碳纳米管增强聚合物纳米复合材料研究进展

辛 菲,许国志

(北京工商大学材料与机械工程学院,北京100048)

碳纳米管增强聚合物纳米复合材料研究进展

辛 菲,许国志*

(北京工商大学材料与机械工程学院,北京100048)

综述了近几年国内外在碳纳米管增强聚合物纳米复合材料力学性能方面的研究进展,主要介绍了以聚氨酯和聚酰亚胺为基体的复合材料。讨论了碳纳米管的各种改性方法及其作用原理,并对各种改性和制备方法的有效性进行了比较。最后,对碳纳米管增强聚合物纳米复合材料的发展前景进行了展望。

聚合物;碳纳米管;复合材料;研究进展

0 前言

近年来碳纳米管(CNT)增强聚合物纳米复合材料领域的发展非常快。CNT本身有着出众的电学、热学和力学性能。例如,CNT的拉伸模量和拉伸强度理论上是最强不锈钢材料的10~100倍。2000年,YU等[1]测得的单个多壁碳纳米管(MWCNT)的弹性模量在0.27~0.95TPa之间,拉伸强度在11~63GPa之间。单壁碳纳米管(SWCNT)的弹性模量在0.32~1.47TPa之间,拉伸强度在10~52GPa之间[2]。这些特性使得CNT成为提高聚合物基复合材料力学性能的理想材料。

在聚合物中添加含碳填料用以提高聚合物的力学性能,降低质量或者起导热作用并不是一种新的方法。炭黑已经被广泛用于增强橡胶和塑料,例如:它被广泛用在赛车轮胎上来降低热磨损。碳纤维也是一种用途广泛的工业材料,被广泛应用于汽车、飞机和自行车等领域。然而,最有潜力的还是CNT,利用其力学强度已经生产出了新的工业产品。例如,含有CNT的网球拍和高尔夫球杆等运动器材已经在市场上售卖。CNT的生产方法越来越简便,其价格也越来越便宜,CNT将会超过碳纤维,成为聚合物基复合材料生产中的主要填料。

目前已经有很多关于CNT增强聚合物纳米复合材料力学性能的综述[3-14],但最近CNT增强聚合物纳米复合材料领域又有一些明显的进展。本文将主要介绍近几年CNT增强聚合物纳米复合材料的发展状况,特别是其力学性能。

1 CNT的改性方法

众所周知,为了获得最佳的力学性能,CNT必须有最好的分散效果。除非CNT与聚合物之间经过非常细致的加工和处理,否则由于CNT的团聚使得CNT之间或者CNT与聚合物链之间的载荷传送非常差,导致界面滑动,严重影响力学性能[15]。因此,对CNT进行改性对其在聚合物中的加工和应用都是十分重要的。一般来说,通过改性会明显提高CNT的分散性和它与聚合物之间的应力应变传递。对CNT改性和超声分散被广泛用于改善CNT在溶液中的分散状况[16-22]。

CNT改性主要有2种方法:共价键改性和非共价键改性。

1.1 共价键改性

共价键改性可以通过直接在CNT的侧壁引入化合物或者是添加合适的官能团来达到目的[10,11,23]。这种改性方法因为将sp2杂化轨道的碳原子改变成了sp3杂化轨道,使得CNT的外层结构受到破坏,导致其性能如电学性能等受到影响[24],但是这种改性方法可以提高CNT在溶液和聚合物中的分散度和相容性。总体来讲,像—COOH和—OH之类的官能团可以通过采用氧气、空气、浓硫酸、浓硝酸、盐酸或者是混酸等氧化剂对CNT进行氧化使之在CNT的侧壁上生成相应的官能团[25-26]。酸处理的 MWCNT表面存在着一些缺陷点,这些缺陷点位于生成的羧酸官能团与MWCNT表面相接的C—C键上[27-28]。CNT表面羧基基团的数量随着酸化处理的温度和时间的增加而增加[29],同时也取决于氧化处理的方法和氧化试剂。

—COOH和—OH之类的官能团的存在有助于在CNT表面接上有机化合物[30-32]或无机材料,而这些物质对于提高CNT的相容性具有非常重要的作用。CNT的这种改性可以发生在末端或侧壁,从而提高其在溶液和聚合物中的相容性和分散度[33-34]。SWCNT可以通过在不同的温度下与氟气反应使其在侧壁上引入氟原子[35],这种氟改性的CNT在异丙醇或者是二甲基甲酰胺的溶液中超声后显示出了非常好的相容性[36-37]。氟改性的CNT也可以与溶于氯仿中的格式试剂或烷基锂发生反应从而得到侧壁含有烷基的CNT[38]。SWCNT也可以通过硝基化反应[39-40]、烯基化反应[40]、芳基化反应[41-42]直接在其侧壁上进行改性。

