Influences of milling and grinding on machined surface roughness and fatigue behavior of GH4169 superalloy workpieces

Xun LI,Chunming GUAN,Peng ZHAO

School of Mechanical Engineering and Automation,Beihang University,Beijing 100191,China

1.Introduction

Different machining processes and conditions have direct influences on machined surface integrity,which lead to a significantly different fatigue performance of a workpiece.It is very important for load-bearing structures in the field of aviation because fatigue fracture,accounting for over 80%of loadbearing failures,is significantly influenced by the final surface integrity of parts.1,2Therefore,scholars have focused on this research field and obtained many positive achievements.Ulutan and Ozel3provided a comprehensive overview of machining-induced surface integrity in titanium and nickel alloys,which gave a theoretical reference for further research on the influences of processing technologies and parameters on surface integrity.CIRP’s collaborative working group on surface integrity has studied machined surface integrity utilizing five different machining processes with dozens of machining conditions.4The research achievements indicate that different machining processes will lead to a great difference in surface integrity indicators,such as surface roughness,surface micro topography,surface hardening,and residual stress,because of different processing mechanisms.Therefore,for a given material,how to select the machining process and parameters properly is extremely important to improve the fatigue properties of workpieces.

Surface roughness is an important index to describe machined surface micro topography.Compared with other surface integrity indices,it also has a crucial influence on the fatigue life of a workpiece.5Many scholars conducted positive research on the influence of surface roughness on fatigue life according to fracture mechanics,surface local micro-stress concentration,and some other theories.Suraratchai et al.6studied the effect of surface roughness on the fatigue life of aluminum alloy specimens.Itoga et al.7analyzed the influence of different surface roughness on the rotary bending fatigue life of high strength steel.Yao et al.8presented the effects of high-speed milling parameters on the surface topography and fatigue behavior of Ti1023 workpieces.The results have shown that predicting the fatigue life of specimens based on the surface stress concentration factor is more accurate than that based on machined surface roughness.

From the previous research achievements utilizing the same machining process,it can be concluded that the higher the surface roughness values are,the deeper the micro notches on the machined surface are,and the more serious the local microstress concentration is.It will lead to a negative influence on the fatigue performance of a workpiece.

GH4169,as one of the most commonly used nickel-based superalloys,is widely used in manufacturing aero-engine blisks,blades,drive shafts,and other load-bearing structures.3,9GH4169 is machined mainly by numerical control(NC)milling process at present.However,excellent mechanical and thermal properties also lead to poor machinability,which limits further improvement on machining precision and surface integrity because of fast tool wear,cutting chatter,and high cutting force.10

It has been indicated that high-speed grinding utilizing super abrasive wheels is an effective process on machining GH4169 to improve precision,surface quality,and machining efficiency.11,12At the same time,the fatigue strengths of workpieces can be increased by cubic boron nitride(CBN)grinding process because the finish surface integrity is improved.13,14Therefore,many scholars have conducted positive research on high-speed grinding because of its high flexibility and machined surface quality,especially in manufacturing the key parts of aero-engines,such as blisks and blades.15,16

However,the influence law and action mechanism of surface roughness on the fatigue behavior of a workpiece with different machining processes have not been studied systematically and deeply.According to the experimental results of milling and grinding,surface roughness and micro topography generated by different machining parameters are comprehensively developed.

Then,based on the action mechanism of the surface microstress concentration factor on the fatigue performance of a specimen,the influences of different machining processes on the fatigue behavior of the specimen are comparatively analyzed.From the results of fatigue life tests,it can be obtained that the fatigue behavior decreases with an increase ofmonotonically utilizing different machining processes instead of Raor Rz.

2.Comparative analysis of machined surface roughness between milling and grinding

The surface roughness and micro topography of side milling are studied and compared with those of high-speed grinding utilizing super abrasive wheels in the following experimental conditions.

Material:Nickel-based superalloy GH4169(solution treatment and aging),hardness is about HV423,and the dimensions of the workpiece are 12 mm×20 mm×50 mm.

