Recent Progresses on Optimal Design of Heat Integrated Water Allocation Network

Zhang Chijin; Ren Congjing; Liao Zuwei; Sun Jingyuan; Wang Jingdai; Yang Yongrong

(1.State Key Laboratory of Chemical Engineering, College of Chemical and Biological Engineering, Zhejiang University, Hangzhou 310027; 2.Ningbo Research Institute, Zhejiang University, Ningbo 315100)

Abstract: Energy integration and mass integration are important approaches to achieve energy saving and emission reduction in the process industry.Generally, the methods can be classified into two groups, viz.: conceptual design methods and mathematical programming methods.The former includes mainly graphical methods based on pinch technology that is operated easily.A feasible solution can be quickly obtained.Conceptual design methods are sequential in nature including two steps, namely: targeting and designing.The latter is based on superstructure optimization, and corresponding algorithm is adopted to solve the model.The trade‐offs and connections among the entire network can be established and explored.Multiple factors can be considered and optimized simultaneously by mathematical programming methods.This paper describes the synthesis of heat integrated water allocation networks (HIWAN) based on both conceptual design methods and mathematical programming methods systematically.In addition, the characteristics and shortcomings of the existing research methods are summarized, and the future research direction is prospected.

Key words: heat integrated water allocation network; conceptual design; mathematical programming.

1 Introduction

As the energy crisis and water shortage become more and more serious, the energy and water cost of process industry has also increased.Additionally, the environmental regulations and laws become stricter and stricter with the strengthening of sustainable development concept.It is of significance to achieve energy conservation and emission reduction of process industry.Heat integration and mass integration are the main ways to reduce resource consumption and emissions.

There are many streams that need to be cooled or heated in the same production process.For example, raw materials need to be preheated to a certain temperature before entering the reactor, and products may need to be cooled before entering the separation unit or storage unit.A reasonable match among streams can make full use of the energy of these streams and improve energy utilization efficiency.Heat integration represented by heat exchanger networks aims to determine the minimum utility consumption when all cooling or heating requirements are met.As the research goes further, such a technology is gradually evolved into a more comprehensive optimization problem, which considers total annual cost,process design, interplant heat integration and multi‐period heat exchanger networks, etc.

Water collocation networks (WAN) is one of the special forms of mass integration, which is used to improve the water efficiency and to reduce the consumption of fresh water and the discharge of wastewater through rational reuse.Water networks can generally be divided into two categories, viz.: fixed flowrates and fixed mass loads.Each water‐using unit needs to meet specific concentration and temperature requirements, and the temperature of discharged water is usually limited by be ambient temperature.

Based on the above research, there are a large number of streams in the water network that need to be heated or cooled to meet operating conditions.A heat integrated water network, which can simultaneously consider water and energy usage, is proposed.The corresponding optimization design methods of it can be divided into twocategories, viz.: the conceptual design method and the mathematical programming method.

