Development of Organic Soil Suitable for Biodiesel-Based Drilling Fluids

YAN Jun

[a]Drilling Technology Research Institute of Shengli Petroleum Engineering Corporation Limited, Sinopec (SLDTI), Dongying City,Shandong, China.

Abstract The oil-based drilling fluid system has the advantages of excellent lubricating performance, strong inhibitive ability,good sidewall stability and good temperature resistance,etc., however, which also has disadvantages of polluting the environment, easy to catch fire, and higher preparation cost, etc. In the development of biodiesel drilling fluid system, we no longer use diesel or crude oil, instead,it is replaced by biodiesel. Biodiesel also has better environmental friendliness, stronger biodegradability,higher safety performance and renewable advantage (Xin,2005) while meeting specific requirements and achieving relevant performance. Biodiesel drilling fluid is more suitable for actual drilling operations for the more fragile ecology and higher demand environment. However, the organic soil on the market is basically developed for the white oil system. Therefore, we developed organic soil suitable for biodiesel systems by combining the actual situation of organic soil in the market through the measures of comparison, optimization, modification, etc.

Key words: Biodiesel; Resistance to elevated temperature; Organic soil; Filtration loss

1. OPTIMIZATION OF ORGANIC BENTONITE

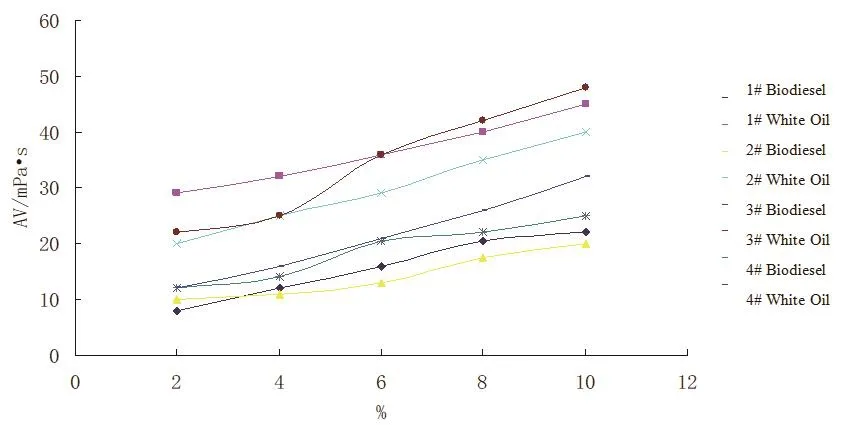

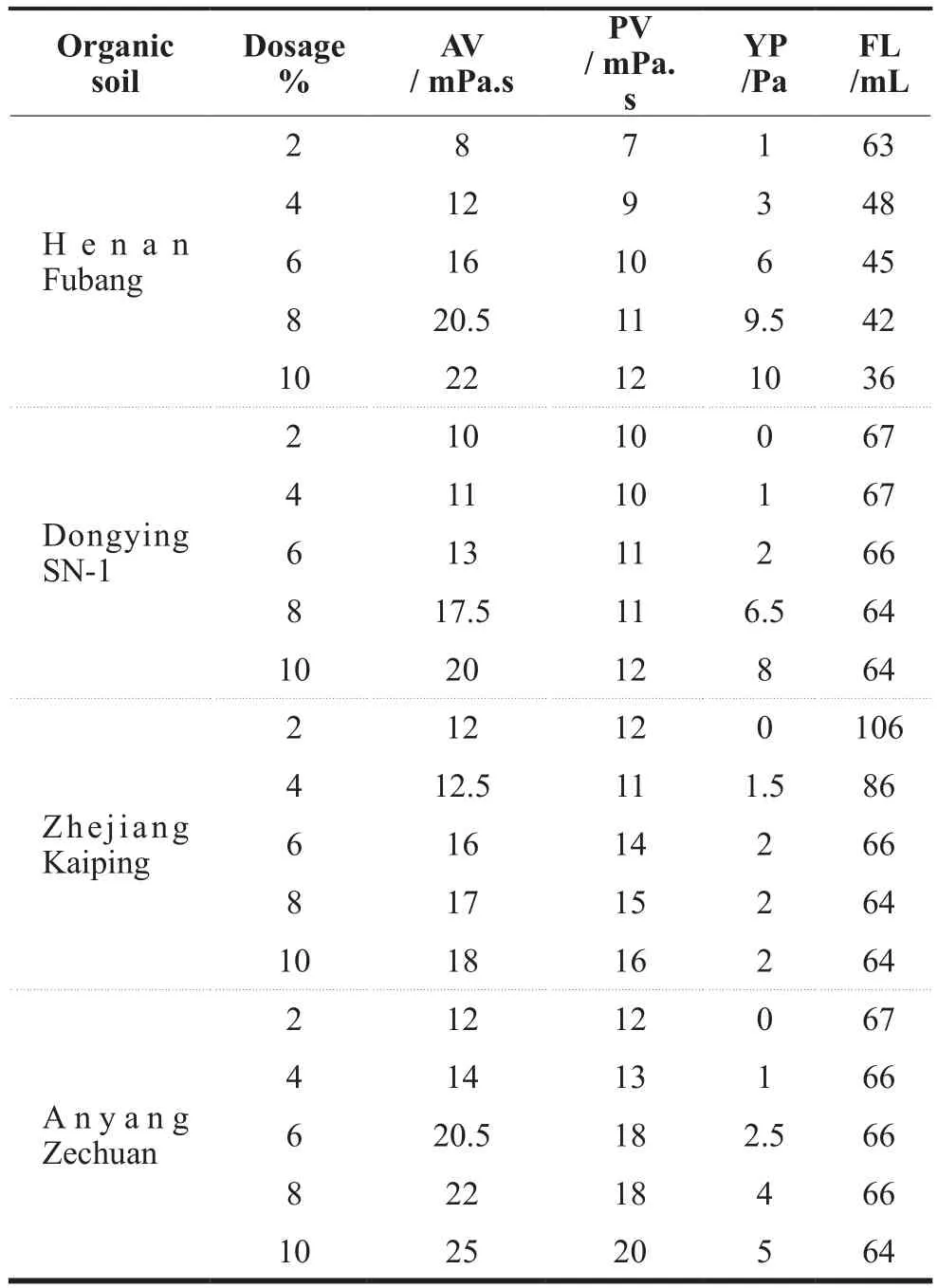

In order to screen organic soil suitable for biodiesel-based drilling fluids, 4 kinds of organic soils were selected and respectively carried out experiments in 7# white oil and biodiesel, they were made by 4 manufacturers with relatively mature production technology, namely 1#Henan Fubang, 2#Dongying SN-1, 3#Zhejiang Kaiping,4#Anyang Zechuan, etc., different amounts of organic soil were respectively added into 300mL biodiesel and 300mL white oil, and the rheological property of Bingham fluid and API filtration loss were then measured.

In general, the AV, PV and YP of organic soils sold on the market in white oil are higher than that of in biodiesel,among them; organic soil from Anyang Zechuan has a slightly worse performance in white oil. The organic soil sold on the market has almost no effect of reducing filtration loss in biodiesel. Among them, organic soil from Henan Fubang can reduce the filtration loss, while the filtration loss was still 36mL after having added 10%organic soil. Organic soil from Zhejiang