Numericalinvestigation of unsteady mixing mechanism in plate film cooling

Shuai Li,Zongjing Yuan,Gang Chen∗State Key Laboratory for Strength and Vibration ofMechanicalStructures,School of Aerospace,Xi'an Jiaotong University,Xi'an 710049,China Shaanxi Province Key Laboratory for Service Environment and Controlof Advanced Aircraft,Xi'an Jiaotong University,Xi'an 710049,China

Letter

Numericalinvestigation of unsteady mixing mechanism in plate film cooling

Shuai Li,Zongjing Yuan,Gang Chen∗

State Key Laboratory for Strength and Vibration ofMechanicalStructures,School of Aerospace,Xi'an Jiaotong University,Xi'an 710049,China Shaanxi Province Key Laboratory for Service Environment and Controlof Advanced Aircraft,Xi'an Jiaotong University,Xi'an 710049,China

H I G H L I G H T S

.Under the unsteady flow dynamics,the details of the flow and heat-transfer characteristics are obtained by large eddy simulation.

.Investigation ofthe law ofmutualinterference between gas films in parallelholes.

A R T I C L E I N F O

Article history:

Received 30 May 2016

Received in revised form

24 July 2016

Accepted 7 August 2016

Available online 24 August2016

2)采用EDEM离散元软件建立除尘截割头仿真模型,进行工作过程仿真模拟,其中孔径为25 mm的方案3除尘效果最佳,除尘率为90%,由此确定最佳吸尘效果的孔径尺寸为25 mm。

Mixing mechanism Anti-symmetric vortices Mutualinterference Film cooling Large eddy simulation

A large-scale large eddy simulation in high performance personal computer clusters is carried out to present unsteady mixing mechanism of film cooling and the development of films.Simulation cases include a single-hole plate with the inclined angle of30°and blowing ratio of0.5,and a single-row plate with hole-spacing of 1.5D and 2D(diameters of the hole).According to the massive simulation results, some new unsteady phenomena ofgas films are found.The vortex system is changed in differentposition with the development of film cooling with the time marching the process of a single-row plate film cooling.Due to the mutualinterference effects including mutualexclusion,a certain periodic sloshing and mutual fusion,and the structures of a variety of vortices change between parallel gas films.Macroscopic flow structures and heat transfer behaviors are obtained based on 20 million grids and Reynolds number of 28600.

©2016 The Authors.Published by Elsevier Ltd on behalf of The Chinese Society of Theoretical and Applied Mechanics.This is an open access article under the CC BY-NC-ND license(http:// creativecommons.org/licenses/by-nc-nd/4.0/).

With the development of the aeronautic industry,the military fighters in the pursuit of high speed and high mobility performance,or large civilaircraft pursues the great capacity,higher demands of high performance aero-engine are urgently proposed. Turbine blades are one of the most important components of the aircraft aero-engine,which works at the very extreme conditions such as the high temperature,high speeds,and high pressure loads. The increase ofaero-engine thrust mainly depends on the increase of the turbine inlet temperature.This means that the cooling of a turbine blade becomes the first priority in a high-performance gas turbine engine.The inlet temperature ofcurrent advanced gas turbine engine has reached about 2200 K,in which the 400 K more than the melting point of metalmaterials of turbine blades.So the advanced turbine blade cooling design becomes one of the most important and urgent key technologies,such as the film cooling in Fig.1[1].There are many open small holes in blade surfaces and when the cool medium is injected into the mainstream with high temperature,the cold air filmexists on the surface ofblades to protect the materials.

The ideas of the film cooling technology begin in the 1870s. The research in film cooling of the flow and heat transfer is mainly divided into two aspects:one is committed to the mixing mechanism of gas film cooling,and the other focuses on the gas film cooling performance for complex models.For the mixing mechanism of the gas film cooling,new simulation methods, and the influence factors of gas film cooling are the main two key issues.Ongoing theoretical exploration and the theory of calculation methods both make great foundation for the research of the gas filmcooling mixing mechanism.Liu et al.[2]put forward a new calculation model(turbulent Prandtl number distribution model)to improve the accuracy of gas film cooling calculation. Meanwhile,Lee and Kim[3]put forward a kind ofspecialmethods for optimization design of fan hole plate final cooling.Völker and Zehe[4]set up a method to forecast flow field and temperature field in cold flow pipe,according to correlation design of different aerodynamic parameters,which is a part of film cooling.These investigations lie mainly in the micro structure of the flow field.However,there are many factors that can affect the film cooling performance as follows:

Fig.1.(Color online)Heat transfer coefficient distribution of turbine blade with film cooling by numericalsimulations[1].

(1)The geometric parameters of the gas film hole,such as the size of injection angle,aperture,length,aperture ratio,hole spacing,the number of rows,and the shape of the hole.(2)The aerodynamic parameters of hole,such as the mainstream speed,blowing ratio,momentum ratio ofcold air from the mainstream,development situation of mainstreamturbulence boundary layer before the gas filmholes,pressure gradient,etc.Nemdiliet al.[5]and Guo etal.[6]focus on the influence ofthe geometric parameters ofthe gas film hole(jet angle,the shape of the hole,hole spacing,etc.) on the mixing mechanism of film cooling.Jovanovićet al.[7]and Duggleby et al.[8]focus on aerodynamic parameters ofthe gas film hole(blowing ratio,momentum ratio,density ratio,development ofmainstream turbulence boundary layer before the gas film hole, etc.)Suryanarayanan et al.[9]and Zhou et al.[10]using the experimentaltechnology,study the influence ofblowing ratio on the turbine blade film cooling efficiency.Li et al.[11]study the film cooling efficiency of rotating blade.