2 Conceptual Design Methods

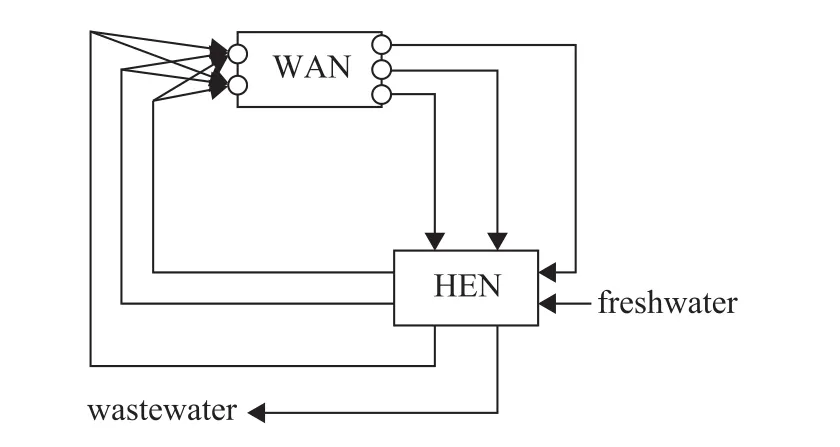

Conceptual design is essentially a sequential design method shown in Figure 1, which divides the design procedure into two steps: first obtaining the WAN with minimum water and energy consumption, then designing the heat exchanger network (HEN) based on the WAN.The design of the HIWAN was initiated by a research group from the Manchester University[1‐4].They proposed a two‐step approach which is suitable for both no water‐reuse[3]and maximum water‐reuse[4].The WAN is designed by a new graphical tool ‒ Two‐Dimensional Grid Diagram of the concentration versus temperature coordinate system.Feng, et al.[5]explored the impact of non‐isothermal mixing in the WAN on utility consumption in the HEN, and proposed three criteria:(I) Non‐isothermal mixing of streams cannot reduce utility consumption; (II) If the non‐isothermal mixing of streams does not increase the utility consumption,then the total heat exchange load can be reduced; (III)Only if the temperature differences of both mixing streams are less than the minimum temperature approach,the non‐isothermal mixing could reduce the utility consumption.Leewongtanawit and Kim[6]modified the Two‐Dimensional Grid Diagram and established the Water Energy Balance Diagram to improve the energy recovery of the WAN.They also introduced a separate system to guide the reduction of the heat transfer area by maximizing the temperature approach.In addition to the water using units of fixed mass loads, the water using units of fixed flowrates are also considered by researchers.Manan, et al.[7]established a Heat Surplus Diagram to guide the simultaneous water and energy optimization.This method is suitable for both water using units of fixed mass loads and water using units of fixed flowrates.Subsequently, Wan Alwi, et al.[8]combined the Heat Surplus Diagram[7]and the Composite Curve of WANs[9]to construct a Superimposed Mass and Energy Curves (SMEC), and proposed six heuristic rules to guide the WAN design to reduce the utility consumption.Luo, et al.successively used the problem table[10]and the T‐H composite curve[11]to explore the influence of non‐isothermal mixing of streams on the energy consumption of WANs, and proposed guidelines for simplification of HENs.In addition to T‐H composite curve, there are H‐F composite curve shown in Figure 2.Based on the separation system and finally matched composite curve, the corresponding HEN can be obtained, which is shown in Figure 3.Martínez‐Patiño, et al.[12]established a four‐step process: firstly, obtaining the minimum water consumption of the WAN through the pinch technology;secondly, the Temperature Concentration Diagram is established to describe water‐using units; thirdly, direct or indirect heat transfer design is implemented; finally,the networks are merged.Hou, et al.[13‐14]established the Temperature and Concentration Order Composite Curve (TCOCC) based on the concept of Concentration Potential[15].This method is suitable for single‐contaminant and multi‐contaminant WAN problems.Xie, et al.[16]applied this method to the problem of a fixed flowrate WAN and proved the principle of Single‐Temperature‐Peak Design: When each subsystem of the WAN has only one temperature peak, this network requires less utility consumption.Based on the Single‐Temperature‐Peak Design principle, a two‐step method is proposed in which the first step is to design a WAN that meets the Single‐Temperature‐Peak principle, and the second step is to obtain a HEN through a heuristic method.Liao, et al.[17]introduced the enthalpy‐flowrate diagram to regulate the heat exchange matches between streams, the obtained HENs are in parallel structure.Later, the authors[18]developed the evolving procedures to convert this parallel structure HEN into sequential‐parallel hybrid structure HEN in the same diagram and to convert sequential structure HEN into developed hybrid structure HEN in the temperature ‒ enthalpy diagram.Hong, et al.[19]also proposed a heat exchange block concept in the temperature ‒ flowrate diagram to design hybrid structure HENs.As shown in Figure 4, this method constructs HENs based on the heat exchange load and a hybrid structure of series and parallel connection can be obtained.

Figure 1 Conceptual design of heat integrated water allocation networks

Figure 2 Cold composite curve and hot composite curve on H-F diagram T-H diagram

Figure 3 Illustration for the separate systems on T-H diagram and the matching composite curve

Figure 4 Heat transfer blocks diagram for a four-water-unit example

3 Mathematical Programming Methods

Apart from the conventional HENs, both the temperature and flowrate of streams are unknown in the HEN ofHIWAN.Thus, the design problem of HIWAN is highly nonlinear and non‐convex and is difficult to solve.The mathematical programming methods for HIWAN can be divided into two categories, viz.: the sequential design methods and the simultaneous design methods.

