Improving mechanical properties of Mg-Sn alloys by co-addition of Li and Al

Zhen Pn, Huheng Pn,*, Yu Hung, Zhiho Zeng, Zhng-Zhi Shi, Chuin Yng,Yuping Ren, Lu-Ning Wng, Gowu Qin

a Key Laboratory for Anisotropy and Texture of Materials (Ministry of Education), College of Materials Science and Engineering, Northeastern University, Shenyang,110819, China

b Beijing Advanced Innovation Center for Materials Genome Engineering,Key Laboratory for Advanced Materials Processing of Ministry of Education,School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing, 100083, China

c Jiangxi Provincial Engineering Research Center for Magnesium Alloy, Gannan Normal University, Ganzhou, 341000, China

Keywords:Mg wrought alloy Nano-precipitations Strengthening Grain refinement Mechanical properties

A B S T R A C T In this work,a novel low-alloyed Mg-Sn-Li-Al alloy with high-strength has been developed.The addition of ~1 wt%Li into the Mg-2Sn wt.%binary alloy can change the type of strengthening phases in Mg-2Sn-1Li sample(TL21),involving the formation of both Li2MgSn and Mg2Sn phases.The co-addition of ~1 wt% Al and ~1 wt% Li can further induce the higher density of both micron-sized phases and nano-precipitations in the Mg-2Sn-1Li-1Al sample (TLA211).The nano-precipitations can inhibit the grain growth, which thus lead to the fine grain size of ~1.38 μm in TLA211 sample, and ~1.59 μm in the TL21 sample.Besides, the profuse nano-phases would improve the yield strength via Orowan hardening effect.Consequently,the TL21 sample can exhibit the high yield strength of ~204 MPa,and elongation of ~6.6%.The TLA211 sample exhibits the much higher yield strength of~250 MPa,ultimate tensile strength of ~291 MPa,and also high elongation of ~9.0%.The high strength-ductility synergy, together with the low-Sn content, make the present Mg-Sn based alloy to be potential for the wider industrial applications.

1.Introduction

Magnesium alloys have obvious advantages of low density, high specific strength and excellent damping properties, which exhibit great potential for weight-saving in the fields of transformation, aircraft and automobiles [1-6].Despite of that, the low absolute strength and poor formability limit the wide application of Mg alloys [7,8].Alloying is an effective method to improve mechanical properties, and it has been reported that the Mg alloys containing rare-earth elements(Y,Ce,Sm and Gd) can possess much improved strength and plasticity [7,9,10].However,the cost of Mg-RE based alloys is much higher than those of RE-free Mg alloys,which seriously affects the industrial usages.Consequently,it would be much attractive to develop the RE-free Mg alloys with both the low cost and excellent mechanical properties.

Since the cost of Sn is much lower than that of rare earth elements,Mg-Sn-based alloys have received particular attentions in the field of lowcost Mg alloy.According to the binary Mg-Sn phase diagram, the solubility of Sn in the α-Mg matrix is approximately 14.48 wt%at 561°C,and the solute Sn can precipitate to form large amount of the Mg2Sn strengthening phase[2,11-13].Under the same extrusion conditions,the strength and elongation of the Mg-Sn alloy were improved as the Sn content increasing.When the Sn content reached 4 wt%, the yield strength(YS),ultimate tensile strength(UTS)and elongation(EL)of the Mg-Sn alloy were 170 MPa, 277 MPa and 17.9%, respectively [14].To further improve the strength of Mg-Sn based wrought alloys, the micro-alloying strategy has been carried out.For example, the indirect-extruded Mg-8Sn-1Al-1Zn alloy exhibited an excellent strength-ductility synergy with YS of 245 MPa,UTS of 310 MPa,and EL of 17.5%[15].Luo et al.[16]investigated the effect of Zn/Al mass ratio on the microstructural evolution and mechanical properties of Mg-3Sn-5Zn-xAl alloy,and the results showed that the UTS and EL of the alloy were highest when the Al content is ~1 wt%,reaching 340 MPa and 20.1%.Kim et al.[17] reported that the addition of 4 wt% Al to Mg-7Sn-1Zn alloy promoted dynamic recrystallization (DRX) and dynamic precipitation during extrusion and the UTS can reach as high as 340 MPa,accompanied with high EL of 17.7%.

