Raoultella terrigena RtZG1 Electrical Performance Appraisal and System Optimization

GONG Kang (龚 康), CHEN Ting (陈 婷), LÜ Liangyu (吕梁彧), BAO Guangsen (包广森), LU Changrui (陆昌瑞), ZHANG Yunlong (张云龙)

College of Chemistry, Chemical Engineering and Biotechnology, Donghua University, Shanghai 201620, China

Abstract: The aims of this study are to provide a strain and its optimal application in electro-producting performance for revealing the electrical generating mechanism in the future. We constructed microbial fuel cells (MFCs) device that was a bipolar chamber MFC, using metal ion media (MIM) and water as anode and cathode reaction substation fluid, respectively. In this study, we identified an isolate as Raoultella terrigena, named RtZG1, which could produce electron. Also, we optimized the conditions of electrical energy generation. The continuous output current could reach about 200 μA within 3 h when the ratio of electro-bacterial fluid to matrix fluid was 1∶4, the temperature was 37 ℃, the carbon-nitrogen ratio of the inorganic salt medium was 10∶1, as well as the concentration of MIM was 1. Based on the optimization, it is clear that the most suitable conditions of electricity production for this strain lay the foundation for the application of this strain.

Key words: microbial fuel cell (MFC); Raoultella terrigena; electro-bacteria; conditions optimization

Introduction

Microbial fuel cells (MFCs) are emerging to utilize biomass[1]. The basic principle of MFCs is that microorganisms are oxidized by organic matter at the anode, producing electrons and protons. The protons were transmitted inside the battery and reached the cathode together with the electrons transmitted through external circuits[2-3]. H2O is formed by binding with oxygen under the action of a catalyst[4-5]. Because of characteristics of degrading organic matter and outputting electricity outwards, MFCs have gradually become one of the research hotspots in today’s society. Its application in the field of wastewater treatment would change the disadvantages of high energy consumption in sewage treatment processes and to be concerned widely at domestic and oversea markets[6-8].

Previous studies have shown that pure bacteria systems are more beneficial to electrical production of MFCs[9]. Therefore, in recent years, the study of electro-bacteria is being concerned, and the identified bacteria in China is also gradually increasing[10]. At present, more than 30 kinds of electro-producing microorganisms have been reported, and more studies focus onShewanellasp.andGeobactersp.[11-13]. There are many factors affecting the production of electro-bacteria, so the optimization of MFCs’ electro-producting performance is always a hot topic of research[14-15].

Based on the construction of bipolar chamber MFCs, we try to explore the feasibility of RtZG1 degradation of glucose and at the same time to generate electrical energy using glucose as the representative degradation. In addition, we try to find the optical production conditions ofRaoultellaterrigenaelectricity. It is provided some research basis for MFCs treatment of degradable materials and wastewater treatment.