Experimental research is mainly used for gas film cooling of complex models.However the obtained experiment results are limited by experimentalconditions which cannot completely provide all the accurate reference data for turbine blade film cooling design.Owning to the rapid development of the large-scaled supercomputer,the detail data of flow field and the heat transfer in film cooling can be obtained in larger-scale simulation, which can provide a basic guidance to the optimization design of blade cooling structure geometry parameters.Shangguan etal.[12] present many detail data based on hybrid thermal lattice Boltzmann method with a grid of 200 million on a GPU-cluster for the unsteady mixing mechanismofthe plate filmcooling,which is very important to high efficient film cooling design for blades.However for the limitations of the lattice Boltzmann method(LBM),the numericalReynolds number is justabout 5000 even with 200 million grids.In this paper,based on the large eddy simulation(LES)for unsteady Navier-Stokes equation the unsteady mixing mechanism of plate film cooling on Reynolds number of 28600,which is very near to the real blade conditions,will be carried on to investigate the laws ofunsteady mixing mechanism.

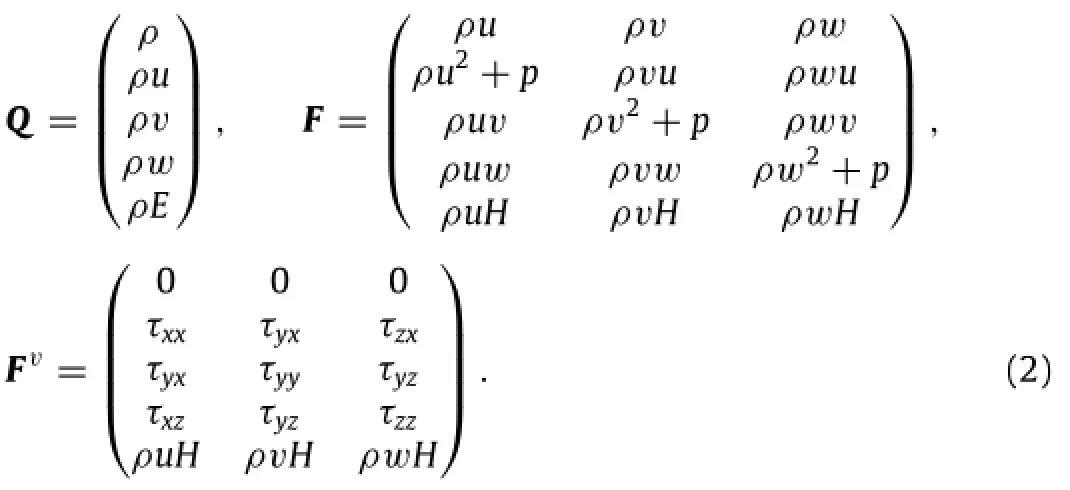

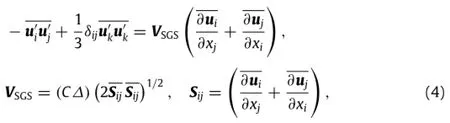

The unsteady flow and heat transfer of the gas film cooling is simulated by LES method.The three dimensional unsteady governing Navier-Stokes equation in the conservation form is as follows

Fig.2.Experimental model.

Fig.3.Diagrammatic drawing ofmodelabout data extraction.(For interpretation of the references to colour in this figure legend,the reader is referred to the web version ofthis article.)

Table 1 Detail data of the experimental model.

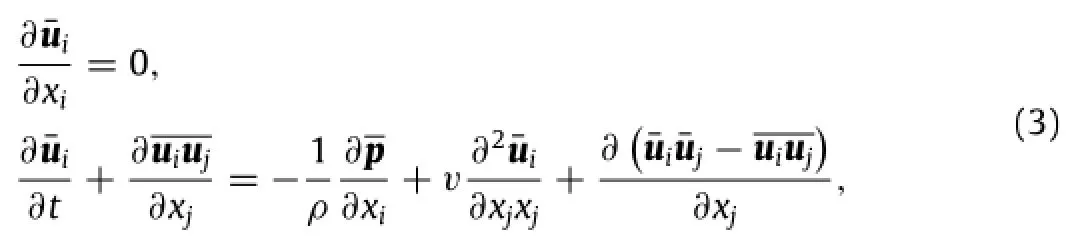

The momentum equation deals with a filtering function and then the two filter equations were obtained:

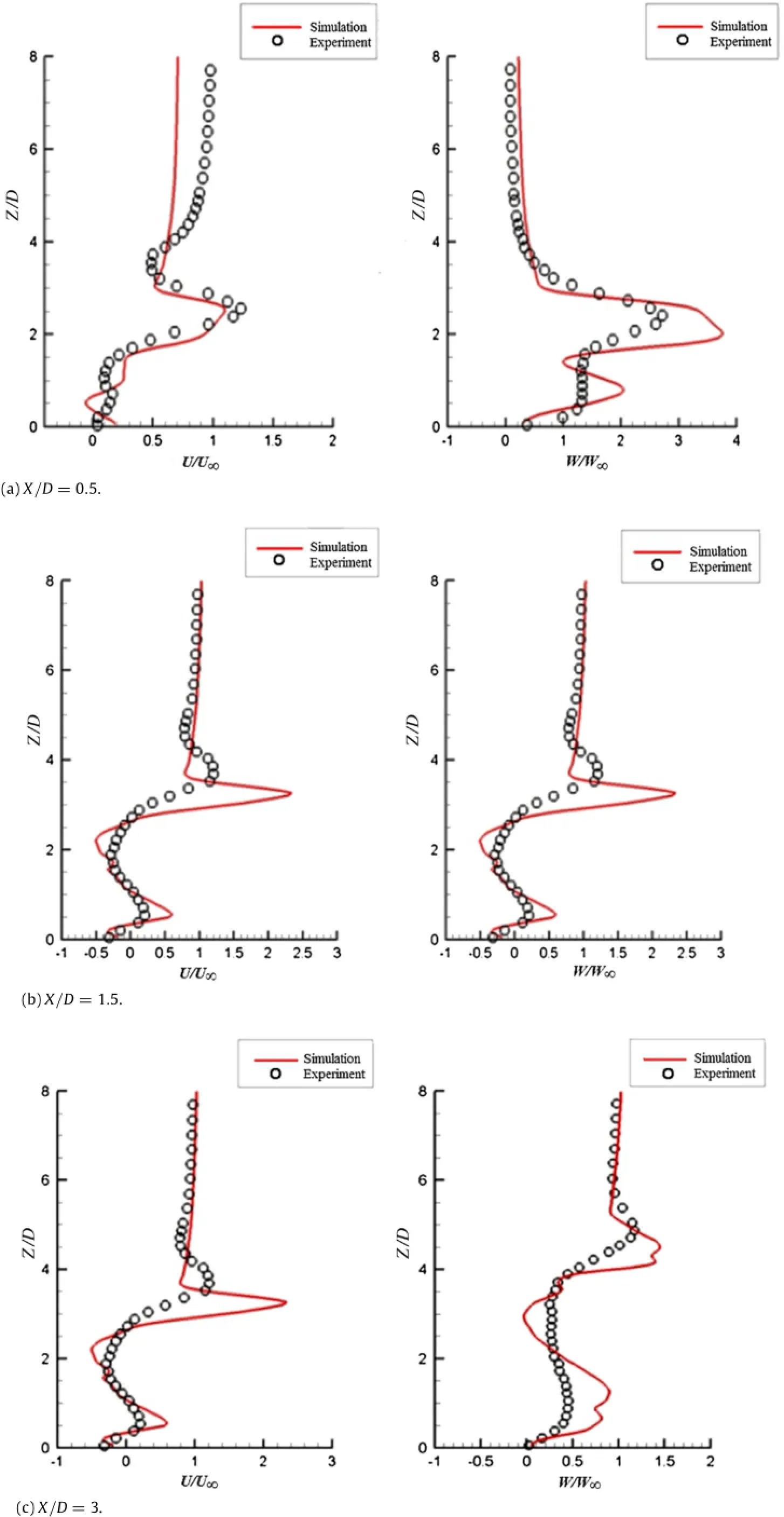

Fig.4.Results ofnumericalvalidation:speed ratio in flow direction and normaldirection.

Fig.5.Computationalmodel.

where C is the modelconstantsetto a value of0.15 in presentstudy and∆is the representative elementdimension which is calculated from the volume of each finite element.