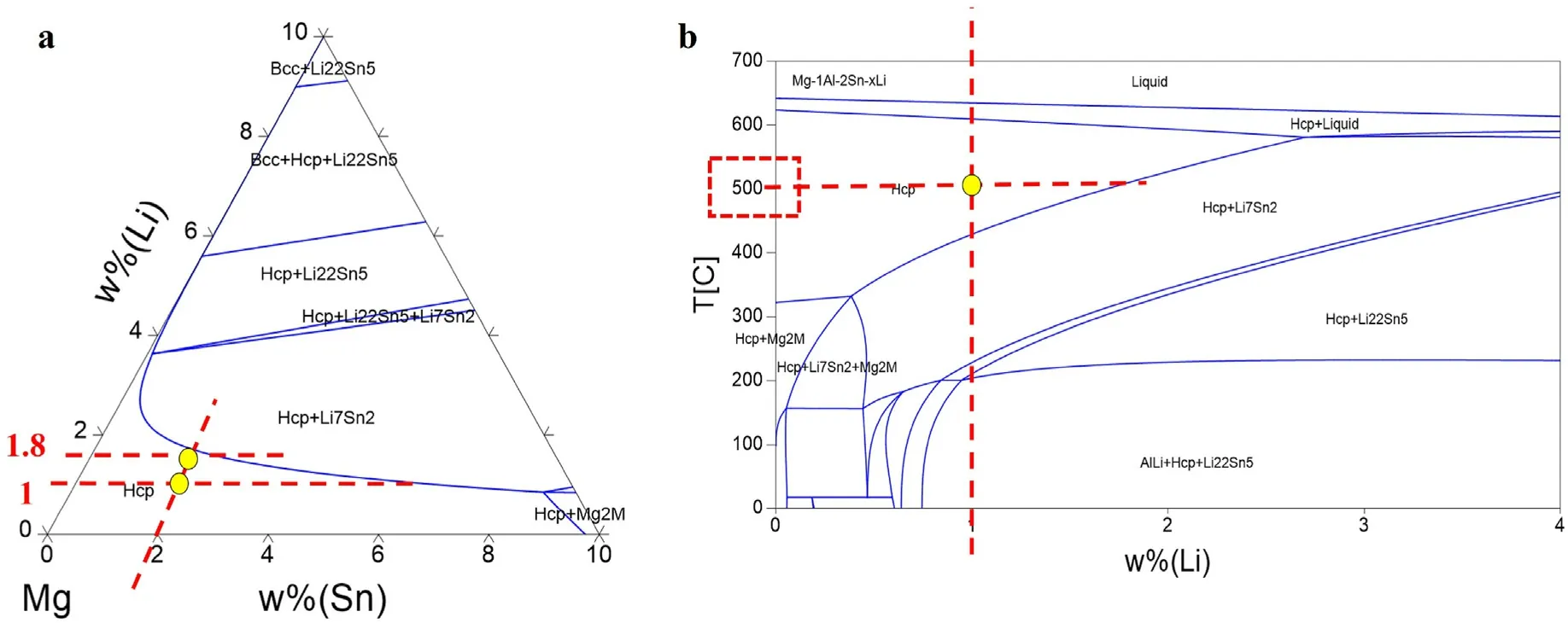

Fig.1.The phase diagram of (a) the Mg-xSn-yLi alloy at 500 °C; (b) the Mg-2Sn-xLi-1Al alloy.

Table 1 Process parameters of T6, TL21,TL22 and TLA211 alloys.

Although Mg-Sn alloys with high strengths have been developed,the content of Sn is generally higher than 8 wt%, which leads to the unfavorable cost and relatively high density.Therefore,the development of Mg-Sn alloys with high strength-ductility and also a low Sn content is yet a great challenge.In this regard,micro-alloying with other elements,such as Li and/or Al,into Mg-Sn alloys with low Sn content has become a promising routine.Addition of the lightest Li element can further reduce the density and c/a-axis ratio of Mg alloys,thus improving the ductility of Mg [18].For example,Jiang et al.[12] found that the addition of trace amounts of Li element(~0.3 wt%)can significantly improve the YS and EL of as-cast Mg-5Sn alloys,with YS of 77 MPa and EL of 15%.In addition, the addition of Li can change the type of strengthening phases in Mg-Sn alloys, involving the formation of both Li2MgSn and Mg2Sn phases,and they can effectively hinder the dislocations motion,which leads to the enhancement of Mg-Sn alloys properties.Aluminum (Al), as a conventional element, has been widely used in the alloying of magnesium alloys[19].The addition of Al does not affect the phase formation of Mg2Sn in Mg-Sn based alloying system [20], which can also lead to the solid solution strengthening [21].Therefore, Al is a suitable element to be added to Mg-Sn alloys.Meanwhile, there are few studies on the addition of Al to Mg-Sn-Li based alloys.In this work, we designed the alloy composition according to the calculated phase diagram,and both Li and Al elements have been added into the Mg-Sn based alloy.The effect of Al and Li contents on the microstructure and mechanical properties of Mg-Sn-Li-(Al)alloy was clarified.

