Enhancement of magnetic and dielectric properties of low temperature sintered NiCuZn ferrite by Bi2O3-CuO additives

Jie Li(李颉) Bing Lu(卢冰) Ying Zhang(张颖) Jian Wu(武剑) Yan Yang(杨燕)Xue-Ning Han(韩雪宁) Dan-Dan Wen(文丹丹) Zheng Liang(梁峥) and Huai-Wu Zhang(张怀武)

1State Key Laboratory of Electronic Thin Film and Integrated Devices,University of Electronic Science and Technology of China,Chengdu 610054,China

2College of Communication Engineering,Chengdu University of Information Technology,Chengdu 610225,China

3Chongqing Engineering Research Center of Intelligent Sensing Technology and Microsystem,Chongqing University of Post and Telecommunications,Chongqing 400065,China

Keywords: NiCuZn ferrite, Bi2O3-CuO additive, magnetic properties, dielectric properties, ferromagnetic resonance(FMR)linewidth

1. Introduction

With the rapid development of the fifth generation of communication technology (5G), electronic devices continue their trend toward miniaturization,integration,multifunctionality, and in particular higher electromagnetic, frequencies.High frequency devices challenge researchers to the radio frequency(RF)applications.[1]Hence,a traditionally used magnetic material, NiCuZn ferrite, with high permeability, good chemical stability, low eddy-current loss, and high resistivity, benefit from enhanced properties to meet the modern requirements for high frequency device applications.[2-4]Considerable efforts have been already made to further improve the sintering properties, electrical resistivity, chemical stability, and permeability at intermediate to high frequencies.[5]To tune material properties,both the microstructure and magnetic properties of NiCuZn ferrites can be changed by adding different types of dopants. Many dopants, such as Bi2O3,CuO,V2O5,Co2O3,and combinations(B2O3-MoO2,Bi2O3-Nb2O5),were introduced into NiCuZn ferrites to enhance their sintering and magnetic properties, but there has been no researches on dielectric properties of ferrites.[6-12]

The Bi2O3and CuO were studied and found to be efficiently conducive to lowering the sintering temperature of ferrite. The Bi2O3is an excellent liquid-phase sintering aid that can lower temperature and promote grain growth.[13-15]The CuO is also considered as a good sintering aid for NiCuZn ferrite.[16]Hence, the eutectic mixture of Bi2O3-CuO has a relatively low melting point below 800°C, so that the doping of CuO and Bi2O3is likely to facilitate the integrality of reaction and improve the densification of ferrite due to liquidphase sintering. Xieet al. has used Bi2O3-CuO to lower the sintering temperature of LiZnTi ferrite and obtained a good microstructure and also good ferromagnetic properties, but there was no research on dielectric properties.[17]Therefore,the effect of Bi2O3-CuO additive on the microstructure, and properties of low-temperature-sintered NiCuZn ferrites,especially the dielectric and gyromagnet properties, were studied. The outcome of this study can be used for developing the low-temperature co-fired ceramics(LTCC)and producing electronic devices.

2. Experiment

ThepolycrystallineNiCuZnferritematerial(Ni0.22Cu0.20Zn0.58Fe2O4), which contains different quantities of Bi2O3-CuO, were synthesized by using a solid state method. Firstly, raw materials, including NiO, CuO, ZnO,and Fe2O3, were weighed according to their stoichiometric ratio. Next,these powders were mixed in a ball and milled for 16 h. The obtained slurry was dried and pre-sintered at 800°C for 4 h. Subsequently, the pre-sintered powders were doped with 1 wt%Bi2O3-x-wt%CuO(x=0.0 to 0.8 in steps of 0.2)and milled again for 12 h. The dried powders were pressed into toroidal samples with polyvinyl alcohol (PVA) under a pressure of about 10 MPa. Finally,the samples with different Bi2O3-CuO additives were sintered at 900°C for 4 h.