1.2 非共价键改性

非共价键改性方法最大的优点是它不会破坏CNT的结构,同时也能提高其相容性和可加工性。这种类型的改性主要包括表面活性剂、生物大分子或者是用聚合物包覆等方法。

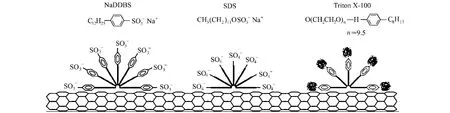

CNT能够通过加入阴离子、阳离子或非离子型表面活性剂在水溶液中得到很好的分散[43-46]。阴离子表面活性剂如十二烷基硫酸钠(SDS)[47-49]和十二烷基苯磺酸钠(NaDDBS)[50-51]是常用的用来减少 CNT 在水中团聚的表面活性剂。表面活性剂与CNT之间的相互作用依靠表面活性剂本身的结构,如它们的烷基链长,端基基团的大小和电荷等。SDS相对于NaDDBS和辛基苯基聚氧乙烯醚(Triton X-100)来说和CNT具有较弱的相互作用,这是因为它没有苯环。事实上苯环和CNT表面之间的π-π共轭作用明显提高了表面活性剂分子与碳层的结合和表面覆盖度[46]。NaDDBS分散效果好于Triton X-100是因为它的端基和更细长的烷基链。图1是不同表面活性剂在CNT表面的吸附示意图[46]。

图1 不同表面活性剂在CNT表面的吸附示意图Fig.1 Schematic diagram of surfactants adsorbed onto the CNT surface

也有用蛋白质和DNA来对CNT进行改性的报道[52]。蛋白质的疏水部分对于其在CNT上的吸附有着重要的作用。现在已经能够通过可控及独特的方法将蛋白质吸附在CNT上[53],这种吸附的机理包含蛋白质上的氨基基团对N羟基琥珀酰亚胺的亲核取代反应。其非共价键改性是通过sp2杂化轨道使得CNT上的π键发生离域作用与聚合物分子中的π键相互作用来实现的[53-54]。CNT能够在非共价键改性之后相容于有机溶剂[55]或者是水溶液[56]中部分归功于官能团对它更好的覆盖度[57]。

非共价键改性的第三种类型是用聚合物对其进行包覆改性。聚合物可以在CNT的周围形成超大分子[58-60]。Blau等[61-64]制备了共聚物包覆的 CNT,由于这种共聚物生成的包覆层是永久固定的,所以明显增强了CNT在极性与非极性溶剂以及聚合物中的分散。但是这种方法的主要缺点是包覆分子与CNT之间的作用力较弱,因此在复合材料中CNT的有效载荷传递会较低。

2 CNT增强聚合物复合材料力学性能

CNT由于其非常优秀的力学性能和较高的长径比使得它成为一种十分优秀的增强填料用于研制CNT增强聚合物纳米复合材料。事实上,已经有很多种聚合物用来作为基体制备这种材料。本文主要介绍其中2种聚合物的CNT增强材料的力学性能。

2.1 聚氨酯/CNT纳米复合材料

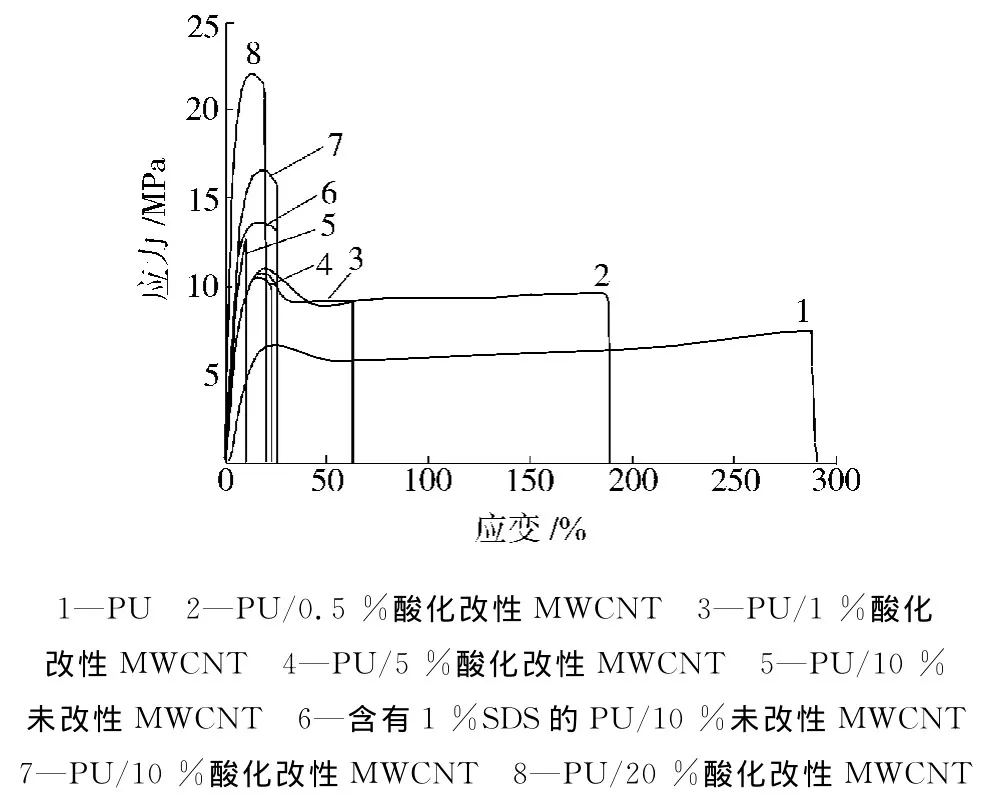

聚氨酯(PU)是一种用途十分广泛的材料,它被广泛应用于涂料、黏结材料、形状记忆高分子材料、医用材料等领域。PU由交互的硬段和软段组成,硬段由交互的二异氰酸盐和扩链剂分子(如二醇或二胺)组成,软段由直线长链状的二醇构成,硬段与软段的热动力学不稳定会使PU发生相分离。PU/CNT复合材料[65-74]最近吸引了大家的关注,不同 PU/CNT 复合材料的力学性能列于表1中[75-84],可见,将CNT加入PU中可以大幅提高材料的拉伸强度和拉伸模量。例如,用溶液混合法将酸化的MWCNT加入PU中可以提高材料的拉伸强度和拉伸模量[85-86],如图2所示。

