Predict the evolution of mechanical property of Al-Li alloys in a marine environment

Wei Li , Lin Xiang , Guang Wu , Hongli Si , Jinyan Chen , Yiming Jin , Yan Su ,Jianquan Tao ,**, Chunyang Huang a,,*

a State Key Laboratory of Explosion Science and Technology, Beijing Institute of Technology, Beijing,100036, China

b Chongqing Innovation Center, Beijing Institute of Technology, Chongqing, 400044, China

c First Research Institute of the Ministry of Public Security for PR China, Beijing,100036, China

d Southwest Technology and Engineering Research Institute, Chongqing, 400039, China

Keywords: Marine environment Al-Li alloy Machine learning Corrosion

ABSTRACT The ocean is one of the essential fields of national defense in the future,and more and more attention is paid to the lightweight research of Marine equipment and materials.This study it is to develop a Machine learning (ML)-based prediction method to study the evolution of the mechanical properties of Al-Li alloys in the marine environment.We obtained the mechanical properties of Al-Li alloy samples under uniaxial tensile deformation at different exposure times through Marine exposure experiments.We obtained the strain evolution by digital image correlation (DIC).The strain field images are voxelized using 2D-Convolutional Neural Networks(CNN)autoencoders as input data for Long Short-Term Memory(LSTM) neural networks.Then, the output data of LSTM neural networks combined with corrosion features were input into the Back Propagation (BP) neural network to predict the mechanical properties of Al-Li alloys.The main conclusions are as follows: 1.The variation law of mechanical properties of 2297-T8 in the Marine atmosphere is revealed.With the increase in outdoor exposure test time, the tensile elastic model of 2297-T8 changes slowly, within 10%, and the tensile yield stress changes significantly, with a maximum attenuation of 23.6%.2.The prediction model can predict the strain evolution and mechanical response simultaneously with an error of less than 5%.3.This study shows that a CNN/LSTM system based on machine learning can be built to capture the corrosion characteristics of Marine exposure experiments.The results show that the relationship between corrosion characteristics and mechanical response can be predicted without considering the microstructure evolution of metal materials.

1.Introduction

The ocean is one of the essential fields of national defense in the future, and more and more attention is paid to the lightweight research of Marine equipment and materials [1-3].Al-Li alloy has received attention for its high strength,low density,and corrosion resistance.As alloy materials serve in the Marine environment for a long time, the mechanical properties of Al-Li alloy metal are degraded by temperature, humidity, PH value, etc., thus reducing service time,resulting in the loss of ships and other equipment[4].Therefore,it is vital to predict Al-Li alloy's mechanical properties in the Marine Environment.

Many researchers have done a lot of research on the performance of Al-Li alloy in a Marine exposure environment [5-9].Several studies have reported the relationship between corrosion behavior and mechanical properties of Al-Li alloys by accelerated tests [10-13].The researchers found that the degradation of mechanical properties of Al-Li alloy is mainly due to the size and location of the corrosion pit, which causes the hollow inside the metal material[8,11].Zhao studied the corrosion behavior of 7A85 aluminum alloy exposed to industrial Marine atmospheric environment for five years and provided corrosion data of 7000-series aluminum alloy in Marine atmospheric environment through corrosion rate and evolution of microstructure structure(corrosion residues) [14].Zhang verified the correlation between mechanical properties and corrosion behavior by observing the microstructure evolution of 2297 Al-Li alloy [15].

The above investigations found that the degradation of mechanical properties of Al-Li alloys in the marine environment is very complex [16-18].Therefore, it is crucial to understand the relationship between the marine environment and corrosion characteristics and the resulting changes in microtexture and mechanical properties [19-22].ML is a very effective method for studying the coupling effects of such multiple factors[23,24].More and more researchers are using this method to analyze the accelerated material design and predict material properties.Therefore,machine learning is essential to establish the relationship between the marine environment and corrosion characteristics to predict the mechanical properties of Al-Li alloys in the marine environment.