The phase formation of the samples was characterized by using x-ray diffraction (XRD, CuKαradiation,Rigaku, Japan). The microstructures were examined with a scanning electron microscope (SEM, JSM-6490, JEOL).The bulk density of the sample was evaluated by using the Archimedes method in distilled water. The complex permeability was measured by using an impedance analyzer(E4991B, Agilent). Vibrating sample magnetometer (VSM,MODEL, BHL-525, Japan) measurements, with±2500 Oe(1 Oe=79.5775 A·m-1) magnetic field, were carried out to investigate the magnetic properties. The ferromagnetic resonance (FMR) linewidth (ΔH) of the samples required the preparation of the spherical samples with a diameter of about 1.0 mm. They were measured by using the TE106 cavity perturbation method at 9.55 GHz.

3. Results and discussion

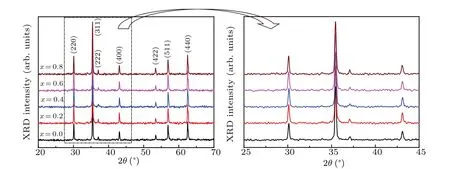

The XRD patterns for samples with different Bi2O3-CuO content are shown in Fig. 1. The crystal planes are indexed,according to their diffraction peaks, to (220), (311), (222),(400), (422), (511), and (440) (see Fig. 1). The results indicate that a pure spinel phase of NiCuZn ferrite is obtained after sintering at 900°C. Furthermore, the Bi2O3-CuO additive is able to lower the sintering temperature of sample and facilitate the synthesis of NiCuZn ferrite. In addition,it can be seen that there is no shift toward higher nor lower angles with increasing the amount of Bi2O3-CuO additive,indicating that the Bi3+ion does not enter into the lattice site nor change the lattice shape. Furthermore,neither a CuO phase nor any other related second phase appears in the XRD results,showing that the increased CuO phase has entered into the crystal lattice,occupying the lattice vacancies, and enhancing the properties of the sample.

Fig.1. XRD patterns of samples with different Bi2O3-CuO additives.

Both the microstructure and morphology of ferrites can provide valuable information to understand the sintering properties and the effects on the physical and chemical properties of ferrite. The cross-section SEM images and the bulk density of the samples are shown in Fig. 2. All samples are densely sintered,while the Bi2O3additive accelerates the synthesis of NiCuZn ferrites and promotes the grain growth.Moreover,the grain sizes in these samples are slightly different from each other. For all samples, because the constantxof the Bi2O3additive is kept unchanged, while the constantxof the CuO additive is varied, the observed difference in grain-size difference ought to originate from the CuO effect. In NiCuZn ferrite, there are 32 octahedral sites ( B-sites), and Cu2+ion preferred to occupy octahedral site (B site).[18]All the metal ions occupy 16 B-sites, so there are 16 vacancy locations at B-sites. Hence, in the present study, the content of CuO is slight, and the CuO preferred to occupy the lattice vacancies(B-sites). Hence the grain size of sample is little changed. In addition, the constantxof the CuO additive is small, and it does not generate a second phase. Hence,the SEM images reveal the characteristic shape of spinel NiCuZn ferrites,which is the main cause for the magnetic and dielectric properties of the samples.

Figure 2 also shows the bulk density of the sample. The bulk density is calculated from the following formula:

whereW1is the weight of the sample in air, andW2is the weight of the sample in distilled water. The bulk density of the NiCuZn ferrite is improved significantly by using the Bi2O3-CuO additive. The maximum value of the bulk density is 5.04 g/cm3. The bulk density first increases and then decreases. Based on the value of saturation magnetization and coercivity (as shown in Fig. 5), the reason for this may be that the Cu2+ions first occupy the lattice vacancies (beforex=0.4) and they are located at the grain boundaries (afterx=0.4).[19]

Fig.2. SEM images and bulk density of samples with different Bi2O3-CuO additives.

