Ballistic performances of the hourglass lattice sandwich structures under high-velocity fragments

He-xiang Wu , Jia Qu , Lin-zhi Wu a

a Key Laboratory of Advanced Ship Materials and Mechanics, College of Aerospace and Civil Engineering, Harbin Engineering University, Harbin,150001,China

b School of Civil Engineering, Northeast Forestry University, Harbin,150040, China

Keywords: Hourglass lattice sandwich structures Ballistic performances high-velocity Finite element analysis

ABSTRACT In this paper, the numerical simulation method is used to study the ballistic performances of hourglass lattice sandwich structures with the same mass under the vertical incidence of fragments.Attention is paid to elucidating the influences of rod cross-section dimensions, structure height, structure layer, and rod inclination angle on the deformation mode,ballistic performances,and ability to change the ballistic direction of fragments.The results show that the ballistic performances of hourglass lattice sandwich structures are mainly affected by their structural parameters.In this respect, structural parameters optimization of the hourglass lattice sandwich structures enable one to effectively improve their ballistic limit velocity and, consequently, ballistic performances.

1.Introduction

Sandwich structures as a kind of lightweight structures have been widely used in aerospace industry, marine engineering,vehicle engineering,and other important fields.This is due to their superior mechanical properties such as high specific strength,high specific stiffness, and good energy absorption, as well as special functional characteristics including good thermal insulation,sound insulation,fire prevention,and moisture resistance[1-3].With the development of energy efficiency strategy and material saving measures, the application scope of sandwich structures has been further expanded to promote their in-depth exploration.Sandwich structures are composed of three parts: upper panel, lower panel,and sandwich layer.The panels are made from solids,among which metals and fiber-reinforced polymer composites are usually used as matrix materials.They have high modulus,high strength and small thickness.By contrast, sandwich structures consist of the foam structures,honeycomb structures,or lattice structures[4,5].Metals and polymers are often used as the matrix materials.They have small density and large thickness.

Considering the actual application of the sandwich structures in the engineering, increasing attention has been paid to their static performances, in particular, bearing capacity, failure mode, and energy absorption [6,7].At the elastic stage, the mechanical properties of sandwich structures can be predicted theoretically [8].When the strain of such structures under loading is beyond the elastic deformation range, the description of its mechanical characteristics becomes a challenge.Then, experimental observation and numerical simulation become the main tools.In that regard,many scholars have carried out the experimental research on outof-plane compression and bending of sandwich structures.According to the results, the performances of the matrix materials used in panels and sandwich layers as well as the density, pore shape and pore size,and wall thickness of the sandwich layers exert different influences on the failure mode, bearing capacity, and buckling resistance of the whole sandwich structures [9-11].Moreover, the design and development of novel hybrid sandwich structures have also received extensive attention from the researchers.In this respect,a great variety of sandwich structures has been reported over the past years, among which are nanophased foam sandwich composites, honeycomb-corrugation hybrid sandwich structures, gradient foam sandwich composites, and pomelo peel bionic hierarchical honeycomb structures [12-15].It is found that their bearing capacity and energy absorption performances are better than those of simple sandwich structures.

In engineering, more and more devices and equipment are increasingly adopting sandwich structures.However,the problems of falling objects and stringent requirements for bearing impact and collision,especially the security protection demand in the militaryindustrial complex, led to the need for thorough investigation of the dynamic mechanical properties of sandwich structures,including the impact behaviors in a certain velocity range and the penetration of bullets and fragments.At present,numerous studies are dedicated to the analysis of the dynamic mechanical characteristics of foam sandwich and honeycomb sandwich structures.The research contents involve the influences of two aspects on the mechanical parameters, deformation characteristics, failure mode,ballistic limit velocity, and energy absorption capacity of the sandwich structures.One aspect is the design modification of sandwich structures, including panel materials, panel thickness,gradient design of panels, foam thickness, foam density, gradient design of foam density, honeycomb microtopological structure design, etc.[16-21].The other considers various characteristics of the impact objects,e.g.shrapnel,namely,their shape,density,size,and velocity [22-26].Besides, comparative study and comprehensive application of foam sandwich and honeycomb sandwich structures has been recently performed by different research groups.Crupi et al.[27,28] studied their buckling behaviors by using theoretical and experimental tools.Fatemeh et al.[29] conducted the impact experimental study on the foam-filled honeycomb sandwich structures and revealed an increase in the ballistic limit velocity and specific energy absorption capacity.

Some scholars also focus on the influences of penetration direction on the impact resistant performances of foam sandwich and honeycomb sandwich structures.The research results show that the impact resistant performances of such structures in the diagonal direction are superior to that in the vertical direction.Moreover,with the increase of the angle between the ballistic trajectory and the normal of the target, the lateral deformation of the sandwich structures are increased, and the impact resistance performances are enhanced [30].Therefore, if the shrapnel penetration direction of the vertical impact can be changed, the impact resistance of the sandwich structures can be improved certainly.However, the uniform distribution of the foams and the orientation of the honeycomb walls along the normal direction of the target fail the change in the vertical penetration direction of the shrapnel.In turn, the rod inclination angle of the lattice sandwich structures play a key role in changing vertical penetration direction of the shrapnel and can be tuned according to the needs of engineering applications,thus improving the impact resistance performances of safety protection structures.Moreover,continuous improvement of the 3D printing technology allows one to fulfill the requirements for the processing of complex lattice structures [31].

At present,most of the researchers mainly focus on the ballistic performances of the foam sandwich and honeycomb sandwich structures, but seldom pay attention to the lattice sandwich structures.In this study, hourglass lattice sandwich structure models are established.Based on the existing research on the statics properties of the hourglass lattice sandwich structures, the ballistics performances of the hourglass lattice sandwich structures are further studied.The influence of structural parameters on the ballistics performances is discussed carefully,and the ability of the hourglass lattice sandwich structures to modify the trajectory direction of the vertical incidence fragments is further studied.Our work aims to explore the design method of lattice sandwich structures with high ballistic performances, and provides a new design idea for the safety protection combined devices in engineering.

