Model prediction of inactivation of Aeromonas salmonicida grown on poultry in situ by intense pulsed light

Jingwen Wang,Zhenzhen Ning,Yifan Chen,Xinglian Xu,Huhu Wang

Jiangsu Collaborative Innovation Center of Meat Production and Processing, Quality and Safety Control, College of Food Science and Technology,Nanjing Agricultural University, Nanjing 210095, China

Keywords: Aeromonas salmonicida Intense pulsed light Inactivation Chicken meat Model

ABSTRACT The aim of this study was to evaluate the factors inf luencing the inactivation effect of intense pulsed light(IPL) on Aeromonas salmonicida grown on chicken meat and skin,and to further develop prediction models of inactivation.In this work,chicken meat and skin inoculated with meat-borne A.salmonicida isolates were subjected to IPL treatments under different conditions.The results showed that IPL had obvious bactericidal effect in the chicken skin and thickness groups when the treatment voltage and time were 7 V combined with 5 s.In addition,the lethality curves of A.salmonicida were f itted under IPL conditions of 3.5-7.5 V.The comparison of statistical parameters revealed that the Weibull model could best f it the mortality curves and could accurately predict the mortality dynamic of A.salmonicida grown on chicken skin.And further a secondary model between the scale factor b and the treatment voltage in Weibull model was established using linear equations,which determined that the secondary model could accurately predict the inactivation of A.salmonicida.This study provides a theoretical basis for future prediction models of Aeromonas,and also provides new ideas for sterilization approaches of meat-borne Aeromonas.

1.Introduction

Global chicken meat production was predicted to reach a new high of one hundred million tons in 2022,according to a report released by United States Department of Agriculture[1].Most consumers are fond of various chicken meat because of its unique flavor and high protein content.However,microbial attachment and growth commonly reduce the freshness and shelf life of chicken meat.Chilled chicken may be contaminated with microorganisms anywhere in the supply chain,causing a high risk to food safety and public health.In particular,the slaughter procedures and contacted surfaces,such as convey belts and utensils,may substantially increase the bacterial loadings of chicken carcasses and cutting parts,shortening the shelf life in the cold chain.Besides of well-knownPseudomonasspp.,other spoilage microorganisms,such asAeromonasspp.,have also been reported to determine spoilage process of chilled meat during storage.Aeromonasspp.can produce a variety of extracellular enzymes to degrade proteins,fats and polysaccharides in the meat matrix[2],providing them with nitrogen and carbon sources for growth and leading to spoilage of meat.Wang et al.[3]showed thatAeromonassalmonicidais the dominant spoilage bacterium in chilled chicken meat and its secreted extracellular enzymes can strongly degrade muscle proteins in chilled chicken meat with strong putrefactive power.Elbehiry et al.[4]found thatAeromonascan spread from the intestine to chicken carcasses through processed water,leading to severe contamination of chicken carcasses.In addition,some foodborne outbreaks have been associated withAeromonas,causing infectious shock[5],illness and even death,as it can produces some extremely potent virulence factors including enterotoxins,exotoxins,and hemolysins[6].A.salmonicidacan be widespread and persistent in the food chain,and its severe infectivity causes significant economic losses in aquaculture[7].The current control of the disease caused byA.salmonicidais mostly done with antibiotics after the onset of the disease or at the breeding site,but over time and with the misuse of antibiotics,it has developed antimicrobial resistance characteristics[8].This suggests that reducingA.salmonicidapopulations from food processing will be an important way to ensure food safety and reduceAeromonasinfections.