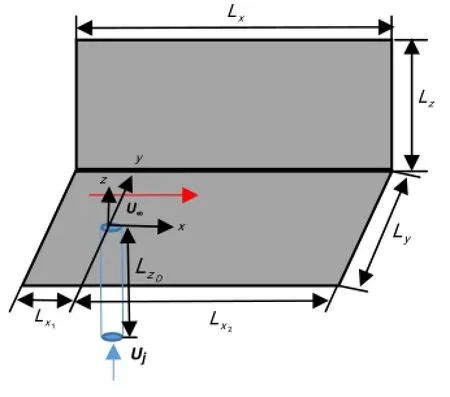

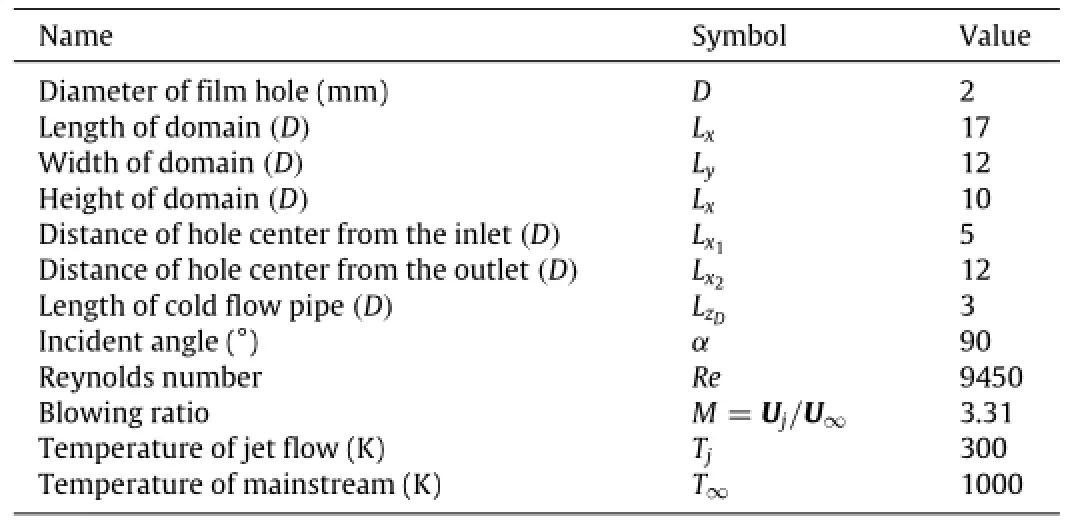

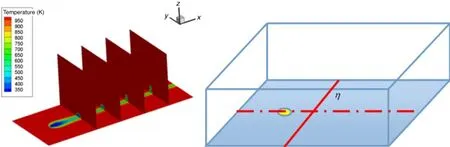

In order to validate the LES simulation method for plate film cooling,the experimental model[13]is presented as in Fig.2.The detail data[13]of the modelis shown in Table 1.

To verify the accuracy ofthe numericalsimulation,the numerical data(speed ratio of flowing velocity with the mainstream in center line)is compared with the experiment data.The situation of the data extraction is shown as the red line in Fig.3.W and U are the flow directions.The comparison between the experiment and numerical simulation is shown in Fig.4.The data is chosen from the distance far from the hole,such as X/D=0.5,1.5,and 3,respectively.Itis obvious thatvariation trend ofnumericalpredicted speed ratio data and experimentaldata agrees well.Following the results of the numerical validation,the error of comparison between experiment and numerical simulations is little.Taking into account the experimental system error and calculation error,the simulation ofplate film cooling by LES method is good enough for unsteady mixing mechanism analysis.

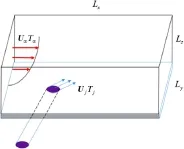

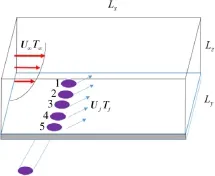

Under the inclined angle of 30°and blowing ratio of 0.5, the change law of mixing mechanism with different time is discussed.The fluid is models as incompressible air.The lengths of computational domain in three different coordinates are Lx,Ly, and Lz,such as Fig.5.A uniform velocity U∞is given atthe inlet of hot air and the temperature of hot air is T∞.No-slip adiabatic wall is prescribed at the body surface.The meshes near the holes are refined in order to keep the nondimensional walldistance Y+less than 1.The LES computations involve the grids of 21.8 million with 368X256 X232 in the three directions.The coordinate ofthe holesisReynolds number is Model parameters are.Blowing ratio is M=0.5.The mainstream temperature isand the cool flow temperatureCooling efficiency of adiabatic wallis

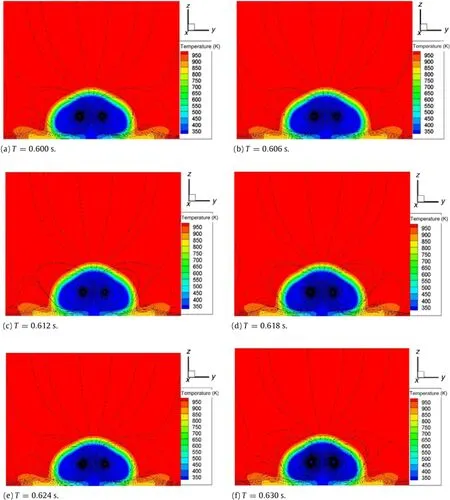

According to the flow field and cooling efficiency vary as time going on,the mixing mechanism as the film going on can be achieved.The results of three cross sections are chosen as shown in Fig.6.On this cross section,anti-symmetric vortices are stable at different time in Fig.7.The cooling efficiency remains the same in Fig.8.The film stays in the stable stage,when the film has just started.The film is carried by anti-symmetric vortices close to the wall.The generation of this phenomenon is due to the high intensity of jet flow.At the beginning of gas film,the normal shear is strong,so the anti-symmetric vortices formed by shear stress of impacting from jetflow are stable.