1 Materials and Methods

1.1 RtZG1-MFCs’ electric model design for electricity production

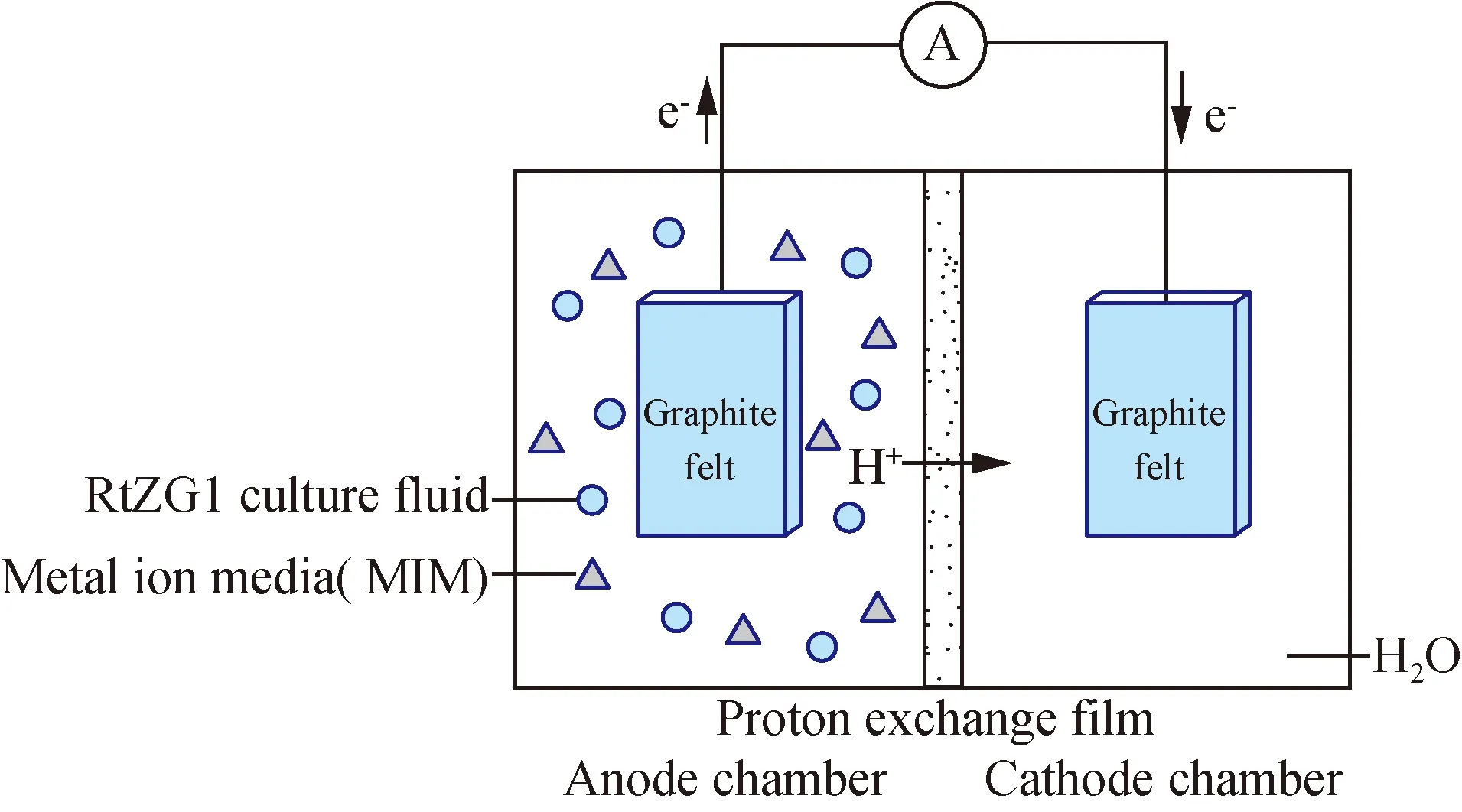

Figure 1 shows a bipolar chamber MFCs made of glass material (Xinxian Xincheng’s Instrument Technology Co., Ltd., Beijing, China), with an anode chamber at the left and cathode chamber at the right. The volume of the polar chamber is 500 mL. Proton exchange film (Shanghai Wensum Experimental Equipment Co., Ltd., Chuzhou, China) was sandwiched between the glass material.Raoultellaterrigenawas provided by Nucleic Acid and Structural Biology Group, Donghua University, China. The experimental model anode and cathode use graphite felt[16-17]. Anode and cathode effective area is 25 cm2. The electrodes are connected by a missile line, and the final recorded current signal is collected by a digital recorder (Yusheng Victory Technology Co., Ltd., Shanghai, China). The current was recorded every 15 min, and OriginPro was used to analyze the data[18].

1.2 Preliminary construction of microbial power production system

The RtZG1 was cultured in inorganic salt medium, and then we connected the battery and checked the closure of this device[19]. Water is used as cathode chamber solution and air aeration is oxygenated. The MIM and bacteria solution used as anode chamber solution[20]. The reactor is placed in a thermostatic water bath, and the temperature range is (30.0±0.1) ℃. After dumping into the reaction fluid, we can close the battery device, start to run and collect electrical information.

In Refs. [21-22], the MIM is considered as a substation fluid for the anode of the MFCs reactor. The main components of MIM include: 8.8 g/L NaCl, 330 mg/L MgCl2·7H2O, 275 mg/L CaCl2, 14 mg/L KH2PO4, 21 mg/L K2HPO4, 56 mg/L Na2HPO4·7H2O, 10 mg/L FeSO4·7H2O, 5 mg/L MnSO4·H2O, 3.1 mg/L NH4Cl, 2 mg/L KCl, 1 mg/L CoCl2·6H2O, 0.1 mg/L CuSO4·5H2O, 0.1 mg/L H3BO3, 0.25 mg/L Na2MoO4, 0.24 mg/L NiSO4, and 1 mg/L ethylene diamine tetraacetic acid (EDTA); deionized water is settled to 1 L. It can prepare the concentration of anode substation fluid about 10 (10×MIM), and then a certain amount can be diluted.

The main components of inorganic salt medium are as follows: 5 g/L K2HPO4, 2 g/L KH2PO4, 0.1 g/L NaCl, 0.2 g/L MgSO4·7H2O, 10 g/L glucose, and 1 g/L NH4Cl; deionized water is settled to 1 L. pH is 7.0±0.2. Then it was sealed with tin foil and sterilized it about 20 min.