表1 PU/CNT复合材料的力学性能Tab.1 Mechanical properties of PU/CNT composites

图2 不同CNT添加量时PU/CNT复合材料的应力应变曲线Fig.2 Stress-strain profiles of PU/CNT composites at different CNT contents

从图2可以看出,含有10%(质量分数,下同)MWCNT-COOH的PU复合材料的拉伸强度比未添加的PU增强了108%,比相同添加量的未改性MWCNT的PU复合材料提高了68%。当添加量达到20%后,PU复合材料的拉伸强度和拉伸模量分别从原来的7.6MPa升到了21.3MPa(增幅180%)和50MPa升到了420MPa(增幅740%)。MWCNT上的亲水功能基团有助于提高其和PU中—CONH—基团的相互作用。因此,改性MWCNT和PU基体这种强的相互作用大大增强了MWCNT在PU中的分散程度,同时也增强了它们之间的界面黏附,从而提高了材料的整体力学性能。

复合材料力学性能同时也取决于CNT酸处理时的温度。添加90℃处理的MWCNT的复合材料比添加140℃处理的MWCNT的复合材料的拉伸模量有更大的提升,这说明强烈的表面处理会降低力学性能[29]。Kuan等[80]将用氨基改性的 MWCNT 加入到水性PU中,他们发现添加量为4份时,材料的拉伸模量由77MPa提高到了131MPa(增幅70%),拉伸强度由5.1MPa提高到18.9MPa(增幅270%)。氨基改性CNT和PU之间形成的共价键有助于提高界面强度和拉伸强度。CNT的种类对于提升材料的力学性能也有影响,MWCNT对于提高材料的模量更为有效,而SWCNT更有助于提高材料的拉伸长度和拉伸强度。这两者对于PU的不同的增强效果与CNT在多羟基化合物中的分散的剪切变稀指数和形状系数有关。

聚合物接枝也是一种十分有效的提高分散度和材料力学性能的方法,因为这种方法可以在聚合物与CNT之间形成很强的化学键。Xia等[87]用同位聚合法制备了聚已酸内酯基聚氨酯接枝的SWCNT(PU-g-SWCNT)和聚丙二醇接枝的 MWCNT(PPG-g-MWCNT),并将它们与PU制备成了PU复合材料。这2种材料的力学性能都有提高。PU中添加0.7%PU-g-SWCNT,其弹性模量相对于纯PU和未接枝PU/SWCNT复合材料分别提高了约278%和188%。这是由于PU-g-SWCNT和PPG-g-MWCNT有更好的分散效果和更强的CNT和PU之间的界面相互作用。Wang等[77]也发现PU中添加1%~10%的PU改性的 MWCNT(PU-g-MWCNT)时会使拉伸强度提升63%~210%。储能模量和软段的玻璃化温度(Tg)会随着PU-g-MWCNT的添加量的提高而提高。复合材料软段的Tg从-20℃移至-5℃,这显示PU-g-MWCNT与PU基体中的软段无定形区兼容。最近Mc Clory等[79]报道了用加成聚合反应制备的热固性PU/MWCNT纳米复合材料。添加0.1%和1%MWCNT到PU中,其弹性模量分别提高了97%和561%,然而,无论是0.1%还是1%MWCNT的添加量,其极限的拉伸强度都提高了397%。在这种复合材料中,添加0.1%CNT相比纯PU,其断裂伸长率从83%提高到了302%。

也有用熔融加工方法制备的复合材料纤维的力学性能提高的报道。材料纤维的弹性模量相比纯PU纤维提高了27倍。Sen等[78]研究了用静电纺丝技术制备的含有SWCNT的PU薄膜。酯基改性的PU/SWCNT薄膜的拉伸强度提高了104%,正切切线模量提高了250%。因此,这些在力学性能上的加强可以归因于CNT在整个聚合物基体中的高分散度以及CNT与PU之间良好的界面相互作用。

2.2 聚酰亚胺/CNT纳米复合材料

聚酰亚胺(PI)由于其良好的介电性质,柔韧性,较高的Tg,优异的热稳定性和辐射电阻特性而使其具有多种用途,如:封装材料、电路板和层间介质等。PI在聚合物基CNT纳米复合材料中可以充当十分优秀的聚合物基体[88-89]。不同PI复合材料的力学性能如表2所示[88,90-96],大部分的研究都报道了添加 CNT 可以提高PI的力学性能。例如,含有5%MWCNT-COOH的同位聚合的PI相比纯PI在拉伸模量和拉伸强度上都有提高[91],分别提高了33%和7%。然而,相比纯PI,未改性PI/CNT纳米复合材料只显示出了很小的增强作用。PI与MWCNT-COOH之间强的相互作用或许可以使PI/MWCNT-COOH材料在拉伸强度和拉伸模量上获得更大的增强。