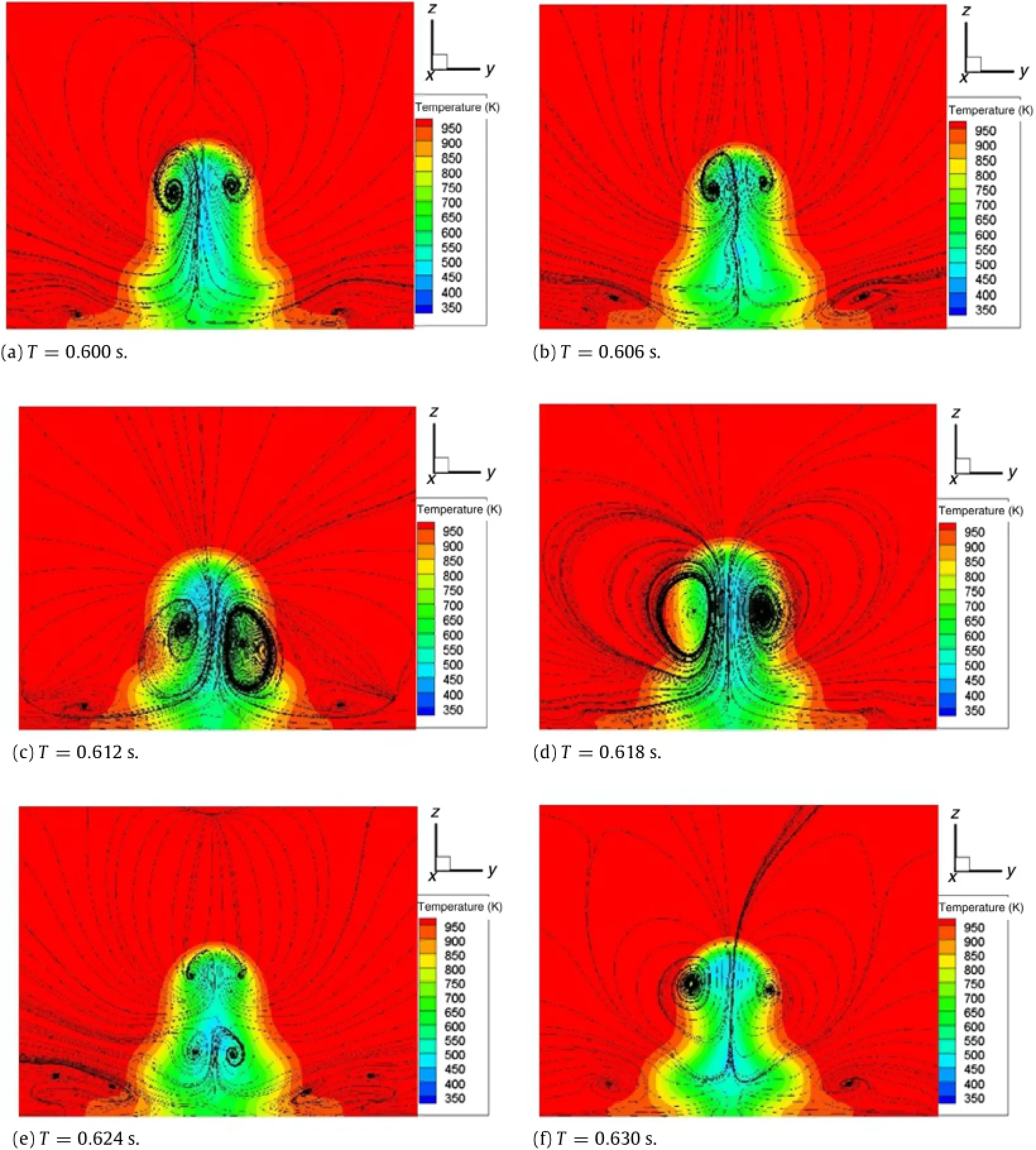

On the cross section of X/D =15,anti-symmetric vortices are elevated in Fig.9 compared with that in Fig.7.The secondary vortex and the horseshoe vortex are found obviously in the six snapshots in Fig.9.But in Fig.10,the cooling efficiency is almost keeping the same relatively.It is concluded that the gas filmbegins to appear unstable as anti-symmetric vortices rising far from the wall.Meanwhile the change of the flow field is not enough to change the temperature of the wall.Then the film stays in mix stage.The generation of this phenomenon is because of cooler mixed fluid is carried close to the wall by secondary vortex and the horseshoe vortex,when anti-symmetric vortices rise.At the middle process of gas film,the normalshear is wear,so the antisymmetric vortices formed by shear stress of impacting from jet flow are mainly impacted by mainstream.

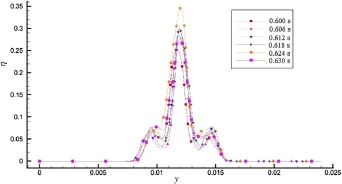

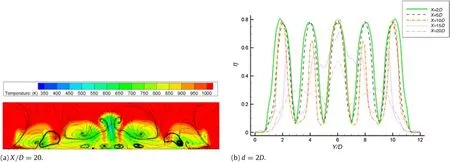

On the cross section of X/D=20,the anti-symmetric vortices are asymmetric no longer as shown in Fig.11.Also the cooling efficiency occurs periodic exhibition to swing as shown in Fig.12. At the position far away from the inclined hole,anti-symmetric vortices rise far from the wall,when the mainstream permeates the bottom of them.Because of the energy of film is weak,the anti-symmetric vortices slosh in the mainstream,affected by the infiltration action.So the film carried by anti-symmetric vortices stays in the dissipation stage.

Above all,in the process of generation and development of the gas film,the characteristics of different stages are mainly determined by the performance of anti-symmetric vortices,which affected the structure ofthe gas film.Meanwhile,the anti-symmetric vortices are affected by the shear stress of jet flow at the beginning and affected by infiltrationaction with the developmentofthe film.

Computational domain of a single-row plate is the same as a single-hole plate.The arrangement offive holes is shown in Fig.13, and the serial number of the middle hole is 3.Parameters are the same as a single-hole plate,while hole spacing is d=1.5D and d=2D.