1.3 RtZG1 growth curve determination

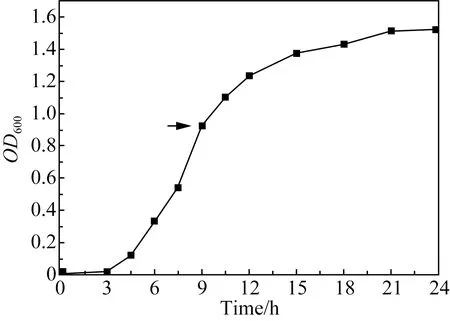

The RtZG1 was inoculated in an inorganic salt medium. And we placed medium on a thermostatic shaker at 37 ℃ and 160 r/min, and the growth curve of RtZG1 was determined. The 1 mL culture fluid was collected and measuredOD600every 1.5 h. The growth of the curve was drawn using allOD600values within 24 h. When the strain reaches logarithmic phase, it will be available to the subsequent experiments[23-24]. The RtZG1 growth curve was shown in Fig. 2.

Fig. 1 Diagram of the RtZG1-MFCs experimental device

Fig. 2 RtZG1 growth curve

1.4 Optimization of electricity production conditions of RtZG1-MFCs

1.4.1EffectoftheratiobetweenbacterialfluidvolumeandMIMontheelectricalproductionofRtZG1