Cutter:∅10 mm AlTiN coated carbide cutters with four teeth are utilized in all side milling experiments,as shown in Fig.1.

Grinding wheel:The structure of a barrel wheel is shown in Fig.2(a),where D is the maximum diameter of the wheel,Reis the radius of the circular arc generatrix,Leis the height of the barrel,and d is the diameter of the wheel shaft.A 300#CBN electroplated wheel(EP wheel)and a 300#CBN resin-bonded wheel(RB wheel)are shown in Fig.2(b)and(c),respectively,the structure parameters of which are D=34 mm,Re=3 mm,Le=4 mm, d=8 mm and D=42 mm, Re=3 mm,Le=3.5 mm,d=8 mm,respectively.The plunge grinding process is utilized,as shown in Fig.3.

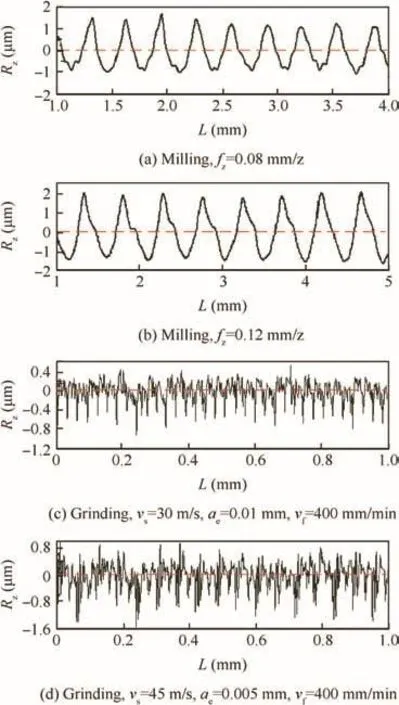

Utilizing grinding and milling respectively,test workpieces are machined by different machining parameters.According to previous research achievements,the machined surface roughness parallel to the maximum principal stress direction has a much greater influence on the fatigue property than that perpendicular to the maximum principal stress direction.8,17Therefore,the influence mechanism of the surface roughness parallel to the maximum principal stress direction on the fatigue property of a workpiece should be focused and developed.From Figs.1 and 3,the feed direction of the milling cutter and wheel is parallel to the load direction,which is parallel to the maximum principal stress under uniaxial tensile load.Therefore,the surface roughness along the feed direction is measured.Meanwhile,the micro-hardness rate NHVand residual stress σHof the machined surface are also obtained.The results are shown in Table 1 and Fig.4.The x-axis of the curve is the measure length L and the y-axis is the machined surface roughness.Parameters including cutting speed vs,cutting depth ae,feed rate per tooth fz,feed speed vf,and grinding width w are also listed below.

Fig.1 Schematic diagram of side milling.

Fig.2 Structure and grinding wheels.

Fig.3 Schematic diagram of plunge grinding.

Fig.4 Surface roughness curves of milling and grinding.

From the above experiment results,it can be known that the surface roughness after milling is about 0.8 μm while that after grinding is about 0.3 μm under the experimental conditions.Just analyzing the value of Ra,the surface roughness machined by milling is two times or more than that machined by grinding.Meanwhile,the value of Rzmachined by milling is one to three times than that machined by grinding.

Based on the research results of Neuber18and Arola and Williams,19the micro-stress concentration factor Kthas asignificant influence on the fatigue property of a specimen,which can be expressed as:

Table 1 Machining parameters of milling&grinding and machined surface integrity.

where ρ is the effective pro file valley radius of the surface texture,n represents the stress state(n=1 for shear and n=2 for tension),and λ refers to the ratio between the spacing and depth of the asperities.

Actually,it is very difficult to obtain an effective value of ρ.In order to simplify this question,the difference of ρ is usually ignored when analyzing the influence of machined surface roughness on the fatigue behavior of a specimen,even utilizing different machining processes.19,20Taking Fig.4 as an example,the curves of surface roughness machined by milling and grinding are significantly different.Although Rzof surface roughness machined by milling is slightly higher than that by grinding,the corresponding ρ of milling surface is much higher than that of grinding surface,which has a great influence on Ktand cannot be ignored,especially for comparative analysis of different processes.