ML has been widely used in many aspects, such as image recognition, prediction of mechanical properties, autonomous driving,etc.Tang maps one-dimensional data to three-dimensional data for constitutive modeling of materials[25-29].Yang uses DIC techniques to model inelastic composites from stress-strain data generated under different loading paths[30].Muhammad obtained the microtexture of the Alsi10Mg aluminum alloy produced by laser melting by Computed Tomography,got the local strain distribution during the uniaxial tensile deformation by DIC, and successfully predicted the local strain, plasticity, anisotropy, and the evolution of failure during the tensile deformation by using the artificial neural network method[31].Christopher uses the voxelized mesh data generated by 3D-CNN-autoencoders as the long short-term memory neural network input to predict the mesh's deformation and the force-displacement curve generated during the structural deformation.Therefore, it is feasible to use ML to predict the mechanical properties of Al-Li alloys in the marine environment.Furthermore,there is currently no work on ML methods to predict the mechanical behavior of alloy materials in marine environments[32].

Therefore,the main goal of this work is to develop an ML-based prediction method to study the evolution of the mechanical properties of Al-Li alloys in the marine environment.We obtained the mechanical properties of Al-Li alloy samples under uniaxial tensile deformation at different exposure times through Marine exposure experiments and obtained the strain evolution by DIC.The strain field images are voxelized using 2D-CNN autoencoders as input data for LSTM neural networks.Then, the output data of LSTM neural networks combined with corrosion features were input into BP neural network to predict the mechanical properties of Al-Li alloys.

2.Experimental characterization

2.1.Specimen and materials

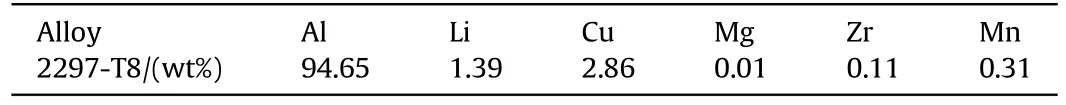

2297-T8 Al-Li alloys are prepared from metals of Al(94.65%),Li(1.39%), Cu (2.86%),and other metals.The heat treatment technology is as follows: the solution temperature is 515°C for 80 min,then 3% cold deformation is applied, and then the aging temperature is 160°C for 12 h.The chemical composition of sample 2297-T8 is shown in Table 1.Heat treatment technology is provided by Zhengzhou Light Alloy Research Institute Co., LTD.

Table 1Chemical composition of 2297-T8 (wt%).

2.2.Field exposures in a marine environment

The field exposures sample is a standard tensile sample with dimensions, as shown in Fig.1.The experiment was located at the Southwest Institute of Technology and Engineering, its Marine environment field test site.The samples are arranged at 45°angle and fixed to the ends of a test shelf to prevent the movement of specimens in extreme weather, as shown in Fig.2.

In this study, 40 samples were put into the field exposure test,and five samples were taken every three months.The samples were then subjected to tensile testing to assess their mechanical response during the field exposure.The tensile tests were carried out at room temperature using an MTS E45.105 servo-hydraulic tensile machine with a 100 kN load cell capacity.The tensile test was carried out at a rate of 2 mm/min,and each test was carried out five times to confirm that the experimental data was accurate and repeatable.DIC systems are also utilized to capture the strain progression in tensile testing.The XTDIC-3D program was used to examine the DIC data.The DIC image has a 0.01 mm/pixel resolution and was utilized as a CNN training picture.

Before tensile tests,the taken back samples from field exposure places need to be cleaned; 3% nitric acid solution is used for ultrasonic cleaning in an ultrasonic cleaning machine with a frequency of 50 Hz.The primary purpose of cleaning the corrosion products is to avoid future corrosion product film and residual salt out on the field exposure test process.Then samples were weighed,calculating the loss of mass.

