The effect of Ti and Zr content on the structure, mechanics and energy-release characteristics of Ti-Zr-Ta alloys

Ji-yu Meng , Jing-zhi He , Bin Zhng , Jin Chen ,**, Shun Li , Dun Niu , Yu Tng ,*

a Xi’an Modern Chemistry Research Institute, Xi'an, 710065, China

b College of Aerospace Science and Engineering, National University of Defense Technology, Changsha, 410073, China

Keywords: Energetic structural materials Ti-Zr-Ta Multi-element alloy Energy release characteristics

ABSTRACT Energetic structural materials (ESMs) are a new type of structural materials with bearing and damage characteristics.In this work the microstructure,mechanical properties and energy release characteristics of multi-element Ti-Zr-Ta alloys with good casting performance were studied.The microstructure of the TixZrTa alloys gradually change from BCC+HCP to single BCC structure with the increase of Ti.While the Ti2ZryTa alloys was still uniform and single BCC structure with the increase of Zr.The evolution of microstructure and composition then greatly affect the mechanical properties and energy-release characteristics of Ti-Zr-Ta alloys.The synergistic effect of dual phase structure increases the fracture strain of TixZrTa(x=0.2,0.5)with the Ti content decreases, while the fracture strain of TixZrTa (x=2.0,3.0, 4.0) gradually increase with the Ti content increases caused by the annihilation of the obstacles for dislocation movement.And as Zr content increases, the fracture strain of Ti2ZryTa alloys decrease, then the oxidation reaction rate and fragmentation degree gradually increase.The higher oxidation rate and the lager exposed oxidation area jointly leads the higher releasing energy efficiency of TixZrTa alloys with low Ti content and Ti2ZryTa alloys with high Zr content.

1.Introduction

Energetic structural materials (ESMs), which were first proposed by Hugh in the form of reaction fragments [1], were a new type of structural materials with dual characteristics of bearing and damage [2-6].As potential reaction fragments or shells, some characteristics, including decent strength and plasticity [7-9] and high density and high potential releasing energy[2,10],are required for ESMs.To enhance the potential releasing energy, refractory metals Ti,Zr,Al,etc.Were often selected as the constituents of ESMs because of their high oxidation activity and combustion heat values[11,12].

So far, most existing reports on ESMs have focused on the mechanics and energy-release characteristics of one material, or the effect of adding element on classic system[7,13,14].Mock et al.[15]studied the impact initiation behavior of PTFE/Al ESMs with different Al particles sizes,and found that the smaller the size of Al particles, the lower the impact reaction threshold.Hu et al.[16]studied the influence of different microstructures of Al/Ni ESMs on the mechanical properties and energy-release characteristics of the alloys.The ESMs with Ni continuous phase(Nicp)structure had the higher quasi-static compressive strength and fracture strain,which reach 325 MPa and 21.3% respectively, and reaction performance were also better than those of the alloy with Al continuous phase(Alcp) structure.Shang et al.[17] studied the damage and penetration characteristics of W-Zr long-rods.The violent reaction behavior of W-Zr ESMs contributes to the large perforation and damage area of subsequent plates than inert materials.Su et al.[14]studied the penetration performance of 50%Wp/Zr41·2Ti13·8Cu12·5Ni10Be22.5amorphous alloy.The amorphous projectiles all showed self-sharpening when penetrating the target plate.And the addition of 50% W particles greatly improved the penetration performance of Zr-based amorphous projectiles.Increasingly, with the development of alloy design concept, the potential of multi-principal elements alloy as energetic structural material has been gradually explored, such as high-entropy alloys[9,18-20].

In this study, Ti-Zr-Ta multi-principal elements alloys with good casting performance[21]were selected as the basic alloy.The relationship between the microstructure, mechanical properties and energy-release characteristics of the alloys were studied by adjusting the content of active elements Ti and Zr in the alloys.This work provides some meaningful theoretical and experimental results for the application of multi-principal elements alloys in energetic structural materials.

2.Experiments

The bulk TixZrTa (x= 0.2, 0.5, 1.0, 2.0, 3.0, 4.0) and Ti2ZryTa(y=0.5,0.75,1.0,1.25,1.5)alloys were prepared by arc-melting and annealing.High-purity raw metals (>99.9%) were melted in the vacuum furnace under a Ti-gettered argon atmosphere.The ingot was remelted at least eight times to achieve a homogeneous distribution of elements.The annealing of as-cast TixZrTa and Ti2ZryTa alloys were carried out by HVGQ-2235 horizontal vacuum highpressure gas quenching furnace.Firstly, the as-cast alloys were placed neatly in the boron nitride crucible,and then put into the gas quenching furnace.Secondly, the furnace cavity with samples was vacuumed to vacuum degree of 1×10-1MPa.Thirdly,the samples were annealed at 1200°C for 12 h and then gas quenched by highpurity argon.