To reduce the microbial contamination in meat products,appropriate prevention and control strategies are crucial;Chemical approaches have been widely used in the chicken industry due to their effective inhibitory effects.Anang et al.[9]reported that lactic acid could significantly reduce the levels of spoilage bacteria in chicken meat.However,if the doses and duration of these chemical sterilization substances (e.g.sodium hypochlorite) are not well controlled,disinfection by-products on food can be extremely harmful to human health.Recently,numerous novel physical preservation strategies have emerged,including high voltage electric field sterilization[10],ultrasonic sterilization[11],and irradiation sterilization[12].These strategies naturally have their own unique advantages,such as mild temperature,low impact on the edible quality of the food and absence of residues.However,they also have some unavoidable problems,such as high cost,low inactivation efficiency,and the possibility of color damage.Another emerging physical sterilization is intense pulsed light (IPL),which has been reported to sterilize food,packaging and medical equipment in a short period of time[13].Instead of a standard light source,IPL uses a tubular pulsed xenon lamp,which emits pulsed light with high instantaneous peak energy,including far-UV,near-UV and visible light,to destroy bacteria on food surfaces or in certain transparent liquids.The spectrum of IPL is comparable to that of sunlight,but with more energy of about 20 000 times.In contrast to ordinary UV light,the inactivation of microorganisms by IPL is a synergistic effect of the various spectra and usually causes irreversible damage to microorganisms[14].Studies have shown that pulsed light has a significant inactivation effect on foodborne pathogenic bacteria such as pathogenicEscherichia coli[15]andSalmonella[16].Ganan et al.[17]conducted an experiment with instant-dry bacon that showed a reduction of 1.51 (lg (CFU/cm2)) inListeria monocytogenestreated by 9 J/cm2IPL,while no color or sensory changes were observed during 30 days of storage.

The objective of this study was to determine the effect of IPL on the inactivation ofA.salmonicidagrown on chicken under various conditions and to further develop a mathematical model-fitted inactivation curve forA.salmonicida.The results of this study may provide a basis and guidance for the utilization of IPL sterilization in the meat industry.

2.Materials and methods

2.1 Strain incubation and sample preparation

Three strains ofA.salmonicidaisolated from chilled chicken meat and numbered NCM 25,NCM 27,and NCM 29,were stored in the microbial lab of the National Center of Meat Quality and Safety Control in China (NCM,Nanjing City,Jiangsu Province).Each strain was streaked on the LB plate and then cultured at 28 °C for 20 h.A single colony of each strain was selected and cultured into a 7 mL of TSB for 20 h at 28 °C.

The chicken skin and meat were purchased from a local market.They were cut into parts with sizes of 4.5 cm × 4.5 cm,put into bags and irradiated with an irradiation dose of 7 kGy[18].The activated strains were diluted to 105CFU/mL with sterile saline solution.The diluents of threeA.salmonicidastrains were mixed in equal quantities,and 105CFU/mL of the mixture was inoculated on the upside of chicken skin or meat.The samples were air-dried for 30 min at the biosafety cabinet.All growth media were provided by Hopebio-Technology (Qingdao,China).

2.2 Treatment with IPL

The inoculated meat or skin was divided into 5 groups for different treatments: skin group (placing the chicken skin inoculated withA.salmonicidain the IPL device),meat group (placing the meat inoculated withA.salmonicidain the IPL device),barrier film group (covering the chicken skin inoculated withA.salmonicidawith a modified atmosphere packaging film),cold adaptation group (storing the inoculated skin at 4 °C for 24 h and then treating with IPL),thickness group (increasing 3 cm thick for the inoculated skin,then treating with IPL).The reasons for the treatments setting are explained in the part of discussion.The samples in five groups were treated at 7 V for 5 s by an IPL device (ZWS,China).The untreated group was set as the control group,and the samples in each group were replicated five times.

After treatment,approximately 25 g of samples were transferred to sterile bags and 225 mL of saline was poured into each bag.The samples were then homogenized for 60 s (JumboMix3500,Interscience,Saint Nom la Brétèche,France),and the bacterial solution in the homogenization bag was diluted 10 times in a gradient of sterile normal saline.Total 100 µL of bacterial solution was coated with three appropriate dilutions and incubated at 28 °C for 24 h.Bacterial counts were performed by automated image colony counting(Interscience,France).

2.3 Modeling of bacterial inactivation

The IPL frequency in this study was 1 Hz,and the voltage was set at 7.5,6.5,5.5,4.5,and 3.5 V,respectively.Each group of samples was treated for 10 s with interval of 1 s.Five replicates were set up in each group.The number of live bacteria after treatment was counted by the plate counting method.

A mechanical model of the first-order inactivation ofA.salmonicidaunder different voltages was established.The Linear[19],Weibull[20],and Boltzmann models[21]with Eq.(1),(2),and(3),respectively,were fitted by the Origin 2021 software (Origin Lab Corporation,Northampton,MA,USA).

