentration,the changing trend of it was on the contrary,as fermentation proceeded,the content of sodium chloride showed a continuously increasing trend,and it approached 5% at 330 d.The possible reason for this result might lie in the fact that with the moisture evaporation,sodium chloride has gradually permeated from the surface into the fat portion of the ham,and the salt content in the samples was increasing until saturation.Compared with Xuanwei ham and Saba ham,the sodium chloride content was lower[7],while it was higher than that of Iberian dry-cured ham[19],which may relate to the producing technology and the moisture concentration in the final products.The additional amount of sodium chloride to ham directly affects the final quality of the ham.If the addition is not enough in ham,the proliferation of pathogenic microorganisms cannot be inhibited effectively.when the content of it was higher in hams,excessive intake of hams has been proven to cause the risk of hypertension and cardiovascular disease[20].

Fig.2 Physicochemical properties,amino acids and biogenic amine of Sanchuan ham at different processing stages.

As shown in Fig.2b,the changing trend of pH experienced a fluctuation and then reached the highest point of 6.65 at the fermentation of 330 d,which was slightly higher than other results.Li et al.[7]have found that pH was 5.38 in Sanchuan ham,which might relate to the discrepancy of raw material or the processing method.It is known that different geographical factors and varied climatic conditions at different locations will result in a diverse and unique microbial composition in the environment[21],which may affect the formation of quality in the natural production of Sanchuan ham.The content of nitrite content remained at a comparatively high level from 0 d to 60 d,but after that,it showed a gradual decrease.Finally,it remained at a stable level of 0.15 mg/kg.The phenomenon may be attributed to the fact that as fermentation proceeded,common nitrite-reducing bacteria includingLeuconostoc,Weissella,LactobacillusandPediococcusgrew in Sanchuan ham producing several antibacterial substances which reduced nitrite to nitrogen dioxide,nitrogen monoxide and nitrogen[22].So,the nitrite content falls rapidly.On the other hand,owing to the production of Sanchuan ham did not add nitrite to increase color,the content of nitrite was significantly lower than the national health standard safety level of 20 mg/kg.

3.2 Free amino acid analysis

The dynamic change of free amino acids during the fermentation of Sanchuan ham was performed (Supplement Table 1).As shown in Fig.2c,the change of total amino acids showed a gradual increase trend from 0 to 300 d,except for 270 d,but at the fermentation of 330 d,amino acids content exhibited a sharp decrease.On the one hand,the possible reason for this result might lie in the fact that in the middle of the fermentation period,suitable temperature and lower sodium chloride concentration made protease activity higher,which degraded proteins in Sanchuan ham into amino acids.While at the end of fermentation,with the lower environment temperature,fewer moisture content,higher sodium chloride content,the activity of aminopeptidase and protease hydrolyzing protein to amino acids were restrained,resulting in amino acids content located at a lower level.On the other hand,degradation reactions may be mainly responsible for the decrease in the amounts of free amino acids,which were further degraded to any other compounds such as volatile compounds[23].

Table 1 Taste activity value (TAV) of free amino acids in Sanchuan ham during processing

Contrasted with fresh hams,the content of total free amino acids in the ripe stage of Sanchuan ham has grown 14 folds.The content of histidine,however,was the highest among all free amino acids.From the initial to 180 d,it displayed a gradual increase trend,and at 180 d it reached the highest of 422.08 mg/100 g.But afterward,its content decreased with the extension of fermentation time.At the end of fermentation,it accounted for 21.48% of total amino acids.Notably,some reports have suggested that histamine is responsible for producing biogenic amines in fermented foods[24].These results indicated that the first 6 months of fermentation possibly were the peak period for producing histidine and from the angle of food security,the fermentation process of Sanchuan ham is better than 6 months.