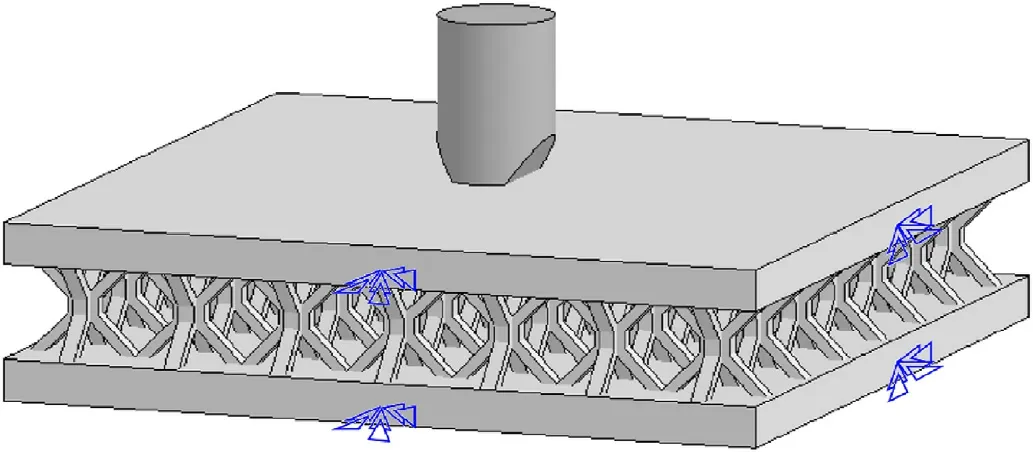

2.Computational models

2.1.Finite element models

On the one hand, compared with common lattice structures such as tetrahedron, pyramid, Kagome,and other topological configurations, hourglass lattice structures have a large rod diameterlength ratio, small node spacing, and strong buckling resistance[32].On the other hand, according to the studies on high-velocity ballistic performances, the use of fragments allows one to reflect the penetration law of a conical projectile body,but also of a blunt cylindrical projectile.Hence, in this paper, the hourglass lattice structures are selected to establish the corresponding sandwich structure models and to describe the ballistic performances under the fragments penetration via numerical simulation.The calculation models consists of hourglass lattice sandwich structures and fragments, as is shown in Fig.1.The hourglass lattice sandwich structures are composed of three parts,i.e.,the upper and the lower panels with equal geometrical dimensions, and the hourglass lattice structures, welded together as illustrated in Fig.2(a).The hourglass lattice structures are formed by arraying the hourglass cell structures in plane.The configuration of the hourglass cell structures is present in Fig.2(b).The hourglass cell structures are made of two interlocking assembly strips which are welded into the specimen after interlocking.The configuration of the interlocking assembly strips is present in Fig.2(c).The fragments is a cylinder with two blunt cutting surfaces on both sides of the head and a flat flange in the middle,as shown in Fig.2(d).In Fig.2,cis the length of the panels,dis the width of the panels,eis the thickness of the panels,nis the height of the nodes in assembly strips,mis the width of the nodes in assembly strips,his the height of the assembly strips,tis the width of the rods in assembly strips, and is also the thickness of the assembly strips,α is the inclination angle of the rods in assembly strips,ais the width of the flat flanges,bis the diameter of the cylinders.lis the length of the cylinders,β is the angle between the blunt cutting surfaces and the vertical planes.Here, in order to fully explain the influences of structural parameters on the hourglass lattice sandwich structures, nine different types of hourglass lattice sandwich structures(referred to as H1,H2…, and H9, respectively) are taken for studying their ballistic performances.Notably, multi-layer hourglass lattice sandwich structures are included.The density of the hourglass lattice structures is defined as

Fig.1.Calculating models of hourglass lattice sandwich structures.

Substituting the geometric parameters of the hourglass lattice structures into Eq.(1)allows one to determine its density and mass.The same mass of the sandwich structures with different types of hourglass lattice structures can be maintained by simply varying the thickness of the panels.For comparison, the calculations are performed for solid panels with the identical mass(denoted as H0).

The calculation models from Fig.1 were embedded in LS-DYNA finite-element software to assess the ballistic performances of the hourglass lattice sandwich structures.The outer panels and the hourglass lattice structures were fixed connection with each other and the panels of sandwich structures were fixed on all sides.Without loss of generality, the fragments were offset diagonally from the center of the panels,causing impact at the initial velocity perpendicular to the panels.Solid 164 elements (explicit threedimensional elements) were used for the finite element models,the maximum mesh size of the hourglass lattice sandwich structures was 1 mm,and the maximum mesh size of the fragments was 0.5 mm to ensure mesh convergence [33-36].In the penetration process between the fragments and the sandwich structures,CONTACT_ERODING_SINGLE_SURFACE was adopted.Based on the existing research results on the influence of friction, the friction was ignored in this study [20].Combined with practical engineering applications, the 10CrNi3MoV (ship steel 921 A) and Johnson-Cook model were used for the outer panels and core of the hourglass lattice sandwich structures.The material parameters were as follows: density ρ = 7800 kg/m3, Young modulusE= 205 GPa,Shear modulusG= 777.6 MPa, Poisson's ratio μ = 0.28, material constantA=760 MPa,B=500 MPa,n=0.53,C=0.014,m=1.13,melt temperatureTm= 1765 K, room temperatureTr= 300 K,specific heatcp=400.9 J/(kg·K),fracture constantD1=1.13,D2=0,D3=0,D4=0,andD5=0[37].Compared with the rigid model,the simulation results considering mass loss were closer to the experimental results under the high velocity penetration.Therefore,the 35CrMnSiA and plastic-kinematic model with mass loss were used for the fragments.The material parameters were as follows:density ρ = 7850 kg/m3, Young modulusE= 206 GPa, Poisson's ratio μ = 0.3, yield strength σys= 1280 MPa, ultimate strength σbs=1620 MPa,and failure strain ε=1[38].The incident velocity of the fragments referred to the velocity of the bullet in conventional military propulsion devices.Here,v= 1400 m/s andv= 800 m/s were selected respectively for the simulation.The geometric parameters found for different types of hourglass lattice sandwich structures and fragments were respectively given in Tables 1 and 2.For the geometric parameter values, it was necessary to consider that the spacing between nodes should be less than the diameters of the fragments.It avoided the fragments made no contact with the hourglass lattice structures during the penetration process.Otherwise, the ballistic performances of the hourglass lattice sandwich structures would be greatly weakened.