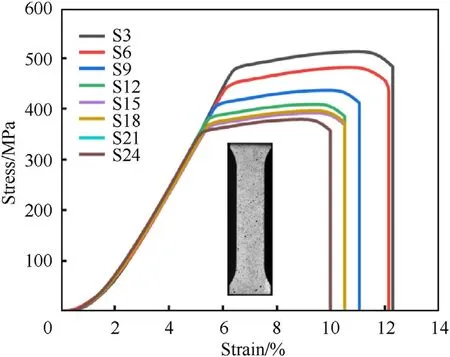

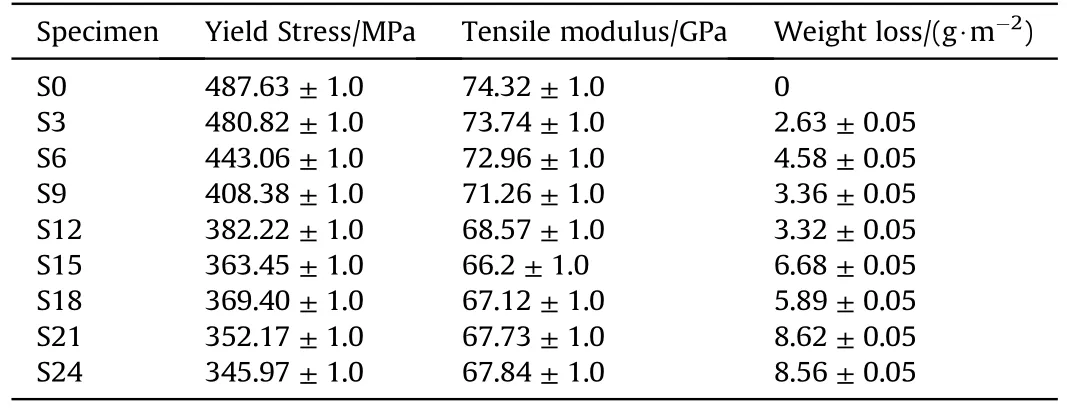

The engineering stress-strain curves of 2297-T8 at various intervals during a filed exposure test exposed to uniaxial tension are shown in Fig.3.Table 2 summarizes the average tensile yield stress,tensile modules of elasticity, weight loss, and accompanying standard deviations for each sample.The samples were named according to the following rules: Initial condition was designated as S0,3 months of exposure was designated as S3,then came S9,S12,S15,S18,S21 and S24.The tensile yield stress and tensile modules of elasticity of 2297-T8 drop steadily when the field exposure test period increases, as shown in Fig.3.The main reason is that with prolonged exposure to the outdoors, the oxidation film on the surface of Al-Li alloy is gradually decomposed,leading to the direct contact between the matrix metal and the corrosion solution,resulting in a sizeable decreasing trend of tensile strength.At the same time, Young's modulus is gradually reduced.In addition, the corrosion rate of S3,S6,and S9 is higher,but then with the increase of time,the corrosion rate decreases and reaches a stable value,like S12 and S15.When it comes to a particular stage,the corrosion rate will increase again, such as S18, S21, and S24.There is a layer of corrosive material deposition on the surface of samples, which further prevents corrosion, but once the corrosion through declinerosion material depositions,the corrosion rate of 2297-T8 will be accelerated.This is because, in this study, the time of the first sample was July.July is one of the warmest months of the year.Table 3 shows the annual, monthly mean daily maximum temperature and daily minimum temperature of the field exposure test location.