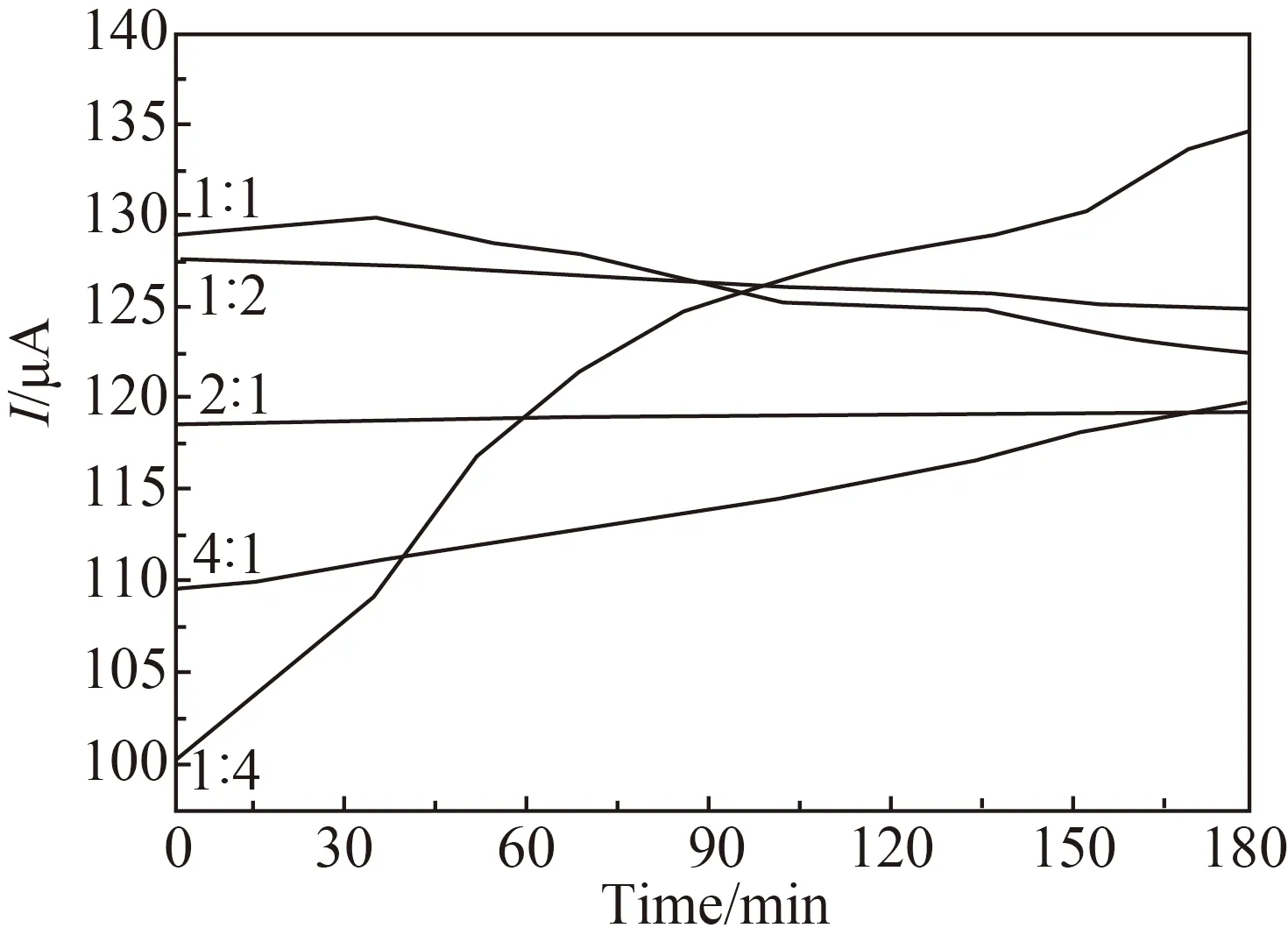

RtZG1 is cultured into a phosphor medium with inorganic salt medium and is used in the battery[25]. By setting the ratio of different volumes of media and MIM, such as 1∶4, 1∶2, 1∶1, 2∶1, 4∶1, we can obtain the best power yield of RtZG1 under the gradient ratio[26]. The current is detected every 15 min, and we plot the electrical production and time curves within 3 h. The production of the amount of bacterial fluid and MIM was shown in Fig. 3.

Fig. 3 Production of the amount of bacterial fluid and MIM

1.4.2InfluenceoftemperatureonRtZG1production

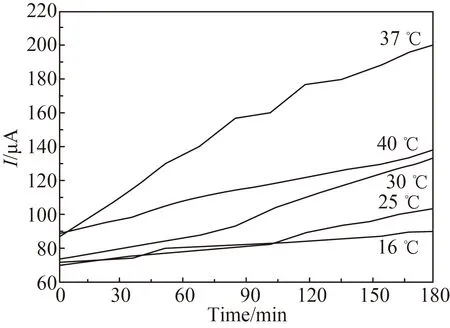

By setting the temperature of different MFCs reactions, the optimal electrical production and the temperature of RtZG1 is obtained[27]. The current is detected every 15 min, and we describe curves about the electrical production and time within 3 h. The production of the temperature of RtZG1 was shown in Fig. 4.

Fig. 4 Production of the temperature of RtZG1

1.4.3Effectofthecarbon-nitrogenratioontheelectricalproductionbyRtZG1

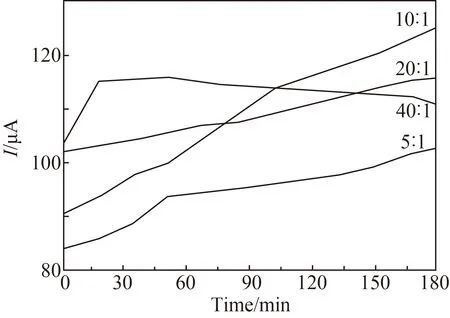

Setting different carbon-to-nitrogen ratio of the culture media, the carbon-nitrogen ratio interval is set at 5∶1, 10∶1, 20∶1, and 40∶1, respectively. After culturing 9 h, the strain was taken out and an electrical experiment was carried out to obtain the best yield of RtZG1 under the optical carbon-nitrogen ratio[28-29]. The current is detected every 15 min, we draw the electrical production and time curves within 3 h. The production of carbon-nitrogen ratio to RtZG1 was shown in Fig. 5.

Fig. 5 Production of carbon-nitrogen ratio to RtZG1

1.4.4ImpactofanodesubstatefluidconcentrationonthepowerproductionofRtZG1

By setting different concentrations of MIM, it is possible to find out whether metal ions can improve the transportation efficiency of the charge generated by RtZG1 consumption of glucose at different concentrations[30]. The current is detected every 15 min, we plotted the electrical production and time curves within 3 h. Anode substation liquid concentration of RtZG1 production was shown in Fig. 6.

Fig. 6 Anode substation liquid concentration of RtZG1 production

2 Results and Discussion

2.1 RtZG1 growth curve determination

As can be known from Fig. 2, it is clearly learned thatOD600reaches the most suitable growth condition of RtZG1 strains during logarithmic growth period. Therefore, we confirm the optical culture time for electro-producing conditions, and we use 9 h culture condition from all experiments.

2.2 Effect of the ratio of bacterial fluid volume and MIM on the electrical production of RtZG1

As shown in Fig. 3, the electrical production of RtZG1 was affected by the different proportions of bacterial fluid and MIM. When the ratio was 1∶2, 1∶1, 2∶1, and 4∶1, respectively, the slope between current and time decreased. The ratio was 4∶1, and the electrical production of RtZG1 increased. When the amount of fungi gradually increased relative to MIM, its electrical production capacity was significantly reduced. With the proportion of strains increasing, the volume of MIM gradually decreased. As a result, the number of metal ions is corresponding reduced. The current result is 0, when the fluid is 0 and the volume of MIM is still 400 mL. Accordingly, the presence of RtZG1 can consume glucose in the medium, leading to the current. Additionally, if MFC is lack or low concentration of metal, its effects will decline over time even if the concentration of strains is high. Therefore, the bacterial fluid is essential, and the optical ratio is 1∶4 between number of bacteria and MIM.