Kaiping has the worst effect of reducing filtration loss, the filtration loss was 106mL after having added 2% organic soil, and the filtration loss was still 64mL even after adding 10%. The effect of organic soil in reducing the filtration loss is more obvious in the white oil system, organic soil from Anyang Zechuan can control the filtration loss to be below 10mL when adding a smaller amount of 4%, the remaining three organic soils also had a good effect on reducing filtration loss when the amount is more than 4%. This shows that the pertinence of organic soils sold on the market is extremely strong, some organic soils are developed for the white oil system, such as organic soil from Zhejiang Kaiping, and some are developed for the diesel system,such as organic soil from Anyang Zechuan. Therefore, the organic soil sold on the market can’t be directly applied to the biodiesel system, organic soils suitable for biodiesel systems need to be developed.

Figure 1 Apparent viscosity comparison of different fluids

Table 1 Rheological Properties Comparison After Adding Organic Soil in Biodiesel

2. DEVELOPMENT OF ORGANIC BENTONITE

2.1 Synthetic Strategies of Organic Soil

The synthetic route of organic soil for conventional oilbased drilling fluids is: Dissolve 100grams of sodium soil into 1200mL of distilled water, begin to add organic modifiers( reaction dosage ratio of 110mmol/100grams of sodium soil) to conduct organic modification when being heated to 65 °C with stirring, take out after 2 hours of reaction, cool and precipitate, filter, and wash with distilled water several times, stove for about 4 hours at 100 °C, grind, organic soil products with elevated temperature resistance can be obtained (Peng, 2004). The raw materials for preparing biodiesel have a wide range of sources and complex reactions, so the composition of biodiesel is more complicated,in addition to the main substance fatty acid methyl ester, there are a small amount of oleic acid and other substances. Quaternary ammonium salt modifiers will also be consumed by impurities such as oleic acid while being adsorb with sodium bentonite. Therefore, the dosage of modifiers is an important factor in the development of organic soils suitable for biodiesel-based drilling fluids. The modifiers typically adopt dodecyl trimethyl ammonium bromide and cetyl trimithyl ammonium bromide, the different lengths of the carbon chain can affect the adsorption effect (Liu, 2006), therefore, the nature of the modifier is also a factor to be considered.