The crystal structures of TixZrTa and Ti2ZryTa alloys were characterized by X-ray diffractometer (XRD; Rigaku SmartLab 9 KW).Their microstructure and element distribution were performed by scanning election microscopy (SEM; JXA-8530) equipped with back-scattered electron (BSE; JXA-8530) and energy-dispersive(EDS).The quasi-static mechanical properties of samples with the size of φ5 mm × 10 mm were tested by DDL100 universal mechanical testing machine.

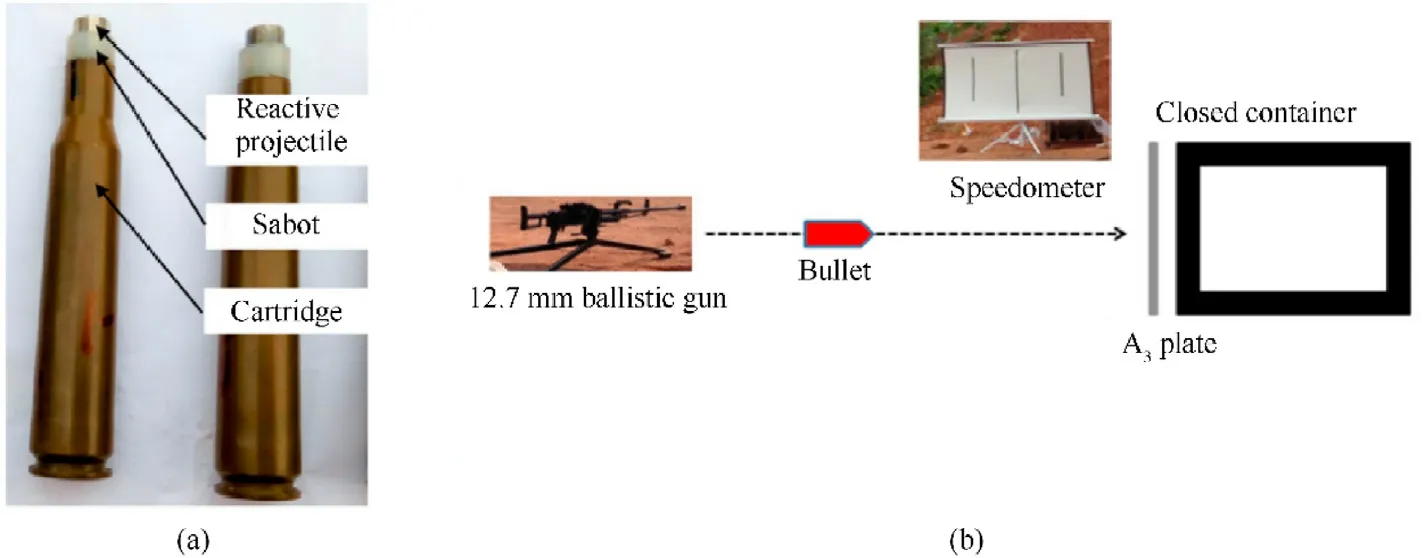

The impact energy-release characteristics of TixZrTa(x=2.0,3.0,4.0) and Ti2ZryTa (y= 0.5, 0.75, 1.0) alloys were measured by a ballistic experimental system including a ballistic gun with a diameter of 12.7 mm, a speed measuring device (speedometer), a closed experimental container with a pressure measuring device,as shown in Fig.1.The experimental container was 27 L in volume.The A3 steel plate with 2 mm thickness was used as the impact panel of container.The alloy projectile was installed in the nylon projectile holder.The launching speed of projectile in this experiment was controlled as about 1300 m/s.

3.Result

3.1.The microstructure of the TixZrTa and Ti2ZryTa alloys

Fig.2(a)shows the XRD patterns of TixZrTa(x=0.2,0.5,1.0,2.0,3.0,4.0)alloys.And the single XRD patterns of TixZrTa(x=0.2,0.5,1.0)alloys is shown in Fig.S1,which the weak diffraction peaks are more obvious.It can be seen that with the increase of Ti content,the lattice structure of TixZrTa alloys change from BCC + HCP dualphase structure to single BCC structure.The SEM-BSE images of the TixZrTa are shown in Figs.2(b)-2(g).When Ti content is low,TixZrTa alloys show complete and continuous dendritic morphology,such as Ti0·2ZrTa as shown in Fig.2(b).Inter-dendrites(the dark region) are rich in Ta, while dendrite arms (the light region)are rich in Zr,as shown in Fig.2(h).As Ti content increases,the continuous dendrite morphologies are destroyed, as shown in Figs.2(c) and 2(d).The Ta-rich phase in Ti0·5ZrTa gradually spheroidize.The center of spheroidized phase is radial, and the edge is surrounded by dark Zr-rich phase.In Ti1·0ZrTa alloy, the dendrite morphology disappears completely.And instead, Ta-rich precipitates form at the grain boundary.Also, the Ti0·5ZrTa and Ti1·0ZrTa alloys matrix display the typical basket morphology caused by spinodal decomposition,as shown in the red box in the upper right corner of Figs.2(c) and 2(d).As Ti content further increases,the morphology and element distribution of TixZrTa alloys gradually become uniform (Figs.2(e)-2(g) and 2(i)).