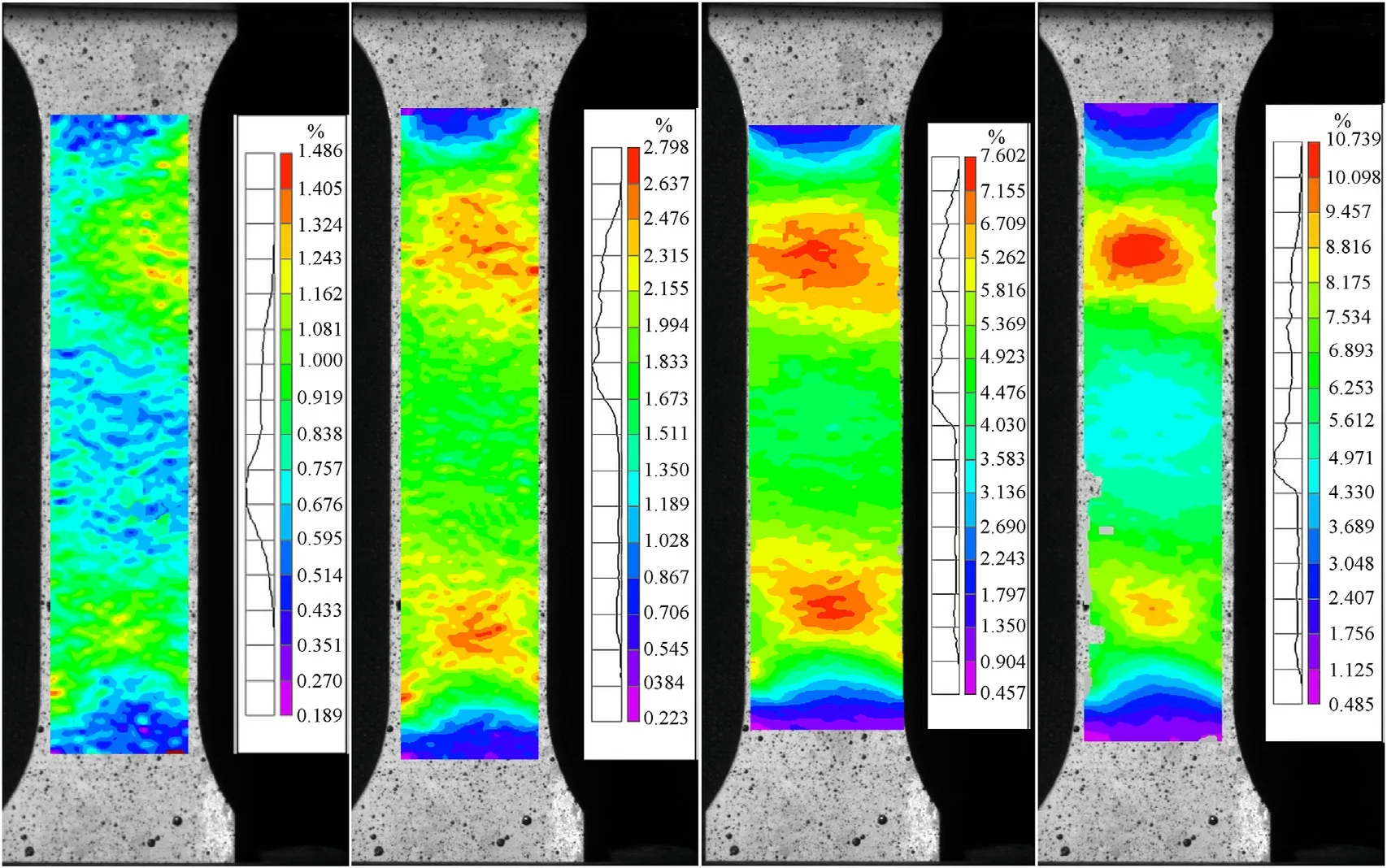

The DIC maps for strain (εyy) development at the different tensile stresses of the S6 specimen are shown in Fig.4.It should be noticed that the stress concentration still occurs at the pit with a 3%axial stain(see Fig.4).At the same time,it can be observed that the plastic deformation of the sample is not uniform, which is also caused by the existence of a corrosion pit.With the further deformation, the change near the corrosion pit is drastic.Finally, the specimen is damaged near the corrosion pit,which is different from the S0 specimen, resulting in a decrease in tensile yield stress and tensile modules of elasticity.

Fig.1.Standard tensile specimen geometry.The unit is mm.

Fig.2.The sample was used for the field exposure test.

Fig.3.Engineering stress-strain curves of 2297-T8 with different times under filed exposure test subjected to uniaxial tension.

Table 2Average tensile yield stress,tensile modules of elasticity,weight loss,corrosion rate for 2297-T8 with different times under filed exposure test.

Table 3Annual,monthly mean daily maximum temperature,daily minimum temperature of field exposure test location.

In brief, the 2297-T8 tensile specimens show different tensile yield stress and tensile modulus of elasticity at other times under the field exposure test.In addition,compared with the sample with a constant environment, the variation of strain stress is closely related to the natural environment, resulting in an uneven local change in the model.This heterogeneous deformation behavior is related to specimens' stress-strain and corrosion rate.Therefore,the relationship between corrosion rate, temperature, and strain evolution is significant to understanding the performance of 2297-T8 Al-Li alloy in the Marine Environment.We can combine image recognition technology with strain data from DIC to study its deformation behavior.Therefore, CNN neural network and RNN recurrent neural network based on machine learning can be further developed and verified to predict the mechanical behavior of 2297-T8.