WhereYis the logarithm of the bacteria numbers,andY0is the logarithm of initial numbers ofA.salmonicida.In Eq.(1),ais the value as the processing time increases (equivalent to the inactivation effect of IPL),andb1is the tolerance ofA.salmonicidato IPL.In Eq.(2),b2is the parameter that defines the shape of the inactivation curve.In Eq.(3),A1is the initial bacterial concentrations ofA.salmonicidaon chicken skin treated without IPL,andA2is the final bacterial concentrations ofA.salmonicidaon chicken skin treated with IPL.

The coefficient of determination (R2),square root of MSE(RMSE),residual sum of squares (RSS),mean square error (MSE),and Akaike information criterion (AIC) were used to determine the fitting degrees of the models[22].A second-level linear model with the impulse voltage as the independent variable and the model scale factor as the dependent variable is used to determine the quantitative relationship between the two variables,and the relative error between the predicted value[23].To confirm the accuracy of fitting model,we used the parameters of 7 V and 5 s as the validation group.

2.4 Statistical analysis

The data were collected in five replicates (n=5) and reported as means ± standard deviation (SD).Differences between each tested group were analyzed by one-way ANOVA with IBM SPSS Statistics 22 (IBM Corp.,Armonk,NY,USA),and the multiple comparisons were tested by the least significant difference test.The Origin software was used to fit the kinetic models (Origin Lab Corporation,Northampton,MA,USA).

3.Results

3.1 Effect of potential conditions on the inactivation of IPL

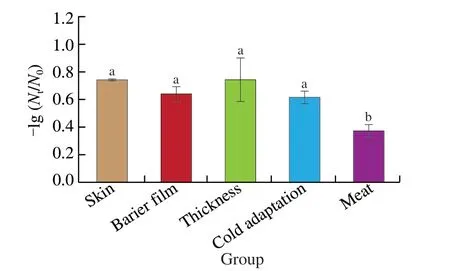

Fig.1 showed the number of reducedA.salmonicidaunder 7 V for 5 s ranging from 0.37 to 0.75 (lg (CFU/cm2)),with skin group displaying the highest reductions,whereas meat group reduced fewer populations,just reaching 0.37 (lg (CFU/cm2)).The barrier film and cold adaptation groups reduced the numbers ofA.salmonicidaby 0.64 and 0.61 (lg (CFU/cm2)),respectively.There were significant differences between the flesh and the skin,indicating that differences in muscle texture and skin structure had a significant effect on the sterilization effect.There was no significant difference between the skin group and the barrier film group,indicating that the packaging film had no attenuation effect on the bactericidal effect.No difference was observed between the cold adaptation and the skin group,indicating that the low-temperature cold chain environment may not increase the sensitivity of bacteria to pulsed light.Obviously,the meat group was different from that of the other four groups,with a significant decreasing trend.Based on the results,the skin group was selected to model the inactivation ofA.salmonicida.

Fig.1 Germicidal effect of intense pulsed light on Aeromonas under different treatment conditions.Values represent the mean ± SD (n=5).Values with different lowercase letters (a-b) in different treatment conditions were significantly different (P < 0.05).

3.2 Bacterial inactivation dependence on parameters of IPL

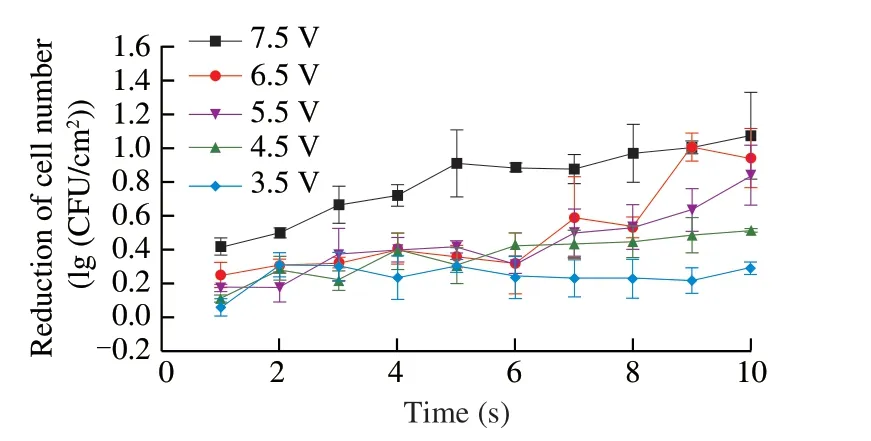

The reduction of cell numbers was shown in Fig.2,and the inactivation depends greatly on the voltage between 3.5 and 7.5 V,with a maximum reduction of more than 1 (lg (CFU/cm2)).Apparently,the treatment time significantly affects the cell reductions,especially at 6.5 and 7.5 V.While the cell reductions remained stable at 3.5 V,showing about 0.2 (lg (CFU/cm2)).Treatment for 5 s may be an attractive period,as the number of cells decreased rapidly after 5 s treatment and then remained slightly reduced at 7.5 V.There is an opposite trend observed at 6.5 and 5.5 V,suggesting a slight reduction at the first 5 s treatment and a sharp reduction at the last 5 s treatment.