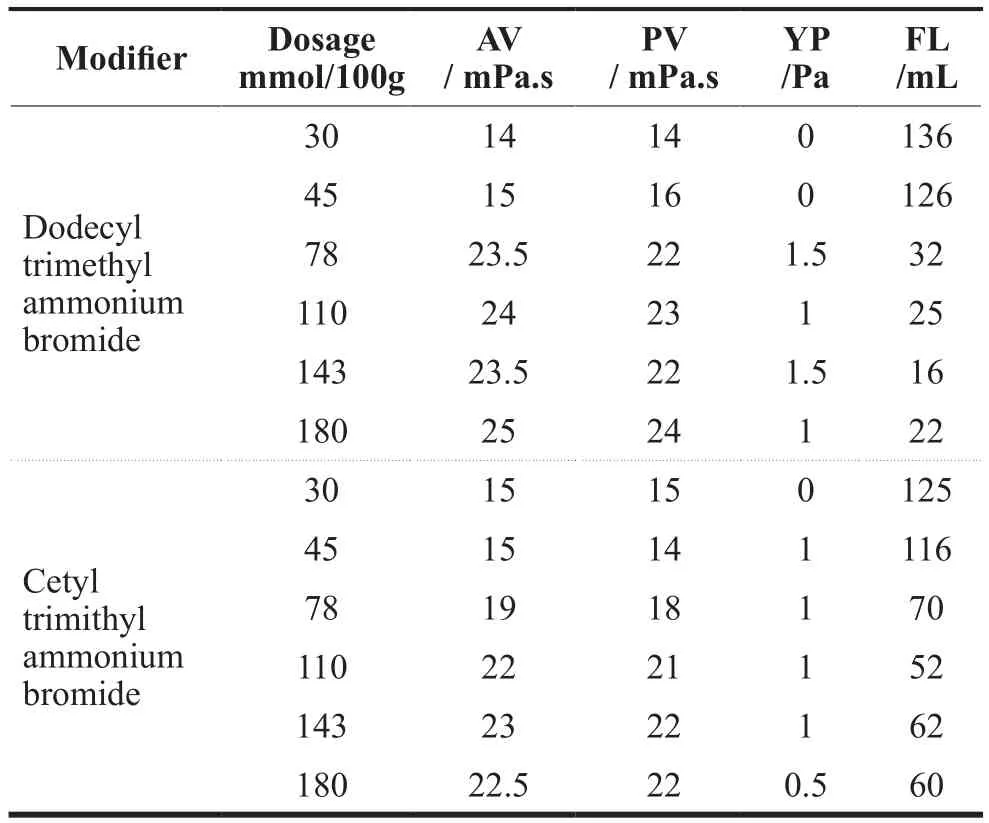

2.2 Indoor Synthesis Experiment of Organic Soil

Considering the two factors of modifier dosage and the properties of the modifier, experiments were carried out separately. Different molar masses of dodecyl trimethyl ammonium bromide and cetyl trimithyl ammonium bromide were added into the 100grams of sodium bentonite, and then dissolved into 1200mL of distilled water, took out after 2 hours of reaction, cooled and precipitated, filtered, washed with distilled water for two times, stoved at 100~105 °C for about 4 hours, and grinded, organic soil products with elevated temperature resistance were obtained. Then 3% of the organic soil was added to 400mL of biodiesel to measure rheological property and filtration loss.

Figure 2 Filtration comparison after adding organic soil in biodiesel

Table 2 Preparation and Evaluation of Organic Soil

2.2.1 Effect Evaluation of Dodecyl Trimethyl Ammonium Bromide Modifying Organic Soil

The dosage of modifiers is too small when the molar mass is 30mmol and 45mmol, only a small part of sodium soil’s surface is modified, the dispersion in biodiesel is incomplete, therefore, the rheological property is relatively poor and yield point is zero, filtration loss exceeds 100mL.The filtration loss shows the change rule of decreasing firstly and then increasing while the dosage of modifier increases, the minimum filtration loss is 16mL when the dosage is 143mmol/100g, apparent viscosity and plastic viscosity increase, yield point is 1 Pa. The properties of organic soil are the best when the dosage of modifier is the sum that the sodium soil fully adsorbs the added impurity consumption of biodiesel. Excess modifiers no longer play a role in the improvement of rheological property when the dosage of modifier continues to increase, therefore, the yield point is maintained at about 1 Pa, the plastic viscosity and apparent viscosity do not change substantially, excessive modifier will change the original tough filter cake texture and lead to an increase in filtration loss.

