Modifications in aroma characteristics of ‘Merlot’ dry red wines aged in American,French and Slovakian oak barrels with different toasting degrees

Haocheng Lu,Binhao Cheng,Yibin Lan,Changqing Duan,Fei He,*

a Center for Viticulture and Enology, College of Food Science and Nutritional Engineering, China Agricultural University, Beijing 100083, China

b Key Laboratory of Viticulture and Enology, Ministry of Agriculture and Rural Affairs, Beijing 100083, China

Keywords:Wine Aroma Oak Barrel Oak species Toasting degrees Geographic origin Aging

ABSTRACT Aging in oak barrels is widely used in enology which could bring flavor changes and aromatic complexity to wines.In the present study,the aroma compounds were analyzed from the ‘Merlot’ dry red wines,which were fermented in two types of fermenters (stainless steel tank and rotated oak barrel) and aged in six types of oak barrels (three geographic origins × two toasting degrees) for different time (0,3,6 and 9 months,respectively).Results showed that 30 volatiles were associated with barrels and increased during oak aging.The fermenters could influence the intensities of the toast,leathery,smoky,fruity,floral and caramel aromas.The concentration of whisky lactone,eugenol,cis-isoeugenol,and the intensities of the toast and spicy aromas were highest in the wines aged in American oak and were lowest in the wines aged in French oak barrels.The concentrations of guaiacol,syringol,trans-isoeugenol,furfural alcohol,vanilla,cis-whisky lactone enabled the medium toasting barrels to be distinguished from the light toasting ones.The compounds originating from the barrels could be used to distinguish the types of different barrels,but the other general grape-derived and fermentation-derived volatiles could not. The fermenters,oak species and toasting degrees of the barrels all had significant effects on the aroma profiles of the aged ‘Merlot’ dry red wines,but the influence of the geographic origin was not obvious.

1. Introduction

Aroma performance is a key sensory quality of the wine that directly influences the preference of consumers.Generally,wine aroma compounds could be derived from grapes,fermentation,and aging[1].Wine aging could be divided into two successive periods:barrel (or tank) aging and bottle aging,each of which had specific effects on the wine aromas.Barrel aging had been used for more than 200 years[2],and the corresponding effects on wine included not only the extraction of certain compounds from the wood,such as lactones,furanic compounds,phenolic aldehydes and volatile phenols,but also the formation of new volatile compounds[3],as well as the transformation,oxidation[4],hydrolysis-esterification[5-7],and sorption[8]of some compounds originating from the grapes and fermentation.Many researchers had demonstrated many factors which influenced the quantities of the aroma compounds associated with barrel aging,including the botanic oak species[9-11],the geographic origin of the oak[12-14],the wood grain tightness[11,15],the wood seasoning and toasting process[9],the ratio of the barrel surface to its volume[16],and the contact time between wines and barrels[4,14,17].

Nowadays,France and America are the major sources of oaks for barrels.In Europe,the most popular oak species employed for cooperage areQuercusrobur(Q.pedunculata) andQ.sessilis(Q.petraea,andQ.sessiliflora),whileQ.albais the most widely distributed American oak species.The most significant feature that could differentiate French oak from American oak wascis-whisky lactone (also named oak lactone) and the ratios ofcis-/trans-whisky lactone[14,18,19]were higher in the latter.With the development of the wine industry,the limited production and the relatively high price of the French oaks in particular,oaks from other European countries had attracted increased interest.These countries include Spain,Hungary and Slovakia,which had the same oak species as France.Besides,some Russian oaks (Q.sessilis) low in lactones were also used.Such oaks could be referred to as East European oaks.Andrei Prida[14]found that the composition of East European oaks was in between that of French and American oaks,and could be distinguished from French oaks by 2-phenylethanol,eugenol and vanilla.

The degrees of toasting during barrel-making were another factor that influenced the aging aromas of the wines.The concentration of many oak aroma compounds,such as furanic compounds,phenolic aldehydes and volatile phenols could be increased by toasting[20].But as toasting continues,the concentrations of some compounds,such as vanillin,syringaldehyde and whisky lactones decrease through volatilization and thermal degradation[20].

Just as the differences between oak barrels could influence the aroma compounds in the wines,wine composition itself could also influence the extraction of volatile compounds from oak woods.Higher alcohol levels could increase the extraction of whisky lactones and vanilla[9,21].Other influencing factors included the SO2concentration[22],ellagitannins[21],polyphenolic compounds[21].

In China,extensive studies have been performed regarding the techniques to improve wine quality.Most of the studies focus on the viticulture or the fermentation stage.There is much space for investigating the choice of oak barrels during wine aging.Although many previous studies have investigated the influence of oak barrels on wine composition.There were few reports in the Yanqing region with a typical continental monsoon climate.In the present research,the ‘Merlot’ wines fermented in tanks or oak barrels were aged for 0,3,6 and 9 months in new AmericanQ.alba,French and SlovakiaQ.petraeabarrels,of light or medium toasting,to follow the evolution patterns of the aroma compounds during aging and to determine the characteristic compounds those were obtained from the different barrels.

2. Materials and methods

2.1 Samples

In 2012,‘Merlot’ grapes were harvested at commercial maturity with a total acidity of 6 to 7 g/L and total soluble solids of 24-25 °Brix from a vineyard in Yanqing County (40°45’34’’N,115°97’2’’E),Beijing.Vines in this winery were planted in the year of 2000 and grown on their own roots under a north-south row orientation with a modified vertical shoot positioning (M-VSP) trellis system.The harvested grapes were immediately transported to the winery,destemmed and crushed,and then sulfur dioxide (60 mg/L) was added to the must.

Two types of fermenters were used in this study: Type 1: stainless steel tanks (TF) of 20 hL capacity.Type 2: rotated oak barrels (BF)made from French (Q.petraea) oaks with a volume of 20 hL,which had been used for seven years.All fermenters were located in the same fermentation environment.The fermenters were filled to about 75%-80% capacity.

After loading in the fermenters,20 g/hL of the commercial yeast L2323 (LALLEMAND,France) was added after rehydration to each fermenter to start the alcoholic fermentation.The fermentation temperature was kept at 20-25 ºC with full punching down three times daily.When the wine reached the end of the alcoholic fermentation(the reducing sugar was below 4 g/L),the wine was pressed off the skins and seeds.The malolactic fermentation was then started by inoculation with the commercial malolactic bacteria LALVIN 31(LALLEMAND,France).After the malolactic fermentation,the wines were settled in the fermenter for five days and then the free-run wine was racked off the gross lees and transferred into oak barrels of different types.