表2 PI/CNT复合材料的力学性能Tab.2 Mechanical properties of PI/CNT composites

正如之前讨论过的,用含有—COOH基团的酸处理得到的改性MWCNT,其含有的—COOH基团有助于增进和PI链段中—O—基团的相互作用。另一项研究显示了含有等离子体改性MWCNT的PI复合材料的拉伸模量和拉伸强度有缓慢的增加[93]。在PI中添加0.5%的等离子体改性MWCNT可以将拉伸模量从2.17GPa提高到4.56GPa,拉伸强度从124.5MPa提高到249MPa,分别提高110%和100%。这个令人印象深刻的结果归功于在等离子体改性MWCNT和PI之间形成了化学键。当改性MWCNT含量更高时(高于0.5%),拉伸模量和拉伸强度反而下降,这个结 果 与 其 他 的 报 道 相 符[92,97]。Zhu 等[92]发 现,PI/MWCNT复合材料的拉伸强度在MWCNT含量小于5%时随着MWCNT含量的增加而升高,之后继续增加MWCNT含量,其拉伸强度开始下降。加入5%MWCNT的PI/MWCNT复合材料的拉伸强度相比纯PI提高了40%,这归因于MWCNT在纳米复合材料中的良好分散。当MWCNT含量更高时,MWCNT不能获得较好的分散,团聚成大的集束导致了拉伸强度的下降。Jiang等[97]也发现添加1.89% (体积分数)MWCNT的PI/MWCNT复合材料的弹性模量有明显的提高,但继续增加MWCNT的含量,则弹性模量开始下降。

有研究指出,在很低的SWCNT含量下(0.30%),PI/SWCNT 复合材料的力学性能相比纯PI表现出了轻微的升高(拉伸强度升高5%,弹性模量升高18%),然而在更高的SWCNT含量下(1%),PI/SWCNT复合材料的力学性能显示出了明显的提升(拉 伸 强 度 升 高 9%,弹 性 模 量 升 高 90%)[90]。PI/CNT复合材料的力学性能取决于对CNT的改性方式。在较低含量的MWCNT(最大到0.99%)的情况下,氨基改性PI/CNT复合材料的拉伸性能高于酸改性PI/CNT复合材料[95]。然而,在MWCNT含量超过2.44%时,酸改性PI/CNT复合材料的拉伸性能要好于氨基改性PI/CNT复合材料。酸改性CNT可以和PI分子中的CO键形成氢键。然而,氨基改性CNT和聚酰胺酸的成键会降低它的亚胺化反应。聚酰胺酸的力学性能低于PI,同时聚酰胺酸也比PI更脆。因此,在PI中添加氨基改性CNT会影响PI基体的力学性能。通过添加乙烯基三乙氧基硅烷改性MWCNT对PI进行增强[94]的研究发现,0.5%的添加量就可以将拉伸模量和拉伸强度分别提高60%和61%。拉伸性能的提升取决于乙烯基三乙氧基硅烷和MWCNT的比例。当乙烯基三乙氧基硅烷与MWCNT的比例为2∶1时,复合材料显示出了比其他比例的材料更好的拉伸性能,因为只有这个比例能够在PI基体中构建互穿网络。

许多其他的研究也发现了复合材料的模量有所增加,但拉伸强度却没有增加也没有降低[96,98]。相比纯的聚合物,CNT的加入会导致复合材料模量的增加和拉伸强度的下降(18%)。然而,弹性模量的增加是很少的,例如,添加14.3%CNT只能使其提高37%[98]。PI/SWCNT纳米复合材料力学性能的提高取决于样品的类型,如薄膜、棒形和纤维[96]。拉伸模量、极限强度和断裂伸长率对于添加1%SWCNT的薄膜都有增加。对于挤出的复合材料棒材(直径约1mm),力学性能没有明显的改变。但是当挤出的棒材被拉成更小的直径时,其力学性能有了明显的改变。这是因为随着纤维直径的下降,后续的纤维拉伸过程产生了不断增加的径向排列。

3 结语

过去几年,在CNT增强聚合物纳米复合材料领域取得了长足的进展,大量的新型材料被研制出来,这些材料都有着出色的力学性能。在这些材料中,共价键改性的CNT对于增强聚合物来说是一种极好的添加剂,它可以在CNT与聚合物之间达到优良的应力应变传递。这些改性的关键都是找到一种方法来提高CNT在聚合物中的分散度。尽管有各种各样的方法来实现分散度的提高,但是在提高分散度和改善界面性能方面仍然有许多机遇与挑战。其中一个挑战就是达到CNT的最优改性,这样可以使CNT与聚合物基体之间的界面性质达到最佳,并同时提升CNT的分散度。

在实际应用中,熔融加工是最常用的制备CNT增强聚合物纳米复合材料的方法,而其中的问题仍然需要解决。为了获得最好的性能,选择合适的CNT的改性方法、合适的聚合物基体、适当的加工条件如温度、剪切速率和混合时间等都是十分重要的。总的来说,更好地分散在聚合物中的CNT以及改善它们之间的界面性质是研发出高性能聚合物基复合材料的关键。

[1] Yu M F,Lourie O,Dyer M J,et al.Strength and Breaking Mechanism of Multiwalled Carbon Nanotubes Under Tensile Load[J].Science,2000,5453(287):637-640.

[2] Yu M F,Files B S,Arepalli S,et al.Tensile Loading of Ropes of Single Wall Carbon Nanotubes and Their Mechanical Properties[J].Physical Review Letters,2000,84(24):5552-5555.

[3] Thostenson E T,Ren Z F,Chou T W.Advances in the Science and Technology of Carbon Nanotubes and Their Composites:A Review[J].Composites Science and Technology,2001,61(13):1899-1912.

[4] Baughman R H,Zakhidov A A,Heer W A.Carbon Nanotubes—The Route Toward Applications [J].Science,2002,5582(297):787-792.