Fig.6.(Color online)Cross section drawing.

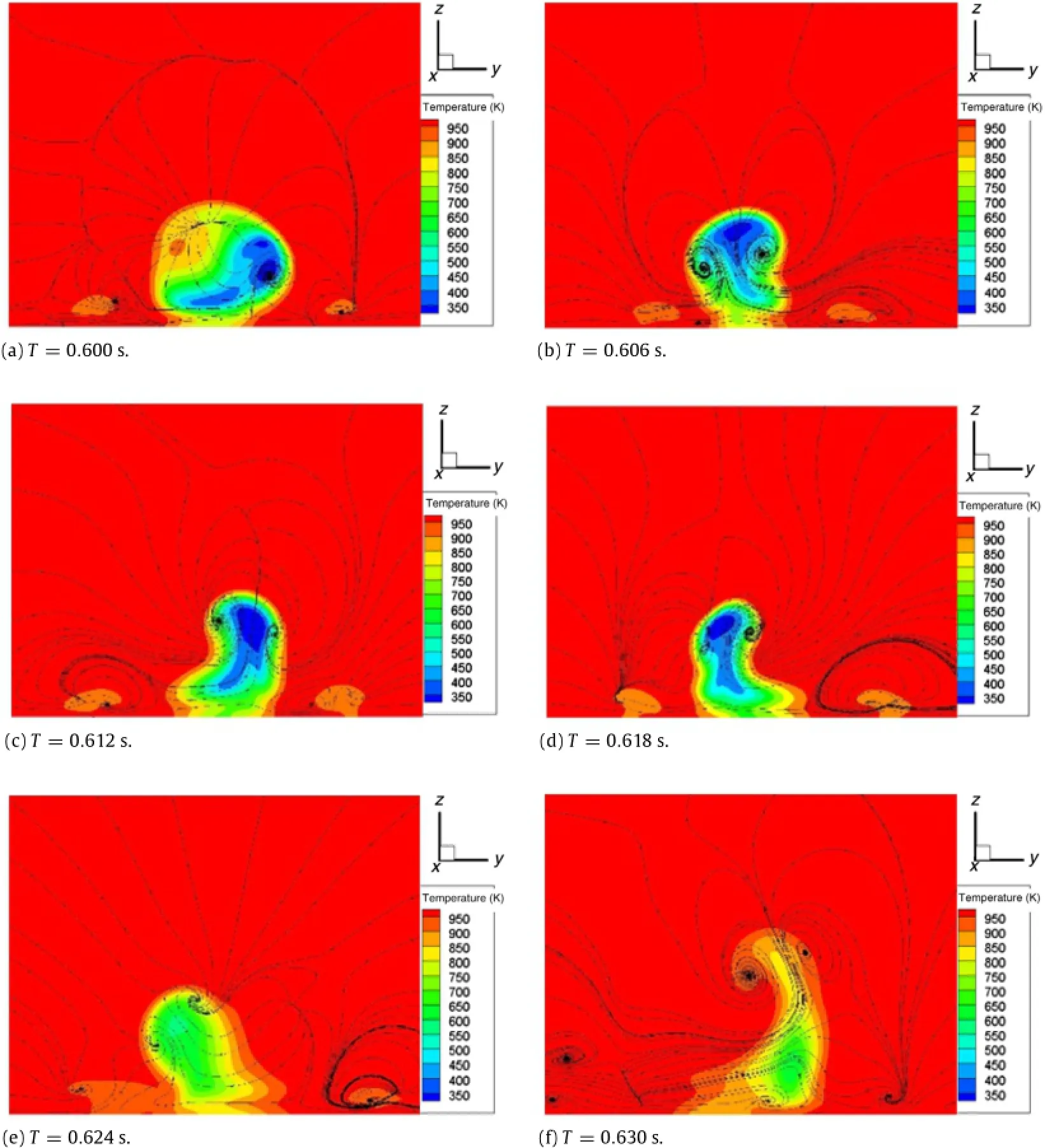

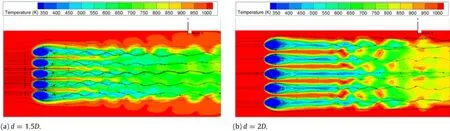

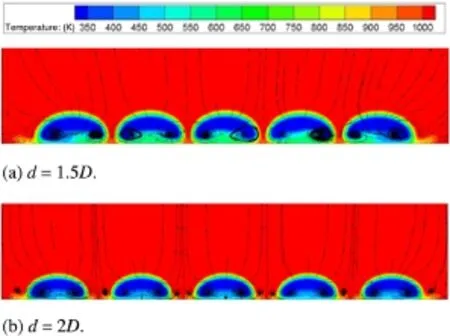

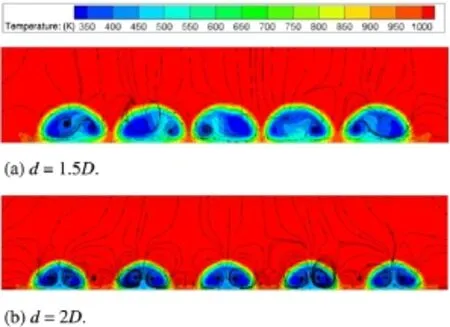

In this section,the main work is about plate film cooling with two kinds of hole-spacing of 1.5D and 2D.The two hole-spacingsare selected,for considering thatnarrower hole-spacing cannot apply to the engineering,which reduce the intensity in the process of manufacturing,while hole spacing is too large,the gas film cooling effectis the same as a single-hole plate.According to the currentliteratures,the two hole-spacing is finally chosen as the research objects.In Fig.14,the characteristics of mixing mechanism films are more apparent because of mutual interference between gas films in the three stages(stable stage,mixed stage and dissipation stage) mentioned above.It is obvious that Stable Stage stays longer when hole-spacing is 2D,while merger phenomenon appears between the films when hole-spacing is 1.5D in Fig.14(a).The merger phenomenon appears because of films are so close to each other that films merge together with the development of films.In addition, mainstream extrude films inward.When hole-spacing is 2D,after the stable stage,the instability of films flow has played a major role between films in parallel.The interference occurs in the form of periodic sloshing,so periodic rejection and attraction due to the mutual interference occur in Fig.14(b).

Fig.7.(Color online)Results offlow field and temperature atthe cross section of X/D=5.

Fig.8.Results of cooling efficiency with different time at the cross section of X/D=5.

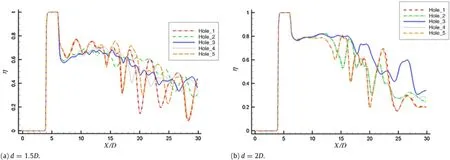

Next,the change law of film cooling efficiency is discussed.In the two pictures of Fig.15,middle gas film(film 3)is relatively stable in the process ofthe gas film flow,while the films atthe edge change strongly.The reason is thatthe influence on the middle film coming from both sides is the same,while other films are affected unequally by the mainstream.In the two pictures,after a certain stage ofstable,the cooling efficiency of5 different films has certain cyclical shocks,indicating that the films occur periodic offset the centerline of films.And cooling efficiency along the exhibition on the different cross sections is compared,as shown in Fig.16.From the two pictures of Fig.16,it is concluded that with the development of film cooling,films extrude towards the middle.

Fig.9.(Color online)Results of flow field and temperature at the cross section of X/D=15.

Fig.10.Results of cooling efficiency with different time at the cross section of X/D=15.

As shown in Fig.17,in the cross section X/D=1,gas films of d=2D are higher than thatof d=1.5D,which is mainly due to the mentioned extrusion.And the extrusion is stronger when the films are closer to mainstream.From Figs.18-20,it is concluded that flow direction of vortex belongs to adjacent side of the adjacent two anti-symmetric vortex is opposite,indicating that mutual repulsion occurs between the adjacent films.The horseshoe vortex exists in cross section when hole-spacing is 2D,but not for holespacing of 1.5D because of no enough space between films.