2.2.Validation of FE models

Fig.2.Geometric models: (a) Hourglass lattice sandwich structures; (b) Hourglass cell structures; (c) Assembly strips; (d) Fragments.

Table 1Geometric parameters of hourglass lattice sandwich structures.

Table 2Geometric parameters of fragments.

In order to verify the reliability of the finite-element models established in this study, a comparative verification analysis was carried out for the existing research results.Considering that the hourglass lattice sandwich structures in the present research were compared to the solid panels with the same mass,the penetration for 93 W rod into semi-infinite 4340 steel plates, reported in Ref.[39], were selected.The material parameters and external conditions were the same as in work[39].Fig.3 displays the depth of penetration and the velocity history curves at different striking velocities for the projectile.It can be seen that the numerical simulation results in this paper are in good agreement with the data from the existing references.In addition, the ballistic performances of metal materials are researched both in this study and in Ref.[39], so the same damage pattern is selected as Ref.[39] to ensure the reliability of the established finite-element models.

3.Results and discussion

3.1.Deformation patterns

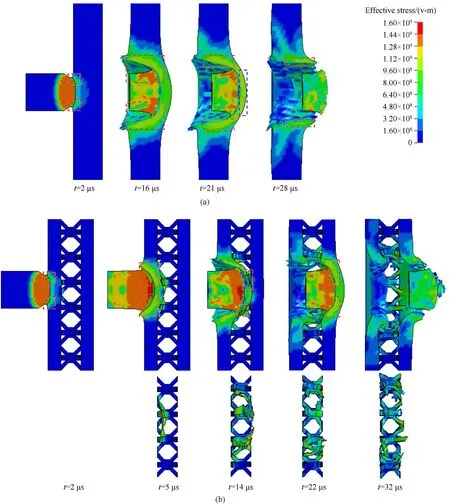

The deformation mode can directly reflect the action mechanism of the bullet during penetration into the structures.Unlike the solid panels, the lattice sandwich structures reveal the complex interactions between the panels and the lattice structures in the penetration process.Figs.4 and 5 displays the deformation diagrams of the solid panels and the H1-type hourglass lattice sandwich structures under the vertical incidence penetration conditions at velocity of 1400 and 800 m/s,respectively.The time of the same key interaction positions between the fragments and the structures is selected in Figs.4 and 5.In order to elucidate the effects and changes of lattice structures during penetration, the separate deformation diagrams of the lattice structures at the same time point are also presented in the figures.

According to Fig.4(a), the fragments are incident vertically at the initial velocity of 1400 m/s.The solid panels is subjected to shear deformation once being in contact with the fragments(t= 2 μs, indicated by a red box in the figure).Although in the penetration process, shear deformation is dominated in the solid panels (t= 16 μs,t= 21 μs, indicated by a red box in the figure),there are also some tensile deformation areas(t=21 μs,indicated by a blue box in the figure).Finally, under the shear action of the fragments,the solid panels is penetrated(t=28 μs,indicated by a red box in the figure).

As shown in Fig.4(b),the fragments are incident vertically at the initial velocity of 1400 m/s.In the penetration process, the front panels of the hourglass lattice sandwich structures undergoes the same shear deformation in the contact area at the initial penetration stage (t= 2 μs, indicated by a red box in the figure), and the stress state of the front panels is dominated by the shear action of the fragments(t=5 μs,indicated by a red box in the figure).In this case, the hourglass lattice structures support the front panels and are exposed to both bending and shearing.When the front panels hits the rear panels, the front panels suffers shear failure that is afterwards transmitted to the hourglass lattice structures during extrusion (t= 14 μs, indicated by a red box in the figure).Subsequently, the fragments is applied to the rear panels, mainly by shearing (t= 22 μs, indicated by a red box in the figure).At this point, the hourglass lattice structures are under tensile deformation from the rear panels.Finally,trying to resist the shear action of the fragments, the rear panels is destroyed and the hourglass lattice sandwich structures is penetrated (t= 32 μs).At the same time, the hourglass lattice structures will be further damaged due to tensile action.

Fig.3.Comparison of Ref.[39] and the simulation results for different striking velocities.

Fig.4.Deformation patterns at v = 1400 m/s: (a) Solid panels; (b) Hourglass lattice sandwich structures.

As seen in Fig.5(a), the fragments are incident vertically at the initial velocity of 800 m/s.Once the fragments has entered in contact with the solid panels and penetrated it, the shear deformation is induced (t= 3 μs,t= 7 μs, indicated by a red box in the figure).With the increase of penetration depth, the velocity of the fragments decreases continuously, and the tensile deformation gradually becomes the main state in the solid panels (t= 22 μs,indicated by a blue box in the figure).During the penetration process, cavities are formed around the fragments due to its invasion into the panels and the decrease of the fragment velocity(t=31 μs,indicated by a blue box in the figure).Finally, the solid panels is cracked and damaged at the maximum deflection point,namely the solid panels is penetrated by the fragments(t=40 μs,indicated by a blue box in the figure).