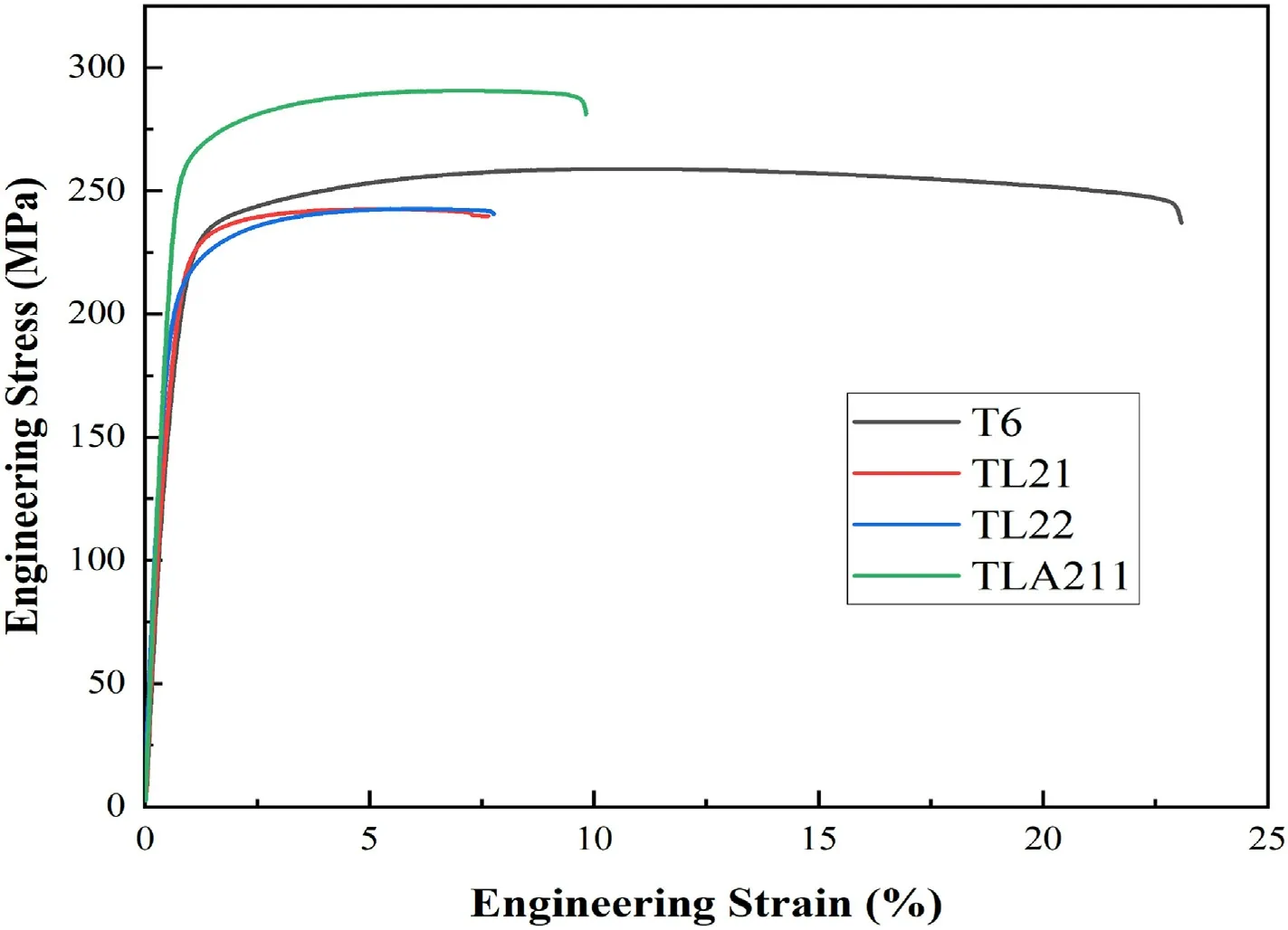

Fig.2.Tensile engineering stress-strain curves of as-extruded T6, TL21, TL22 and TLA211 samples.