Based on the formation mechanism and characteristics of surface roughness measurement curves,a surface roughness curve can be decoupled into two parts.One part is the kinematic surface roughness curve influenced by the machining process,parameters,and geometry of the cutting tool or wheel.By subtracting the kinematic part from the measurement curve,the other part,the stochastic surface roughness curve,is achieved,which is influenced by the defects of the cutting tool edge or abrasive grains,built-up edges(BUE),cracks,high-frequency vibration,and so on.The decoupling analysis steps are listed as follows.

Table 2 Decoupled results of surface roughness values after milling.

(1)Transform the measure length axis of the surface roughness measurement curve from ‘L/mm” to ‘t/s” through the velocity of 1 mm/s.

(2)According to the machining process,parameters,and geometry of the cutting tool or grinding wheel,the period T of the kinematic surface roughness curve can be obtained.Therefore,the corresponding frequency F influenced by machining conditions can be expressed as 1/T.Taking Fig.1 as an example,T=fz/v and F=v/fz,where fzis the feed per tooth of side milling,and v=1 mm/s.

(3)Utilizing the calculated frequency F,the kinematic surface roughness curve can be obtained by low-pass filtering the transformed time-domain curve of surface roughness.Then,by subtracting the kinematic part from the measurement curve,the stochastic surface roughness curve and its maximum heightcan be obtained.Taking Fig.4(c)and(d)as examples,the kinematic surface roughness curve in the feed direction is a horizontal straight line,and its maximum heightis zero;therefore,the maximum height of the stochastic surface roughness curveis equal to Rz.

Utilizing the above decoupling method,the decoupling curves of surface roughness curves after milling or grinding and their maximum heights are shown in Tables 2,3,and Fig.5.

According to the experimental results above,it can be obtained that when the milling parameter fzincreases from 0.08 mm/z to 0.12 mm/z,Raand Rzwill increase by 41.8%and 41.2%,respectively.increases by 32.4%,butdecreases by 26.5%with an increase of fzfrom 0.08 mm/z to 0.12 mm/z.It shows thatis influenced by the wear of the cutter edge and so on instead of cutting parameters.Meanwhile,it can be found that+>Rz.When the measured surface roughness curve is decoupled into a kinematic curve and a stochastic curve,the highest and lowest points of each curve are usually at different positions,so the maximum height of the measured curve is lower than the summation of the maximum heights of the kinematic and stochastic curves.

A surface machined by grinding is formed by small and irregularly distributed abrasive grains.From Fig.3,it can be obtained that the geometry of the grinding wheel and grinding parameters have no effect on the kinematic surface roughness curve and its maximum height=0,because the kinematic surface roughness curve in the feed direction is a straight line in theory.

Therefore,the maximum height of the stochastic surface roughness curveis equal to Rzunder the grindingexperimental conditions,which will lead to a more serious micro-stress concentration and has a more negative influence on the fatigue property of a specimen even the values of Rzformed by grinding and milling are substantially equal.The decoupled results of surface roughness curves after grinding are shown in Table 3.

Table 3 Decoupled results of surface roughness values after grinding.

Fig.5 Decoupled results of surface roughness curves after milling.

Combined with the current research results,it can be known that the formation mechanism and characteristics of surface roughness utilizing different machining processes and parameters should be taken under consideration when studying the influence mechanism of machined surface roughness on the fatigue life of a specimen.The simple conclusion that the higher the surface roughness value is,the more serious the micro-stress concentration is,and the worse the fatigue property is,is not comprehensive.

3.Influence of machined surface roughness on the fatigue life of a specimen

In order to verify the analysis above,machining experiments on the GH4169 material are carried out.Specimens with an approximately circular cross-section are machined utilizing milling or grinding,and fatigue tests are also conducted.

The machining parameters are shown in Table 1.The specimen rotates 6°during the interval of every two feed paths shown in Figs.6 and 7.