Fig.4.DIC maps of strain evolution at different tensile strains of S6 specimen.

3.Proposed machine framework

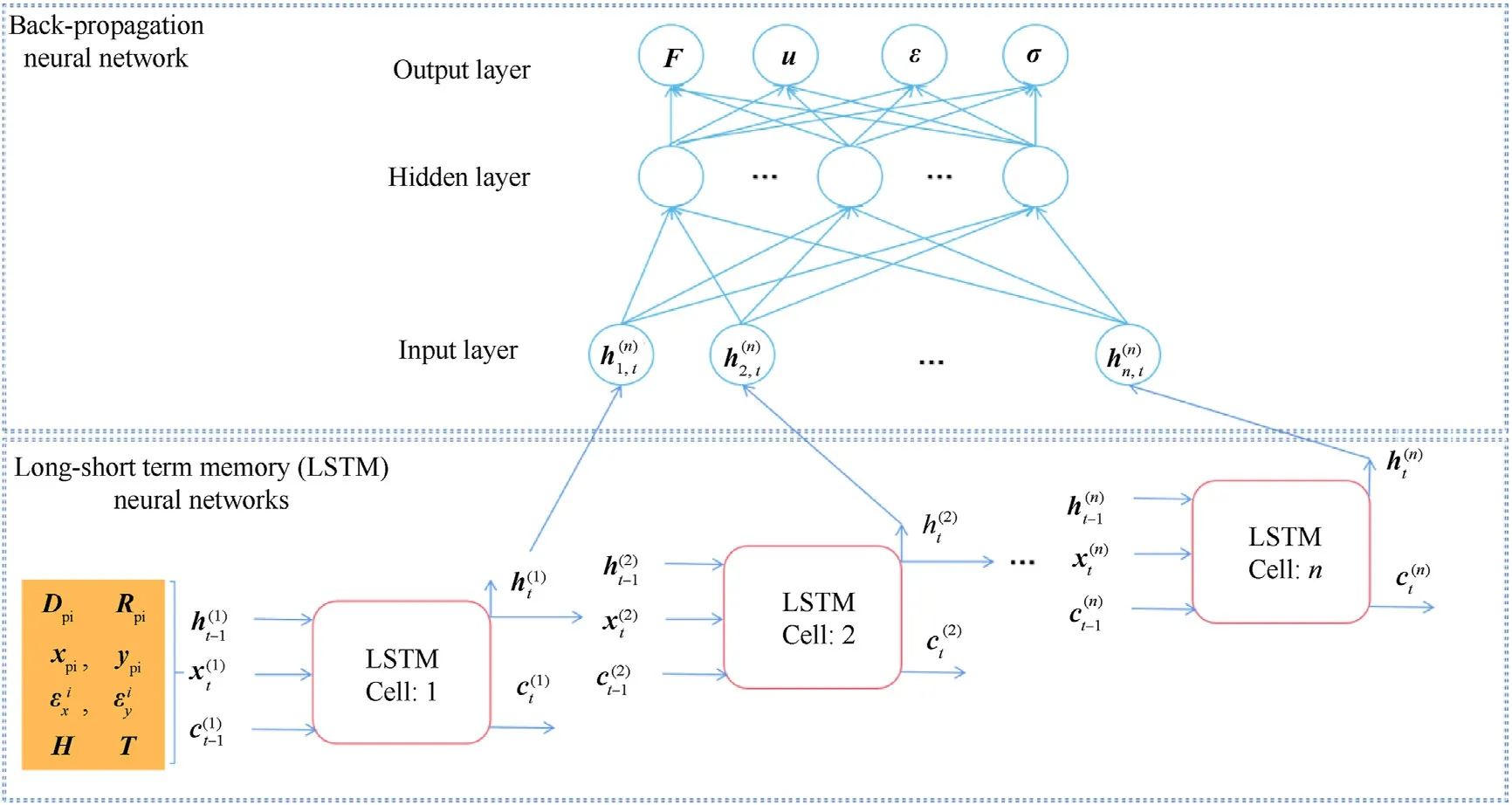

This work aims to develop a machine learning framework based on the CNN neural network and LSTM neural network to predict the tensile yield stress and tensile elastic modulus of 2297-T8 Al-Li alloy during uniaxial tensile loading under different exposure test times.The framework combines methods and programs in field exposure testing and machine learning to predict residual mechanical properties of other metal materials in field exposure tests.The system employs DIC to collect local strain evolution,voxels the samples through CNN neural networks, and then feeds this flattened potential space into the LSTM-NN to predict tensile yield stress and tensile elastic modulus under uniaxial tensile loading.

3.1.2D-CNN autoencoders

2D-CNN autoencoders are shown schematically in Fig.5.2DCNN voxels the pictureN(0)x×N(0)yand serves as the feature recognition input vector [32,33].Voxelization of local strain cloud pictures generated by DIC and images of initial state samples were performed in this work.The primary goal is to create a specific relation between corrosion properties and, tensile yield stress,tensile modules of elasticity.

3.2.LSTM neural networks

Fig.5.A 2D-CNN-autoencoder architectural diagram.

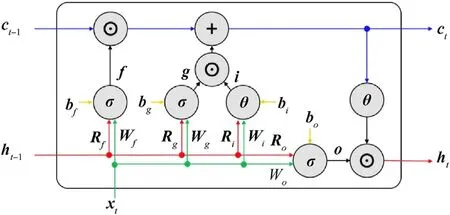

Fig.6.Schematic of an LSTM cell© [34].

An LSTM cell is depicted schematically in Fig.6.An LSTM neural network is a type of recurrent neural network that, by adding memory units, can minimize computation error.To control the error propagation.ct-1is the memory cell’s state, and ht-1is an intermediate hidden state at t-1.f is a forget gate,i is an input gate,g is a candidate gate, and o is an output gate that controls the evolution of error response.