Fig.2 Aeromonas’ lethal curve under different voltages.Values of cell numbers represent the mean ± SD (n=5).

3.3 Models development

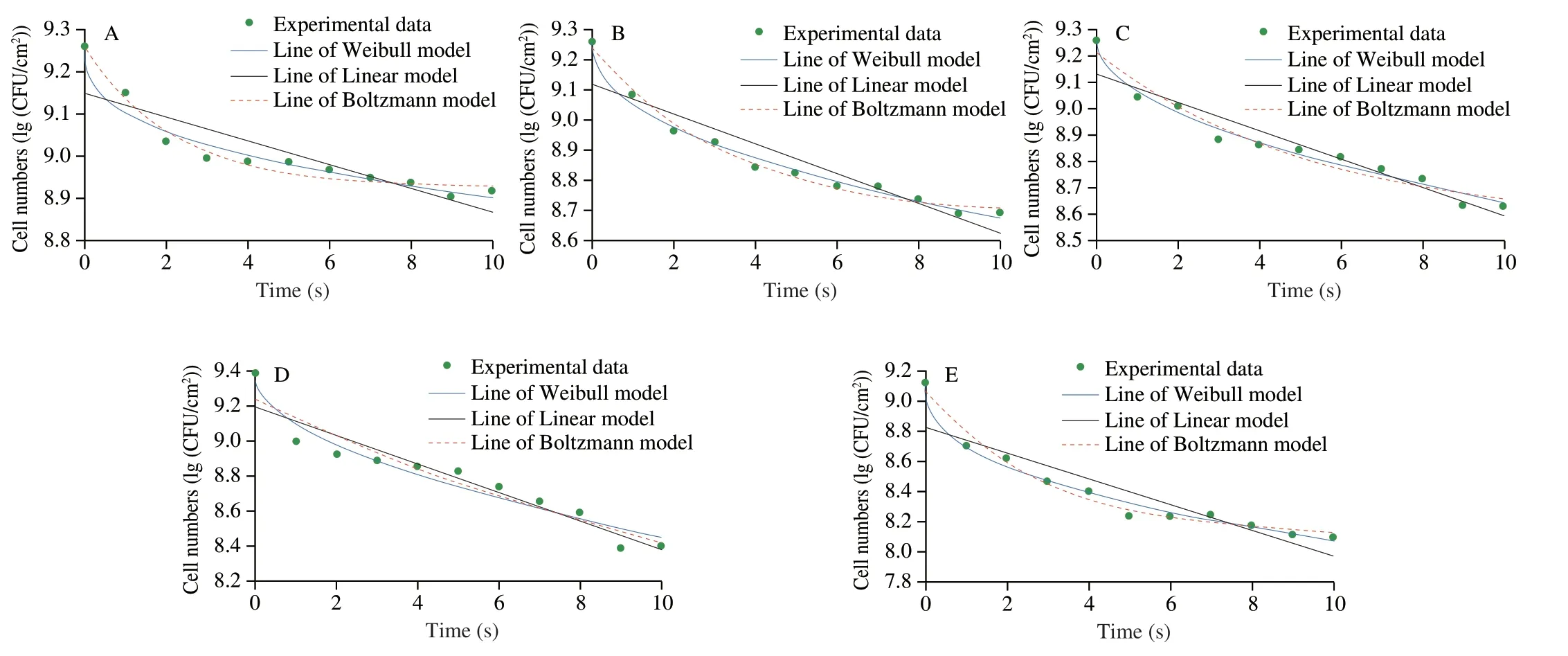

We chose microbial prediction models such as the Weibull,and Boltzmann models that are commonly used to describe the inactivation profiles observed in non-thermal processes.Then,we compared the fitted parameters to select the best model to accurately predict the lethality ofA.salmonicidain chicken skin.Three common models were fitted to the numbers of live cells after IPL treatment.Fig.3 showed the inactivation curves ofA.salmonicida,and Table 1 showed the fitted parameters of each model.For the evaluation of model fits,R2,RMSE,AIC,RSS,and MSE were chosen.The closerR2is to 1,the higher the correlation between the independent and dependent variables,the more accurate the prediction of the corresponding model.RMSE can be used to measure the average deviation of the actual and predicted values.An AIC can assess the model,and the smaller the AIC,the more likely the model is to be correct.As can be seen from Table 1,the fitting determination coefficientR2of the linear model is the smallest,while other statistical indicators are higher than the other two nonlinear models,and the fitting effect is poor.The nonlinear model was significantly better than the linear model in the present work.In addition,by comparing the statistical metrics of the other two nonlinear models,it was found that the Weibull model had the highestR2and the lowest information criterion,and its RMSE was lower than that of Boltzmann model.