Fig.6 Schematic diagram of the side milling process.

Fig.7 Schematic diagram of the grinding process.

The cross-section of the specimen is a regular 60-sided polygon of which the side length is approximate 0.26 mm(the effect of the axial cutting depth on surface integrity can be ignored when utilizing side milling).The acute angle of every two adjacent sides is 6°and the local stress concentration is negligible,so the effect of sharp corners on the fatigue life of the specimen can be ignored.

All fatigue experiments are carried out on a GPS100 highfrequency digital tension-compression fatigue testing machine as shown in Fig.8.

The maximum tensile load σmaxis set to 1055 MPa and the cyclic stress ratio R is 0.1 based on the ultimate strength of GH4169 material.The clamping of fatigue specimens and their failure mode are shown in Fig.9,and the experimental results are shown in Table 4.

Fig.8 Fatigue life testing machine.

Fig.9 Clamping and failure mode of the fatigue specimens.

According to Table 4 above,the relationship between the surface roughness Rzand the specimen’s fatigue life is not obvious.Utilizing milling,the fatigue life of a specimen increases with an increase of Rz.In contrast,utilizing grinding,the fatigue life of a specimen decreases with an increase of Rz.Meanwhile,the comparison results between grinding and milling also show that the fatigue life of a specimen machined by milling is two to three times longer than that of grinding,despite of the fact that Rzof the former is one to three times higher than that of the latter.

Combining the results of fatigue life tests and decoupling analysis of surface roughness curves,it can be obtained that the maximum height of the stochastic surface roughness curvehas a significant influence on the fatigue life.The fatigue life of a specimen decreases with an increase ofmonotonically,as shown in Fig.10.

According to the results of GH4169 surface integrity tests,the amplitude of the residual compressive stress utilizing grinding is much higher than that utilizing milling.At the same time,the micro-hardness utilizing grinding is also slightly higher.Both of them have a positive influence on improving the fatigue property of a specimen.These results show clearly that the maximum height of the stochastic surface roughness curve is the main factor that influences the fatigue life of a GH4169 specimen,even utilizing different machining processes.The conclusion that the fatigue performance reduces with an increase of surface roughness is not suitable when utilizing different machining processes.In order to get essential reasons of surface roughness affecting the fatigue performance of a specimen,it is necessary to analyze the machined surface based on the formation mechanisms and characteristics of different processes.

Fig.10 Fatigue life test results of GH4169 and the maximum height of the stochastic surface roughness

4.Conclusions

(1)Under the same experimental conditions,the fatigue behaviors of GH4169 specimens machined by milling and grinding do not reduce or increase with an increase of the surface roughness value Raor Rz.The characteristics of surface roughness curves and the formation mechanism of surface micro topography utilizing different processes play a very important role in the fatigue property of a workpiece.

(2)Based on frequency spectrum analysis, amachined surface

roughness curve can be decoupled into a kinematic surface roughness curve and a stochastic surface roughness curve,the maximum heights of which are expressed asandrespectively.The fatigue behavior of GH4169 specimens decreases with an increase ofmonotonically,evenutilizing different machining processes.

(3)Surface residual stress and surface hardening have a positive effect on the fatigue behavior of GH4169 specimens,but the maximum height of the stochastic surface roughness curve is the most sensitive to the fatigue life of specimens.

Table 4 Results of fatigue life tests of GH4169 specimens.

Acknowledgements

The authors would like to thank the anonymous reviewers for their critical and constructive review of the manuscript.This study was supported by the Aeronautical Science Foundation of China(No.2016ZE51039).

1.Mu ZT,Zeng BY,Jin P,Hong J,Zhang DF.Fatigue of helicopter structures.Beijing:National Defense Industry Press;2009.p.14–5[Chinese].

2.Tao CH,Zhong PD,Wang ZR,Nie JX.Failure analysis and prevention for rotor in aero-engine.Beijing:National Defense Industry Press;2008.p.6–7[Chinese].

3.Ulutan D,Ozel T.Machining induced surface integrity in titanium and nickel alloys:a review.Int J Mach Tools Manuf 2011;51(3):250–80.