The oak woods used for new barrels were harvested from Missouri in the USA (Q.alba,AO),France (Q.petraea,FO) and Slovakia (Q.petraea,SO),respectively.The barrels made from these oaks were toasted at two levels using traditional methods.The starting temperature of the light toasting program was 180 ºC for 10 min,and then 200 ºC for 20 min.For medium toasting,the starting temperature was 180 ºC which was held for 10 min,then raised to 220 ºC for 35 min.All the oak barrels were the same Bordeaux style and had the same volume of 225 L.

The two wines from the two different fermenters were put into the six types of new barrels with a duplicate for each type.And also put into stainless tanks as the control.The wines aged in light toasting barrels,medium toasting barrels,and stainless tanks were coded as LT,MT,and CK,respectively.There were three factors investigated in our study: 1) the fermenter type,which was coded with TF and BF;2) the barrel geographic origin,which was coded with AO,FO,and SO;3) the toast levels,which was coded with MT and LT.The CK was represented for wines aging in stainless tanks.In the following analysis,we used ‘XX-XX-XX’ to respent for “the fermenter typethe barrel geographic origin-the toast level” for the fourteen wines:TF-AO-MT,TF-AO-LT,TF-SO-MT,TF-SO-LT,TF-FO-MT,TF-FO-LT,TF-CK,BF-AO-MT,BF-AO-LT,BF-SO-MT,BF-SOLT,BF-FO-MT,BF-FO-LT and BF-CK.They were aged for nine months and were sampled four times: 0,3,6,and 9 months.For each wine,there were two biological replicates × two technical replicates.These samples were stored in freezers at -20 ºC until the aroma compounds of these samples were analyzed.

2.2 Physicochemical parameter detection

The enological parameters of the samples,including alcohol level,residual sugar,total acidity and pH were analyzed based on the methods given by GB/T 15038-2006 (the National Standard of the People’s Republic of China for wine,2006).In brief,the alcohol content was determined by the distillation/densimetry method.The residual sugar was detected by titration with Fehling’s reagent.Wine pH was determined using a pH meter (Sartorius PB-10,Germany).Total acidity of wines was titrated with 0.05 mol/L NaOH to an endpoint of pH 8.2 and was expressed as tartaric acid equivalents.

2.3 Headspace solid-phase extraction

The majority of aromatic compounds from the wine samples were extracted by headspace solid-phase microextraction (HS-SPME)coupled with gas chromatography-mass spectrometry (GC-MS)[23-25].5 mL wine mixed with 10 μL of 2.004 g/L 4-methyl-2-pentanol(internal standard) and 1 g NaCl was prepared in 20 mL vial capped with a PTFE-silicon septum.Then the vial containing the sample was moved to the heating equipment.After equilibrating at 40 °C for 30 min,the SPME fiber was inserted into the headspace of the vial to extract the volatile compounds at 40 °C for 30 min.The heating/stirring equipment was stirred at 500 r/min.The SPME fiber was thermally desorbed by being inserted into the GC injector for 8 min.

2.4 Liquid-liquid extraction

Liquid-liquid extraction was only used to extract compounds mainly extracted from the oak barrels.The 25 mL of wine was put into a 50 mL centrifuge tube,5 g/L ammonium sulfate was added and the tube was shaken until the ammonium sulfate was completely dissolved.The internal standards in this part wereo-vanillin(2.002 mg/L),3,4-dimethylphenol (1.027 mg/L) andγ-caprolactone(2.043 mg/L).Every 25 mL sample had 40 μL of mixed internal standards added.Then,5 mL of dichloromethane was added to the solution.The solution was shaken to uniformly mix the sample and then centrifuged 15 min at 8 000 r/min.The organic liquid layer was decanted to another tube.Then a further 5 mL of dichloromethane was added to the inorganic solution,shaken and centrifuged,before being added to the first extract.The combined dichloromethane extract was dried with anhydrous sodium sulphate,and transferred to another tube.That solution was concentrated to a final volume of 1 mL under an N2stream,prior to being analyzed by GC-MS.

2.5 GC-MS Conditions and volatile compounds analysis

An Agilent 6890 GC coupled to an Agilent 5975 mass spectrometer was used.The capillary column was 60 m × 0.25 mm and 0.25 μm film thickness (J &W Scientific,Folsom,CA,USA).The flow rate of the helium carrier gas was 1 mL/min.In order to inject the samples,the SPME fiber was placed at GC inlet,for 25 min,which was operated in the splitless mode.The oven temperature program was: 1 min at 50 ºC then raised to 220 ºC at 3 ºC/min and held at this temperature for 5 min.The mass detector was operated in the full scan mode (m/z30-350) with electron ionization (EI) mode at 70 eV.Peak areas were found by setting the Chemstation software (Agilent Technologies) to autotune mode.Compound identification was based on retention indices of reference standards combined with mass spectra matching in the standard NIST 11 library.When reference standards were not available,tentative identification was made based on mass spectra matching in the standard NIST 11 library,or based on the comparison of the retention indices sourced from the NIST Standard Reference Database (NIST,Chemistry Web Book)[23].

For the quantitative analysis,a synthetic matrix was synthesized according to the basic enological parameters of the sample wines.It was made from distilled water with 14% (V/V) ethanol (HPLC quality),5 g/L tartaric acid,and the pH was adjusted to 3.8 with NaOH solution.All standards were dissolved in ethanol (HPLC quality) and mixed.Then the combined solution was diluted by the model wine to 15 levels.For the general volatiles,4-methyl-2-pentanol was added into the combined solution as the internal standard.For oak-related volatiles,o-vanillin was used as the internal standard for furans and lactones,3,4-dimethylphenol was used as the internal standard for volatile phenols andγ-caprolactone was used as the internal for phenolic aldehydes.The extraction and analytical procedures were identical for these samples.The regression coefficients of the calibration curves were all above 99%.If there weren’t standards for some volatile compounds,the concentrations were calculated from the calibration curves of compounds with the closest chemical structures and the number of carbon atoms.The detailed quantification information is in Supplementary Table 1.

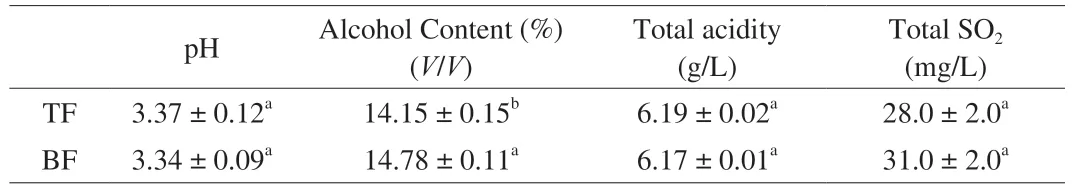

Table 1 Physicochemical parameters of the original wines fermented in the two fermenters before aging.