Taste formation is a complex process involving many biochemical reactions.To be more specific,protein is hydrolyzed by protease secreted by microorganisms in ham to produce peptides.Furthermore,the peptides are hydrolyzed by peptidases to produce tasteful amino acids[25-26].Taste activity value (TAV) is an important indicator for evaluating taste,which is generally calculated as the ratio between the concentration and threshold of compound[27].The amino acid of which TAV was greater than 1 was considered an active component in food affecting the taste perception of the sample[17].Moreover,the larger the TAV value was,the greater the contribution of the amino acid to the taste.As shown in Table 1,the TAV of Asp,Glu and His was higher than 1 during the entire fermentation stages.However,aspartic acid,glutamic acid and histidine mainly endow sour,sour and bitter to foods respectively,indicating that sour and bitter were the primary taste of Sanchuan ham,peculiarly sour taste.Furthermore,from days 60 to 300,TAV of Asp,Glu,Ala,Val,Met,Ile,Leu,Phe,His,Lys,Arg were larger than 1,which means dry and ripe stages were the key period to producing the characteristic taste of Sanchuan ham and these free amino acids are an important part of the formation of flavor substances in fermented Sanchuan ham.Our results were in agreement with the statement of the previous study that the most abundant amino acids were Glu,Val,Ala,Leu and Lys in the five Yunnan dry-cured and Iberian hams[4,28].

3.3 dynamic change of biogenic amines in Sanchuan ham

As shown in Fig.2d,a total of 7 types of biogenic amines were detected during the processing of Sanchuan ham,including phenethylamine,putrescine,cadaverine,histamine,tyramine,spermidine and spermine.However,tryptamine was not detected in the whole fermentation.Moreover,the concentration of total biogenic amine in fresh Sanchuan ham was the lowest,only 5.84 mg/kg,and it increased substantially in the middle and late stages of curing,but during thedrying period,the increase in the total biogenic amine concentration was not significant.In the late stage of fermentation,the concentration of it has reached its peak at 158.08 mg/kg.Consequently,the development of biogenic amine was mainly in the ripening stage.The results may relate to the processing technology of Sanchuan ham.When ham was covered with plant ash,fermentation temperature usually was above 15 °C,histidine and tyrosine decarboxylase as well as phenylalanine with certain activity to promote decarboxylation of free amino acids in ham to produce biogenic amines.

The concentration of cadaverine was the highest of all biogenic amines and continued to increase during the processing of Sanchuan ham,reaching the maximum value of 69.24 mg/kg at 300 d,but began to decrease significantly at the end.Our result was in accordance with the previous conclusion that cadaverine was the most abundant biogenic amines in two Portuguese traditional blood dry-cured sausages[20].Whereas the content of spermine during the fermentation period was only next to cadaverine and the changing trend of it was similar to cadaverine.Besides,the concentration of spermidine and spermine is maintained at a stable level,especially the concentration of spermidine is always at a relatively lower level.Histamine,the most toxic of all biogenic amines,was encountered frequently in fermented meat products[29],and the concentration of it fluctuated within the range of 0.35–22.52 mg/kg,which remained below the 100 mg/kg fresh matter acceptable limit[30].Similarly,Laranjo et al.[20]reported that histamine and other vasoactive amines remained at low levels in traditional blood dry-cured sausages,indicating that fermented meat products were relatively safe.The content of tyramine situated at comparatively higher level,while Hu et al.[31]have reported that the production of tyramine may relate toBacillusandStreptococcus,which can utilize tyrosine to produce tyramine.

3.4 Alpha diversity of the microorganism

The alpha diversity indices,including the Sobs,Shannon,Simpson,ACE,Chao,and Coverage index,were used to evaluate the richness and diversity of bacterial communities during the production of Sanchuan ham.The complexity of the microbiota in Sanchuan ham samples correlated positively with the ACE and Chao indices,but negatively with the Shannon and Simpson indices.In addition,ACE,Chao,two indices,represent community richness,whereas both Shannon and Simpson indices reflected the species diversity in the community.

As shown in Fig.3a,Sobs indices in surface samples kept decreasing,while it in the interior samples gradually tended to stabilize,indicating that community structure of interior samples was more evenly than in surface samples.Based on Shannon and Simpson indices of bacteria (Figs.3b,3c),both surface and interior samples,all decreased initially and then increased,which indicated species diversity gradually decreased from curing stage to the dry stage and after dry period,its diversity recovered slowly.Our results were in agreement with those found in suan yu[32].For surface samples,based on ACE and Chao indices of bacteria (Figs.3d,3e),they kept decreasing from curing period to fermentation finished,but for interior samples of Sanchuan ham,the two indices remained at a stable level,which suggested that richness of the surface microbiota in Sanchuan ham gradually decreased with the fermentation time prolonged,while the richness of the interior microbiota in Sanchuan ham almost had no variation.Our results were consistent with the findings of other authors,who also stated that Chao and ACE indexes both decreased in Panxian ham samples[11].Good’s coverage in all samples was over 99% (Fig.3f),indicating that almost all of the microbes from Sanchuan ham have been detected.