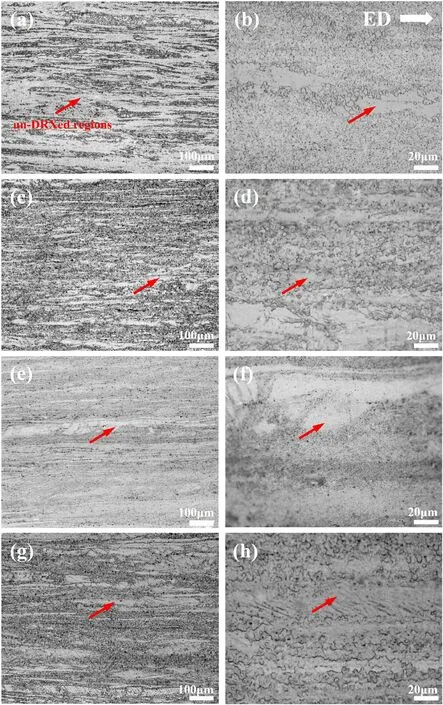

Table 2 Mechanical properties of as-extruded T6, TL21, TL22 and TLA211 samples.

2.Experimental procedures

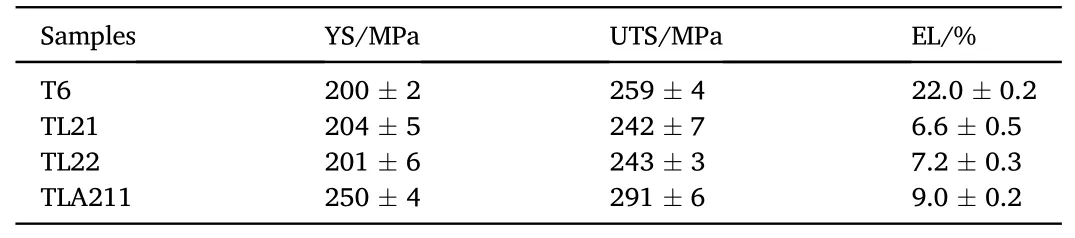

Fig.3.OM images of as-extruded (a, b) T6 sample; (c, d) TL21 sample; (e, f) TL22 sample; (g, h) TLA211 sample.

Fig.4.SEM images of the as-extruded (a, b, c) TL21 sample and (d, e, f) TLA211 sample.

In order to optimize the alloying composition and also give guidance for heat treatment and thermal processing,the phase diagrams of Mg-Sn-Li (0-10 wt% Sn, 0-10 wt% Li, isothermal cross section at 500°C) and Mg-2Sn-xLi-1Al alloys were predicted by Pandat software, as shown in Fig.1.The alloying compositions were designed under the principle of formation of single-phase regions of in the both Mg-Sn-Li and Mg-Sn-Li-Al alloys.Consequently, the alloy ingots with nominal compositions of Mg-6Sn,Mg-2Sn-1Li,Mg-2Sn-1.8Li,and Mg-2Sn-1Li-1Al(denoted as T6,TL21,TL22,and TLA211,respectively)were prepared.The raw materials used to melt the experimental alloys were pure Mg(99.9 wt%),pure Sn(99.9 wt%),pure Li(99.9 wt%),and pure Al(99.9 wt%),which were put into a crucible and melted in a QHV-JZL700 vacuum induction furnace under argon protection.Finally,the molten alloy was cast into the mold to obtain the ingot.The obtained ingots were homogenized and then indirectly extruded at 250°C with an extrusion ratio of 23:1 and a die exit speed of approximately 0.35 mm/s to produce extruded rods with a diameter of 10 mm.The specific preparation parameters are shown in Table 1.The tensile test was performed with a dog bone specimen, 25 mm in length and 5 mm in diameter,on the Shimazu AG-X Plus with the initial tensile strain rate of 1×10-3s-1,and three parallel samples were tested.