2.6 Odor activity values (OAVs) and aroma series

Odor activity values (OAVs) were used to represent the sensory impact of the aroma compounds.The OAVs were calculated by dividing the concentration of the compounds by their sensory thresholds[24,26,27].If the compounds were present at abovethreshold levels (OAV >1),these compounds were recognized to have the potential to actively contribute to the aroma of the wines[28,29].If the OAVs were lower than 1 but higher than 0.1,these compounds could also potentially contribute to the wine aromas by additive effects[28].But if their OAVs were lower than 0.1,their effects on wine aromas could be negligible[30].

The active aroma compounds were divided into thirteen series with similar odor descriptors.From this,it should be possible to predict the overall aroma profiles of the wines based on their numerical GC-MS analysis data.The thirteen series were: (1) fruity,(2) floral,(3) herbaceous,(4) nutty,(5) caramel,(6) earthy,(7)chemical,(8) fatty,(9) toast,(10) oaky,(11) spicy,(12) smoky and(13) leathery.They were modeled from the literature and the widely employed wine aroma wheel[31].

Some compounds were allocated to more than one series[32,33],because of the great complexity of olfactory perception.Using the OAVs of each compound in a given series,it was possible to model the total intensities of each aroma series and hence the series contribution to the overall aroma.This would also allow the correlation of the quantitative information obtained by the chemical analysis with the sensory properties of the samples.

2.7 Statistical analysis

Statistical software SPSS 19.0 was used to perform the factor analysis and identify general compounds and compounds associated with barrel aging.Before the analysis,all variables were meancentered and scaled to unit variance.This multivariate analysis method reduced one set of variables into a lesser number of new variables which could represent the original variables and found the associations among the original variables.To better interpret these factors,the principal components were used to extract factors from all the original variables after varimax rotation of the data[21,34,35].The factor values for the samples drawn from the wines during aging were calculated to facilitate an objective comparison during the wines development.The value of each factor was calculated by multiplying the coefficients of volatile compounds in the factor loading matrix by their corresponding concentrations.The Figures were prepared by using Origin 9.0 software.

3. Results and discussion

3.1 Physicochemical parameters

The enological parameters of the original wines fermented in the two fermenters (TF and BF) before aging were shown in Table 1.The total acidity and pH in the original wines showed no difference indicating the similar maturity of grapes fermenting in the two fermenters,although the tank fermented wines had a little lower alcohol concentration than the barrel fermented wines.

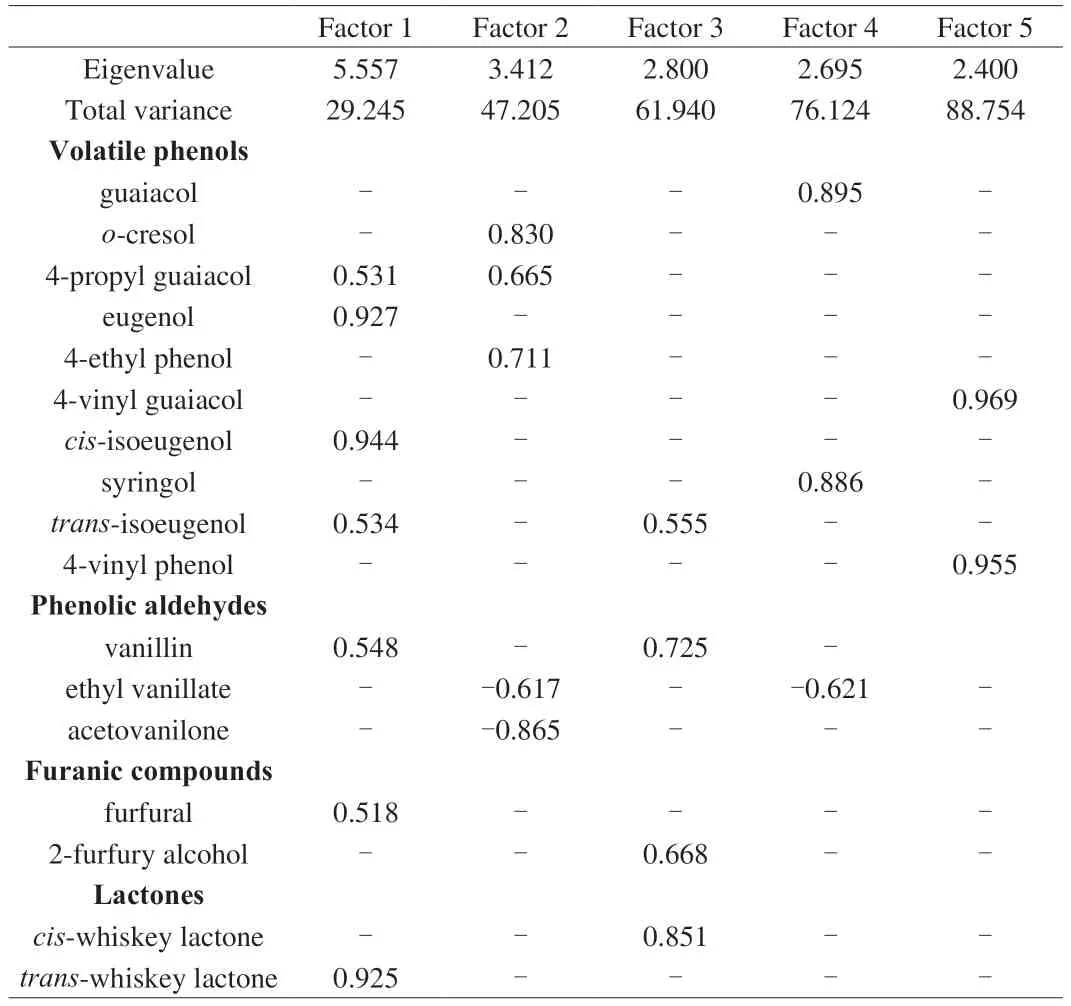

3.2 Effects of aging in different barrels on compounds associated with barrels

As shown in Supplementary Table 1,33 volatiles that resulted from oak aging were detected by liquid-liquid extraction,including 17 volatile phenols,5 phenolic aldehydes,9 furan,derivatives and 2 lactones.There were only 17 compounds of OAVs >0.1 associated with oak barrels and their concentrations were shown in Supplementary Table 2.Most of the selected compounds had increased concentrations in the first three months of the aging period and slowed down in the last six months,except for ethyl phenols and vinyl phenols.When selecting the influencing factors using the factor analysis,it had been suggested to explain at least 80% of the total variances[21].We found that five factors,which included all of the 17 volatiles mentioned above,had higher eigen values than 1,and explained 88.8% of the total variance 1.Using varimax rotation,the coefficients of all variables in the five factors were calculated and were shown in Table 2.To simplify the presentation of the result,only coefficients >0.50 were listed.