Fig.3 Alpha diversity of Sanchuan ham in different processing stages,a: Sobs index,b: Shannon index,c: Simpson index,d: ACE index e: Chao index,f: Coverage index.(*** P <0.001,** P <0.01,* P <0.05).

3.5 Microbial succession during Sanchuan ham fermentation

The Illumina HiSeq platform was employed to sequence the V3-V4 regions of the 16S rRNA gene of 32 samples,thereby obtaining more than 0.96 million clean tags after concatenation and quality control.The clean reads with an average length of 440 bp were clustered into 1360 OTUs at 97% similarity level.These OTUs were clustered into 36 phyla,73 classes,157 orders,283 families,638 genera and 962 species.

At the bacterial phyla level,a total of 5 phyla were identified from all Sanchuan ham samples (Fig.4a).FirmicutesandActinobacteriaplayed a dominant role on the surface samples of Sanchuan ham,and their relative abundance was maintained above 55% during the entire fermentation.But for interior samples of Sanchuan ham,FirmicutesandProteobacteriawere the primary phyla during the curing and dry period,whereasFirmicutesandActinobacteriaproved the most abundant microorganism in the ripe period.Therefore,FirmicutesandActinobacteriawere the two main microbial flora in Sanchuan ham.However,FirmicutesandProteobacteriawere the most abundant phyla among Jinhua,Xuanwei,Rugao Ham and dry sausages from Northeast China at the phylum level which was slightly different from our results[3,33].Besides,the microbial flora between the surface and the interior of Sanchuan ham was not in full agreement.Moreover,even during the same period,the dominant microorganism was also slightly different.

Fig.4 Changes in relative abundance of the microbial community at the phylum level (a) and at the genus level (b) of Sanchuan ham in different fermentation stages.HS represents surface sample of Sanchuan ham and HI represents interior sample of Sanchuan ham.Y,F,C represent curing,dry and ripening period,respectively.

At the bacterial genus level,a total of 11 genera were classified among the different Sanchuan ham samples with a relative abundance greater than 0.1%.As shown in Fig.4b,for exterior samples of Sanchuan ham,Staphylococcus,Psychrobacter,norank-ccyanobacteria,Rothiawere the dominant genera during the curing period,but they were quickly replaced byStaphylococcusin the dry period,while in the ripe period,norank-c-Actinopolysporaceae as well asStaphylococcusbecame comparative predominant in the final Sanchuan ham products.For interior samples of Sanchuan ham,Latobacilus,Psychrobacter,Bifidobacterium,Staphylococcusplayed a dominant role in the curing period,and their relative abundance was 23.65%,12.23%,12.18%,9.86%,respectively.However,during the dry stage,the relative abundance ofStaphylococcusincreased to a maximum value of 69.08% andKluyverabecame the second dominant group with a relative abundance of 13.87%.At the end of fermentation,Staphylococcusdecreased to 13.42% andNocardiopsiswere the most dominant genera,which suggested thatStaphylococcusand Nocardiopsis may play a significant role in the ripening of Sanchuan ham.As a result,we can conclude that the dominant microbes of the early stage and the end of fermentation were slightly different,but both in the exterior and interior of Sanchuan ham in the dry stage,Staphylococcusalways was the primary genus.Therefore,dry stage has a great impact on microbial community structure.Staphylococcuswas a significant strain throughout the whole fermentation.Previous researches reported thatStaphylococcuswhich can grow and reproduce in a high-salt environment has been the dominant bacteria in many traditional Chinese bacon and drycured fish and it could compete for the nutrients at the lower pH and water activity[34-36].Besides,the change trends of bacteria in the interior have slight discrepancies with those of exterior of Sanchuan ham,which further proved that microbe changes in the exterior and interior of Sanchuan ham did not occur at the same time.For example,comparative of the bacteria in the exterior and interior of Sanchuan ham,we found that the abundance of lactic acid bacteria as beneficial bacteria,such asLatobacilusandBifidobacterium,increased in the interior.Parallel results were also reported by Hu et al.[33]thatLactobacilluswas the major genus in traditional dry sausages from Northeast China,and the possible key reasons might lie in the fact thatLactobacillushas the ability to adapt to acidic conditions in comparison with other lactic acid bacteria,such asLactococcusandWeissella[37].