In Fig.5(b), the fragments are incident vertically at the initial velocity of 800 m/s.In the initial contact with front panels of the hourglass lattice sandwich structures and the subsequent penetration process, shear deformation still prevails (t= 3 μs,t= 8 μs,indicated by a red box in the figure).However,due to the decrease in the incident velocity of the fragments, there is also a significant tensile effect.While hitting the rear panels,the front panels suffers shear failure (t= 22 μs, indicated by a red box in the figure), and cavities arise around the fragments during this process (t= 25 μs,indicated by a blue box in the figure).Then, the fragment velocity further decreases, and the main failure mode of the rear panels is tensile deformation(t=37 μs,t=67 μs,indicated by a blue box in the figure).Eventually, the fragments penetrate the hourglass lattice sandwich structures.In the whole penetration process of the fragments through the hourglass lattice sandwich structures, the actions of the hourglass lattice structures are the same as those calculated at the incident velocity of 1400 m/s.

Fig.5.Deformation patterns at v = 800 m/s: (a) Solid panels; (b) Hourglass lattice sandwich structures.

According to the above analysis, in the penetration process of high-velocity fragments, the main failure mode of the panels is shear deformation failure.When the velocity of the fragments decreases to a certain value,tensile deformation failure will gradually become the main failure mode of the panels.In addition, some cavities emerge around the fragments.When the hourglass lattice sandwich structures is penetrated by the fragments, the hourglass lattice structures not only suffers shear failure, but also supports the front and rear panels through bearing bending and tensile action, thus improving the ballistic performances of the hourglass lattice sandwich structures.

3.2.Velocity histories

The ballistic performances of the lattice sandwich structures can be reflected by the residual velocity of the fragments after penetration.The smaller is the residual velocity,the better is the ballistic performances of the lattice sandwich structures,which is beneficial for related protection devices.

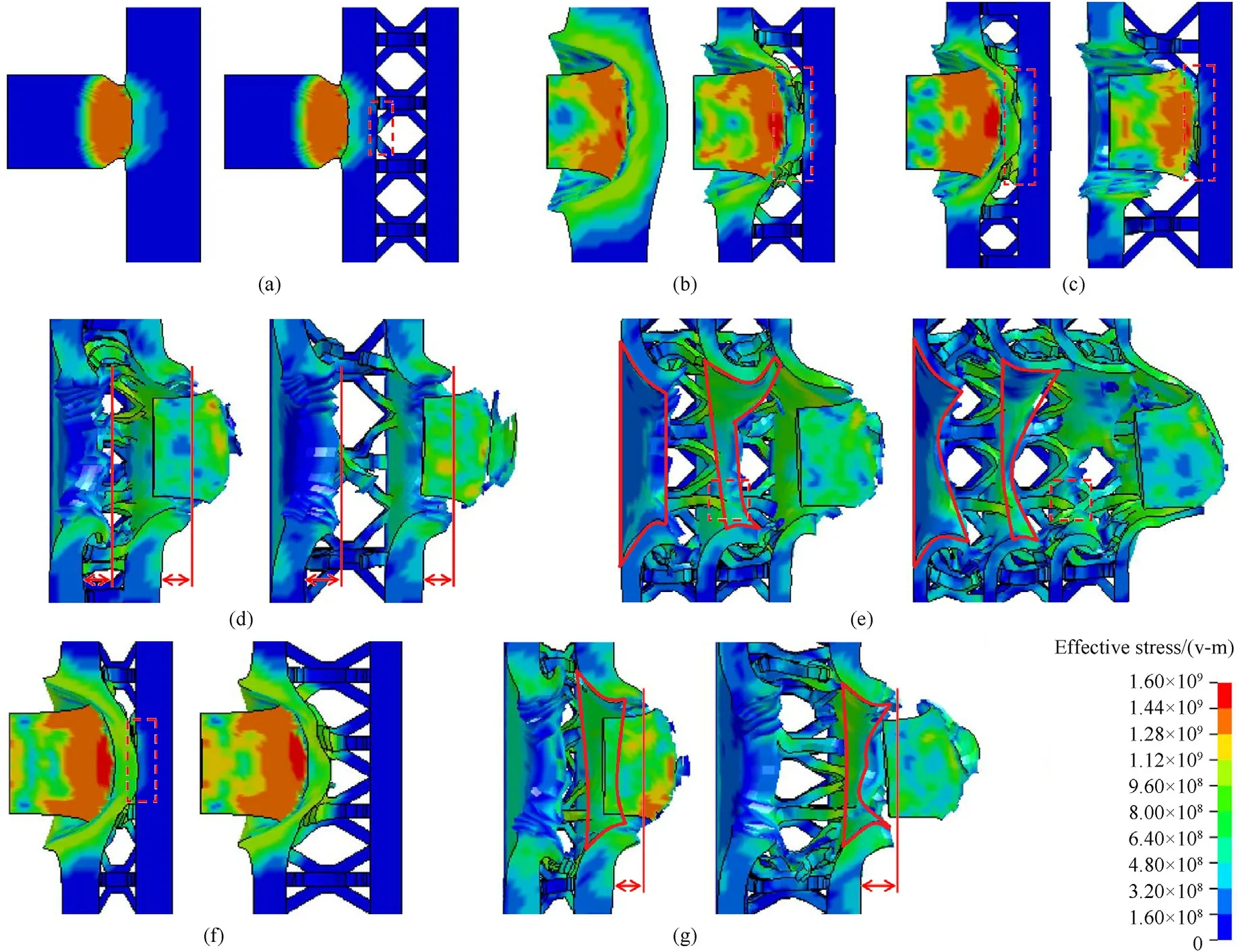

Fig.6 shows the velocity history curves of the vertically incident fragment penetrating different types of hourglass lattice sandwich structures at a velocity of 1400 m/s.As shown in the figure, the ballistic performances of the hourglass lattice sandwich structure depend on its structural parameters.Such structures can absorb the kinetic energy of the fragments through plastic deformation and fracture failure.The velocity of the fragments decreases continuously and reaches a stable value(so-called residual velocity)once the structures is completely penetrated.For comparison, the calculation results for solid panels with the same mass are also presented in the figure.Fig.7 displays the deformation diagrams at the critical time points marked in Fig.6.