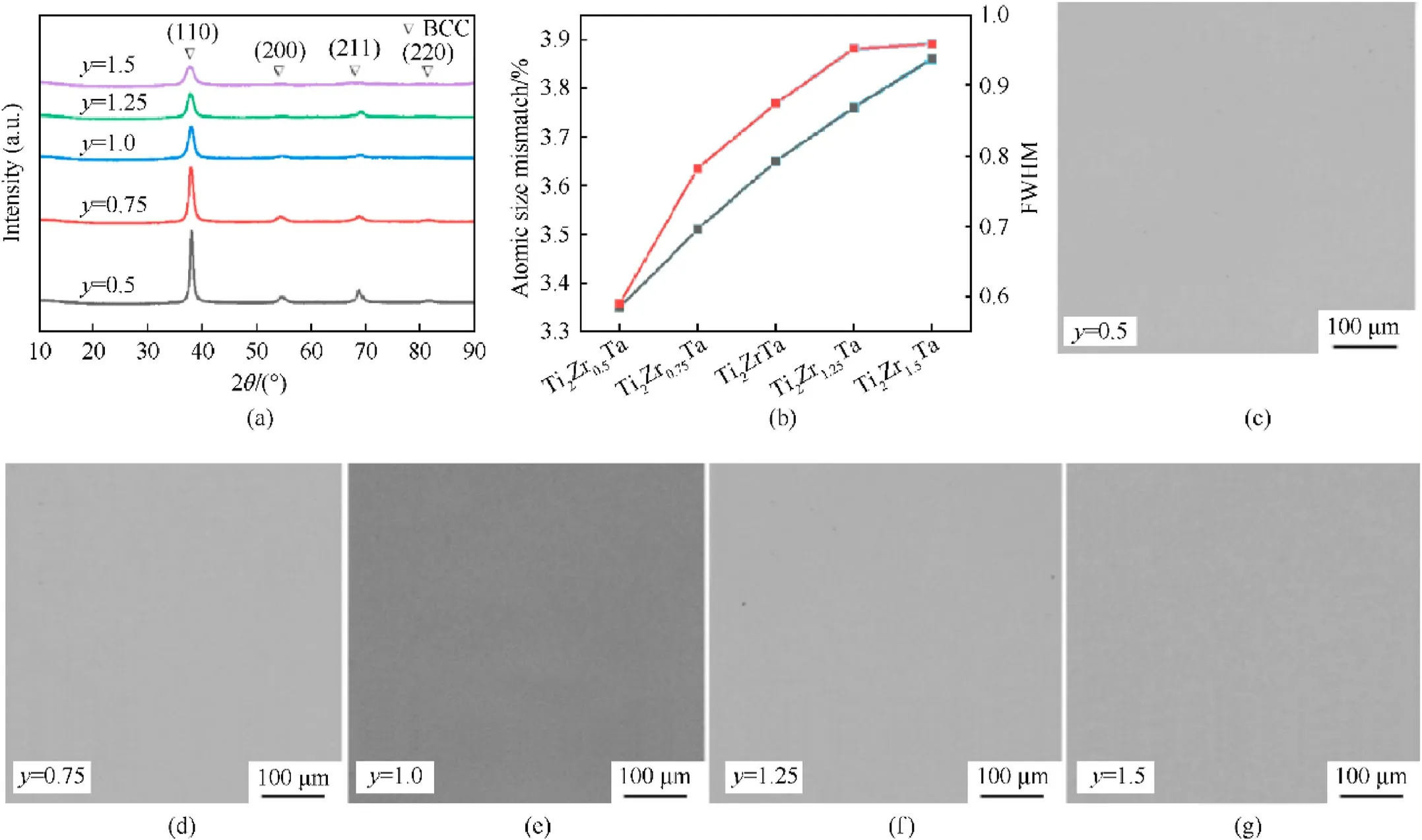

Unlike the influence of Ti element, which greatly affects the structure and morphology of Ti-Zr-Ta alloy, the change of Zr content doesn’t play a significant impact on the microstructure of Ti-Zr-Ta alloy.As shown in Figs.3(a)and 3(c)-3(g)including XRD patterns and SEM-BSE images, all Ti2ZryTa (y = 0.5, 0.75,1.0,1.25,1.5) alloys maintain a single BCC structure and homogeneous element distribution.However,the atomic size mismatch and peak width at half-height(FWHM)of the Ti2ZryTa(y=0.5,0.75,1.0,1.25,1.5)increase with the increase of Zr content,as shown in Fig.3(b).