The XPS measurements are carried out to further analyze the cation oxidation states and the chemical composition of synthesized samples,for they closely relate to the catalytic activity of metal oxides. The Fe 2p x-ray photoelectron spectroscopy (XPS) spectra for all the samples are displayed in Fig. 3. Both the detailed binding energy (BE) obtained from the Gaussian fitting and the assignments for each peak are accomplished by comparing with the data from the literature.[20]The Fe 2p spectra are composed of two spinorbit doublets characteristics of Fe 2p3/2(710.5 eV, Fe3+in octahedral site, and 712.5 eV, Fe3+in tetrahedral site) and Fe 2p1/2(724.2 eV, Fe3+in octahedral site, and 726.8 eV,Fe3+in tetrahedral site)and two shakeup satellites at 718.1 eV,732.8 eV, respectively. The area ratios of Fe2+:Fe3+are 2.84:2.6,3.61:2.58,4.1:2.51,4.51:2.6,and 4.39:2.51,ascending with the Bi2O3-CuO additive content increasing. The proportion of Fe2+ion was increasing with Bi2O3-CuO additive increasing, which attests that part of O2-ions provide electrons and form chemical bonds with Cu2+ion. In the present research, in Ni0.22Cu0.20Zn0.58Fe2O4ferrite, Ni, Cu, Zn, and Fe ions occupy corresponding crystalline sites. Hence, the Cu2+ion additive prefers to occupy the lattice vacancy. The changes of Fe2+ions and Fe3+ions also attest to this fact.

Fig.3. Fe 2p XPS spectra of samples with different Bi2O3-CuO additives.