Table 1 Comprehensive statistical analysis of four lethal model fitting of Aeromonas in chicken skin.

Fig.3 Inactivation curve of Aeromonas in chicken skin treated with intense pulsed light at (A) 3.5,(B) 4.5,(C) 5.5,(D) 6.5 and (D) 7.5 V by Weibull model,Linear model and Boltzmann model.Black circles represent the experimental data (n=5) at each time.

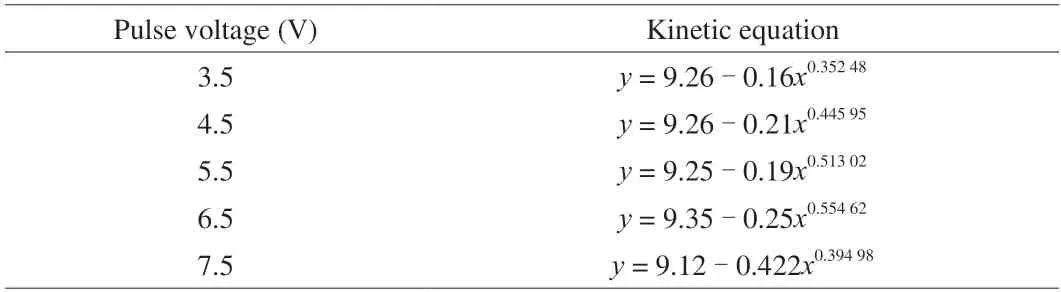

Based on the values ofR2,RMSE,RSS,MSE and AIC,the Weibull model gave the best fit values,and the kinetic equations are shown in Table 2.Since the Weibull model could not explain the effect of different voltages on the inactivation ofA.salmonicida,a second-model was developed.A linear equation is usually used to describe the quantitative relationship between the scaling factorband voltage variables,and the results are shown in Fig.4,indicating that the scaling factorbincreases exponentially with voltage.

Table 2 Kinetic equation of Weibull model fitting for Aeromonas under five voltages.

Fig.4 Effect of intense pulsed light treatment voltage on Weibull parameter b.Black circles represent the experimental data (n=5) at each time.

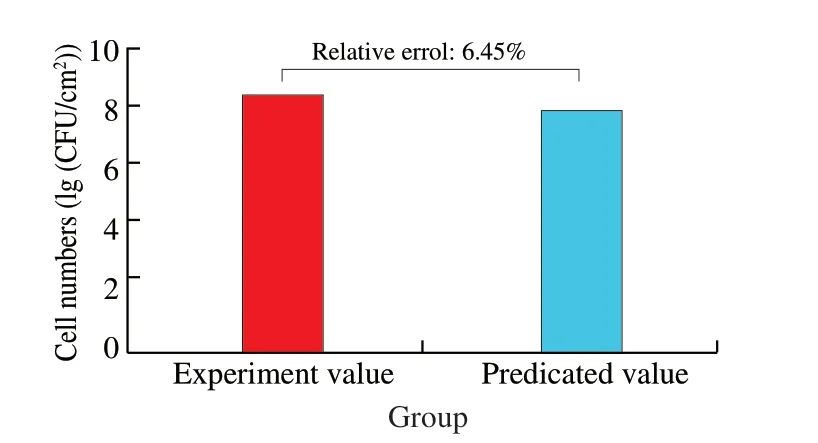

3.4 Model verification

To verify the accuracy of the secondary model,the parameters of the IPL treatment were set to 7 V for 5 s.As can be seen in Fig.5,the predicted values obtained were close to the experimental values,and their relative error was only 6.5%,indicating the success of the killing model obtained in this study.