3.2.The mechanical properties of TixZrTa and Ti2ZryTa alloys

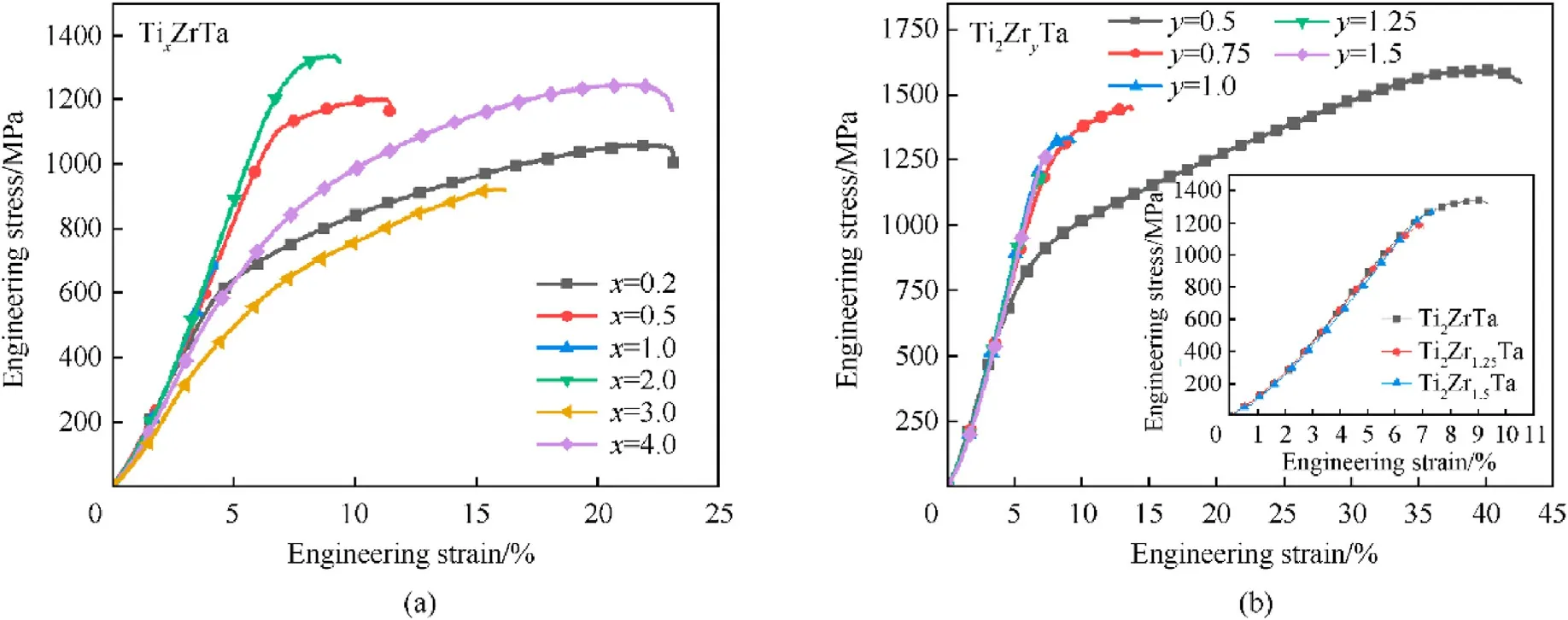

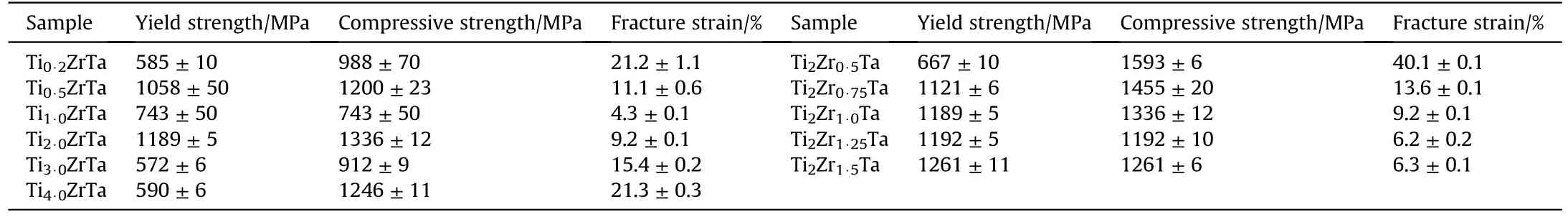

Figs.4(a)and 4(b)show the compressive stress-strain of TixZrTa(x=0.2,0.5,1.0,2.0,3.0,4.0)and Ti2ZryTa(y=0.5,0.75,1.0,1.25,1.5)alloys, respectively.The yield strength, compressive strength and fracture strain of TixZrTa and Ti2ZryTa alloys are listed in Table 1.As shown in Fig.4(a), ternary equimolar TiZrTa alloy has the lowest compressive strength and fracture strain in TixZrTa(x=0.2,0.5,1.0,2.0, 3.0, 4.0) system, namely 743 ± 50 MPa and 4.3 ± 0.1% respectively.Take TiZrTa as the starting point,increasing and decreasing Ti content both enhance the fracture strain of TixZrTa alloys, while make the yield strength and compressive strength increase rapidly and then decrease.The fracture morphology of TixZrTa(x=0.2,1.0,2.0) alloys with different microstructure are shown in Figs.S2-S4.It can be seen that the fracture morphology of the Ti0·2ZrTa alloy,which have BCC + HCP dual-phase structure, is a typical ductile fracture morphology.The Ti1·0ZrTa alloy with grain boundary precipitation is a typical brittle intergranular fracture.And the fracture mode of Ti2·0ZrTa with single BCC structure is mainly brittle cleavage fracture.

