无传统模具的混凝土制造的愿景

无传统模具的混凝土制造的愿景

Vision of Concrete Fabrication Without Conventional Moulds

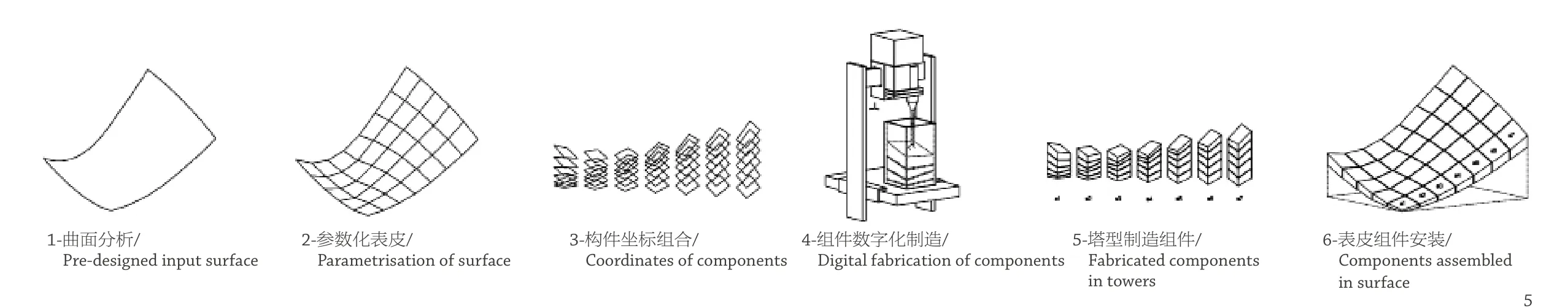

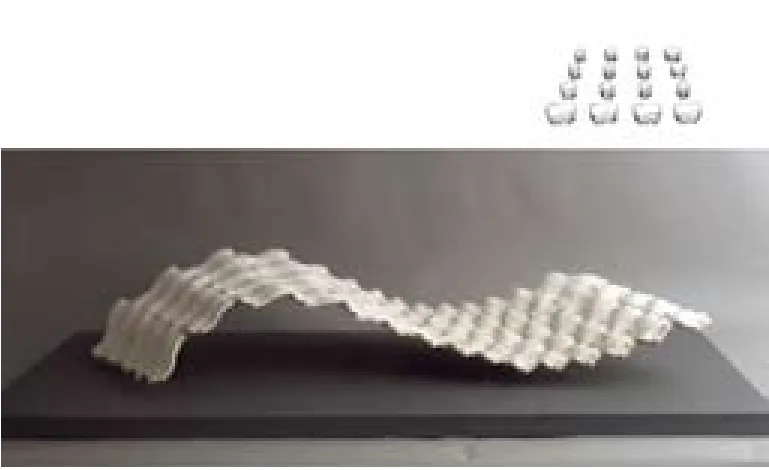

再投铸造、高效和可持续性制造工艺专注于开发智能而简单的设计和预制几何形状复杂的建筑构件的方法,这种方法节约资源,且大大减少了建筑垃圾。在现代建筑中,复杂几何形状的构件用于混凝土或砂浆建筑维护结构、隔断墙、水平和垂直遮阳元件和人行道的建设。在现有方法下,3个维度都弯曲的建筑构件只能通过采用复杂的模板和高度工业化的预制技术来生产,成本很高。前述的再投铸造方法采用参数化系统,用数学算法将三维构件细分为能够堆放到塔里的更小部件。此外,用前面的元件模制后续元件的形状。这种CNC控制的制造方法依赖于采用数字制造技术铸造愿景的连续工艺流程。然后,将这些构件的塔架运到现场,一一分离,再组装成所需的空间形状。

设计团队/Design Team: Povilas Cepaitis, Lluis Enrique Monzo, Diego Ordoñez, Carlos Piles/AA School of Architecture

Cast on Cast, efficient and sustainable fabrication process is focused upon the development of a smart but simple methodology to design and prefabricate building elements with complex geometries, which is resource efficient and considerably reduces construction waste. Complex geometries are utilized in contemporary architecture for the construction of concrete or mortar building envelopes, partition walls, horizontal and vertical shading elements and pavements. Building elements that are curved through all three dimensions can only be produced under current methods by using sophisticated formwork installations and highly industrialized prefabrication technologies at high cost. Te proposed Cast on Cast methodology uses a parameterization system in which mathematical algorithms subdivide three dimensional elements into smaller components that can be stacked in towers. Furthermore, the previous element is used to mold the shape of the subsequent element. Tis CNC controlled fabrication method relies on the consecutive process of casting elements using digital fabrication technology. Tese towers of elements are then transported to the site where they are detached and assembled into the desired spatial shape.

4 浇筑层相叠加形成的塔型/Cast on cast components fabricated in towers

5 浇筑层叠加过程/Cast on cast process

6 a-b-b-c逻辑/a-b-b-c logic

7 角度逻辑/Angle logic

8 六角形逻辑/Hexagon logic