Table 2 Factor loading matrix after varimax rotation of volatile compounds associated with oak barrels.

Factor 1 explained 29.2% of the total variance of all the positive variables.Most of the compounds incorporated in factor 1 originated from greenwood,except for vanillin and furfural,which came from the degradation of lignins and carbohydrates during the toasting process.As shown in Fig.1a,there was little difference between the wines fermented in the stainless steel tank and oak barrel.This might be because the oak barrel has been used for seven years and a previous study showed that the amount of extractable compounds in the oaks of the oak fermenter could be expected to be minimal after 8 years’utilization[36].The factor values of all the wines increased quickly in the first three months due to the rapidly increased concentrations of eugenol,trans-eugenol,cis-andtrans-whisky lactone.The increased concentration ofcis-whisky lactone in AO was most obvious.After aging for three months,the concentration ofcis-whisky lactone was 195.81 µg/L in TF-AO-MT,266.38 µg/L in TF-AO-LT,256.47 µg/L in BF-AO-MT and 294.06 µg/L in BF-AO-LT,which was in agreement with the reports from Ortega-Heras[21]and Pérez-Prieto[37].Over the next 6 months,the factor values of wines fermented in tanks increased,which was contrary to the barrelfermented wines.For the duration of aging,the factor values of the barrel-fermented wines were higher than the tank-fermented wines.Furfural was the principal compound giving these results.However,at the end of aging (9 month),the factor values of the barrel-fermented wines were no more higher than the tank-fermented wines because of the decreased concentration of furfural.This might because that the furfural could be reacted to furfural alcohol[38],2-furanmethanethiol[39],and adducts with (+)-catechin[40].

Factor 2 included five compounds originating in the toasting process,although the 4-ethylphenol,which increased during aging,was likely to come mainly from decarboxylated cinnamic acids due to the action ofBrettanomycesandDekkerayeast[21,41].When its concentration was greater than its threshold (620 µg/L)[42],it had a negative sensory effect.Theo-cresol and 4-propylguaiacol,originating from the thermal dehydration during toasting[43,44],were positively correlated with factor 2.Acetovanilone was also a product of the toasting process[45],and had a negative association with ethyl vanillate.The values of factor 2 (Fig.1b) were stable or declined slightly during the first three months and were less than zero,because the extraction of acetovanilone and ethyl vanillate was more rapid than volatile phenols[46],and the concentration of 4-ethylphenol was still low.But after the first three months,the values of these wines increased quickly,approximately linearly.Non-barrel origin 4-ethylphenol,and other volatile phenols were responsible for this phenomenon.

As was shown in Table 2,factor 3 included four variables,all of which had positive contributions.Thetrans-whisky lactone,with its wood and coconut aromas,andtrans-isoeugenol,contributing clove and spicy aromas[28],which existed in unseasoned wood,were the markers of the oak aged wines.Vanillin originated from the degradation of lignins during the aging period and 2-furfury alcohol was transformed from furfural.In factor 3,the factor values of the tank fermented wines were higher than those of the wines fermented in the barrels (Fig.1c).For the latter wine,the factor values increased slowly during the first 6 months but more rapidly for the last 3 months.In contrast,the factor values of the wines fermented in the tank increased quickly during the first 3 months and then slowly for the last 6 months.Furfuryl alcohol,which was biologically formed from furfural but not extracted from the wood[47,48],was the cause of the difference.For example,after aging for 3 months,the concentration of furfuryl alcohol was 8,027.96 µg/L in TF-AOMT,nearly one hundred times higher than that in the original wine(84.57 µg/L).At the same time,the concentration of furfuryl alcohol in BF-AO-MT was only 2154.36 µg/L.But after aging for 9 months,the concentration of furfuryl alcohol in BF-AO-MT wines was augmented to 10,814.78 µg/L and there was 10,527.54 µg/L in TF-AO-MT wines.As shown by factor 1,the timing of furfural transformation to the corresponding alcohol was seemingly dependent on the fermenters used for the base.

The variance explained by factor 4 (14.2%) was similar to that explained by factor 3.It included three compounds,all of which came from the toasting process.The values of this factor (Fig.1d) were consistent in most of the wines.The values were stable during 0 to 3 months,increased rapidly in the next 3 months.Then the treatments showed two distinct trends.The values kept increasing in BF-CK,TFCK,TF-AO-MT,TF-AO-LT,TF-SO-MT,BF-FO-LT while declined quickly during the last 3 months in the last treatments.Guaiacol was the main contributor to these changes.For example,TF-SO-LT wines had the highest factor value when aging 6 months with 816.61 µg/L guaiacol,but there was only 75 µg/L guaiacol in BF-FL-LT after 6 months of aging,which had the lowest factor value.The declining trend of guaiacol was also found by Chira et al.that the maximum extraction of guaiacol occurred during the first nine months and declined then at the end of the aging point[43].Two possible reasons might lead to the decline of guaiacol: (i) the guaiacol in the wine and oak barrels was a dynamic balance that could be adsorbed on the surface of the oak barrel;(ii) during aging,the guaiacol could form polymeric pigments with anthocyanins which led to its decrease[49].

Factor 5 comprised two volatile phenols: 4-vinyl guaiacol and 4-vinyl phenol.Hydroxycinnamate decarboxylase fromBrettanomycesconverted ferulic acid,p-coumaric acid,caffeic acid,the cinnamic acids of grapes and wine into vinylphenol,which in turn was converted into ethylphenols by vinylphenol reductase[50].So the concentration of ethylphrnol had a significant effect on the wine quality.The values of wines (Fig.1e) fermented in the barrels were lower than the tank fermented ones,most of which stayed stable during the aging period.The difference of the barrel fermented and tank fermented wines might be due to the action ofBrettanomyces,which was normally considered as unwanted spoilage yeast,although in all wines the concentration of vinylphenols and ethylphenols were below their threshold.