Fig.1.(a) Bullet sample and (b) schematic diagram of setups for the ballistic experiment [18].

Fig.2.(a)The XRD patterns of the TixZrTa(x=0.2,0.5,1.0,2.0,3.0,4.0)alloys;SEM-BSE images of(b)Ti0·2ZrTa;(c)Ti0·5ZrTa;(d)Ti1·0ZrTa;(e)Ti2·0ZrTa;(f)Ti3·0ZrTa;(g)Ti4·0ZrTa alloys.(The red box shows the BSE of the alloy at high magnification.).The EDS of the (h) Ti0·2ZrTa and (i) Ti2·0ZrTa.

Fig.3.(a) The XRD patterns while (b) atomic size mismatch and peak width at half-height (FWHM) of the Ti2ZryTa (y = 0.5, 0.75, 1.0, 1.25, 1.5); The BSE of (c) Ti2Zr0·5Ta; (d)Ti2Zr0·75Ta; (e) Ti2Zr1·0Ta; (f) Ti2Zr1·25Ta; (g) Ti2Zr1·5Ta.

Fig.4.Compressive mechanical properties of (a) TixZrTa (x = 0.2, 0.5, 1.0, 2.0, 3.0, 4.0) and (b) Ti2ZryTa (y = 0.5, 0.75, 1.0, 1.25, 1.5) alloys (the illustration in Fig.4(b) is the compressive mechanical properties of Ti2ZryTa (y = 1.0,1.25,1.5) alloy).

Table 1The yield strength(MPa),compressive strength (MPa)and fracture strain (%) of the TixZrTa (x = 0.2, 0.5,1.0, 2.0, 3.0, 4.0) and Ti2ZryTa (y = 0.5, 0.75,1.0,1.25,1.5) alloys.

By contrast, as Zr content increases, the yield strength of Ti2ZryTa alloys increase monotonously,while the compressive strength and fracture strain gradually decrease, as shown in Fig.4(b).The fracture morphology of Ti2ZryTa (y= 0.5, 1.25) alloys with the obvious difference in mechanical properties are shown in Figs.S5 and S6.The fracture of Ti2Zr0·5Ta, which have a good plasticity,have a lot of slip bands and dimples.Meanwhile, the fracture morphology of Ti2Zr1·25Ta alloy, which have poor strength and plasticity, have a few dimples but mainly shows brittle cleavage fracture.

3.3.Impact energy-release characteristics of TixZrTa and Ti2ZryTa alloys

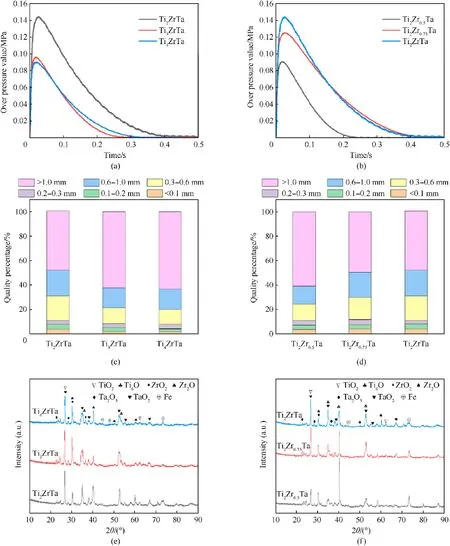

In order to explore the influence of Ti and Zr content and mechanical properties on the energy release characteristics of the alloy, the TixZrTa (x= 2.0, 3.0, 4.0) and Ti2ZryTa (y= 0.5, 0.75,1.0)alloys with large differences in mechanical properties have studied for impact response test.Figs.5(a) and 5(b) show the quasi-static over-pressure curve generated by TixZrTa (x= 2.0, 3.0, 4.0) and Ti2ZryTa (y= 0.5, 0.75,1.0) alloys projectile penetrated into a 27 L closed chamber at ~1300 m/s.It has been shown that the peak of quasi-static pressure of the alloy was related to the energy release.Ames [22] proposed that the relationship between the peak of quasi-static over-pressure in the container and the increased total energy was shown in Eq.(1).