The low-magnification images were observed by optical microscopy(OM), and the X-ray diffraction (XRD, Smart Lab X-ray diffractometer)was used for phase analysis.The Cu target was used with the tube voltage of 40 kV,the current of 200 mA,and the continuous scanning modes with speed of 5°/min and the measurement 2θ range of 10°-100°were adopted.The morphology and composition of the alloy phase were detected by scanning electron microscope (SEM, JEOL JSM-7001F microscope).The grain structures and dislocation defects werecharacterized by the transmission electron microscope(TEM,JEOL JEM-2100F),with an accelerating voltage of 200 kV.

Table 3 EDS analysis results for the chemical composition of the second phases indicated by yellow arrows in Fig.4.

3.Results

3.1.Mechanical properties

Fig.2 shows the engineering stress-strain curves of as-extruded Mg-Sn based samples, and the YS, UTS, and EL values are listed in Table 2.Compared with the as-extruded Mg-6Sn binary alloy (T6 sample), the UTS and EL of the as-extruded TL21 alloy were decreased (~242 MPa and ~6.6%,respectively).The strength of the as-extruded TL22 alloy is basically similar with that of the as-extruded TL21 alloy, with UTS of~243 MPa and EL of ~7.2%.It suggests that the increased Li content from 1 wt%to 1.8 wt%has limited effect on the mechanical properties of Mg-2Sn-xLi sample.With addition of minor Al element(1 wt%),the YS of as-extruded TLA211 sample is obviously improved to ~250 MPa, with the strength increment of ~50 MPa as compared to the as-extruded TL21 sample.Besides,the high UTS of ~291 MPa and EL of ~9%can be also obtained in the TLA211 sample.

The OM images of the as-extruded Mg samples are shown in Fig.3,with ED arrows showing the extrusion direction.The typical bimodal grain structure consisting of the DRXed grains and coarse unrecrystallized grains (un-DRXed grains, as marked by arrows) can be detected, and the recrystallization fractions of the T6, TL21, TL22 and TLA211 samples can be estimated to be ~37.8%,~41.2%,~41.5%and~49.2%, respectively.It can be seen that the increase of Li content has limited effect on the degree of recrystallization, while the addition of minor Al increases the degree of recrystallization in the Mg-Sn-Li-Al alloy.

Fig.5.XRD patterns of the as-extruded T6 alloy, TL22 alloy and TLA211 alloy.

Fig.6.TEM images of the as-extruded TL21 alloy:(a,b)subgrain lamellae in the unrecrystallized region;(c-f)nano-sphere phase and nano-block phase;(g-i)residual dislocation.

Fig.7.STEM images of the as-extruded TL21 alloy: (a, b) HAADF images of the nanophases; (c, d) STEM images of the recrystallized grains.

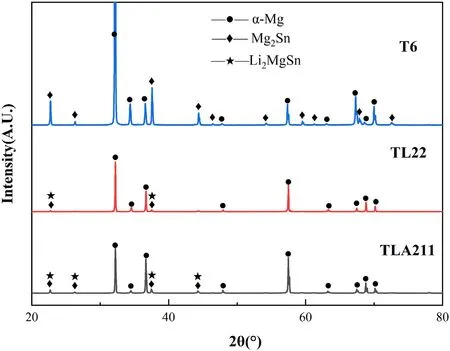

Fig.4 shows the typical SEM images of as-extruded TL21 and TLA211 samples, and micron-sized phases were formed in the matrix of TL21 sample along the ED (Fig.4a and b), mainly the block phases and the continuously distributed sphere phase, of which the average diameter was ~1.5 μm.The similar sphere and long strip-like phases are also formed in the TLA211 sample(Fig.4d and e).To determine composition of the second phase in Mg alloy, the EDS spectrum analysis was performed,and the mapping results are shown in Fig.4c and f.Table 3 listed the point scanning results of the second phases, which are mainly composed of the Mg and Sn elements.Wang et al.[22]studied the phase diagrams of Mg-Sn-Li ternary alloys and showed that Mg2Sn and Li2MgSn are formed at high temperatures, so it can be inferred that the formed second phases are possibly Mg2Sn and/or Li2MgSn.The XRD analysis was further performed to confirm these results, as shown in Fig.5.In addition,the EDS results show that the addition of Al does not lead to the Al enrichment in the TLA211 alloy,and the EDS scanning results at points E and F and the also XRD results show that there are no new Al-containing phases formed in the alloy.