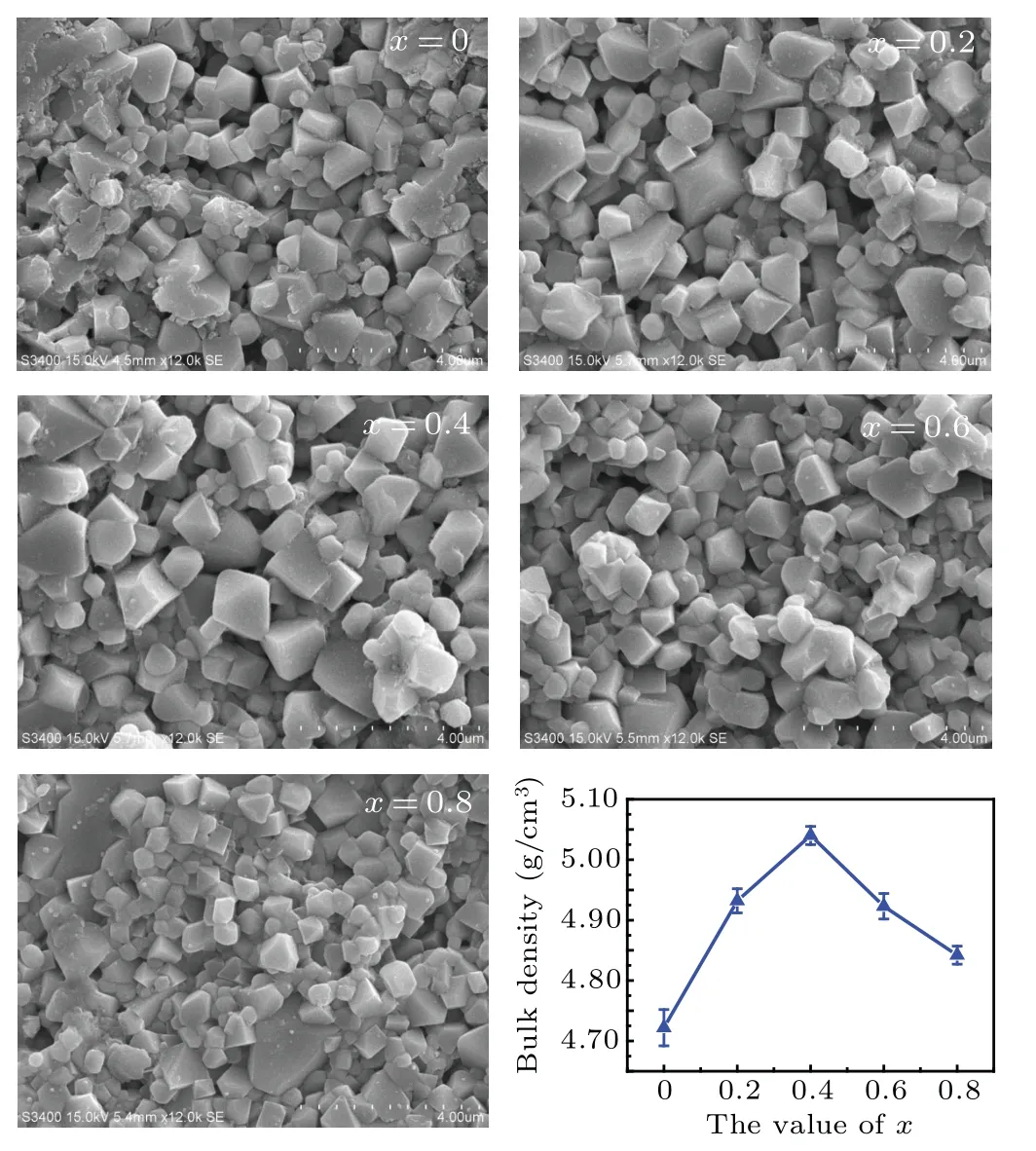

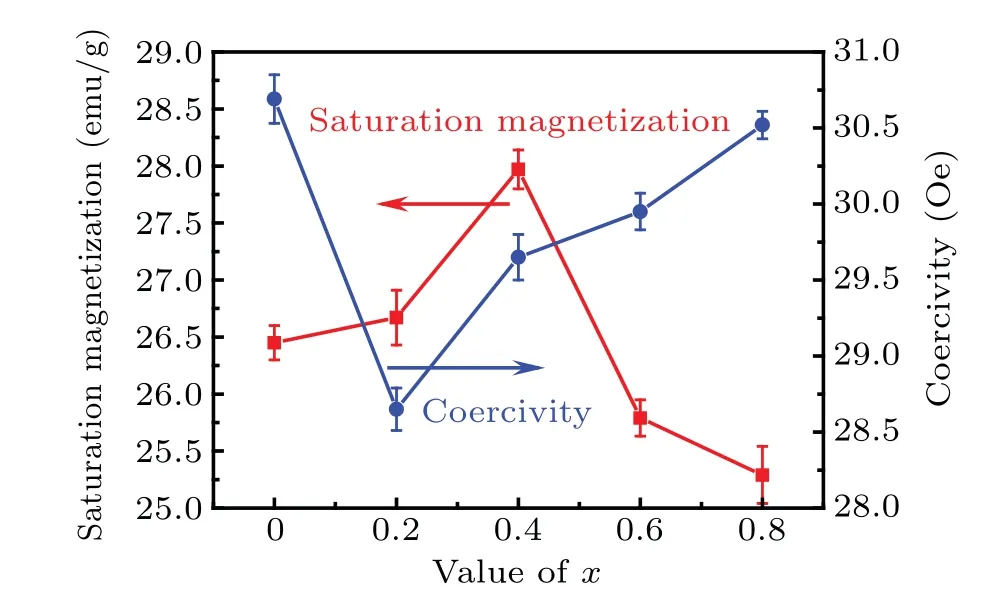

The magnetic hysteresis loops for the different samples are illustrated in Fig. 4. These curves reveal a characteristic soft magnetism. Variations in the saturation magnetization(Ms) and coercivity (Hc) of the samples are shown in Fig. 5.With the increasing of Bi2O3-CuO additive constant,the saturation magnetization of the sample first increases to a maximum value (x=0.4,Ms=27.97 emu/g) and then decreases.In addition,the coercivity first decreases to a minimum value(x=0.2,Hc=28.65 Oe)and then increases. The proportion of Fe2+ion decreases with Bi2O3-CuO additive increasing,which is shown in Fig.3. Most of Cu2+ions occupy the octahedral sites,and the Fe2+ions prefer to occupy the tetrahedral sites. The coercivity of sample(x=0.2)ferrite is smaller than those of other samples,which was also reported by Yang and Luo.[21]

Fig. 4. Magnetic hysteresis loops of samples with different Bi2O3-CuO additives.