[5] Andrews R,Weisenberger M C.Carbon Nanotube Polymer Composites[J].Current Opinion in Solid State and Materials Science,2004,8(1):31-37.

[6] Breuer O,Sundararaj U.Big Returns from Small Fibers:A Review of Polymer/Carbon Nanotube Composites[J].Polymer Composites,2004,25(6):630-645.

[7] Harris P J F.Carbon Nanotube Composites[J].International Materials Reviews,2004,49(1):31-43.

[8] Wang C C,Guo Z X,Fu S K,et al.Polymers Containing Fullerene or Carbon Nanotube Structures[J].Progress in Polymer Science(Oxford),2004,29(11):1079-1141.

[9] Xie X L,Mai Y W,Zhou X P.Dispersion and Alignment of Carbon Nanotubes in Polymer Matrix:A Review [J].Materials Science and Engineering R:Reports,2005,49(4):89.

[10] Coleman J N,Khan U,Blau W J,et al.Small but Strong:A Review of the Mechanical Properties of Carbon Nanotube-polymer Composites [J].Carbon,2006,44(9):1624-1652.

[11] Coleman J N,Khan U,Gun′ko Y K.Mechanical Reinforcement of Polymers Using Carbon Nanotubes [J].Advanced Materials,2006,18(6):689-706.

[12] Moniruzzaman M,Winey K I.Polymer Nanocomposites Containing Carbon Nanotubes [J]. Macromolecules,2006,39(16):5194-5205.

[13] Li C,Thostenson E T,Chou T W.Sensors and Actua-tors Based on Carbon Nanotubes and Their Composites:A Review[J].Composites Science and Technology,2008,68(6):1227-1249.

[14] Endo M,Strano M S,Ajayan P M.Potential Applications of Carbon Nanotubes [J].Topics in Applied Physics,2008,111:13-62.

[15] Velasco-Santos C,Martinez-Hernandez A L,Castano V M.Carbon Nanotube-polymer Nanocomposites:The Role of Interfaces[J].Composite Interfaces,2005,11(8/9):567-586.

[16] Cadek M,Coleman J N,Barron V,et al.Morphological and Mechanical Properties of Carbon-nanotube-reinforced Semicrystalline and Amorphous Polymer Composites[J].Applied Physics Letters,2002,81(27):5123-5125.

[17] Sandler J K W,Pegel S,Cadek M,et al.A Comparative Study of Melt Spun Polyamide-12Fibres Reinforced with Carbon Nanotubes and Nanofibres[J].Polymer,2004,45(6):2001-2015.

[18] Coleman J N,Cadek M,Blake R,et al.High-performance Nanotube-reinforced Plastics:Understanding the Mechanism of Strength Increase [J].Advanced Functional Materials,2004,14(8):791-798.

[19] Dalmas F,Chazeau L,Gauthier C,et al.Multiwalled Carbon Nanotube/Polymer Nanocomposites:Processing and Properties[J].Journal of Polymer Science,Part B:Polymer Physics,2005,43(10):1186-1197.

[20] Dufresne A,Paillet M,Putaux J L,et al.Processing and Characterization of Carbon Nanotube/Poly(styreneco-butyl acrylate)Nanocomposites[J].Journal of Materials Science,2002,37(18):3915-3923.

[21] Kilbride B E,Coleman J N,Fraysse J,et al.Experimental Observation of Scaling Laws for Alternating Current and Direct Current Conductivity in Polymer-carbon Nanotube Composite Thin Films[J].Journal of Applied Physics,2002,92(7):4024-4030.

[22] Mc Carthy B,Coleman J N,Czerw R,et al.A Microscopic and Spectroscopic Study of Interactions Between Carbon Nanotubes and a Conjugated Polymer[J].Journal of Physical Chemistry B,2002,106(9):2210-2216.

[23] Singh P,Campidelli S,Giordani S,et al.Organic Functionalisation and Characterisation of Single-walled Carbon Nanotubes[J].Chemical Society Reviews,2009,38(8):2214-2230.

[24] Park H,Zhao J,Lu J P.Effects of Sidewall Functionalization on Conducting Properties of Single Wall Carbon Nanotubes[J].Nano Letters,2006,6(5):916-919.

[25] Liu J,Rinzler A G,Dai H,et al.Fullerene Pipes[J].Science,1998,5367(280):1253-1256.

[26] Zhang X,Sreekumar T V,Liu T,et al.Properties and Structure of Nitric Acid Oxidized Single Wall Carbon Nanotube Films[J].Journal of Physical Chemistry B,2004,108(42):16435-16440.

[27] Cho J W,Kim J W,Jung Y C,et al.Electroactive Shape-memory Polyurethane Composites Incorporating Carbon Nanotubes[J].Macromolecular Rapid Communications,2005,26(5):412-416.

[28] Zhang Y,Shi Z,Gu Z,et al.Structure Modification of Single-wall Carbon Nanotubes [J].Carbon,2000,38(15):2055-2059.

[29] Georgakilas V,Kordatos K,Prato M,et al.Organic Functionalization of Carbon Nanotubes [J].Journal of the American Chemical Society,2002,124(5):760-761.

[30] Hemon M A,Chen J,Hu H,et al.Dissolution of Single-walled Carbon Nanotubes[J].Advanced Materials,1999,11(10):834-840.

[31] Chen J,Hamon M A,Hu H,et al.Solution Properties of Single-walled Carbon Nanotubes[J].Science,1998,5386(282):95-98.