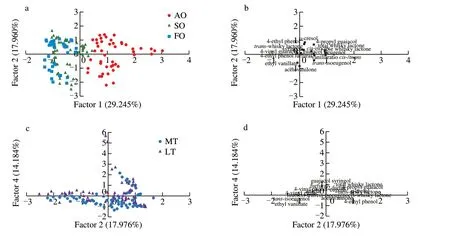

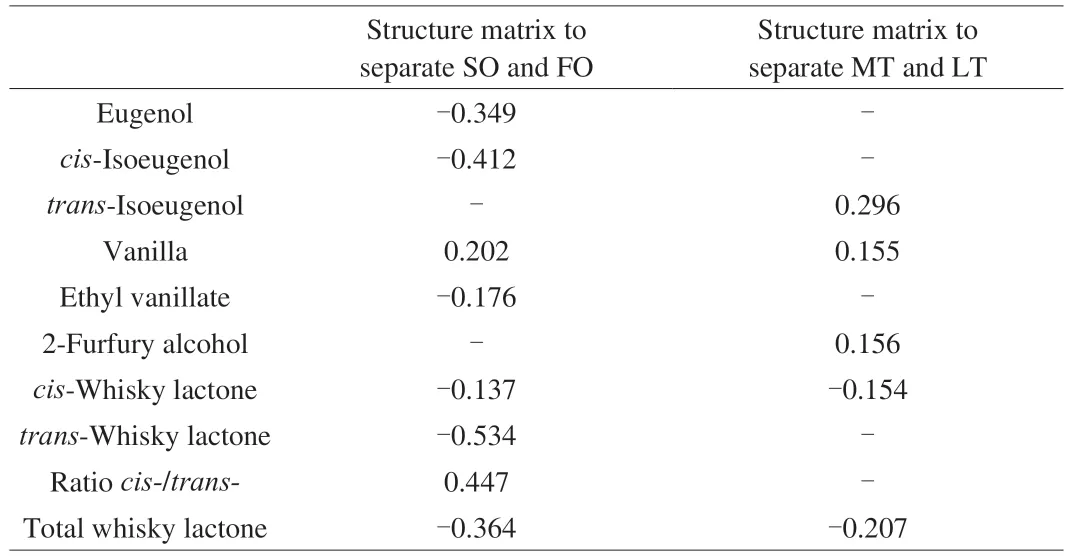

The principal component analysis of all compounds associated with oak barrels was used to analyze the influence of the species and the geographic origins of oak barrels (Fig.2a and Fig.2b).Factor 1 and factor 2 were examined further because they explained 47.2% of the total variance.The positive correlation of eugenol,cis-andtrans-isoeugenol,cis-whisky lactone,in factor 1 (Fig.2) showed that American oak barrels could be distinguished from European barrels,which was in agreement with the findings of Prida[14]and others who worked with different species[36,51].A previous research reported that furanic aldehydes had the potential for distinguishing the oak samples from different species[52],and furfural was found to have a positive impact on factor 1 in the present study.That might result from the different concentrations of carbohydrate in the green wood of the different oak species.As shown in Fig.2,the samples from French and Slovakian barrels could not be separated by factor 1 and factor 2.This lack of discrimination in the geographic origins was,at least in part,due to the fact that the same oak species were used,and the side of the forest where the trees came from,the part of the tree used for the staves,and the cutting and seasoning of the staves were very similar[20].However,the stepwise discriminant analysis did distinguish these two geographic origins with the discriminant rates greater than 90%.The structure of the stepwise discriminant function matrix revealed the compounds which could distinguish Slovakia and French barrels (Table 3).The concentrations ofcis-whisky lactone,eugenol andcis-isoeugenol were higher than in the American barrels than those in the Slovakian barrels and were lost in French barrels,which was again in agreement with Prida[14],partially in agreement with Pizarro[52],who considered that the French barrels had the highestcis-eugenol.Thetrans-whisky lactone levels were highest in the wines aged in the Slovakian oak,followed by the French barrels and then the American barrels.Prida[14]suggested that eugenol and vanilla could be used as markers to differentiate the French and the East European oaks,which was in agreement with our results.Neither the geographic origins nor the toasting levels affected the concentrations of vanilla and ethyl vanillate.

Fig.2 Results of PCA for the barrels of different geographic origins (a,b) and toasting degrees (c,d).a: Loading plot for the wines aged in the barrels of the three geographic origins with the wines sampled at 3,6 and 9 months.b: Scores plot for the volatile compounds associated with the oak barrels.c: Loading plot for the wines aged in the barrels of the two toasting degrees sampled at,3,6,and 9 months.d: Scores plot for the volatile compounds associated with the oak barrels.AO,the wines aged in the America oak barrels;FO,the wines aged in the French oak barrels;SO,the wines aged in the Slovakian oak barrels.MT,the wines aged in the medium toasting oak barrels;LT,the wines aged in the light toasting oak barrels.

Table 3 Structural matrix of the stepwise discriminant function.

Considering that the compounds in factors 2 and 4 arose from the toasting process,these two factors were used for a PCA analysis(Fig.2c and Fig.2d).At the same time,the stepwise discriminant function was used to indicate the results (Table 3).Six compounds,including guaiacol,syringol,trans-isoeugenol,furfural alcohol,vanilla,andcis-whisky lactone,distinguished the light toasting barrels from the medium toasting ones (Fig.2d).It was well known that toasting oak altered the concentrations of many compounds[20,32].Volatile phenols and phenolic aldehyde were formed by the thermal dehydration of lignins[20,21].Furfural could be transformed into furfural alcohol during aging originating from the thermal dehydration of carbohydrates[21,52],and part of whisky lactone arose from the lipid oxidation during the toasting process[52,53].For this reason,these compounds could indicate the difference in toasting.It was found that the concentration oftrans-isoeugenol increased in the wines aged in the medium toasting barrels.

The concentrations of the above aroma compounds were analyzed and then the sum of OAVs were used to describe the special aroma characteristics of various barrels (Supplementary Table 3).The main aroma descriptors were nutty,roasted,oaky,spicy,smoky and leathery (Supplementary Table 1).Furfural was the only compound that had a nutty aroma.The nutty aroma of wines from medium toasting barrels was always stronger than in the wines from light toasting ones because of the source of furfural[21,52].The nutty aroma had the lowest intensity among all of the aroma series,just from 0 in TF-CK to 0.14 in TF-AO-MT.The roasted aroma,which included the contributions from furfural and furfuryl alcohol,was higher in the wines fermented in the tanks and the wines aged in medium toasting barrels.During the first 3 months of aging,this aroma type increased then stayed steady or increased slowly over the next 3 months,and had no consistent trend in the last 3 months.The oak aroma was associated with eugenol,cis-andtrans-whisky lactone,vanilla and ethyl vanillate,so the wines from the American barrels were highest on this character.For example,the OAV of oak in BF-AO-LT was 23.63,much higher than those of 9.33 in BF-SO-LT and 10.15 in BFFO-LT.The oak aroma of wines from the light toasting American and Slovakian barrels was higher than the medium toasting ones because of the concentration of whisky lactone.Though the three volatile phenols with smoky aromas all came from toasting,the intensity of the smoky aroma did not reflect the level of toasting.The greatest increase of this aroma took place during 3 to 6 months,but decreased or did not vary during the last 3 months.The spicy notes were mainly due to volatile phenols and phenolic aldehydes,and were in keeping with factor 4.Ethyl phenol had leathery aroma,and was identified with factor 5.Some compounds associated with barrels had caramel aroma but were of low intensity,so they were combined together and were analyzed as below.