For the ferrite, the magnetic properties are affected by the chemical composition and ion distribution at the crystallographic site. In this study,both the saturation magnetization and the coercivity are determined by using the chemical formula for Ni0.22Cu0.20Zn0.58Fe2O4. The changes are affected by both the Bi2O3additive and the CuO additive. First,1-wt%Bi2O3additive can lower the sintering temperature and promote the synthesis of NiCuZn ferrites,[8]while the CuO additive changes the magnetic properties. Forx=0.0, the pure NiCuZn ferrite has a saturation magnetization of 26.45 emu/g.With CuO increasing,the Cu2+ion can occupy the lattice vacancies(octahedral sites),leading to enhanced magnetic properties. Forx=0.6 and 0.8,some of the Cu2+ions exist at the grain boundaries and form Cu-O bonds. This has a deteriorating effect on magnetic properties of the samples. Second,the variation ofMsmight be due to the larger grains of ferrites.The SEM images show that the samples withx=0.4 and 0.6 have both a larger grains size. Finally,the bulk density is another factor to change the magnetic properties. The sample withx=0.4 shows high densification, which leads to higher saturation magnetization.

Fig.5. Variations of saturation magnetization(Ms)and coercivity(Hc)with the values of x for samples with different Bi2O3-CuO additives.

The values of coercivity(Hc)of the samples show the opposite trend to the variation inMs, and the changes ofHcare mainly due to chemical composition and CuO additive. The Cu2+ions occupied positions are the main factor changing the value ofHc. The Cu2+ions in lattice vacancy and grain boundary,especially in the grain boundary,Cu2+ions impede the motion of domain wall,which results in the increase ofHcwhenxis larger than 0.4. the formation of CuO precipitates during the sintering of NiCuZn ferrites can be attributed to the sintering process being faster than oxygen diffusion from outside into the pores. This phenomenon has been reported by Barbaet al.[22]and Hsiang and Chuch.[22,23]Moreover,Hcis also determined by the density and microstructure of the ferrite sample. The high densification and high average grain size lead to a lowHc. Furthermore,when an extra amount of Bi2O3-CuO is present at the grain boundary, which can promote a chemical reaction,the demagnetizing field increases at the grain boundaries,which also contributes to the increase ofHc.