Fig.6.Velocity of fragments in hourglass lattice sandwich structures at v = 1400 m/s.

Fig.6(a) depicts the data calculated for H2-type, H1-type, and H3-type sandwich structures with the same mass but different hourglass lattice rod cross-section dimensions; the results for the H0 solid panels are given as the reference.As can be seen, whent= 2 μs, the velocity curve of H1-type hourglass lattice sandwich structures begins to deviate from that of the H0 solid panels.This is because the hourglass lattice structures begin to deform att=2 μs(Fig.7(a)),which makes the velocity of the fragments in the hourglass lattice sandwich structures decrease below than that in the solid panels, and gradually increasing the velocity gap during penetration.Whent= 14 μs, the front and rear panels in the H1-type hourglass lattice sandwich structures collide with each other under the penetration of the fragments,and the difference between the velocities reaches the maximum value (Fig.7(b)).In the subsequent penetration process, due to the action of the hourglass lattice structures, the decrease degree of the fragment velocity in the hourglass lattice sandwich structures is higher, and the duration is longer.Finally, the residual velocities of the fragments penetrating the H2-type, H1-type, and H3-type hourglass lattice sandwich structures differ little, but are lower than that in the H0 solid panels.

Fig.6(b)shows the calculation results for H4-type,H1-type,and H5-type sandwich structures with the same mass but different heights of hourglass lattice structures.As can be seen, whent=11 μs,their velocity curves begin to deviate from each other.Att=11 μs,the front and rear panels of the H4-type hourglass lattice sandwich structures are collide and contact with each other,which aggravates the decrease degree of the fragment velocity in the structures.The H5-type hourglass lattice sandwich structures possess the largest height,and have the longest time of interaction with the fragments.Att= 19 μs, the front and rear panels collide and contact with each other, accelerating the decrease of the fragment velocity (Fig.7(c)).The fragments penetrate the H4-type and H5-type hourglass lattice sandwich structures att=31 μs andt= 39 μs, respectively.There is a significant gap between the residual velocities of the fragments after penetrating the H4-type and H5-type hourglass lattice sandwich structures, and the residual velocity decreases with the increase of the hourglass lattice structure height.The higher height of the hourglass lattice structures results in the greater space between the front and rear panels,thus causing their stronger deformation.An increase in deformation of the panels means the higher kinetic energy of the fragments,which can be absorbed by the structures.Moreover, the longer is the penetration process of the fragments, the larger is the scope furnished by the fragments in the panels and hourglass lattice structures.In this respect, an increase in the kinetic energy of the fragments,absorbed by the structures,reduces the residual velocity of the fragments (Fig.7(d)).

Fig.7.The comparison of the deformation patterns for various structures at v = 1400 m/s: (a) H0 and H1 at t = 2 μs; (b) H0 and H1 at t = 14 μs; (c) H4 at t = 11 μs and H5 at t = 19 μs; (d) H4 at t = 31 μs and H5 at t = 39 μs; (e) H6 at t = 42 μs and H7 at t = 47 μs; (f) H8 and H9 at t = 10 μs; (g) H8 at t = 31 μs and H9 at t = 40 μs.

Fig.6(c)depicts the results calculated for H1-type,H6-type,and H7-type sandwich structures with the same mass and different number of hourglass lattice structure layers.As can be seen, the fragments penetrates the H6-type and H7-type hourglass lattice sandwich structures att= 42 μs andt= 47 μs, respectively, with different residual velocities.The residual velocity of the fragments after penetrating a three-layer hourglass lattice sandwich structures is lower than that in a two-layer hourglass lattice sandwich structures, and even much lower than in a one-layer hourglass lattice sandwich structures.This is due to the fact that the more layers of the hourglass lattice sandwich structures can prolong the penetration of the fragments, thus generating the stronger deformation and the larger damage scope of the panels and the hourglass lattice structures.As a result, more kinetic energy of the fragments can be absorbed by the structures, and the residual velocity is reduced accordingly.This conclusion can be confirmed by the remaining areas of the panels and the hourglass lattice structures after destruction.The smaller are the remaining areas of the panels,the larger are the damaged areas of the panels and the more kinetic energy of the fragments are absorbed (Fig.7(e)).

Fig.6(d) shows the calculation data for H8-type, H1-type, and H9-type sandwich structures with the same mass but different hourglass lattice rod inclination angles.As can be seen, whent=11 μs,their velocity curves begin to deviate from each other.This is because the front and rear panels of the H8-type hourglass lattice sandwich structures collide first, which accelerates the decrease degree of the fragment velocity(Fig.7(f)).The fragments penetrate the H8-type and H9-type hourglass lattice sandwich structures att= 31 μs andt= 40 μs, respectively, with different residual velocities.The residual velocity of the fragments decreases with the increase of the hourglass lattice rod inclination angle.The larger inclination angle of hourglass lattice rods can provide the greater space between the front and rear panels,and the penetration time of the fragments increases accordingly.As a result, the panels and the hourglass lattice structures undergo the stronger deformation and, consequently, the larger damage scope, which means that more kinetic energy of the fragments can be absorbed by the structures, reducing the residual velocity.This is evident from the remaining areas of the panels and the hourglass lattice structures after destruction (Fig.7(g)).

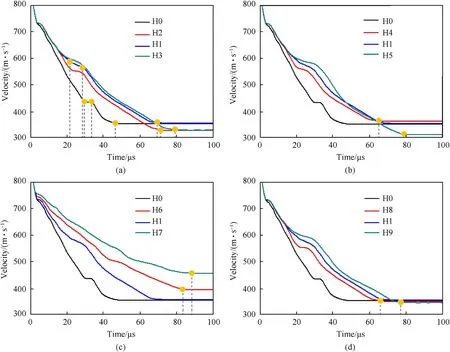

Fig.8 displays the time history curves of the velocity of the fragments in the penetration process for different types of hourglass lattice sandwich structures at a vertical incidence velocity of 800 m/s.As can be seen, when the incidence velocity of the fragments is reduced, the residual velocity changes to various extents depending on the types of the sandwich structures.For comparison,the calculation results for the solid panels with the same mass are given as well.In addition, Fig.9 shows the deformation diagrams at the critical time points marked in Fig.8.