3.3 Effects of aging in different barrels on general compounds

Apart from compounds closely associated with barrels,35 general volatiles were selected with OAVs higher than 0.1.Although most of these compounds came from grapes and fermentation,some of them,such as ethyl lactate,ethyl 2-hydroxy-4-methylpentanoate,isoamyl lactate and 3-methyl-1-pentanol were generated during aging.The concentrations of most higher alcohols,esters and fatty acids decreased during the first 3 aging months.But most of the terpenes,norisoprenoids and even ethyl 2-hydroxy-4-methylpentanoate and ethyl benzoate stayed stable throughout aging.

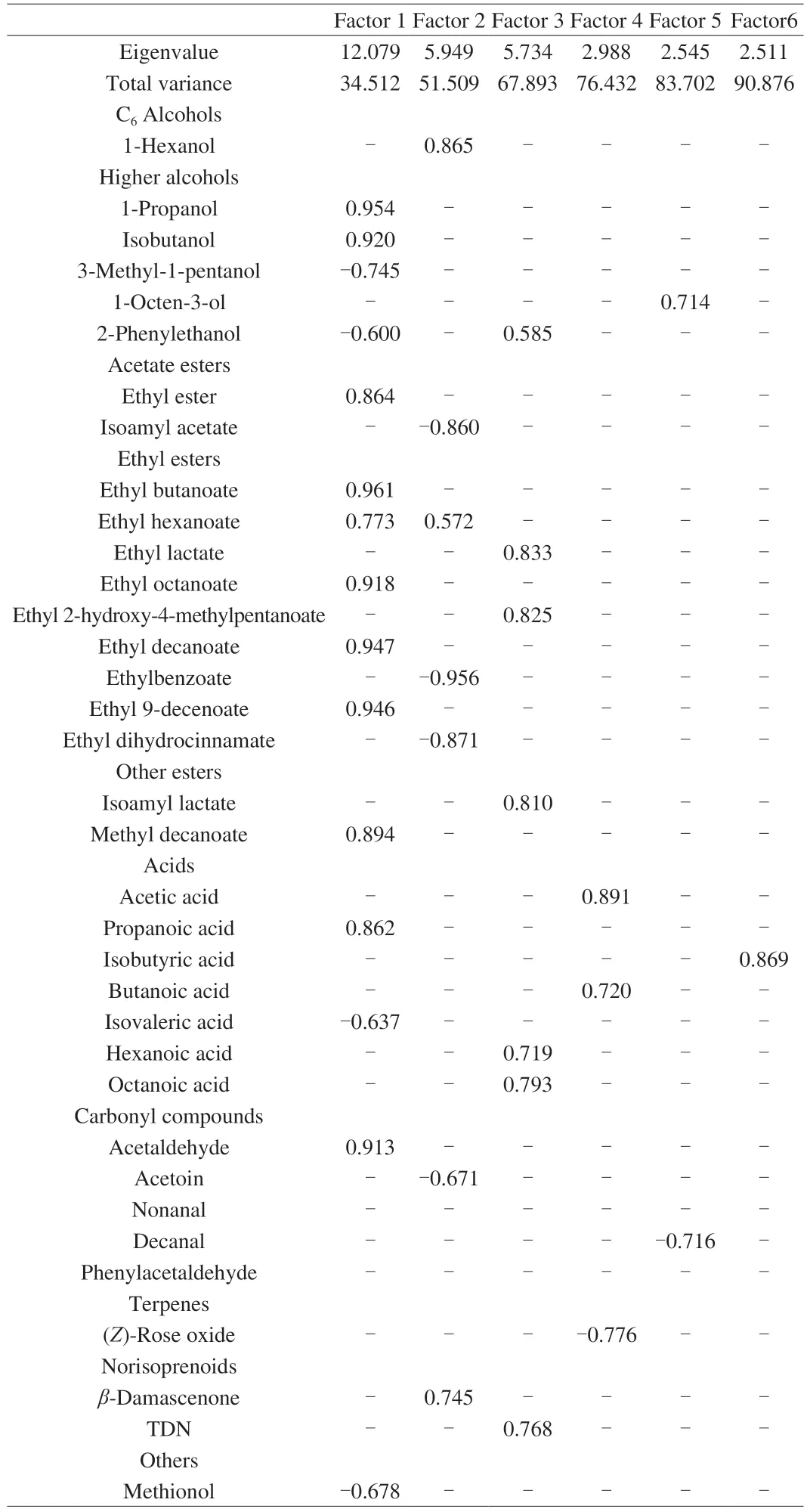

Factor analysis was used to reveal the similarities between the wines and found that 90.9% of the total variance could be explained by the six factors that included all of the 35 compounds.It was also found that even factor 6 had an eigenvalue above 1.The coefficients of the variables,Table 4,were higher than 0.50 after varimax rotation of the six factors.

Table 4 Factor loading matrix after varimax rotation of the primary and the secondary compounds.