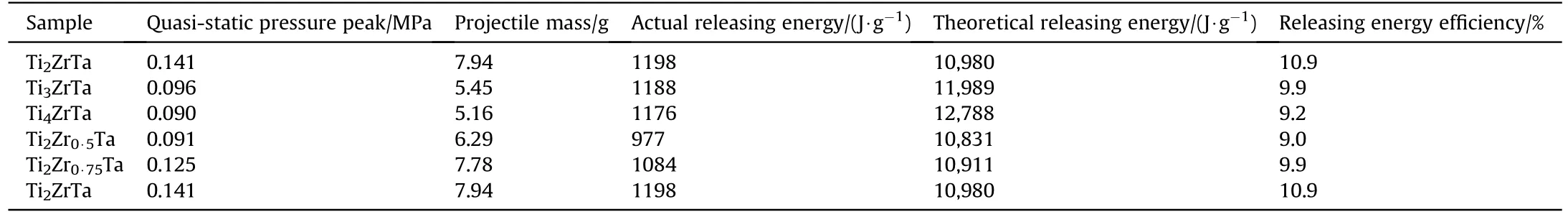

where,ΔQ is the amount of energy released,ΔP is quasi-static overpressure peak, V is the volume of the closed container(V = 0.027 m3), γ is the specific calorific value of the air in the container (in this study γ = 1.4).The actual releasing energy calculated by Eq.(1)and quasi-static over-pressure peak shown in Figs.5(a) and 5(b) are listed in Table 2.As can be seen, the actual releasing energies of TixZrTa alloys all are closed to 1200 J/g while those of Ti2ZryTa increases from 977 to 1190 J/g as Zr content increases.

Figs.5(c) and 5(d) are particle size distribution diagram of the recovered alloys after penetrating the target plate at a speed of 1300 m/s.The proportion of small-sized fragments (<1 mm) of TixZrTa(x=1.0,2.0,3.0)alloys decreases with increasing Ti content,while that of TiZryTa (y= 0.5, 0.75, 1.0) alloys increases with increasing Zr content.

Figs.5(e) and 5(f) show the XRD patterns of the recovered TixZrTa and Ti2ZryTa samples with the size of less than 200 μm,respectively.It can be seen that the recovered fragments are mainly composited of oxides, including TiO2, ZrO2, Ta2O5and et al.It indicates that oxidation reaction occurs during the Ti-Zr-Ta alloys impacting and crushing process.It should be noted that the diffraction peaks corresponding to Fe,which is not the constituent element of Ti-Zr-Ta alloys,are come from the broken steel plate of container.Thus,it can be believed that the impact energy-release of Ti-Zr-Ta alloys mainly came from the oxidation reaction of alloy elements, agreeing the previous reports of high-entropy alloys[18,19,23].Therefore, theoretical releasing energy of TixZrTa(x = 2.0, 3.0, 4.0) and Ti2ZryTa (y = 0.5, 0.75,1.0) alloys could be calculated according to oxidation enthalpy of each component of Ti-Zr-Ta alloys and mixing law.The theoretical releasing energy as well as the releasing energy efficiency(divide theoretical result into actual result one) were listed in Table 2.As can be seen, the releasing energy efficiency of TixZrTa (x = 2.0, 3.0, 4.0) alloys decrease from 10.9% to 9.2% as Ti content increases, while that of Ti2ZryTa(y=0.5,0.75,1.0)alloys increases from 9.0%to 10.9%as Zr content increases.

4.Discussions

4.1.Effects of Ti and Zr content on the microstructure of Ti-Zr-Ta alloys

Our previous work has revealed that the addition of Ti element can enlarge the single-phase solid solution region of Ta-Zr binary phase diagram [21,24].In addition, Ti can also lower the transformation temperature from β-Zr (BCC) to α-Zr (HCP), making the β-Zr be more stable[21,24].Therefore,TixZrTa alloys changes from BCC+HCP dual-phase structure to BCC single-phase structure with the increasing Ti content, as shown in Fig.2.

Moreover, positive mixing enthalpy of Ta and Zr (Ta-Zr: 3 kJ/mol)[25]which would lead to the separation of Ta and Zr,results in the dendrite structure in the dual-phase Ti0·2ZrTa alloy,as shown in Fig.2(g).Because the mixing enthalpy of Ti is similar to that of Zr and Ta (Ti-Zr: 0, Ti-Ta: 1 kJ/mol) [25], Ti elements can be uniformly distributed in Zr-rich and Ta-rich regions.Thus,the increase of Ti content will increase the similarity of the properties of the two regions,and finally achieve uniform mixing,as shown in Figs.2(e)-2(g) and 2(i).