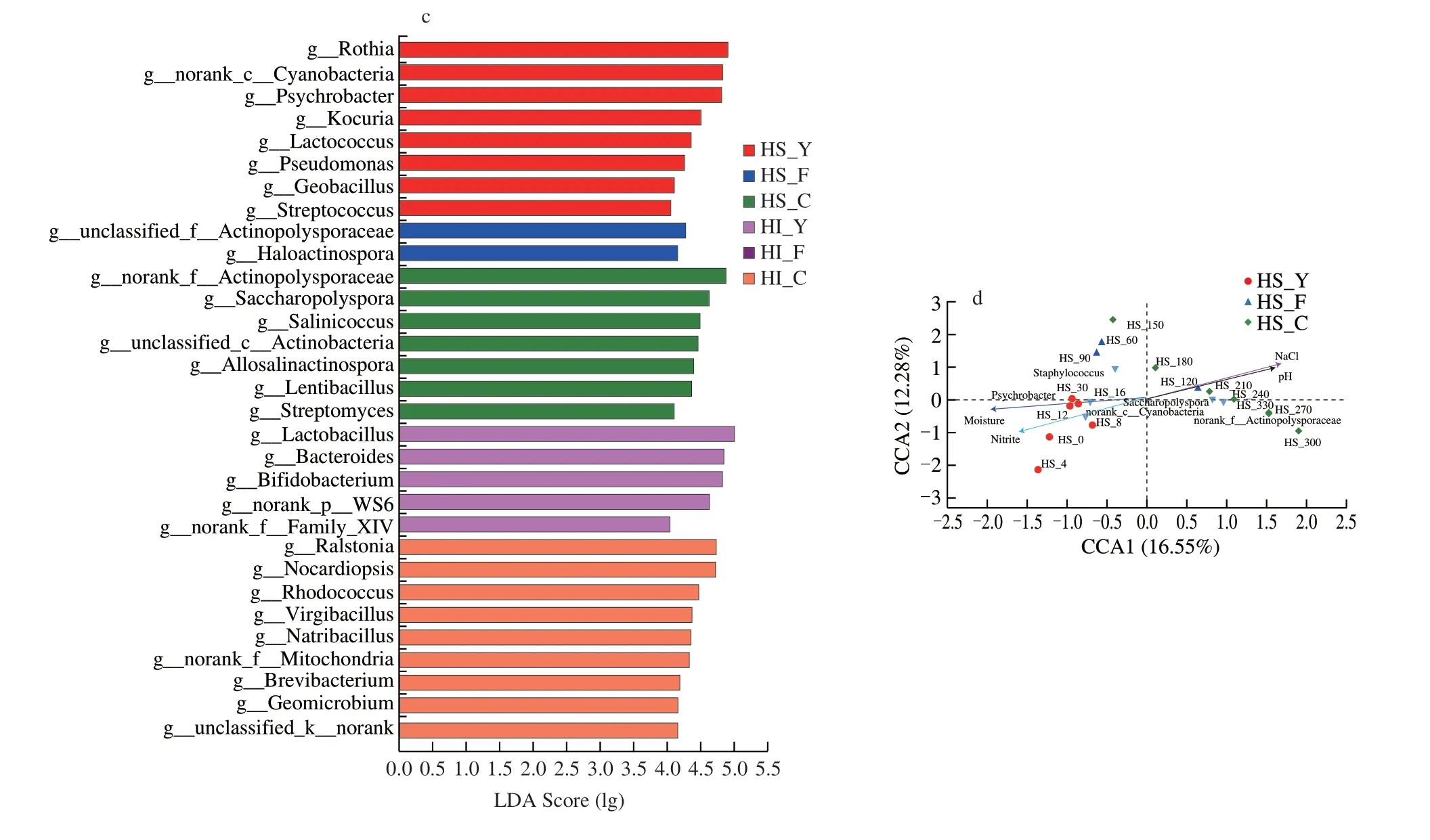

3.6 Cluster analysis and discrepancy species analysis

As shown in Fig.5a,cluster analysis was performed to investigate the dynamic succession of microbial flora during the three fermentation stages.All samples were clustered into three clusters.All dry samples including surfaces (HS-F) and interior (HI-F) samples could be better clustered together consisting of cluster 1.Cluster 2 was composed of all ripe stage samples of surface (HS-C) and interior(HI-C);Cluster 3 was composed of all curing stage samples of surface(HS-Y) and interior (HI-Y).These results indicated the community structure of microbe among the three different fermentation stages was different,while the community structure of external and internal microbe was similar overall.

Fig.5 Analysis of differences between groups of Sanchuan ham.Cluster analysis of bacterial community at different fermentation stages (a).Discrepancy species analysis of bacterial community at surface and interior of Sanchuan ham (b).HS represents surface sample of Sanchuan ham.HI represents interior sample of Sanchuan ham.LEfSe analysis of bacterial community during Sanchuan ham fermentation (c).CCA analysis of the correlation between chemical characteristics and microorganisms in Sanchuan ham (d).HS represents surface sample of Sanchuan ham and HI represents interior sample of Sanchuan ham.Y,F,C represent curing,dry and ripening period,respectively.

Fig.5 (Continued)

To find the species with significant differences in abundance between surface and interior sample groups,we performed a between-group differences analysis of microorganisms using thet-test at the genus level.As shown in