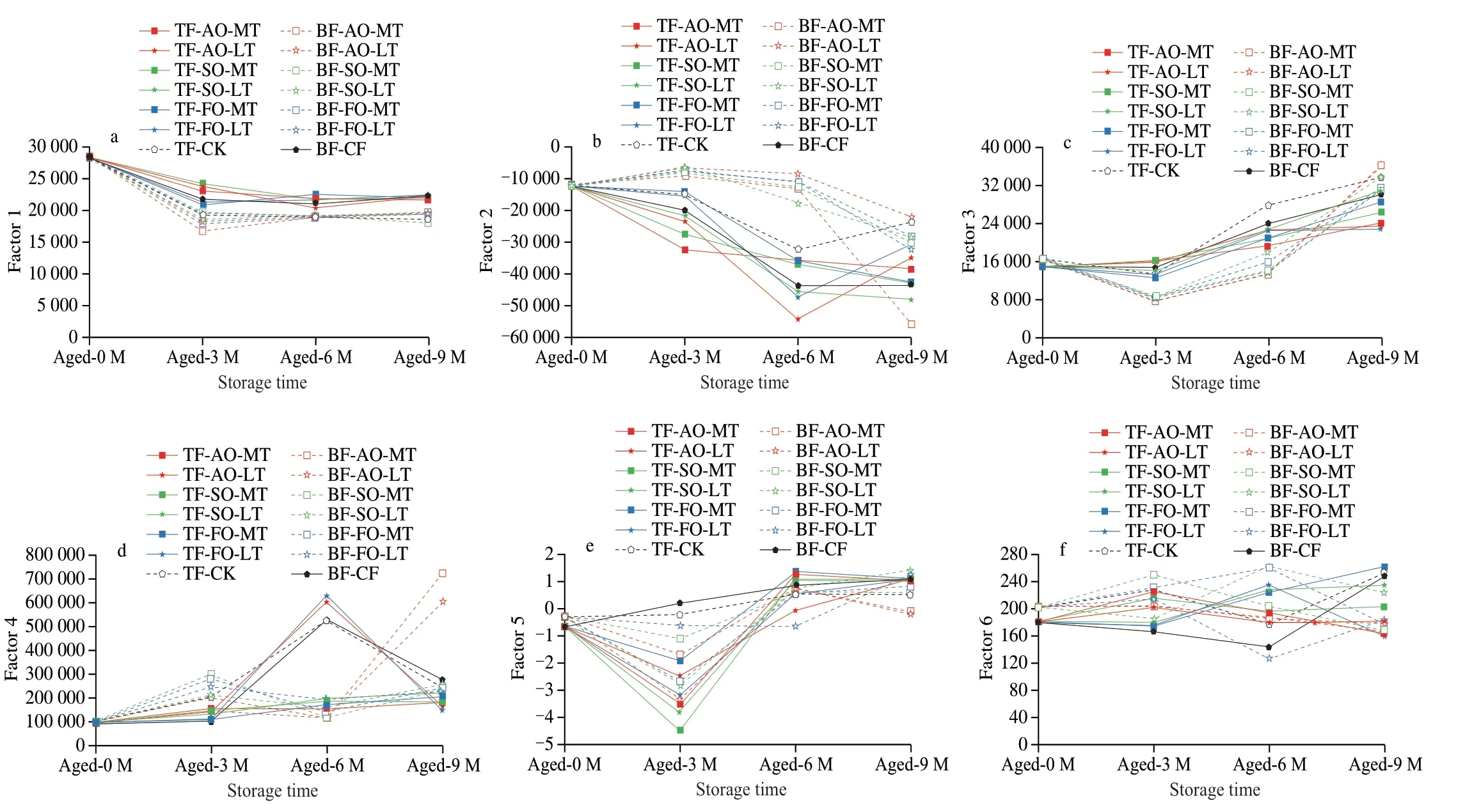

Factor 1 explained 34% of the total variance and was associated with nearly half of the total number of the fermentation-related variables,mainly including higher alcohols and ethyl esters (Table 4).From Fig.3a,the wines which were fermented in the tanks could be distinguished easily from the barrel fermented ones and had higher concentrations than the latter during aging.The decrease in values in wines during the first 3 months of aging might be due to ester hydrolysis.For example,the concentrations of ethyl acetate were 110 359.49 µg/L in TF and 116 179.11 µg/L in BF,respectively.After aging in the barrel for 3 months,the concentration of ethyl acetate ranged from 67 085.96 µg/L to 98 565.5 µg/L in all of the wines.Most of the esters contribute floral and fruity notes to the aroma of the wines[1,28],and were biochemically synthesized more than formed as a result of reaching equilibrium concentrations from acid and alcohol esterification during fermentation[54,55],and gradually hydrolyzed to their corresponding alcohols and acids to approach to an equilibriumduring aging[53].Also in this period,the concentration of higher alcohols decreased to produce their corresponding carbonyl compounds and other compounds.The concentration of propyl alcohol and isobutanol decreased quickly.There were 71 149.36 µg/L of these compounds in BF before aging.Three months later,there were only 37 438.75 µg/L of them in BF-AO-MT,which was nearly half of the original wine.From 3 to 9 months of aging,the factor values of each wine were stable because the concentration of higher alcohol augmented with the concentration of esters declining.

Fig.3 Changes in the values factors 1 to 6 for the compounds associated with grapes and fermentation in the wines aged in different oak barrels for 9 months.In the legend,‘XX-XX-XX’ represented “the fermenter type– the barrel geographic origin -the toast level” for the fourteen wines.BF,the wines fermented in the oak barrels;TF,the wines fermented in the stainless steel tanks;AO,the wines aged in the America oak barrels;FO,the wines aged in the French oak barrels;SO,the wines aged in the Slovakian oak barrels;MT,the wines aged in the medium toasting oak barrels;LT,the wines aged in the light toasting oak barrels.

Factor 2 included C6-alcohol,esters and norisoprenoids and the factor values were below 0 for all of the wines,which originated from grape maturation or fermentation process.From Fig.3b,the wines from the tank fermenters could be separated from the oak barrel fermented wines.And the variation trends of the values for the wines that came from different fermenters were distinctive.The factor values of the tank fermented wines declined in the first 6 months and had different variation trends in the last 3 months,because the concentration of 1-hexanol decreased and the concentration of acetoin increased (Supplementary Table 2).Furthermore,1-hexanol had a positive correlation with factor 2 and was the single compound with an OAV higher than 0.1 in C6-alcohols,which came from the grapes and usually had vegetal and herbaceous characteristics,causing negative effects[55,56].It might transform to the corresponding esters to reduce the vegetal aroma during the aging period.However,the factor values of the wines fermented in barrels increased in the first 3 months but fell at the 6 months,caused by the concentration changes of isoamyl acetate andβ-damascenone.The latter compound,with its floral and fruit aromas and low threshold[28],was one of the most important norisoprenoids and played an essential role in the varietal character of the wines.It had a positive correlation with factor 2.Isoamyl acetate was also an important compound that had obvious banana characters and could be used to distinguish the wines of different aging time as reported by Castro-Vázquez[4].

All variables,principally fatty acids and esters,had positive correlations in factor 3.The production of fatty acids was determined by grapes and fermentation conditions[28].Previous research indicated that yeasts produced more fatty acids if the fermentation conditions were anaerobic[57].According to some reports[4,6],fatty acids,which had fatty,fruity,cheese and rancid characteristics[28],decreased during the aging period,because of sorption by the barrels.This could explain the reason why the factor values of the wines decreased during the first 3 months.These factors also included ethyl lactate,ethyl 2-hydroxy-4-methylpentanoate and isoamyl lactate,which were mainly formed during the aging period and led to the increase of the factor values during 3 to 9 months.

From the values of factors 1 to 6,it could be found that the concentration of the general aroma compounds fluctuated with the changes of the oak species,the geographic origins and the toasting degrees of barrels,but there were no consistent trends in each independent variable.To further evaluate the influence of the oak species and the geographic origins on these general compounds,the above factors were used to do a PCA analysis.But this did not distinguish the wines from the two oak species and the three different geographic origins.Then,the discriminant function was used for that purpose but had the same outcome.The results showed no general compounds that could be used as the markers to distinguish the American,French and Slovakian oaks in the present study.When these statistical analysis methods were used to evaluate the influence of toasting degrees on the general compounds,the same results were obtained.