Evolution of dendrite morphology of Ti-Zr-Ta alloys can be more clearly reflected by phase diagram.Since Ti and Zr are in the same element group and have the similar physical and chemical properties, they can be regarded as one element in pseudo binary phase diagram [21,24].In this Ti/Zr-Ta pseudo binary phase diagram, Ti2ZrTa and Ti2Zr0·5Ta are expressed as (Ti/Zr)3Ta and (Ti/Zr)2·5Ta,respectively,which are located in the red and bule lines of Fig.6.As can be seen, when Ti/Zr content in Ti-Zr-Ta alloys is lower than(Ti/Zr)3Ta and(Ti/Zr)2·5Ta,left side of red and bule lines,there is an obvious solid-liquid two-phase region, which should lead to the dendrite morphology of as-cast Ti0·2ZrTa,Ti0·5ZrTa and TiZrTa alloys.The dendrite morphology of as-cast Ti-Zr-Ta alloys is difficult to be eliminated by annealing at 1200°C for 12 h, because of the relative low annealing temperature, which is lower than typical homogenization temperature(0.9 of melting temperature),and the low diffusion rate caused by the high atomic mass.By contrast, when Ti/Zr content in Ti-Zr-Ta alloys is higher than (Ti/Zr)3Ta and(Ti/Zr)2·5Ta,these compositions have the similar melting and solidification temperature,showing as the coincident liquidus and solidus.Thus, there is no element segregation and dendrite structure in TixZrTa(x=2.0,3.0,4.0)and Ti2ZryTa(y=0.5,0.75,1.0,1.25,1.5) alloys.

4.2.Effects of Ti and Zr content on the mechanical properties of Ti-Zr-Ta alloys

Fig.5.(a)and(b)Quasi-static over-pressure curves;(c)and(d)the particle size distribution diagram of the recovered sample;(e)and(f)XRD patterns with particle size less than 200 μm after TixZrTa (x = 2.0, 3.0, 4.0) and Ti2ZryTa (y = 0.5, 0.75,1.0) alloys projectile hit the target container at a speed of ~1300 m/s.

According to the basic principle of materials science that structure determines properties, the effect of Ti and Zr content on the mechanical properties of Ti-Zr-Ta alloys is achieved through the evolution of microstructure.When the Ti content is low, the Ti0·2ZrTa, Ti0·5ZrTa, and Ti1·0ZrTa alloys have the BCC + HCP dualphase structure as well as the dendrite segregation, spinodal decomposition or grain boundary precipitation.The BCC + HCP dual-phase structures and basket morphology caused by spinodal decomposition in Ti0·2ZrTa and Ti0·5ZrTa alloys can provide relative high strength as well as a certain of synergistic effect for the plastic deformation of grains [27,28].Among these microstructures, the core-shell structure composited of spheroidized Ta-rich phase and Zr-rich matrix can provided the higher resistance for dislocation movement, then Ti0·5ZrTa possesses the higher strength than Ti0.2ZrTa.With the increase of Ti content, the Ti1·0ZrTa alloy gradually appear Ta-rich precipitates at the grain boundary.The precipitates at the grain boundary hinder the movement of dislocations between grains,and then lead to the low compressive strength and fracture strain[29].Thus,the strength of TixZrTa alloy decreases when x increases from 0.5 to 1.0.

As Ti content further increases, the precipitates at the grain boundary disappear and the alloy becomes a single BCC structure(Figs.2(e)-2(g)).Annihilation of the obstacles for dislocation movement greatly increase the strength and fracture strain of Ti2·0ZrTa alloys(Fig.4(a) and Table 2).

Whenxvalue in TixZrTa alloy increases to 3.0 and 4.0, the highcontent BCC destabilizer including Ti and Zr,decreases the stable of single BCC structure, then may lead to the stress-induced transformation and transformation induced plasticity, showing as the high strain hardening,high strength and good plasticity[30-32],as shown in Fig.4(a) and Table 2.

Table 2The quasi-static pressure peak,mass,actual releasing energy,theoretical releasing energy and Releasing energy efficiency of the TixZrTa(x=2.0,3.0,4.0)and Ti2ZryTa(y=0.5,0.75,1.0) alloys projectile hit the target container at a speed of ~1300 m/s.

Fig.6.Binary phase diagram of Ta-Zr [21,26].

Interestingly, although the lattice structure and morphology of Ti2ZryTa(y=0.5,0.75,1.0,1.25,1.5)alloys seem to be independent on the Zr content,as shown in Fig.3,the mechanical performance of Ti2ZryTa is closely related to the Zr content,as shown in Fig.4(b).In Ti2ZryTa system,the largest atomic radius of Zr(Ti:0.147 nm,Zr:0.16 nm, Ta: 0.149 nm) should increase the atomic size mismatch and then the lattice distortion of single-phased BCC alloys [33], as shown in Fig.3(b).On the one hand,the enhanced lattice distortion wound increase the dislocation movement resistance[34]and then increase the yield strength of Ti2ZryTa alloys.On the other hand,the lattice distortion wound increase micro-internal stress in grains[35] and reduce the plasticity, i.e.fracture strain of Ti2ZryTa alloys.Therefore, as Zr content increases, the yield strength of Ti2ZryTa alloys increase monotonously, while the fracture strain gradually decreases, as shown in Fig.4(b) and Table 2.