[32] Chen J,Rao A M,Lyuksyutov S,et al.Dissolution of Full-length Single-walled Carbon Nanotubes[J].Journal of Physical Chemistry B,2001,105(13):2525-2528.

[33] Niyogi S,Hamon M A,Hu H,et al.Chemistry of Single-walled Carbon Nanotubes[J].Accounts of Chemical Research,2002,35(12):1105-1113.

[34] Zhou O,Fleming R M,Murphy D W,et al.Defects in Carbon Nanostructures[J].Science,1994,5154(263):1744-1747.

[35] Mickelson E T,Huffman C B,Rinzler A G,et al.Fluorination of Single-wall Carbon Nanotubes [J].Chemical Physics Letters,1998,296(1/2):188-194.

[36] Mickelson E T,Chiang I W,Zimmerman J L,et al.Solvation of Fluorinated Single-wall Carbon Nanotubes in Alcohol Solvents[J].Journal of Physical Chemistry B,1999,103(21):4318-4322.

[37] Kelly K F,Chiang I W,Mickelson E T,et al.Insight into the Mechanism of Sidewall Functionalization of Single-walled Nanotubes:an STM Study [J].Chemical Physics Letters,1999,313(3/4):445-450.

[38] Boul P J,Liu J,Mickelson E T,et al.Reversible Sidewall Functionalization of Buckytubes [J].Chemical Physics Letters,1999,310(3/4):367-372.

[39] Bahr J L,Mickelson E T,Bronikowski M J,et al.Dissolution of Small Diameter Single-wall Carbon Nanotubes in Organic Solvents [J].Chemical Communications,2001,(2):193-194.

[40] Holzinger M,Vostrowsky O,Hirsch A,et al.Sidewall Functionalization of Carbon Nanotubes[J].Angewandte Chemie—International Edition,2001,40 (21):4002-4005.

[41] Bahr J L,Yang J,Kosynkin D V,et al.Functionalization of Carbon Nanotubes by Electrochemical Reduction of Aryl Diazonium Salts:a Bucky Paper Electrode [J].Journal of the American Chemical Society,2001,123(27):6536-6542.

[42] Bahr J L,Tour J M. Highly Functionalized Carbon Nanotubes Using In-situ Generated Diazonium Compounds[J].Chemistry of Materials,2001,13 (11):3823-3824.

[43] Paredes J I,Burghard M.Dispersions of Individual Single-walled Carbon Nanotubes of High Length[J].Langmuir,2004,20(12):5149-5152.

[44] Duesberg G S,Muster J,Krstic V,et al.Chromatographic Size Separation of Single-wall Carbon Nanotubes[J].Applied Physics A:Materials Science and Processing,1998,67(1):117-119.

[45] Moore V C,Strano M S,Haroz E H,et al.Individually Suspended Single-walled Carbon Nanotubes in Various Surfactants[J].Nano Letters,2003,3 (10):1379-1382.

[46] Islam M F,Rojas E,Bergey D M,et al.High Weight Fraction Surfactant Solubilization of Single-wall Carbon Nanotubes in Water[J].Nano Letters,2003,3 (2):269-273.

[47] Yurekli K,Mitchell C A,Krishnamootri R.Small Angle Neutron Scattering from Surfactant Assisted Aqueous Dispersion of Carbon Nanotubes[J].Journal of the A-merican Chemical Society,2004,126(32):9902-9903.

[48] Jiang L,Gao L,Sun J.Production of Aqueous Colloidal Dispersions of Carbon Nanotubes[J].Journal of Colloid and Interface Science,2003,260(1):89-94.

[49] Poulin P,Vigolo B,Launois P.Films and Fibers of Oriented Single Wall Nanotubes [J].Carbon,2002,40(10):1741-1749.

[50] Safar G A M,Ribeiro H B,Malard L M,et al.Optical Study of Porphyrin-doped Carbon Nanotubes [J].Chemical Physics Letters,2008,462(1/3):109-111.

[51] Tan Y,Resasco D E.Dispersion of Single-walled Carbon Nanotubes of Narrow Diameter Distribution[J].Journal of Physical Chemistry B,2005,109(30):14454-14460.

[52] Guo Z,Sadler P J,Tsang S C.Immobilization and Visualization of DNA and Proteins on Carbon Nanotubes[J].Advanced Materials,1998,10(9):701-703.

[53] Chen R J,Zhang Y,Wang D,et al.Noncovalent Sidewall Functionalization of Single-walled Carbon Nanotubes for Protein Immobilization[J].Journal of the American Chemical Society,2001,123(16):3838-3839.

[54] Lordi V,Yao N.Molecular Mechanics of Binding in Car-bon Nanotube-polymer Composites[J].Journal of Materials Research,2000,15(12):2770-2779.

[55] O′Connell M J,Boul P,Ericson L M,et al.Reversible Water-solubilization of Single-walled Carbon Nanotubes by Polymer Wrapping [J].Chemical Physics Letters,2001,342(3/4):265-271.

[56] Steuerman D W,Star A,Narizzano R,et al.Interactions Between Conjugated Polymers and Single-walled Carbon Nanotubes[J].Journal of Physical Chemistry B,2002,106(12):3124-3130.

[57] Star A,Stoddart J F,Steuerman D,et al.Preparation and Properties of Polymer-wrapped Single-walled Carbon Nanotubes[J].Angewandte Chemie-International Edition,2001,40(9):1721-1725.