The sum of OAVs were also used to describe the special aroma characteristics of various barrels.The main aroma series associated with general compounds were fruity,floral,herbaceous,caramel,earthy,chemical and fatty (Supplementary Table 3).The intensity of the fruity aroma decreased in the first 3 months because of the dehydration of esters[53],but stayed stable from 3 to 9 months because of the increase of 1-propanol,and ethyl ester.The variation in floral and caramel intensities was almost the same,and the wines from different fermenters were inseparable because they all includedβ-damascenone and phenylacetaldehyde at concentrations greater than their thresholds and masked the effects of other compounds.The influence of the oak species,the geographic origins and the barrel toasting levels on the fruity,floral and caramel aroma series were not distinct.There was no regular pattern for all of the wines during the whole period when the herbaceous aroma was analyzed,which related to C6-alcohols,higher alcohols and carbonyl compounds.Another special aroma series associated with general compounds was the earthy aroma,which correlated only with 1-octen-3-ol,whose organoleptic property was described as the mushroom.The wines fermented in different fermenters could be distinguished before aging,but these wines changed individually during aging beyond 3 months.At the end of the aging period,the earthy aroma of the tank fermented wines augmented evidently compared to the beginning of the barrel aging.The concentration of 1-octen-3-ol fluctuated from 4.95 µg/L to 5.63 µg/L after 9 months of aging,which was higher than 3.72 µg/L in the tank fermented original wine (Supplementary Table 2).Compounds that contributed to fatty aroma series were not only associated with fatty acid,but also some esters and carbonyl compounds.The fatty aroma notes of the barrel fermented wines aged in the American oak barrels increased more rapidly during the last 3 months.But the influence of the barrels with their various parameters of the oak species,the geographic origins and the toasting degrees were not obvious on the aroma series associated with general compounds during the whole aging period.

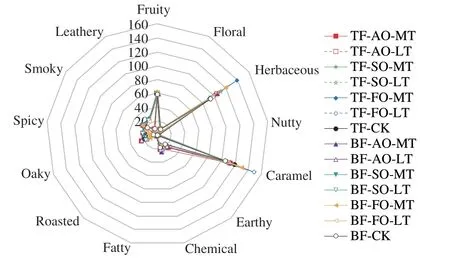

3.4 Aroma profiles of all wines at the end of the aging period

After 9 months,at the end of the trial aging period,the sum OAVs of all thirteen aroma series were used to construct the aroma profiles of the various trial wines,as shown in Fig.4.The floral,caramel and fruity aromas dominated the profiles,accounting for 27.1%-32.7%,25.2%-30.1% and 12.6%-17.3%,respectively.The wines aged in the medium toasting French barrels had the highest floral and caramel aromas,and the lowest was in the wines aged in the American barrels.The wines fermented in the tanks had the highest floral aroma.While the fatty and chemical aroma notes also played important roles in all wine profiles,the wines were not obviously similar.Another four aroma series to make important contributions,but much less than the first three aroma series,were smoky,leathery,spicy and oaky,which were the aromas associated with the barrels.The oak aromas of the wines from most of the light toasting barrels were stronger than those of the medium toasting ones,except for the wines from the barrel fermenters and aged in the Slovakian barrels.The toasting degrees and the fermenters did not influence the spicy aroma.The intensity of the smoky aroma was higher and similar for the wines fermented in the tanks.The leathery aroma was similar to the smoky aroma,except for the wines from the barrel fermenters and aged in the light toasting Slovakian barrels.In all,each wine had its own organoleptic features after 9 months’ aging,according to the types of the fermenters used,the oak species,the geographic origins and the degrees of the barrel toasting.

Fig.4 The spider plot for the different categories of aroma types associated with the grapes and fermentation process for the wines aged in different barrels for 9 months.In the legend,‘XX-XX-XX’ represented “the fermenter type-the barrel geographic origin-the toast level” for the fourteen wines.BF,the wines fermented in the oak barrels;TF,the wines fermented in the stainless steel tanks;AO,the wines aged in the America oak barrels;FO,the wines aged in the French oak barrels;SO,the wines aged in the Slovakian oak barrels;MT,the wines aged in the medium toasting oak barrels;LT,the wines aged in the light toasting oak barrels.

4. Conclusion

After aging,the ‘Merlot’ red wines fermented in the tanks had higher toasting notes,and more leathery and smoky aromas but lower fruity,floral and caramel aromas than those fermented in the barrels.After 3 months of barrel aging,the concentrations of most esters,higher alcohols and fatty acids decreased noticeably.In contrast,some compounds,such as whisky lactone,vanilla,eugenol and so on had been quickly extracted from the oak barrels in the same period.However,the rates of extraction slowed during the following 6 months.General aroma compounds,such as higher alcohols and esters,could not be recognized as the markers to distinguish the oak species,the geographic origins and the toasting degrees of the barrel oaks,though their concentrations could be impacted.The wines from the American oak barrels had the highest total amounts of whisky lactone,eugenol,cis-isoeugenol,as well as the highest toast and spicy aromas.The high concentration oftrans-whisky lactone could be used as a marker of the Slovakian barrels.The difference between the American and European barrels was greater than that between the French and Slovakian ones,reflecting that the influence of oak species was greater than the importance of the geographic origins.The higher concentrations of guaiacol,syringol,trans-isoeugenol,furfural alcohol,vanilla,ciswhisky lactone and the total whisky lactone could distinguish the medium toasting degree barrels from the light toasting ones.The former could bring more toast aroma,but a less smoky aroma to the wines.

Conflict of interest statement

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The authors gratefully acknowledge the financial support received from The Key Project of R&D Program of Ningxia Hui Autonomous Region,China (2022BBF01003) and China Agriculture Research System of MOF and MARA (CARS-29).

Appendix A.Supplementary data

Supplementary data associated with this article can be found,in the online version,at http://doi.org/10.26599/FSHW.2022.9250032.

- 食品科学与人类健康(英文)的其它文章

- GUIDE FOR AUTHORS

- Targeting gut microbiota in osteoporosis: impact of the microbial based functional food ingredients

- Weizmannia coagulans: an ideal probiotic for gut health

- Natural sources,refined extraction,biosynthesis,metabolism,and bioactivities of dietary polymethoxyflavones (PMFs)

- A review of salivary composition changes induced by fasting and its impact on health

- Minerals in edible insects: a review of content and potential for sustainable sourcing