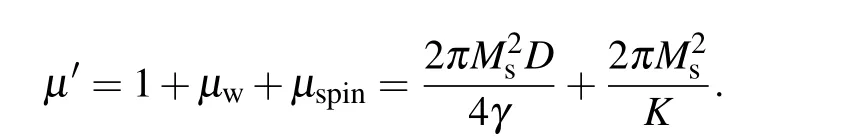

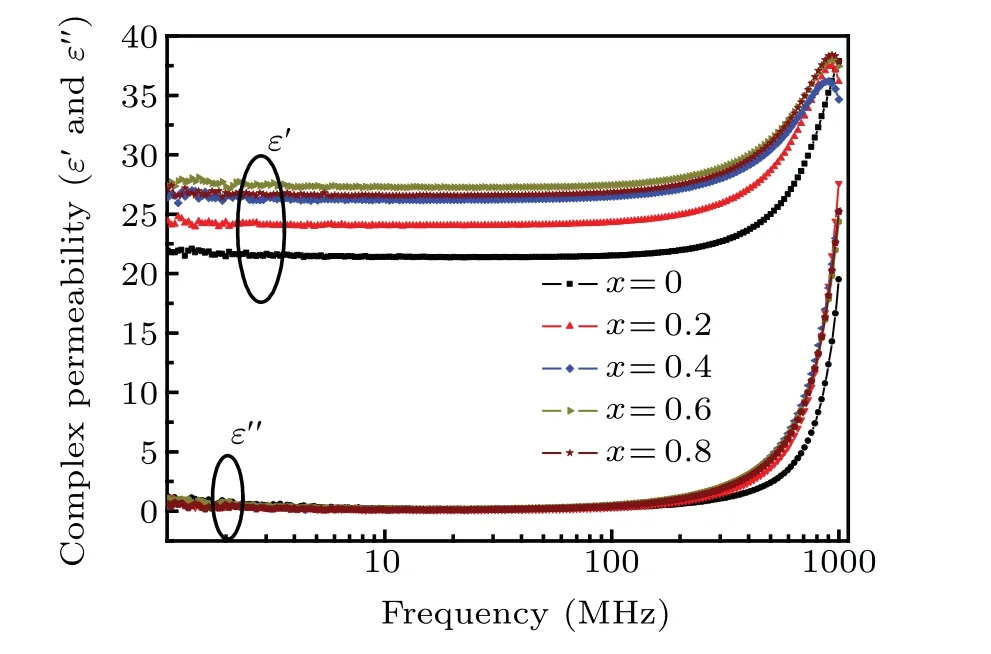

Figure 6 shows the curves of frequency-dependent complex magnetic permeability of samples with different amounts of Bi2O3-CuO additive. The real part of magnetic permeability (µ') first increases up to a maximum value and then decreases. Forx= 0.0, the value ofµ'is about 184.8 at 1 MHz-5 MHz,and the maximum value ofµ'is about 210.2 at 1 MHz-5 MHz forx=0.6. In addition,the imaginary part of the magnetic permeability (µ'') remains small, which attests that the material has low magnetic loss. The NiCuZn ferrite possesses a good complex magnetic permeability and can be used in electronic devices. In this study,the Bi2O3lowers the sintering temperature significantly, leading to high densification. The CuO additive is an important factor as far as the change of the complex magnetic permeability is concerned.As discussed above, some CuO particules can enter into the lattice vacancies, thereby improving the magnetic properties,and superfluous CuO is present along the grain boundary,which creates a negative effect on the magnetic properties.However,the maximum value ofµ'occurs forx=0.6,which is different from the saturation magnetization.For the NiCuZn ferrite,µ'is correlated with the spin rotation and the domain wall motion. The domain wall motion represents a dominant contribution to the magnetization mechanism and can be described as follows:[7,24]

Here,µwis the domain wall susceptibility,µspinthe intrinsic rotational susceptibility,Msthe saturation magnetization,Dthe grain size,γthe domain wall energy,andKthe magnetocrystalline anisotropy constant. Hence, the addition of CuO can affect the grain size and magneto-crystalline anisotropy,which causes theµ'value ofx=0.6 sample to be higher than that ofx=0.4 sample.

Fig.6. Complex magnetic permeability(µ' andµ'')of samples with different Bi2O3-CuO additives.

Fig. 7. Curves of frequency-dependent complex dielectric permittivity (ε'and ε'')of samples with different Bi2O3-CuO additives.

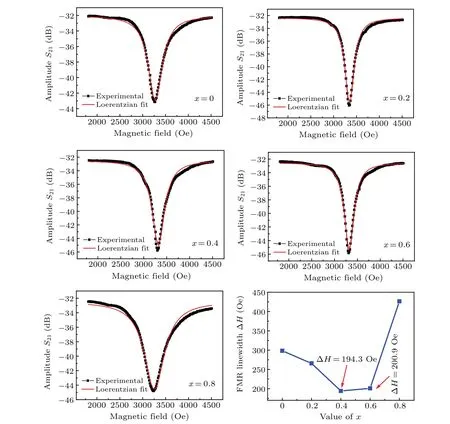

Fig.8. Ferromagnetic resonance(FMR)linewidths based on fitting of Lorentzian to spectra of the samples.

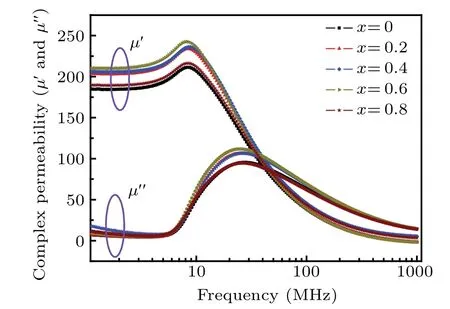

Figure 7 shows the curves of frequency-dependent complex dielectric permittivity(ε'andε'')of samples with different Bi2O3-CuO additives. The dielectric permittivity curves show a similar trend with magnetic permeability increasing.The maximum value of the real part of the permittivity(ε')is about 27.23 forx=0.6. Each of these samples possesses a low imaginary part for the permittivity. The dielectric properties for each of ferrites show a strong relation with hopping of electrons at the octahedral site. The electron exchange between Fe2+and Fe3+, results in a local displacement of the electrons,thereby inducing the polarization.[3]The Cu2+ions occupy the lattice vacancies of the ferrite, forming covalent bonds with O2-ions, which causes the number of Fe2+ions in the ferrite to increase. Furthermore, the electron hopping probability of Fe3+-Fe2+increases with the number of Cu2+ions increasing,thus leading theε'to augment.However,with the further increase of Cu2+ions,the superfluous CuO exerts a negative effect on the dielectric properties. According to the Debye relaxation model, the electric field changes more slowly than the relaxation of materials and the polarization can change with electric field very well at the low frequency,which results in the imaginary part of complex permittivity(ε'') tending to the real part of complex permittivity (ε'). In addition, figure 7 shows that there exists a turning corner for each of these samples while the test frequency is nearly 1 GHz.In ferrite ceramics, the grain boundaries represent a barrier which weakens the electrons hopping,causing the inter-grain conductivity to drop. In addition,owing to the high resistance of grain boundaries,electrons accumulate at grain boundaries and produce space charge polarization. At high frequencies,the constancy of bothε'andε''can be attributed to the fact that the electrons in the grain can no longer follow the alternating field. This is in good agreement with previous results.[25,26]