[58] Cheng F,Imin P,Maunders C,et al.Soluble,Discrete Supramolecular Complexes of Single-walled Carbon Nanotubes with Fluorene-based Conjugated Polymers[J].Macromolecules,2008,41(7):2304-2308.

[59] Yang L,Zhang B,Liang Y,et al.In Situ Synthesis of Amylose/Single-walled Carbon Nanotubes Supramolecular Assembly [J].Carbohydrate Research,2008,343(14):2463-2467.

[60] Ogoshi T,Yamagishi T A,Nakamoto Y.Supramolecular Single-walled Carbon Nanotubes(SWCNTs)Network Polymer Made by Hybrids of SWCNTs and Water-soluble Calix[8]Arenas [J].Chemical Communications,2007,(45):4776-4778.

[61] Curran S A,Ajayan P M,Blau W J,et al.A Composite from Poly(m-phenylenevinylene-co-2,5-dioctoxy-p-phenylenevinylene)and Carbon Nanotubes:a Novel Material for Molecular Optoelectronics[J].Advanced Materials,1998,10(14):1091-1093.

[62] Coleman J N,Dalton A B,Curran S,et al.Phase Separation of Carbon Nanotubes and Turbostratic Graphite U-sing a Functional Organic Polymer[J].Advanced Materials,2000,12(3):213-216.

[63] Mc Carthy B,Coleman J N,Czerw R,et al.Microscopy Studies of Nanotube-conjugated Polymer Interactions[J].Synthetic Metals,2001,121(1/3):1225-1226.

[64] Dalton A B,Stephan C,Coleman C S J N,et al.Selective Interaction of a Semiconjugated Organic Polymer with Single-wall Nanotubes [J].Journal of Physical Chemistry B,2000,104(43):10012-10016.

[65] Sahoo N G,Jung Y C,So H H,et al.Synthesis of Polyurethane Nanocomposites of Functionalized Carbon Nanotubes by In-situ Polymerization Methods[J].Journal of the Korean Physical Society,2007,51(S1):1-6.

[66] Potschke P,Haussler L,Pegel S,et al.Thermoplastic Polyurethane Filled with Carbon Nanotubes for Electrical Dissipative and Conductive Applications[J].KGK Kautschuk Gummi Kunststoffe,2007,60(9):432-437.

[67] Lee C H,Liu J Y,Chen S L,et al.Miscibility and Properties of Acid-treated Multi-walled Carbon Nanotubes/Polyurethane Nanocomposites[J].Polymer Journal,2007,39(2):138-146.

[68] Koerner H,Liu W,Alexander M,et al.Deformationmorphology Correlations in Electrically Conductive Carbon Nanotube-thermoplastic Polyurethane Nanocomposites[J].Polymer,2005,46(12):4405-4420.

[69] Ryszkowska J,Jurczyk-Kowalska M,Szymborski T,et al.Dispersion of Carbon Nanotubes in Polyurethane matrix[J].Physica E:Low-Dimensional Systems and Nanostructures,2007,39(1):124-127.

[70] Meng Q,Hu J,Zhu Y.Shape-memory Polyurethane/Multiwalled Carbon Nanotube Fibers[J].Journal of Applied Polymer Science,2007,106(2):837-848.

[71] Chen X H,Chen X J,Lin M,et al.Functionalized Multi-walled Carbon Nanotubes Prepared by In Situ Polycondensation of Polyurethane [J].Macromolecular Chemistry and Physics,2007,208(9):964-972.

[72] Xiong J W,Zheng Z,Qin X,et al.The Thermal and Mechanical Properties of a Polyurethane/Multi-walled Carbon Nanotube Composite [J].Carbon,2006,44(13):2701-2707.

[73] Kwon J Y,Kim H D.Preparation and Properties of Acid-treated Multiwalled Carbon Nanotube/Waterborne Polyurethane Nanocomposites [J].Journal of Applied Polymer Science,2005,96(2):595-604.

[74] Sahoo N G,Jung Y C,Cho J W.Electroactive Shape Memory Effect of Polyurethane Composites Filled with Carbon Nanotubes and Conducting Polymer [J].Materials and Manufacturing Processes,2007,22(4):419-423.

[75] Buffa F,Abraham G A,Grady B P,et al.Effect of Nanotube Functionalization on the Properties of Singlewalled Carbon Nanotube/Polyurethane Composites [J].Journal of Polymer Science,Part B:Polymer Physics,2007,45 (4):490-501.

[76] He H,Zhang Y,Gao C,et al.Clicked Magnetic Nanohybrids with a Soft Polymer Interlayer [J].Chemical Communications,2009,(13):1655-1657.

[77] Wang T L,Tseng C G.Polymeric Carbon Nanocomposites from Multiwalled Carbon Nanotubes Functionalized with Segmented Polyurethane [J].Journal of Applied Polymer Science,2007,105(3):1642-1650.

[78] Sen R,Zhao B,Perea D,et al.Preparation of Single Walled Carbon Nanotube Reinforced Polystyrene and Polyurethane Nanofibers and Membranes by Electrospinning[J].Nano Letters,2004,4(3):459-464.

[79] Mc Clory C,Mc Nally T,Brennan G P,et al.Thermosetting Polyurethane Multiwalled Carbon Nanotube Composites[J].Journal of Applied Polymer Science,2007,105(3):1003-1011.

[80] Kuan H C,Ma C C M,Chang W P,et al.Synthesis,Thermal,Mechanical and Rheological Properties of Multiwall Carbon Nanotube/Waterborne Polyurethane Nanocomposite [J].Composites Science and Technology,2005,65(11/12):1703-1710.