The XRD results for the as-extruded T6,TL22and TLA211 samples are shown in Fig.5.Since the Li2MgSn and Mg2Sn phases have very close lattice constants,i.e.,α(Li2MgSn)=0.6764 nm and α(Mg2Sn)=0.6759 nm [23], and the two compounds have the same crystal structure, it is hard to distinguish the two phases.According to the work of Zhou et al.[24],the second phase in present Mg-Sn-Li based alloy can be identified to be Li2MgSn,which should be different from the Mg2Sn phases formed in the Mg-6Sn binary alloys.Besides, the solubility of Al element in the Mg matrix is high, and the added 1 wt% Al in the as-extruded TLA211 alloy should has dissolved into the matrix phase.Nevertheless, the Al atoms yet contribute to formation of the high density of new Li2MgSn phase in Mg-Sn-Li-Al sample, which is different from those in the Mg-Sn-Li sample.

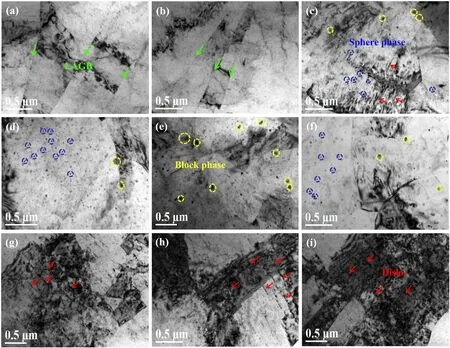

Fig.6 shows the typical TEM images of the as-extruded TL21 sample.Fig.6 (a, b) show that a large number of low angular grain boundaries(LAGBs)are formed,as marked by the green arrows,and these LAGBs in the unrecrystallized region divide matrix into lamellae with width of 0.4-0.8 μm, which should afford the subgrain hardening effect.Fig.6(c-f)show the presence of a high density of sphere and block phases in the Mg matrix, as shown by the blue and yellow dashed circles,respectively.The uniformly distributed nano-phases can pin the migration of dislocations and grain boundaries, which can facilitate the formation of fine recrystallized grains.As a result,both the grain refinement hardening and second phase hardening can be obtained.Fig.6(g-i)shows that high density of residual dislocations can be observed in the Mg matrix, and these dislocations can interact with LAGBs to form dislocation networks,which can also hinder the migration of LAGBs and thus refine the subgrain lamellae.

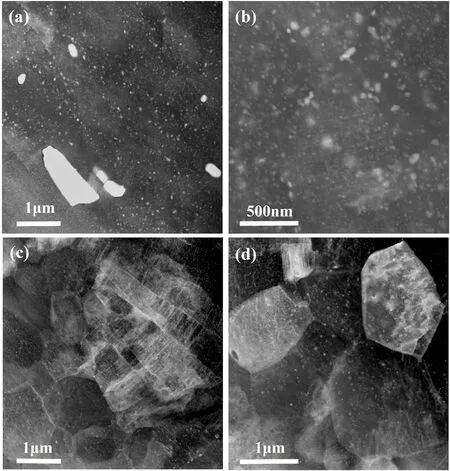

Fig.7 shows the typical STEM images of the as-extruded TL21 alloy.The Mg matrix contains a high density of nano-phases with a size range of 50-70 nm,as shown in Fig.7(a,b).It can be seen that the distribution of nano-phases is heterogeneous, and the nano-phases are mainly formed along grain boundaries in Fig.7a, while the phases are precipitated within grain interiors in Fig.7b.Besides, Fig.7 (c, d) show that the residual dislocations and subgrain boundaries are visible in the un-DRXed regions, while the equiaxed grains with average size of ~1.59 μm are formed in the DRXed regions.Similarly, the high-density nano-sphere phases are distributed inside the grains and also along the grain boundaries,Fig.7d.

The TEM images of the as-extruded TLA211 alloy are shown in Fig.8.There exists a large number of nano-sphere phases(Fig.8a and b),as well as the nano-needle phases (Fig.8c) in the Mg matrix.And some block phases with larger size can be also found in Fig.8(d,e).The high density of subgrain lamellas can be readily observed in the un-recrystallized region, Fig.8f, and the width of lamellae is in the range of 600-800 nm.Some residual dislocations can be found within the subgrain lamellae,and the dislocation types can be determined according to the rule of“g·b=0 invisible” [25].The dislocations shown in the figure are residual dislocations(as shown by red arrows).According to the dark-field TEM images in Fig.8g and h, the profuse <c+a>dislocations can be found under the condition of g =0001 (Fig.8g), and also certain amounts of the <a>-typed dislocations are also detected under the condition of g=11 20 (Fig.8h).Fig.8i shows that there exists a high density of nano-sphere phases within the DRXed regions, which are beneficial for obtaining fine recrystallized grains, and the DRXed grain size is in the range of 0.6-1.5 μm.