Fig.8.Velocity of fragments in hourglass lattice sandwich structures at v = 800 m/s.

Fig.9.The comparison of the deformation patterns for various structures at v = 800 m/s: (a) H0 at t = 31 μs and H1 at t = 25 s; (b) H1 at t = 69 μs, H2 at t = 71 μs and H3 at t = 79 μs; (c) H6 at t = 83 μs and H7 at t = 88 s; (d) H8 at t = 66 μs and H9 at t = 77 s.

In Fig.8(a),the calculation results for H2-type,H1-type,and H3-type hourglass lattice sandwich structures are given along with the data for the H0 solid panels as the reference.As can be seen,during the penetration of the fragments into the H0 solid panels within a period fromt= 29 μs tot= 33 μs, the velocity curve achieves a constant stage.This can be attributed to the formation of cavities around the fragments.The cavities are space between the panels and the fragments when the velocities of the fragments are reduced and the panels are eroded [26].A similar phenomenon can be observed fromt=21 μs tot=28 μs during the penetration process of the fragments into the H1-type hourglass lattice sandwich structures (Fig.9(a)).When the fragments penetrates different structures, its residual velocity in the H1-type hourglass lattice sandwich structures is close to that in the H0 solid panels,while the residual velocity in the H2-type and H3-type hourglass lattice sandwich structures is lower.This is because the decrease of the fragments incidence velocity can prolong the penetration of the fragments, which leads to the change of the failure mode of the panels from shear-dominated to tensile-dominated failure.Here,the thickness of the panels is an important influencing factor.The thicker panels can generate stronger deflection during tensile fracture, which increases the penetration time and enlarges the deformation scope.So, the ballistic performances of the H0 solid panels also have some advantages.Compared with the H1-type hourglass lattice sandwich structures, the H2-type hourglass lattice sandwich structures has the thicker panels, whereas the H3-type hourglass lattice sandwich structures has the larger crosssection dimensions of rods, which exert the pronounced effect on the panels.Consequently, while penetrated by the fragments, the panels in the H2-type and H3-type hourglass lattice sandwich structures can generate larger deflection and absorb more kinetic energy of the fragments (Fig.9(b)).

In Fig.8(b),one can find the results calculated for H4-type,H1-type,and H5-type hourglass lattice sandwich structures.As shown in the figure, the fragments penetrates the H4-type and H5-type hourglass lattice sandwich structures att= 65 μs andt= 79 μs,respectively,and the relationship between the residual velocity and the height of the hourglass lattice structures does not change with the decrease of the fragments incidence velocity.This is because the hourglass lattice structure height is proportional to the panel thickness, which is conducive to the absorption of more kinetic energy of the fragments, thus decreasing its residual velocity.

Fig.8(c) depicts the calculation data for H1-type, H6-type, and H7-type hourglass lattice sandwich structures.As shown in the figure, the fragments penetrates the H6-type and H7-type hourglass lattice sandwich structures att= 83 μs andt= 88 μs,respectively,and the calculated residual velocities at this incidence velocity are completely opposite to the results calculated at the velocity of 1400 m/s.The residual velocity of the fragments after penetrating a one-layer hourglass lattice sandwich structures is lower than that in a two-layer hourglass lattice sandwich structures,and even much lower than in a three-layer hourglass lattice sandwich structures.This is the result of two combined influence.On the one hand, when the incidence velocities of the fragments are reduced, the penetration of the fragments is prolonged significantly.Compared with multilayer lattice structures, the penetration time of the fragments in one-layer lattice structures is the shortest, but enough to reach the effective action areas.On the other hand, when the incidence velocities of the fragments are reduced, the contact stress between the fragments and the structures is decreased during the collision,and the plastic deformation areas of the front panel are decreased obviously.In this case, the role of the hourglass lattice structures is not obvious during the panels are penetrated.According to the above analysis, multilayer lattice structures are no longer advantageous.On the contrary,the one-layer lattice structures are better in shear resistance due to the thicker panels.Therefore, the residual velocities of the fragments are the lowest after penetrating one-layer hourglass lattice sandwich structures(Fig.9(c)).

Fig.8(d)shows the calculation results for H8-type,H1-type,and H9-type hourglass lattice sandwich structures.According to the figure, the fragments penetrates the H8-type and H9-type hourglass lattice sandwich structures att= 66 μs andt= 77 μs,respectively.Furthermore, the residual velocities of the fragments after penetrating the H8-type, H1-type, and H9-type hourglass lattice sandwich structures are found to be basically equal to the residual velocity of the fragments after penetrating the H0 solid panels.This result can be explained from the two aspects.On the one hand,the larger inclination angles of the hourglass lattice rods ensures the greater space between the front and rear panels, and the penetration time of the fragments is longer accordingly, thus increasing the deformation of the front panels.In turn,the greater deformation results in the larger damage scope,meaning that more kinetic energy of the fragments can be absorbed by the structures.Therefore,the residual velocity of the fragments can be reduced.On the other hand,the larger inclination angles of the hourglass lattice rods,the thinner the panels.Then,the deflection of the rear panels is smaller, and the penetration time of the fragments through the panels is shorter.As a result, less kinetic energy of the fragments can be absorbed, and the residual velocity of the fragments becomes higher accordingly(Fig.9(d)).