4.3.Effects of Ti and Zr content on the impact energy-release characteristic of Ti-Zr-Ta alloys

The actual releasing energies of metallic ESMs are decided by the potential releasing-energy value and the releasing energy efficiency.The former one is mainly dependent on the constituent elements of metal.Among Ti-Zr-Ta system, the ideal oxidation enthalpy of constituent elements are Ti:19,732 J/g,Zr:12,042 J/g,Ta 5816 J/g[11,12].Thus,the theoretical releasing energy of Ti-Zr-Ta alloys increases as Ti/Zr content,in other words,increases as the Ta content decreases, as shown in Table 2.

The releasing energy efficiency is co-controlled by the oxidation rate of constituent elements and exposed oxidation area during impact process.On the one hand,the oxidation rate of constituent element is reflected by oxidation activity, i.e.the electronegativity of element.Among Ti-Zr-Ta system, Zr has the lowest electronegativity, and then has the highest oxidation activity.Thus,releasing energy efficiency of both TixZrTa and TiZryTa alloys increases as Zr content increases.On the other hand, the exposed oxidation area of sample is directly related to the size of fragments,which is dependent on the mechanical properties.The smaller fragment size, the larger exposed oxidation area.And the fragmentation degree of samples is mainly decided by their plasticity,i.e.fracture strain during mechanical property test.As shown in Table 1, the fracture strain of TixZrTa alloys increases as Ti content increases whenx>1.0,while that of TiZryTa alloys decreases as Zr content increases.The difference between fracture strain results in that the proportion of small-sized fragments (<1 mm) of TixZrTa(x=2.0,3.0,4.0)alloys decreases as Ti content increases while that of TiZryTa(y=0.5,0.75,1.0)alloys increases as Zr content increases,as shown in Figs.5(c) and 5(d).Meanwhile, Ti is easy to form a dense oxide film in the oxidation process,and then preventing the further oxidation reaction[36].Thus,the higher oxidation rate and the lager exposed oxidation area jointly leads the higher releasing energy efficiency of TixZrTa alloys with low Ti content and Ti2ZryTa alloys with high Zr content, as shown in Table 2.

Therefore, it can be known that the increasing potential releasing-energy and the decreasing releasing energy efficiency make the actual releasing energy of TixZrTa alloys be independent on Ti content.By contrast,enhanced potential releasing-energy and releasing energy efficiency make the actual releasing energy of TiZryTa alloys increase with increasing Zr content, as shown in Table 2.

5.Conclusions

In order to explore the potential of multi-element alloy as ESMs,this work studied the relationships between microstructure, mechanical properties and energy-release characteristics of TixZrTa(x=0.2,0.5,1.0,2.0,3.0,4.0)and Ti2ZryTa(y=0.5,0.75,1.0,1.25,1.5)alloys,some conclusions were obtained as follows.

(1) With the increase of Ti content, TixZrTa alloys change from BCC + HCP dual-phase structure to BCC single-phase structure, due to the enlargement of the single-phase solid solution region of Ta-Zr binary phase diagram and the increase of stability of β-Zr.Meanwhile,the increasing similarity of Zrrich and Ta-rich regions and the coincident liquidus and solidus make the segregation in TixZrTa alloys gradually weakened and microstructure of Ti2ZryTa alloys keep uniform.

(2) Ti1·0ZrTa alloy has the lowest compressive strength and fracture strain due to the precipitates at the grain boundary.As the annihilation of the obstacles for dislocation movement, the fracture strain of TixZrTa (x= 2.0, 3.0, 4.0)gradually increase with the Ti content increases while the synergistic effect of dual phase structure also increases the fracture strain of TixZrTa (x= 0.2, 0.5).As Zr content increases,the lattice distortion of Ti2ZryTa alloys increase,and then leading to the increasing yield strength and decreasing fracture strain.

(3) With the increase of Zr content, the oxidation reaction rate and fragmentation degree of the alloys gradually increases.The higher oxidation rate and the lager exposed oxidation area jointly leads the higher releasing energy efficiency of TixZrTa alloys with low Ti content and Ti2ZryTa alloys with high Zr content.The increasing potential releasing-energy and the decreasing releasing energy efficiency make the actual releasing energy of TixZrTa alloys be independent on Ti content.Meanwhile, enhanced potential releasing-energy and releasing energy efficiency make the actual releasing energy of TiZryTa alloys increase with increasing Zr content.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos.52171166, 11972372 and U20A20231).The SEM analyses of this work was supported by Sinoma Institute of Materials Research(Guang Zhou) Co., Ltd.

Appendix A.Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.dt.2023.01.007.

- Defence Technology的其它文章

- The interaction between a shaped charge jet and a single moving plate

- Machine learning for predicting the outcome of terminal ballistics events

- Fabrication and characterization of multi-scale coated boron powders with improved combustion performance: A brief review

- Experimental research on the launching system of auxiliary charge with filter cartridge structure

- Dependence of impact regime boundaries on the initial temperatures of projectiles and targets

- Experimental and numerical study of hypervelocity impact damage on composite overwrapped pressure vessels