Fig.9 shows the typical STEM images of the as-extruded TLA211 sample.Both the fine nano-sphere phases and the larger sized blockphases can be found, Fig.9 (a, b).Number density of the nano-sphere phases in TLA211 sample is much higher than those in TL21 sample,and also the distribution of nano-sphere phases is more uniform, both along the grain boundaries and within grain interiors.The average size of these fine precipitation phases is estimated to be ~20 nm.Besides,Fig.9(c,d)show the typical STEM images for both the un-DRXed regions and the DRXed grains for as-extruded TLA211 sample.The subgrain lamellae with width ranging from 0.5 μm to 1.0 μm and also the profuse residual dislocations can be readily observed in the former, and the equiaxed grains with average size of ~1.38 μm can be detected in the latter.The nano-particles are also uniformly distributed at the two regions.

4.Discussion

As mentioned above, the co-addition of Li and Al atoms effectively affects the microstructure and mechanical properties of as-extruded Mg-Sn based alloys.In this sense, the microstructure evolution and also the strengthening mechanism of present as-extruded Mg-Sn-Li-Al samples would be illustrated in the following sections.

4.1.Microstructure evolution

The above results show that the DRX degree of the alloy increased from ~37.8%in T6 sample,to the ~41.2%in TL21 sample and ~49.2%in TLA211 sample, and also the average DRXed grain size is decreased from ~2.52 μm in T6 sample, to ~1.59 μm in TL21 and ~1.38 μm in TLA211 sample.It shows that the co-addition of Li and Al has a considerable effect on the DRX process.During the thermo-mechanical processing, the Mg2Sn and/or Li2MgSn particles can act as nucleation sites for DRX due to the large amount of energy stored around the particles in the TL21 and TLA211 samples,i.e.,particle stimulated nucleation(PSN)[26].However,the maximum solubility of Sn atom in Mg matrix can be as high as ~10%,and the micron-sized Mg2Sn phase in T6 sample should be low, which thus lead to the much low DRX fraction of ~37.8%.In contrast,with addition of Li and/or Al atoms,the high amounts of Mg2Sn and Li2MgSn particles have been formed.Importantly,as shown in Fig.4,the number density and size of Mg2Sn and Li2MgSn particles in TLA211 sample are much higher than those in TL21 sample.And the corresponding XRD patterns in Fig.5 further confirm that the diffraction peaks for Mg2Sn and/or Li2MgSn particles in TLA211 sample are higher than those in TL21 sample.Besides,the TEM images in Figs.7 and 9 also show that more micron-sized particles can be observed in the TLA211 sample,as compared with those in the TL21 sample.Consequently, the higher amounts of the Mg2Sn and Li2MgSn particles (>1 μm diameter) formed by adding Al and Li elements can more effectively induce PSN effect in the TLA211 sample[26-28],which thus lead to the higher proportion of DRX,as compared with the TL21 sample.

Fig.9.STEM images of the as-extruded TLA211 alloy: (a, b) formation of coarse and fine particles; (c, d) STEM images showing the formation of subgrain and DRXed grains.

Meanwhile, the above results indicate that the average size of the DRXed grains of the TLA211 alloy (~1.38 μm) is finer than that of the TL21 alloy (~1.59 μm), which is closely related to the dynamic nanoprecipitation during extrusion.It is known that fine precipitates formed during extrusion play an important role in inhibiting grain growth via the pinning effect.It is noteworthy that the nano-precipitates observed in the TLA211 sample are more uniformly dispersed than those in the TL21 sample(Figs.6 and 8),which should be due to the co-addition of Al and Li elements.Moreover,the average sizes of nano-precipitates in TLA211 sample (~20 nm) are much finer than those in TL21 sample(~55 nm).The abundant nano-particles with sizes less than 10 nm can more effectively prevent dislocation movement and limit grain growth than those of particles with size larger than 20 nm.Consequently,the finer grain size in TLA211 sample, as compared with TL21 sample, should be correlated with the higher number density of nano-precipitation with much finer particle size.