4.Jawahir IS,Brinksmeier E,M’Saoubi R,Aspinwal DK,OUteiro D,Meyer D,et al.Surface integrity in material removal processes:recent advances.CIRP Ann – Manuf Technol 2011;60(2):603–26.

5.Maiya PS,Busch DE.Effect of surface roughness on low-cycle fatigue behavior of type 304 stainless steel.Metall Mater Trans A 1975;6(9):1761–6.

6.Suraratchai M,Limido J,Mabru C,Chieragatti R.Determination of a local stress concentration induced by machining and its effect on fatigue life of an aluminum alloy.J Am Oil Chem Soc 2008;77(10):1087–93.

7.Nakajima M,Tokaji K,Itoga H,Shimizu T.Effect of loading condition on very high cycle fatigue behavior in a high strength steel.Int J Fatigue 2010;32(2):475–80.

8.Yao CF,Wu DX,Jin QC,Huang XC,Ren JX,Zhang DH.Influence of high-speed milling parameter on 3D surface topography and fatigue behavior of TB6 titanium alloy.Trans Nonferrous Met Soc China 2013;23(3):650–60.

9.Li W,Guo YB,Barkey ME,Jordon JB.Effect tool wear during end milling on the surface integrity and fatigue life of inconel 718.Procedia CIRP 2014;14:546–51.

10.Choudhury IA,El-Baradie MA.Machinability of nickel-base super alloys:a general review.J Mater Process Technol 1998;77(1–3):278–84.

11.Klocke F,Soo SL,Karpuschewski B,Webster JA,Novovic D,El fizy A,et al.Abrasive machining of advanced aerospace alloys and composites.CIRP Ann – Manuf Technol 2015;64(2):581–604.

12.Wilk M,Tota J.Modern technology of the turbine blades removal machining.8th international conference on advanced manufacturing operations;2007.p.347–55.

13.Kawagoishi N,Chen Q,Kondo E,Goto M,Nisitani H.Influence of cubic boron nitride grinding on the fatigue strengths of carbon steels and a nickel-base superalloy.J Mater Eng Perform 1999;8(2):152–8.

14.Li X,Ma S,Meng F.Surface integrity of GH4169 affected by cantilever finish grinding and the application in aero-engine blades.Chin J Aeronaut 2015;28(5):1539–45.

15.M’Saoubi R,Axinte D,Soo SL,Nobel C,Attia H,Kappmeyer G,et al.High performance cutting of advanced aerospace alloys and composite materials.CIRP Ann–Manuf Technolgy 2015;64(2):557–80.

16.Li X,Meng F,Cui W,Ma S.The CNC grinding of integrated impeller with electroplated CBN wheel.Int J Adv Manuf Technol 2015;79(5):1353–61.

17.Itoga H,Tokaji K,Nakajima M,Ko HN.Effect of surface roughness on step-wise–characteristics in high strength steel.Int J Fatigue 2003;25(5):379–85.

18.Neuber H.Theory of notch stresses.Berlin:Springer Verlag;1958.

19.Arola D,Williams CL.Estimating the fatigue stress concentration factor of machined surfaces.Int J Fatigue 2002;24(9):923–30.

20.Suraratchai M,Limido J,Mabru C,Chieragatti R.Modelling the influence of machined surface roughness on the fatigue life of aluminium alloy.Int J Fatigue 2008;30(12):2119–26.

CHINESE JOURNAL OF AERONAUTICS2018年6期

CHINESE JOURNAL OF AERONAUTICS2018年6期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- An efficient aerodynamic shape optimization of blended wing body UAV using multi- fidelity models

- Effect of multiple rings on side force over an ogive-cylinder body at subsonic speed

- Dynamic temperature prediction of electronic equipment under high altitude long endurance conditions

- Experimental investigation on static/dynamic characteristics of a fast-response pressure sensitive paint

- Takagi-Sugeno fuzzy model identification for turbofan aero-engines with guaranteed stability

- Experimental study on film cooling performance of imperfect holes