2.3 Influence of temperature on RtZG1 production

The temperature has an effect on the electrical output of RtZG1 ( shown in Fig. 4). Each line represents different temperature. With the time prolonging, current significantly increased. When the whole reaction device is placed in the water bath, RtZG1 can effectively degrade glucose at a temperature of 37 ℃. At this point, we recorded about 200 μA current signal during 3 h. Therefore, the temperature of the reactor could determine the efficiency of the production of electro-bacteria. The optimal electrical production temperature of RtZG1 is 37 ℃. Lower temperature will reduce the activity of the strain, and the slope of current and time is small at 16 ℃.

2.4 Effect of the carbon-nitrogen ratio on the electrical production by RtZG1

From Fig. 5, we find RtZG1 can consume glucose in the medium, and protons are transported by metal ions thus generating current. The optical ratio of carbon to nitrogen sources for RtZG1 is 10∶1. During the experiments, we set some different gradients of carbon-nitrogen ratio. For example, when a carbon-nitrogen ratio was 5∶1 and 10∶1, the carbon-nitrogen ratio is 5∶1 and it is lower than 10∶1. When the carbon-nitrogen ratio is 10∶1, the occurrence of electricity has been growing and is higher than others. So, we choose carbon-nitrogen ratio 10∶1 as the suitable ratio.

2.5 Impact of anode substation fluid concentration on the electrical production of RtZG1

In Fig. 6, the concentration of anode substation fluid has influence on electrical production of RtZG1. Electrical production of RtZG1 increased over time, when the ratio was 1×MIM and 0.5×MIM. But, when the ratio is 2×MIM, 5×MIM, and 10×MIM, the slope between current and time decreases. There was a certain number of strains, and it was a certain about its ability to consume glucose in the medium, with the increase of the concentration of metal ions in the solution. Due to the amount of strains, too many metal ions in the proton transfer process are not very important. We could learn that its effect showed irrelevant. It can be learned that when the anode substation fluid concentration is 1×MIM, its power production is higher than the concentration of the other, so we selected 1×MIM as the working concentration.

3 Conclusions

In summary, the electrical production of RtZG1 is optimized in MFCs in this study. Compared with other kinds of electro-producing microorganisms that power production is about 4.14 W/m3or 40 μA[31], RtZG1 has good electrical efficiency. Accordingly, we report thatRaoultellaterrigenahas electro-bacterial properties. The strains in MFCs could use glucose as a single fuel and act on the fuel cells. We found the bacteria were an electrical production bacterium. We constructed a bipolar chamber MFC device that metal ion culture base MIM is used as the anode substation fluid and water as cathode liquid. By collecting the continuous output current within 3 h, it is obtained that the optical conditions as follows: the electrical production ratio between electrical bacteria liquid and the substation fluid was 1∶4, the optical temperature for the electrical production is 37 ℃, the carbon-nitrogen ratio of the inorganic salt medium is 10∶1, and the anode substation liquid concentration is 1×MIM. By optimizing the condition of RtZG1 electrical production, it is clear that the current of RtZG1 in 3 h electrical production is up to about 200 μA.

It is promising for microbial fuel cells’ research. As a new energy source, it could bring convenience to our life. The results of this study provided some basis on the electro-productingmechanism ofRaoultellaterrigena, suggesting some research ideas for MFCs to treat difficult-to-degrade organic matter and environmental problems such as wastewater treatment.

Journal of Donghua University(English Edition)2021年3期

Journal of Donghua University(English Edition)2021年3期

- Journal of Donghua University(English Edition)的其它文章

- Surface Modification of Electrospun Poly(L-lactide)/Poly(ɛ-caprolactone) Fibrous Membranes by Plasma Treatment and Gelatin Immobilization

- Probabilistic Load Flow Algorithm with the Power Performance of Double-Fed Induction Generators

- Outage Probability Based on Relay Selection Method for Multi-Hop Device-to-Device Communication

- Channel Characteristics Based on Ray Tracing Methods in Indoor Corridor at 300 GHz

- Electromagnetism-Like Mechanism Algorithm with New Charge Formula for Optimization

- Prediction of Online Judge Practice Passing Rate Based on Knowledge Tracing