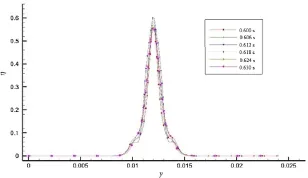

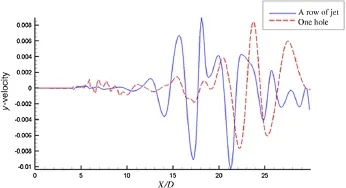

According to the mutual interference between the gas films put forward before,this section focuses on contrast analysis of y-velocity along center line of middle film,which provides data validation for analysis above.

As shown in Fig.21,in the process offilmcooling,we argue that y-velocity along center line of film indicates the migration of gas film.According to the contrast,it can be found in the stable stage, y-velocity is almost zero in single-row plate,while smalldeviation in single-hole plate.Certain cyclicalshock appears as the distance fromthe gas filmhole going on.Through this data,detailed resultof periodic oscillation can be obtained,such as oscillation frequency and precise location where oscillation occurs.The decrease of amplitude indicates attenuation of oscillation and dissipation of the gas film energy.In addition,according to the contrast,the exhibition of periodic oscillation in single-row plate is advance of that in single-hole plate,proving that periodic oscillation occurs in mixed stage of single-row plate.According to Fig.22,the direction ofoscillation ofadjacent films is opposite,which indicates mutualrepulsion between films.In comparison,amplitude of oscillation formiddle filmis respectively small,which indicates the oscillation is mainly generated by the infiltration from mainstream.

Fig.11.(Color online)Results offlow field and temperature atthe cross section of X/D=20.

Fig.12.Results of cooling efficiency with different time at the cross section of X/D=20.

Fig.13.Computationalmodelofa row ofholes in the plate.

The unsteady mixing mechanism of the plate film cooling was investigated by large eddy simulation with more than 20 million grids.The single-hole plate film cooling and single-row plate film cooling in different hole spaces are calculated.The unsteady flow field and cooling efficiency of the adiabatic wall plate are obtained and the influence law of mixing mechanism is concluded.The features of unsteady mixed jet-to-mainstream are varied regularly as time goes on.It can be concluded that the formation process of coolant film affected by the differentaerodynamic characteristics is divided into three different stages with different mixing characteristics,which are stable stage,mix stage,and dissipation stage,and the distribution of vortex system dominates the mixing process.For further analysis,the process of gas film cooling can be divided into different stages according to the different characteristics,and different stages own its special mixing characteristics.Furthermore,the numerical simulation of film cooling with a single-row plate under various hole-spacing is carried out,and the influence law of covering characteristics on different hole-spacing is revealed.The simulated results show thatthe mutualinterference effects between the gas films perform different characteristics in different stages.The mutualexclusion happens atthe stable stage,and a certain periodic sloshing appears in mix stage,while in the dissipation stage,the phenomenon ofthe mutual fusion appears.