Fig.5 Verification of a lethal model of Aeromonas.

4.Discussion

The public prefers chilled chicken because of its unique flavor and high nutritional value[24].However,traditional manufacturing procedures,distribution patterns and cold-chain logistics transportation may increase the potential risk of microbial contamination and foodborne illness.Chemical reagents are often used in the food industry to reduce the presence of bacteria.Compared with chemical sterilization,physical strategies,such as IPL,can reduce the harmful effects of chemical residues on humans and maintain the original taste quality and nutritional value of food.

Since the actual contamination in food processing plants is a mixture of multiple strains,this work uses a cocktail of bacteria isolates rather than individual isolate to avoid deviation from strain heterogeneity.The bactericidal effect of physical sterilization is closely related to the characteristics of the microbial adherent.In this work,5 different groups were established,namely skin group,meat group,barrier film group,cold adaptation group and thickness group,to evaluate the inactivation of IPL to simulate different application scenarios.For example,the skin group was developed to explore the influence of the surface roughness of meat on the disinfection effect.The thickness group is designed to explore the effect of appropriate pulse distance on the sterilization of sample surface.The cold adaptation group is to explore the sensitivity and adaptability of bacteria to temperature when cells subjected to IPL,which provides a certain reference value for cold chain logistics transportation.The establishment of the barrier film group is to study whether the packaging film blocks the effect of pulsed light and whether the sterilization effect has a significant attenuation after meat packaging.

In the present study,a lower inactivation ofA.salmonicidaon meat surface was observed as compared to skin surface.The sterilization mechanism of pulsed intense light leads to a strong relationship between its sterilization effect and the characteristics of the object to which the microorganism is attached.In addition,surface reflectance and other variables can also affect the sterilization effect of IPL[25].Chicken skin has a higher penetration rate of UV and visible light compared to chicken meat,and pulsed intense light is easier for overall sterilization,while chicken meat is almost completely impervious to light due to its poor light transmission and inevitably thicker artificially cut thickness than chicken skin,making the sample almost completely impervious to light,so IPL can only perform surface sterilization and cannot be completely sterilized.The thickness group showed that IPL treatment reduced the number ofA.salmonicida,so it was possible to infer that the pulse distance could affect the germicidal effects.After shortening a certain distance,the microorganisms could be irradiated sufficiently by more spectral radiant energy,and it destroys the cell structure and causes leakage of the contents,which eventually leads to the death of the microorganisms[26].This was in agreement with the finding reported by Farrell et al.[27]who achieved higher levels of bacterial decontamination by reducing the distance between the treated surface and the xenon light source.Pulsed light technology is not only effective in inactivating microorganisms on food and its contact surfaces,but can also be applied at different stages during food processing,such as the packaging procedure,which can be achieved without damaging the packaging systems[28].For example,Kramer et al.[29]found that pulsed light significantly inhibited the growth ofL.monocytogeneson the surface of chicken slices packed in PA/PE laminate film,and did not affect the physical properties of the packaging material.In this study,the numbers ofA.salmonicidain the barrier film group were statistically equal to the skin group,indicating that the use of this wrapping material did not significantly reduce the germicidal effect of pulsed light.The observation validated that the pulsed light can be applied after packaging,avoiding the secondary cross-contamination caused by the packaging site,thus improving the safety and shelf life of food products[30].A slightly low inactivation was observed in cold adaptation as compared to skin group without cold stress,which may result from the cold stress proteins such as the Caps proteins (P34a,P62,P33b,etc.) secreted byA.salmonicidato enhance the resistance to IPL[31].

We observed the reduction ofA.salmonicidaunder different voltages in Fig.2.It is not difficult to find that when the voltage was increased to 5.5 or 6.5 V,the sterilization effect was greatly improved and the reduction showed a rapid increase after 5 s treatment time.This is mainly due to the fact that the sterilization effect is influenced by the pulsed voltage,and when the voltage increases,its energy passage is also increasing,which will lead to an increase in the inactivation effect as well[32].Hwang et al.[33]found that when microorganisms are exposed to IPL,they first have some resistance until the IPL exceeds a specific intensity threshold,showing a rapid decline.This is more similar to the phenomenon of showing a rapid decrease after 5 s mentioned in the results,so it is reasonable to speculate that 5 s is their specific intensity threshold in this paper.Therefore,in this paper when the voltage increases to 5.5 or 6.5 V,the energy passage increases and the deactivation rate increases with the higher charging voltage and the longer processing time.However,when the treatment voltage was 7.5 V,the number of cells decreased slightly after 5 s of treatment.This is in contrast to the phenomena at 5.5 and 6.5 V,mainly due to the fact that when the voltage exceeds a certain voltage threshold,the sterilization effect remains essentially unchanged as the voltage increases[34].