3.1 Sequential design method

The sequential design method decomposes the HIWAN into multiple independent sub‐problems (WAN and HEN).Bagajewicz, et al.[20]proposed a two-step method based on the necessary conditions of single contaminant WAN optimality[21]and the HEN transport model, and established an LP and MILP model.Firstly, the WAN was obtained by minimizing the amount of fresh water and then a transport model was used for designing HEN.However, the necessary conditions for optimality of the WAN are only applicable to the problem of minimizing water consumption.It is not applicable to the WAN, which considers the heat integration.Feng, et al.[22]analyzed the energy consumption performance of different WANs and found that the energy consumption performance of the WAN can be enhanced by reducing the number of fluctuations in the stream temperature.

Based on this discovery, they proposed another two‐step method.The first step is to design a WAN with excellent energy consumption performance, and the second step is to design a HEN.Liao, et al.[23]established a MINLP model allowing the splitting operation of water using units.The fresh water consumption was obtained through the LP model before solving this model.Subsequently, they established a set of cold and hot streams identification methods based on the source‐sink stream concept[24], which can identify hot and cold streams before designing the network.Using the transshipment model and the optimal conditions of the WAN to establish a MILP model to find heat exchange matching, and then optimize the total cost of the entire network based on the heat exchange matching obtained in the first step.Boix, et al.[25]first considered optimizing fresh water consumption, utility consumption and the number of heat exchangers through the MILP model to complete the preliminary design, in which multi‐objective optimization is implemented through the ε‐Constraints method, and then they further used the MINLP model to optimize the total annual cost.After that, De‐León Almaraz, et al.[26]extended the method to the problem of multi‐contaminant HIWAN, comparing the pinch point technique and the mathematical programming method at the second step for designing the HEN.Liu, et al.[27]used the Generalized Disjunctive Programming to establish a MINLP model to optimize the WAN, while considering the energy consumption simultaneously, and then used the pinch technology to design the HEN.Zhao, et al.[28]established a two‐step optimization model for the problem of multi‐contaminant HIWAN.The first step is to use the concept of Concentration Potential in the water unit to design a multi‐contaminant WAN.The second step is to use the Self‐Heating Strategy to reduce the complexity of the HEN, which means that the outlet heat stream of the water unit are used to preheat the inlet cold stream and the unsatisfied heat load is met by the utility.Hong, et al.[29]developed an MILP to target the HIWAN.

3.2 Simultaneous design method

The sequential design method decomposes the HIWAN into multiple sub‐problems, and cannot fully explore the trade‐off relationship between the WAN and the HEN.Therefore, researchers began to implement the simultaneous design methods.Bogataj and Bagajewicz[30]established a HIWAN superstructure as a MINLP model to optimize the WAN and HEN simultaneously based on an improved hierarchical superstructure.Dong, et al.[31]proposed an improved State‐Space superstructure for HIWAN and an iterative solution strategy to find the optimal solution in a richer network structure space.Zhou, et al.further extended the model to the problem of inter‐plant HIWAN allowing direct and indirect reuse schemes for both fixed flowrate[32]and fixed contaminant load[33]problems.In addition, the authors[34]also use the State‐Space superstructure model to optimize the HIWAN, while considering the other stream constraints,such as toxicity, pH value, and chemical oxygen demand.Ahmetović, et al.[35]established a new superstructure model to increase additional heat transfer opportunities,and proposed a Convex Hull Formulation to identify hot streams and cold streams.They also considered integration with process HEN[36]and integration with wastewater treatment units[37].Yan, et al.[38]used nonlinear formulas instead of binary variables to convert the model proposed by Ahmetović, et al.[35]from MINLP to NLP model, which is faster to solve.Ibrić, et al.[39]proposed a simultaneous optimization model with a two‐step solution strategy, which is suitable for pinch and threshold problems.In addition, the author extended the model to include wastewater treatment[40]and proposed a Compact Superstructure[41]with eighteen rules to simplify the complexity and scale of model[42].Above model can be further used for the simultaneous optimization of HIWAN design and HEN problems involving process streams[43]and the optimization of inter‐plant HIWAN[44].Zhou, et al.[45]improved the sequential design method of Liao, et al.[24]into a simultaneous design method, and introduced the Mathematical Programming with Complementary Constraints (MPEC) to simulate the discontinuous variables in the related model.Liu, et al.[46]established sequential optimization design and simultaneous design methods for the HIWAN problem encountered in the industrial park.They used the method of Yan, et al.[38]to convert the MINLP model into NLP model.However,this model only considers the WAN with a fixed flow rate,and does not consider the WAN with a fixed contaminantload.Hong, et al.[47]also proposed a simultaneous strategy for HIWAN synthesis.