Fig.14.(Color online)Flow and temperature field on the surface ofthe plate.

Fig.15.(Color online)Cooling efficiency along the center line ofeach film.

Fig.16.(Color online)Cooling efficiency ofplate on different cross sections.

Acknowledgments

The present work was partially supported by the National Science and Technology Major Project(2013CB035700),the National Natural Science Foundation of China(11672225,11511130053), and the Funds for the Central Universities(xjj2014135).

Fig.17.(Color online)Results offlow field and temperature atthe cross section of X/D=1.

Fig.18.(Color online)Results offlow field and temperature atthe cross section of X/D=2.

Fig.19.(Color online)Results offlow field and temperature atthe cross section of X/D=4.

Fig.20.(Color online)Results offlow field and temperature atthe cross section of X/D=5.

Fig.21.Contrast of y-velocity along center line ofmiddle film.

Fig.22.Contrast of y-velocity along center line ofdifferent gas films,when holespacing is 2D.

[1]T.Hildebrandt,J.Ettrich,M.Kluge,et al.Unsteady 3D Navier-Stokes calculation of a film-cooled turbine stage:Part 2-Cooling flow modeling via discrete cooling holes,in:European Turbomachinery Conference,2003.

[2]C.Liu,H.Zhu,J.Bai,Newdevelopmentofthe turbulent Prandtlnumbermodels for the computation of film cooling effectiveness,Int.J.Heat Mass Transfer 54 (2011)874-886.

[3]K.D.Lee,K.Y.Kim,Shape optimization of a fan-shaped hole to enhance filmcooling effectiveness,Int.J.Heat Mass Transfer 53(2010)2996-3005.

[4]S.Völker,F.Zehe,A modelforcylindricalhole film cooling-Part I:A correlation for jet-flow with application to film cooling,J.ASME 134(2012)061010.

[5]F.Nemdili,A.Azzi,G.Theodoridis,etal.,Reynolds stress transportmodeling of film cooling at the leading edge ofa symmetricalturbine blade model,J.Heat Transf.Eng.29(2008)950-960.

[6]X.Guo,W.Schröder,M.Meinke,Large-eddy simulations of film cooling flows, J.Comput.Fluids 35(2006)587-606.

[7]M.B.Jovanović,D.Lange,A.A.Steenhoven,Effect of hole imperfection on adiabatic film cooling effectiveness,Int.J.Heat Fluid Flow 29(2008)377-386.

[8]A.Duggleby,J.L.Camp,G.Laskowski,Evaluation ofmassively-parallelspectral element algorithm for LES of film-cooling,in:C.ASME Turbo Expo 2013: Turbine Technical Conference and Exposition,V03BT13A008-V03BT13A008.

[9]A.Suryanarayanan,B.Ozturk,M.T.Schobeiri,et al.,Film-cooling effectiveness on a rotating turbine platform using pressure sensitive paint technique, J.Turbomach.132(2010)041001.

[10]L.Zhou,H.Fan,X.Zhang,et al.,Investigation ofeffect ofunsteady interaction on turbine blade film cooling,Eng.App.Comp.Fluid 5(2011)487-498.

[11]S.Li,Z.Li,T.Guo,Numerical simulation study on the effect of rotation on film cooling of blades with compound angle holes,in:C.Proceedings of the 2011 International Conference on Informatics,Cybernetics,and Computer Engineering,ICCE2011,November 19-20,2011,Melbourne, Australia,Springer,Berlin,Heidelberg,2012,pp.429-436.

[12]Y.Shangguan,X.Wang,Y.Li,Investigation on the mixing mechanismofsinglejet film cooling with various blowing ratios based on hybrid thermal lattice Boltzmann method,Int.J.Heat Mass Transfer 97(2016)880-890.

[13]A.Kampe,S.Völker,F.Zehe,A modelfor cylindricalhole film cooling-Part I: A correlation for jet-flow with application to film cooling,J.Turbomach.134 (2012)061010.

∗Corresponding author.

E-mail address:aachengang@mail.xjtu.edu.cn(G.Chen).

http://dx.doi.org/10.1016/j.taml.2016.08.007

2095-0349/©2016 The Authors.Published by Elsevier Ltd on behalf of The Chinese Society of Theoreticaland Applied Mechanics.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Theoretical & Applied Mechanics Letters2016年5期

Theoretical & Applied Mechanics Letters2016年5期

- Theoretical & Applied Mechanics Letters的其它文章

- Two-dimensionalmodeling of the self-limiting oxidation in silicon and tungsten nanowires

- Subset-based localvs.finite element-based globaldigitalimage correlation:A comparison study

- Magnetic induction strength on surface of a ferro-medium circular cylinder

- High temperature effects in moving shock reflection with protruding Mach stem

- The Richtmyer-Meshkov instability of a'V'shaped air/helium interface subjected to a weak shock

- Side force controlon slender body by self-excited oscillation flag