Recently,the model has been widely used to predict the shelf life of food,for example,by monitoring the changes in some indicators such as water activity,microbial populations[35].A good microbial model could reliably predict the number of microorganisms in a processed sample,thus allowing a rapid assessment of the quality and safety of food products[36].In this paper,we found that the statistical parameters of the Weibull model were significantly better than the other two models,so it was selected as the first-order model ofA.salmonicida.The model showed that the pulse voltage obviously determined the inactivation ofA.salmonicida,a similar finding was also reported previously[37].Meanwhile,it can be found that the inactivation in the skin group has a “trailing” effect,i.e.,A.salmonicidaresistance to pulsed light increased with the treatment time.It is mainly the lack of homogeneous populations that leads to a different ability of cells to repair DNA damage and then a“trailing” effect[38].Physical sterilization such as some common ultraviolet sterilization,due to the presence of suspended particles and floc collective will affect the penetration ability,which leads to an inactivation rate with the extension of time and maintain a certain level of unchanged[39],which is also known as the trailing effect.Based on the primary model ofA.salmonicidain the skin,a linear fit of the pulsed intense light treatment voltage to the parameters associated with the primary model was performed to obtain the second model.It can be seen from Fig.4 that there was a good linear relationship between the voltage and scale factorbwithR2of 0.893.To determine the reliability of the primary model,the data obtained from the experiments were compared with the established prediction model,and the relative error was found to be only 6.45%.Therefore,the Weibull model developed in this paper can well predict the lethality ofA.salmonicidain chicken skin.

Since the resistance of different microorganisms to IPL and the effect of IPL on different food ingredients are not fully understood,its application has great limitations.And in practical application,the sterilization effect of pulsed intense light is affected by the tissue state,surface smoothness,processing characteristics,and parameter settings of the muscle.The life span and germicidal efficacy of IPL will decrease with the increase in the number of times of use.As a result,we may combine IPL with other technologies so that pulsed light technology can then be used to its full potential.It has been shown that IPL in combination with ultrasonic techniques[40],heat treatment techniques,acoustic heat treatment,and other techniques can greatly enhance the sterilization effect.

5.Conclusion

In this study,five different treatment groups were used to evaluate the sterilization effect of pulsed light.The results showed that IPL was the most effective in sterilizingA.salmonicidain the skin and thickness groups,and that pulsed light was also suitable for cold adaptation and membrane barriers,providing some theoretical basis for the use of IPL in packaging and cryogenic cold chain.Meanwhile,by comparing the statistical parameters,the Weibull model was the most accurate in describing the inactivation ofA.salmonicidain chicken skin by IPL.Based on this,a secondary model between IPL processing voltage and first-order modal correlation parameters was developed.The results of this study can be used as a theoretical basis for further research on the bactericidal effect of IPL.In this study,we investigated only the treatment voltage and time,while the sterilization effect may be influenced by other factors such as pulse width,the distance between the two plates,etc.This application still needs a lot of experiments for better application in the food processing industry.

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This study was supported by projects funded by grants from the Natural Science Foundation of Jiangsu Province in China(BK20221515),the National Natural Science Foundation of China(32172266),and the Changzhou Science and Technology Support Program (CE20222002).

- 食品科学与人类健康(英文)的其它文章

- Protective effects of oleic acid and polyphenols in extra virgin olive oil on cardiovascular diseases

- Diet and physical activity inf luence the composition of gut microbiota,benef it on Alzheimer’s disease

- Inf luence of nitrogen status on fermentation performances ofnon-Saccharomyces yeasts: a review

- Ganoderma lucidum: a comprehensive review of phytochemistry,eff icacy,safety and clinical study

- Resveratrol combats chronic diseases through enhancing mitochondrial quality

- Demonstration of safety characteristics and effects on gut microbiota of Lactobacillus gasseri HMV18