Fig.5b,Psychrobacter,norank_f_Actinopolysporaceae,Saccharopolyspora,Rothia,unclassified_c_Actinobacteria,Salinicoccus,Kocuria,unclassified_f_Actinopolysporaceae,Allosalinactinospora,Haloactinospora,were the significant different genera for the surface samples of Sanchuan ham,whileLatobacilus,Bacteroides,Bifidobacterium,Kluyvera,Escherichia-Shigellawere observed the significant different genera for the interior samples.

The above results indicate significant differences between the microbial structure of the ham depending on their location.LEfSe analysis was further used to evaluate the importance of microbial species of Sanchuan ham at different processing stages[36].As shown in Fig.5c,at the genus level with LDA scores>4,significant differential species primarily focus on curing and ripe period.For the curing period of surface samples,g_Rothia,g_norank_c_cyanobacteria,g_Psychrobacter,g_Kocuria,g_Lactococcus,g_Pseudomonas,g_Geobacillus,g_Srteptoccuswere biomarkers of Sanchuan ham,whileg_Lactobacillus,g_Bacteroides,g_Bifidobacterium,g_norank_p_WS6,g_norank_f_Family_XIV were biomarkers of the internal sample.For dry period of surface samples,only two genera g_unclassified_f_Actinopolysporaceae,g_Haloactinosporawere identified as the biomarkers.In ripe period,g_norank_f_Actinopolysporaceae,g_Saccharopolyspora,g_Salinicoccus,g_unclassified_c_Actinobacteria,g_Allosalinactinospora,g_Lentibacillis,g_Steptomyceswere detected as the biomarkers of the surface sample,whereasg_Ralstonia,g_Nocardiopsis,g_Rhodococcus,g_Virgibacillus,g_Natribacillus,g_norank_f_Mitochondria,g_Brecibacterium,g_Geomiccrobium,g_unclassified_k_norank were biomarkers of the internal sample.Therefore,these biomarkers of exterior and internal microbes together decided the unique quality of Sanchuan ham.