4 Future Directions

Optimization of HENs and HIWANs has always been the research hotspots in the field of process systems engineering.Many scholars have carried out a lot of research in the past decades.Although great progress has been made, there are still lots of work to do in the future.The conceptual design method of HIWAN needs to be further improved in structural diversity of HEN and optimization of equipment costs.Although this method cannot fully consider the trade‐off relationship between the WAN and the HEN and obtain the optimal solution, it decomposes the HIWAN optimization problem into two sub‐problems, which can greatly reduce the difficulty to solve.Meanwhile, the related solution can be used as the initial value, which is useful for solving the mathematical programming model.Research on the WAN mainly focuses on exploring the influence of stream mixing on the energy performance, while other study on the HEN mainly explores different graphic tools such asT-Hdiagrams to design the number of heat exchangers with less utility consumption.However, the HEN structure obtained by theT-Hdiagram is single, and there is no research aimed at exploring the structural diversity of the HEN.Different HEN structures can be adapted to meet different operating requirements.In addition, the current graphic method does not consider the optimization of the total cost of heat exchanger equipment when designing the HEN, and lacks a systematic method to optimize the cost of the HEN.

Although the mathematical programming method for the optimal design of the heat exchanger network has obtained many theoretical results, the optimization of the HEN has been proved to be NP‐hard MINLP problem.Such problems are difficult to obtain the global optimal solution, and it is even difficult to get a good solution without a good initial value.In order to reduce the difficulty of the solution and ensure the efficiency of the model, the existing research uses a large number of isothermal mixing hypotheses for hierarchical superstructure HEN model, while ignoring non‐isothermal conditions.Obviously, the hierarchical superstructure contains fewer structural possibilities, and it is impossible to obtain a structure where the stream bypasses or the stream continuously passes through multiple heat exchangers and multiple utilities at the same temperature.It can be noted that the development of a model, which is easy to solve and contains more structural possibilities, is of great significance for HEN optimization.

Compared to the HEN optimization problem, the HIWAN is usually more complicated.Firstly, the attributes of the streams in the HIWAN are unknown.It is necessary to introduce logical variables to determine the hot and cold attributes of the streams in the WAN, so that it can be optimized simultaneously with the HEN.Secondly,the combination of the WAN and the HEN leads to more structures, more degrees of freedom and more complex models.Finally, the existing research or decomposition problems cannot be optimized simultaneously, since either wastewater treatment is not considered, or the model structure is less likely, or the model is extremely difficult to solve, which is not conducive to the system optimization of the HIWAN.

- 中国炼油与石油化工的其它文章

- Controlling the Pore Structure and Photocatalytic Performance of the Flexible FeⅢ Metal-Organic Framework MIL-53(Fe) by Using Surfactants

- Acidity Evaluation of Industrially Dealuminated Y Zeolite via Methylcyclohexane Transformation

- Study on Distribution of Electrocatalytic Reaction Efficiency in a Three-Dimensional Electrocatalytic Reactor

- Preparation of Ultra-High Molecular Weight Polypropylene Using Ziegler-Natta Catalyst via Combining Internal Electron Donor and Cocatalyst Loading

- Preparation of Modified Enteromorpha-Immobilized Microbial Agent and Research on Diesel Removal Performance

- Chemoselective Catalytic Hydrogenation of Nitroarenes Using MOF-Derived Graphitic Carbon Layers Encapsulated Ni Catalysts