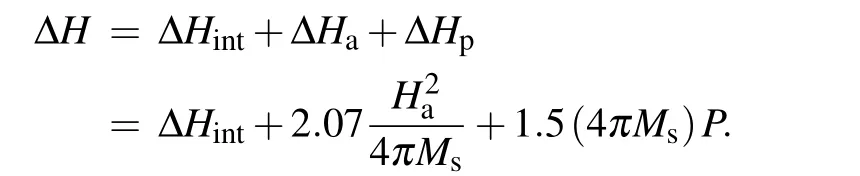

Figure 8 shows the ferromagnetic resonance (FMR)linewidth(ΔH)of Lorentz fitting to NiCuZn ferrites with different Bi2O3-CuO additives.The ΔHvalues for different CuO additives are shown in Fig.8. The value of ΔHfirst decreases,reaching a minimum value and then increasing. The smallest ΔHvalue is about 194.3 Oe forx=0.4. Evidently,the different chemical compositions can have a dramatic effect on ΔHvalue. Also,the grain size distribution,pores,and microstructure play a key role in lowering the ΔHvalue.[27]In this study,the difference in ΔHvalue can be attributed to the correlation between the grain size distribution and Cu2+ion occupancy.Firstly, based on the SEM images (Fig. 2), the samples withx=0.4 and 0.6 have bigger grain sizes,which can enhance the gyromagnetic properties considerably (lower ΔH). Secondly,the densification affects the value of ΔH. The higher the densification of the ferrite,the lower the magnetic loss is. Hence,the samples with higher density show lower ΔHvalue.Finally,thex=0.8 sample has a higher value for ΔH(ΔH=426.4 Oe).This can be explained by the fact that Cu2+ions exist along the grain boundary that hinder the domain walls from displacing.Of course, based on the discussion above, the change of ΔHcan also be expressed as

Here, ΔHintis the intrinsic linewidth,Hathe random anisotropy field,andPattributed to the porosity of grains. In this study,the effect of grain size,densification,and ion occupancy are discussed and the material is found to have potential applications in microwave devices.

4. Conclusions

In summary, the NiCuZn ferrite are successfully synthesized with Bi2O3-CuO as additives in a low-temperature sintering process. The addition of Bi2O3-CuO can enhance the microstructure and magnetic properties. The CuO particles can either occupy lattice vacancies or be located along the grain boundaries, which affects the microstructure and properties considerably. The samples show excellent magnetic and dielectric properties, whenx=0.4 andx=0.6. Hence, it is expected that the NiCuZn ferrites with optimal additives could be a promising material for microwave devices.

Acknowledgements

Project supported by the National Key Research and Development Program of China (Grant No. 2018YFE0115500),the National Natural Science Foundation of China (Grant Nos. 52003256 and 51902037), and the Natural Science Foundation of Shanxi Province, China (Grant No.201901D211259).

- Chinese Physics B的其它文章

- Quantum walk search algorithm for multi-objective searching with iteration auto-controlling on hypercube

- Protecting geometric quantum discord via partially collapsing measurements of two qubits in multiple bosonic reservoirs

- Manipulating vortices in F =2 Bose-Einstein condensates through magnetic field and spin-orbit coupling

- Beating standard quantum limit via two-axis magnetic susceptibility measurement

- Neural-mechanism-driven image block encryption algorithm incorporating a hyperchaotic system and cloud model

- Anti-function solution of uniaxial anisotropic Stoner-Wohlfarth model