Based on the above analysis, it can be seen that, under the condition of vertical incidence at a velocity of 1400 m/s,the failure mode of the hourglass lattice sandwich structures is dominated by shear failure,and the structural parameters of the hourglass lattice structures are the important influencing factors.Increasing the height and the rod inclination angle of the hourglass lattice structures and controlling the number of hourglass lattice structure layers can effectively augment the space between the panels, prolong the penetration time of the fragments, and increase the deformation of the panels and the hourglass lattice structures,thus improving the ballistic performances of the hourglass lattice sandwich structures.Under the condition of vertical incidence at a velocity of 800 m/s, the failure mode of the hourglass lattice sandwich structures is dominated by tensile failure, and the thickness of the panels is the important influencing factors.Increasing the height of the hourglass lattice structures,controlling the number of hourglass lattice structure layers,and increasing the thickness of the panels enable one to effectively prolong the penetration time of the fragments into the panels,and increase the deformation of the panels and the hourglass lattice structures,thus improving the ballistic performances of the hourglass lattice sandwich structures.

3.3.Angle away from the incident ballistic trajectory

Compared with the foam sandwich and honeycomb sandwich structures, the lattice sandwich structures have the capacity to change the trajectory direction.When the bullet penetrates the lattice sandwich structures, its ballistic trajectory will deviate because of the asymmetrical lattice structures distribution around the projectile center.The ability of the lattice sandwich structures to modify the trajectory direction of the fragments can be evaluated by the deviation angle and deviation angular velocity.Deviation angle is the angle of the fragments deviating from the initial incidence direction.Deviation angular velocity is the rotation angular velocity of the fragments deviating from the initial incidence direction.The larger are the deviation angle and the angular velocity,the better is the capacity of the lattice sandwich structures to change the trajectory direction of the fragments.

Fig.10 shows the time history curves of the deviation angle of the fragments penetrating the different hourglass lattice sandwich structures at a vertical incidence velocity of 1400 m/s.The point value on the curves and the corresponding slope at the point represent the deviation angle and the angular velocity,respectively.As shown in the figure,the ability of the hourglass lattice sandwich structures to change the ballistic direction of the fragments is related to the structural parameters of the former.

Fig.10.Angle away from the incident ballistic trajectory for fragments in hourglass lattice sandwich structures at v = 1400 m/s.

Fig.10(a) displays the calculation results for H2-type, H1-type,and H3-type hourglass lattice sandwich structures.As can be seen,the deviation angle and angular velocity of the fragments increase with increasing rod cross-section dimension in the hourglass lattice structures.This is because the larger cross-sections of the rods of the hourglass lattice structures improve the supporting effect on the panels and the resistance to the penetration of the fragments.This, in turn, increases the deviation angle and angular velocity of the fragments relative to the initial incidence trajectory.It is noteworthy that, among the mentioned three types of sandwich structures, the rod cross-section in the H2-type hourglass lattice sandwich structures is very small, and its influences on the incidence ballistic trajectory of the fragments can therefore be ignored.

Fig.10(b)contains the data calculated for H4-type,H1-type,and H5-type hourglass lattice sandwich structures.As shown in the figure, the deviation angle and angular velocity of the fragments decrease with the increase of the hourglass lattice structure height.This is because that larger height of the hourglass lattice structures means the larger pore in the structures.Thus,while the fragments through pore space in the penetration process,the influences of the hourglass lattice structures is weaker.Consequently, the deviation angle and angular velocity of the fragments from the initial incident trajectory are smaller.

Fig.10(c)depicts the results for H1-type,H6-type, and H7-type hourglass lattice sandwich structures.As can be seen in the figure,the deviation angle and angular velocity of the fragments after penetrating a two-layer hourglass lattice sandwich structures are significantly higher than those through a one-layer hourglass lattice sandwich structures, but close to those through a three-layer hourglass lattice sandwich structures.In the two-layer sandwich structures, both hourglass lattice structure layers can simultaneously act on the fragments in the penetration process.In the three-layer sandwich structures, due to the fast penetration velocity, only two hourglass lattice structure layers simultaneously act on the fragments in the penetration process, and the other hourglass lattice structure layers cannot respond in time to the penetration.

Fig.10(d) shows the data calculated for H8-type, H1-type, and H9-type hourglass lattice sandwich structures.As shown in the figure, the deviation angle and angular velocity of the fragments increase with increasing inclination angles of the hourglass lattice rods.The larger is the inclination angles of the hourglass lattice rods, the higher is the hourglass lattice structures.Then, the structures can exert a more prolonged effect on the fragments,thus leading to the larger deviation angle and angular velocity of the fragments with respect to the initial incidence trajectory.

Fig.11 contains the time history curves of the deviation angle of the fragments penetrating various hourglass lattice sandwich structures at a vertical incidence velocity of 800 m/s.As shown in the figure, the decrease of the incidence velocity of the fragments can influence the ability of the hourglass lattice sandwich structures to change the ballistic direction.

Fig.11(a)represents the calculation results for H2-type,H1-type,and H3-type hourglass lattice sandwich structures.As can be seen,the deviation angle of the fragments relative to the initial incidence ballistic trajectories exceeds those at a vertical incidence velocity of 1400 m/s.The decrease in the incidence velocity contrast with the hourglass lattice rods with more pronounced supporting effects on the panels and even stronger resistance to the penetration of the fragments.The deviation angle and angular velocity of the fragments from the initial incidence trajectory still increase with the increase of the rod cross-section dimensions in the hourglass lattice structures.Among these three types of sandwich structures,the rods in the H2-type hourglass lattice sandwich structures also have some influences on the incidence ballistic trajectory of the fragments.

Fig.11.Angle away from the incident ballistic trajectory for fragments in hourglass lattice sandwich structures at v = 800 m/s.

Fig.11(b)displays the results calculated for the H4-type and H5-type hourglass lattice sandwich structures.As shown in the figure,the H5-type hourglass lattice sandwich structures still exerts little influences on the ballistic trajectory of the fragments.Compared with the H1-type hourglass lattice sandwich structures, the H4-type structures have relatively weak influences on the ballistic trajectory of the fragments.This is because the decrease of the incidence velocity of the fragments can reduce the shearing effect and, therefore, enhance the tensile effect on the hourglass lattice sandwich structures.The lower hourglass lattice structures mean the shorter hourglass lattice rods.Thus, the ability to change the ballistic direction of the fragments is reduced.