3.7 CCA analysis

CCA analysis was performed to reflect the relationship between the microbial community and physicochemical factors,including moisture content,NaCl content,pH,nitrite[38].The five most predominant bacterial genera for the surface samples and the chemical properties of Sanchuan ham were selected for correlation analysis.CCA results indicated that moisture,NaCl and nitrite content,pH,explained only a part of variation in bacterial communities (Fig.5d).CCA1 and CCA2 accounted for 16.55% and 12.28% of the variance of bacterial communities.These results suggested that many other factors were associated with microbial flora in Sanchuan ham fermentation,and the factors might include temperature,latitude,longitude and elevation[39].As shown in Fig.5d,the longer the arrow,the stronger the correlation[40].The arrows in Fig.5d indicate that the most important physicochemical factor shaping the microbial succession was NaCl (r2=0.886,P< 0.001),followed by pH (r2=0.772,P< 0.001),moisture content (r2=0.886,P< 0.001) and nitrite (r2=0.798,P< 0.001).They were the most important factors influencing the variation of microbial flora.However,Saccharopolysporaand norank-c-Actinopolysporaceae had a significant positive correlation with NaCl and pH,for the line fromSaccharopolysporaand norank-c-Actinopolysporaceae to the origin with the NaCl and pH presented an acute angle,suggesting that the growth ofSaccharopolysporaand norank-c-Actinopolysporaceae had a significant effect on the change in NaCl content and pH.Similarly,Psychrobacter,norank-c-Cyanobacteria were significantly positively correlated with moisture and nitrite content,which indicated that the growth ofPsychrobacter,norank-c-Cyanobacteria significantly promotes the production of nitrite.Besides,Staphylococcusshowed a positive correlation with moisture.The result showed that the suitable moisture content is beneficial to the growth ofStaphylococcus.

4. Conclusions

To investigate the quality formation mechanisms of Sanchuan ham,we analyzed the dynamic changes of physicochemical properties,biogenic amines concentration and microbial diversity during the fermentation of Sanchuan ham.At the end of fermentation,the content of nitrite remained at a stable level of 0.15 mg/kg which was significantly lower than the national health standard safety level of 20 mg/kg.Contrasted with the fresh samples,the content of total free amino acids in ripe Sanchuan ham has grown 14 folds.Not only were sour and bitter the primary taste of Sanchuan ham,but also the TAV of Asp,Glu,Ala,Val,Met,Ile,Leu,Phe,His,Lys,Arg were larger than 1,which means these free amino acids are an important part of the formation of flavor substances in fermented Sanchuan ham.At the same time,the concentration of cadaverine was the highest of all biogenic amines.From the perspective of food safety,it is necessary to take several measures,such as controlling fermentation temperature and humidity,selecting biological amine oxidase strain for fermentation,controlling the quality of plant ash,to upgrade the edible safety of Sanchuan ham.Staphylococcusplayed a dominant role in the entire fermentation period.In addition,the change trends of bacteria in the interior have slight discrepancies with those of the exterior of Sanchuan ham.Biomarkers of exterior and internal microbes were performed.CCA analysis suggested thatSaccharopolysporaand norank-c-Actinopolysporaceae had a significant positive correlation with NaCl and pH,whereasPsychrobacter,norank-c-Cyanobacteria were significantly positively correlated with moisture and nitrite content.This study provides a theoretical basis for revealing the quality formation mechanisms of Sanchuan ham.

Conflict of interest statement

No conflict of interest exits in the submission of this manuscript,I would like to declare on behalf of my co-authors that the work described was original research that has not been published previously,in whole or in part.This manuscript is not under consideration for publication in any other journal and manuscript is approved by all authors for publication.

Acknowledgement

This work was funded by National Natural Science Foundation of China (31460445);Science and Technology Talents and Platform Program of Yunnan Province,No.202105AF 150049;Yunnan University Key Laboratory of Food Microbial Resources and Utilization (Yunjiaofa [2018] No.135).

Appendix A.Supplementary data

Supplementary data associated with this article can be found,in the online version,at http://doi.org/10.26599/FSHW.2022.9250044.

- 食品科学与人类健康(英文)的其它文章

- GUIDE FOR AUTHORS

- Targeting gut microbiota in osteoporosis: impact of the microbial based functional food ingredients

- Weizmannia coagulans: an ideal probiotic for gut health

- Natural sources,refined extraction,biosynthesis,metabolism,and bioactivities of dietary polymethoxyflavones (PMFs)

- A review of salivary composition changes induced by fasting and its impact on health

- Minerals in edible insects: a review of content and potential for sustainable sourcing