2.2.2 Effect Evaluation of Cetyl Trimithyl Ammonium Bromide Modifying Organic Soil

With the changes of modifier’s dosage, the filtration loss shows the same pattern of change as that with dodecyl trimethyl ammonium bromide. When the dosage is small,the filtration loss is extremely large, the rheological nature is very poor, the plastic viscosity and apparent viscosity are gradually increased to the same degree with the increase of dosage, and the yield point is maintained at 1 Pa. The minimum filtration loss is 52mL when the dosage is 110mmol/100g.

2.2.3 Selection of Dosage and Properties of Modifier

When the dosage of the two modifiers is less than 50mmol/100g, the modification effect of cetyl trimithyl ammonium bromide is better than that of dodecyl trimethyl ammonium bromide, but the modification effect of dodecyl trimethyl ammonium bromide will be better than that of cetyl trimithyl ammonium bromide.The carbon chain of cetyl trimithyl ammonium bromide is relatively long, the adsorption capacity on the surface of sodium soil is poor when compared with dodecyl trimethyl ammonium bromide, resulting the poor modification. The filtration loss is 16mL when dodecyl trimethyl ammonium bromide is taken as the modifier and the dosage is 143mmol/100g, and the filtration loss is 52mL when cetyl trimithyl ammonium bromide is taken as the modifier and the dosage is 110mmol/100g. As a result, dodecyl trimethyl ammonium bromide is selected as organic soil suitable for biodiesel-based drilling fluids,and the optimum dosage is 143mmol/100g.

2.3 Determination of Indoor Synthetic Route of Self-Made Organic Soil

The synthetic route suitable for biodiesel based drilling fluids is as follows: take 100g of sodium bentonite to dissolve in 1200mL of distilled water, stir to heat it to 65℃ and add the Dodecyl Trimethyl Ammonium Bromide (ratio of reaction is 143mmol/100g of sodium bentonite) for organic modification. After 2 hours’reaction, remove and cool for precipitation, filtered and washed with distilled water for several times, drying for about 4 hours under 100℃,ground to powder, and then organic soil products can be obtained in this way.

3. EVALUATIONS ON ELEVATED TEMPERATURE RESISTANCE PERFORMANCE OF SELF-MADE ORGANICS SOIL

3.1 Evaluation Mechanism of Elevated Temperature Resistance

Drilling fluid systems used in deep and ultra-deep wells should have good resistance to elevated temperature.As an essential component of oil-based drilling fluids,organic soil should also have good resistance to elevated temperature. In the experiment, the self-made organic soil and biodiesel were prepared into a system and aged under different temperature conditions, and then the rheological property and filtration loss were measured to evaluate the performance of elevated temperature resistance of the organic soil. Organic soil was prepared from absorbing the quaternary ammonium salt surfactant on the surface of sodium bentonite. When the system temperature of organic soil was too high, part of cationic surfactant would be desorbed into oil-based drilling fluid (Xu, et al.,2003). The desorbed surfactant would reduce the electrical stability of drilling fluid system and affect the stability of the system.

3.2 Indoor Elevated Temperature Aging Test

Samples adopted by the test are: 300mL biodiesel + 3%organic soil (laboratory preparation). The rheological property and filtration loss were evaluated respectively under normal temperature, 120℃,160℃,180℃ and 200℃. With the increase of temperature, the apparent viscosity (AV) and Yield Point (YP) decreased. Under the temperatures higher than 180 ℃, AV and YP decreased significantly, which suggested that extensive surfactant of cations absorbed by the surface of organic soil were desorbed, resulting in the deterioration of the rheological property of organic soil and the reduction of system stability. With the increase of temperature, the amount of filtration loss of the samples was increased. The amount of filtration loss was 38mL at 200℃. Compared with the filtration loss at 180℃, the filtration loss varies greatly and reached 45mL at an aging temperature of 220℃.

Table 3 Elevated Temperature Performance of Organic Soil

CONCLUSION

Through comparative analysis, the best synthetic method of self-made organic soil was established, and the optimal usage of self-made organic soil in biodiesel based drilling was determined to be 3%.

Laboratory evaluation showed that: on the premise of no other additives, the biodiesel with selfmade organic soil can maintain stable rheological and filtration properties, and has good resistance to elevated temperature under elevated temperature of 180℃.

Advances in Petroleum Exploration and Development2019年1期

Advances in Petroleum Exploration and Development2019年1期

- Advances in Petroleum Exploration and Development的其它文章

- Staged Premium Screen Completion Design for Horizontal Well Based on Laboratory Test: A Successful Application in Block 451, Shengli Oil Field

- Simulated Calculation of Bullheading Method When the Well is Empty

- Study on the Affection of Drilling Tools’ Abrasion to the Regular Pattern of Tensile Strength

- Optimization Program for Difficult-to-Produce Reservoir in Bonan Oil Feild

- Producibility Scenario of Unidentified Productive Zone

- A Drilling Liquid to Reduce the Damage Coalbed Methane