[81] Kwon J,Kim H.Comparison of the Properties of Waterborne Polyurethane/Multiwalled Carbon Nanotube and Acid-treated Multiwalled Carbon Nanotube Composites Prepared by In Situ Polymerization[J].Journal of Polymer Science,Part A:Polymer Chemistry,2005,43(17):3973-3985.

[82] Kwon J Y,Kim H D.Preparation and Properties of Acid-treated Multiwalled Carbon Nanotube/Waterborne Polyurethane Nanocomposites [J].Journal of Applied Polymer Science,2005,96(2):595-604.

[83] Guo S Z,Zhang C,Wang W Z,et al.Preparation and Characterization of Polyurethane/Multiwalled Carbon Nanotube Composites[J].Polymers and Polymer Composites,2008,16(8):501-507.

[84] Sahoo N G,Jung Y C,So H H,et al.Synthesis of Polyurethane Nanocomposites of Functionalized Carbon Nanotubes by In-situ Polymerization Methods[J].Journal of the Korean Physical Society,2007,51(S1):1-6.

[85] Sahoo N G,Jung Y C,Yoo H J,et al.Effect of Functionalized Carbon Nanotubes on Molecular Interaction and Properties of Polyurethane Composites[J].Macromolecular Chemistry and Physics,2006,207(19):1773-1780.

[86] Sahoo N G,Jung Y C,Yoo H J,et al.Influence of Carbon Nanotubes and Polypyrrole on the Thermal,Mechanical and Electroactive Shape-memory Properties of Polyurethane Nanocomposites [J].Composites Science and Technology,2007,67(9):1920-1929.

[87] Xia H,Song M,Jin J,et al.Poly(propylene glycol)-grafted Multi-walled Carbon Nanotube Polyurethane[J].Macromolecular Chemistry and Physics,2006,207(21):1945-1952.

[88] Yuen S M,Ma C C M,Chiang C L,et al.Preparation and Morphological,Electrical,and Mechanical Properties of Polyimide-grafted MWCNT/Polyimide Composite[J].Journal of Polymer Science,Part A:Polymer Chemistry,2007,45(15):3349-3358.

[89] Ounaies Z,Park C,Wise K E,et al.Electrical Properties of Single Wall Carbon Nanotube Reinforced Polyimide Composites[J].Composites Science and Technolo-gy,2003,63(11):1637-1646.

[90] Yu A,Hu H,Bekyarova E,et al.Incorporation of Highly Dispersed Single-walled Carbon Nanotubes in a Polyimide Matrix[J].Composites Science and Technology,2006,66(9):1187-1194.

[91] So H H,Cho J W,Sahoo N G.Effect of Carbon Nanotubes on Mechanical and Electrical Properties of Polyimide/Carbon Nanotubes Nanocomposites[J].European Polymer Journal,2007,43(9):3750-3756.

[92] Zhu B K,Xie S H,Xu Z K,et al.Preparation and Properties of the Polyimide/Multi-walled Carbon Nanotubes Nanocomposites[J].Composites Science and Technology,2006,66(3/4):548-554.

[93] Chou W J,Wang C C,Chen C Y.Characteristics of Polyimide-based Nanocomposites Containing Plasmamodified Multi-walled Carbon Nanotubes [J].Composites Science and Technology,2008,68 (10/11):2208-2213.

[94] Yuen S M,Ma C H M,Chiang C L,et al.Poly(vinyltriethoxysilane)Modified MWCNT/Polyimide Nanocom-posites—Preparation,Morphological,Mechanical,and Electrical Properties [J].Journal of Polymer Science,Part A:Polymer Chemistry,2008,46(3):803-816.

[95] Yuen S M,Ma C C M,Lin Y Y,et al.Preparation,Morphology and Properties of Acid and Amine Modified Multiwalled Carbon Nanotube/Polyimide Composite[J].Composites Science and Technology,2007,67(11/12):2564-2573.

[96] Siochi E J,Working D C,Park C,et al.Melt Processing of SWNT-polyimide Nanocomposite Fibres[J].Composites Part B:Engineering,2004,35(5):439-446.

[97] Jiang X,Bin Y,Matsuo M.Electrical and Mechanical Properties of Polyimide-carbon Nanotubes Composites Fabricated by In Situ Polymerization [J].Polymer,2005,46(18):7418-7424.

[98] Ogasawara T,Ishida Y,Ishikawa T,et al.Characterization of Multi-walled Carbon Nanotube/Phenylethynyl Terminated Polyimide Composites[J].Composites Part A:Applied Science and Manufacturing,2004,35(1):67-74.

Research Progress in Carbon Nanotubes Reinforced Polymer Nanocomposites

XIN Fei,XU Guozhi*

(School of Materials and Mechanical Engineering,Beijing Technology and Business University,Beijing 100048,China)

In this article,the recent progress in mechanical properties of carbon nanotubes(CNT)reinforced polymer composites was reviewed,with particular attention to polyurethane and polyimide based composites.Various functionalization methods in the modification of CNT were discussed,and the effectiveness of different processing techniques were compared.Finally,a future outlook for the development of CNT reinforced polymer composites was given.

polymer;carbon nanotube;composite;research progress

TQ322.3

A

1001-9278(2011)08-0001-09

2011-04-12

北京市属高等学校人才强教计划资助项目(PHR200907108)

*联系人,xgzhi@btbu.edu.cn