4.2.Strengthening mechanism

The substantial increase in the mechanical properties of the present Mg-Sn based alloy after the hot extrusion can generally be understood according to the grain refinement hardening and dispersion strengthening.Firstly, Hall-Petch relationship is used to explain the strengthening mechanism,as shown in equation[29-31]:

where σydenotes the yield stress, σ0denotes the frictional stress of dislocation sliding, d means the average grain size, and k denotes the Hall-Petch slope.It suggests that the finer grains are beneficial for improving the yield strength of the alloy.The DRXed grain size of the TLA211 alloy (~1.38 μm) is smaller than that of the TL21 alloy (~1.59 μm),which in turn leads to a higher grain refinement strengthening effect in the TLA211 alloy than that in the TL21 alloy.

Secondly, the addition of Li atom can change the type of strengthening phases in Mg-Sn alloys,and the formed Li2MgSn and Mg2Sn nanophases can improve the yield strength of the TL21 sample by impeding dislocation movement,as compared with that of the Mg-Sn binary alloy.Furthermore,the co-addition of Al and Li atoms into TLA211 sample can induce the higher density of nano-precipitations,which thus induce the more effective Orowan hardening effect [32].In conclusion, the high strength of the TLA211 alloy can be attributed to the finer DRXed grain size and also the uniformly dispersed nano-precipitates with higher density,as compared with the TL21 sample.

Finally, the elongation of present Mg-Sn-Li alloy is also increased from ~6.6% in TL21 sample to ~9% in the TLA211 sample.The finer grain size in TLA211 sample due to minor addition of Al can effectively promote the dislocation transferring across the grain boundaries,which thus relieve the stress concentration,and the ductility can be improved in TLA211 sample.Moreover, the higher density nano-particles inside the grains of TLA211 sample can also effectively block the motion of dislocations, and the high dislocation storage capacity can be thus obtained[33,34].In other word, the more obvious dislocation multiplications in TLA211 sample can thus lead to the higher elongation,as compared with that of the TL21 sample.

5.Conclusions

In this work,the effects of Li and Al additions on the microstructure and mechanical properties of as-extruded Mg-Sn-based alloys were investigated,and the main findings are summarized as following:

(1) The addition of 1 wt% Li can change the type of strengthening phase in the Mg-Sn alloy, which involved to the Li2MgSn and Mg2Sn phases.The fine grain size and the formation of nanoprecipitations lead to the enhanced mechanical properties in TL21 sample, exhibiting the yield strength of ~204 MPa, the ultimate tensile strength of ~242 MPa and the elongation of ~6.6%.

(2) The co-addition of 1 wt% Al and 1 wt% Li atoms can further increase proportion of dynamic recrystallization,and the formation of micron-sized Li2MgSn and Mg2Sn phases should be the major reason.Despite of that,the DRXed grain size in TLA211 sample is obviously reduced, which should be ascribed to the formation of higher density nano-precipitations, as compared with TL21 sample.

(3) The as-extruded TLA211 alloy exhibit the high strength-ductility synergy, with yield strength of ~250 MPa, the ultimate tensile strength of ~291 MPa, and the elongation of ~9.0%.The much finer DRXed grain size and more uniformly dispersed nanoprecipitates contribute to the simultaneous increase in strength and plasticity of the present Mg-Sn-Li-Al alloy.

In this work,a novel Mg-Sn-Li-Al alloying system has been developed,and the trade-off between high-cost and high strength can be solved.The conventional high-Sn content can be reduced to be only ~2 wt%,and the none rare-earth elements of Al and/or Li can lead to the low cost.The high strength-ductility synergy makes the present Mg alloy to be potential for the wider industrial applications.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgment

The work is supported by National Key Research and Development Program of China (2021YFB3701002), National Natural Science Foundation of China (Nos.U2167213, 51971053, and 52271088).H.C Pan acknowledges the financial assistance from Young Elite Scientists Sponsorship Program by China Association for Science and Technology(2019-2021QNRC001-003).And the fund from the Fundamental Research Funds for the Central Universities(N2202020).

Progress in Natural Science:Materials International2023年3期

Progress in Natural Science:Materials International2023年3期

- Progress in Natural Science:Materials International的其它文章

- Research progress of composite cathode materials for Solid oxide fuel cells

- A review on solidification of alloys under hypergravity

- Multi-stimuli bilayer hydrogel actuator for remotely controllable transportation of droplets

- The formation and temperature stability of microemulsion emulsified by polyoxyethylene ether surfactant

- Towards high-efficiency of hydrogen purification in metal hydride

- Research advances on electrode materials for solid oxide electrolysis cells