Fig.11(c) includes the data for H6-type and H7-type hourglass lattice sandwich structures.According to the figure, the deviation angle of the fragments from the initial incidence ballistic trajectory exceeds those at a vertical incidence velocity of 1400 m/s for both the structures.Moreover, the deviation angle and angular velocity of the fragments after penetrating a three-layer hourglass lattice sandwich structures is significantly higher than that through a twolayer structures.This is due to the fact that the decrease of the incident velocity of the fragments can prolong the penetration time, and the three hourglass lattice layers directly respond to the fragments during the penetration.

Fig.11(d) illustrates the results for H8-type and H9-type hourglass lattice sandwich structures.As shown in the figure, the deviation angle of the fragments in the H8-type structures shows no obvious changes, while that in the H9-type structures obviously increases.This is because the decrease of the incidence velocity further prolongs the action time of the hourglass lattice structures on the fragments, which can increase the deviation angle of the fragments from the initial incidence ballistic trajectory.

Based on the above analysis, one can conclude that, under the vertical incidence at a velocity of 1400 m/s, increasing the rod cross-section dimensions of the hourglass lattice structures and controlling the number of hourglass lattice structure layers is an effective way to improve the ability of such structures to change the ballistic direction of the fragments.In turn, under the vertical incidence at a velocity of 800 m/s,the properties can be enhanced through the increase in the rod cross-section dimensions and the rod inclination angle of hourglass lattice structures along with a control of the number of hourglass lattice structure layers.

3.4.Structure design

Based on the above numerical simulation results of the influence of structural parameters on ballistic performances of the hourglass lattice sandwich structures under the vertical incidence conditions ofv= 1400 m/s andv= 800 m/s.Integrating the favorable factors for improving the ballistic performances of hourglass lattice sandwich structures, the hourglass lattice rodcross-section dimensions of H1-type sandwich structures and the hourglass lattice rod inclination angles of H9-type sandwich structures are selected.The height of the hourglass lattice structures is calculated by choosing the node spacing of H5-type sandwich structures.According to the totally opposite influence results of the layer numbers atv=1400 m/s andv=800 m/s,2 layers are selected.In order to obtain the sandwich structures with excellent ballistic performances under the high velocity penetration, the thickness of the panels is increased simply,and the optimal design model of the hourglass lattice sandwich structures is established(the model is denoted as H10).The relevant geometric parameters of the H10-type hourglass lattice sandwich structures are available in Table 3.

Table 3Geometric parameters of H0 solid panels and H10 hourglass lattice sandwich structures.

Fig.12.The initial and residual velocities of fragments for H0 solid panels and H10 hourglass lattice sandwich structures.

The ballistic limit velocity is a commonly used parameter to characterize the ballistic performances of protective materials.In this study, calculating the ballistic limit velocity of the H10-type hourglass lattice sandwich structures enabled one to assess its ballistic performances.For comparison,the ballistic limit velocity of the H0 solid panels with the same mass is also calculated (see the geometric parameter values in Table 3).The fragments is vertically incident onto the structures at different initial velocities and penetrates through the specimens, and the numerical simulation results of the initial impact velocity and the corresponding residual velocity can be obtained.To obtain the ballistic limit velocity of the specimens, the calculation results are fitted using the Jonas-Lambert relation (Eq.(2)), as shown in Fig.12.

whereaandpare the parameters of the model,vIandvRare the initial impact velocity and residual velocity of the fragments,respectively, andvBis the ballistic limit velocity of the protective materials.

Based on the numerical simulation results and Jonas-Lambert model, the ballistic limit velocity of the H0 solid panels isvBH0= 1052 m/s, whereas that of the H10-type hourglass lattice sandwich structures is found to bevBH10=1396 m/s,i.e.,increasing by 32.7%.These results fully confirm that the ballistic performances of hourglass lattice sandwich structures can be effectively improved by designing their structural parameters.

4.Conclusions

In summary, the hourglass lattice sandwich structure models are established in this paper and the influences of their structural parameters on the ballistic performances under the vertical incidence of fragments are discussed by the numerical simulation method.

The hourglass lattice structures support the front and rear panels to improve the ballistic performances of the hourglass lattice sandwich structures while penetrated by the fragments.Under the vertical incidence of the fragments at a high velocity(1400 m/s), shear failure is the dominant failure mode of the hourglass lattice sandwich structures.On the contrary, at a lower incidence velocity of the fragments(800 m/s),the hourglass lattice sandwich structures show tensile dominant failure mode.Furthermore,changing the panel thickness, the rod cross-section dimensions of the hourglass lattice structures, the hourglass lattice structure heights, the number of hourglass lattice structure layers, or the hourglass lattice rod inclination angles allows one to enlarge the spatial distance between the panels and increase the penetration time of the fragments.This positively influences the deformation of the hourglass lattice sandwich structures,effectively improving its ballistic performances and enhancing the ability to change the ballistic direction of the fragments.

The ballistic limit velocity of the hourglass lattice sandwich structures is increased by 32.7% through integrating the favorable influencing factors from the structural parameters.This work improves the ballistic performances of hourglass lattice sandwich structures, which provides a new idea for the design of protection devices.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work is supported by the Defense Industrial Technology Development Program (Grant No.JCKY2018604B004) and the National Natural Science Foundation of China (Grant No.11972007).The financial contributions are gratefully acknowledged.

- Defence Technology的其它文章

- The interaction between a shaped charge jet and a single moving plate

- Machine learning for predicting the outcome of terminal ballistics events

- Fabrication and characterization of multi-scale coated boron powders with improved combustion performance: A brief review

- Experimental research on the launching system of auxiliary charge with filter cartridge structure

- Dependence of impact regime boundaries on the initial temperatures of projectiles and targets

- Experimental and numerical study of hypervelocity impact damage on composite overwrapped pressure vessels