where σ and θ denote the sigmoidal and hyperbolic tangent activation functions.R,W and b are the weights and biases associated to each gate.

where ⊙is the Hadamard product operator.Then The LSTM-NN of the desired output time series response can be obtained by using the time integral correlation feedforward neural network for decoding.

3.3.Development of machine learning framework

3.3.1.Datasetgeneration

The quantity and precision of the input data set have a significant influence on the machine learning algorithm's feasibility and prediction model accuracy.In the present work, the data set consists of two parts: (1) Corrosion characteristics of 2297-T8 Al-Li alloy are obtained through the cleaned sample picture, including the location and size of the corrosion pit;(2)Local strain evolution data is obtained by DIC during the tensile deformation.As detailed below, both datasets are overlaid and concatenated to create a single streamlined dataset.

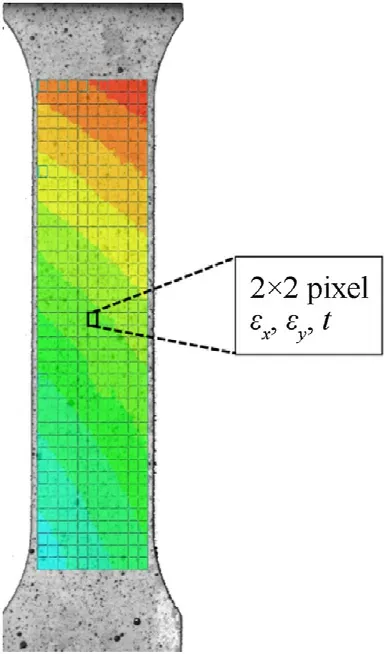

To acquire strain evolution maps during tensile deformation,the DIC pictures are analyzed using the commercial program XTDIC-3D.The image processing step size is 2×2 pixels.Then the data points could be obtained by software, including deformation timet, position coordinatesx,y, and strain values εx,εy(see Fig.7).

Fig.7.Extraction of deformation evolution from processed DIC images.

As mentioned above, the samples in the Marine environment were cleaned to obtain the distribution of corrosion characteristics on the sample surface, such as the location and size of corrosion pits.At this point,the size of the image of corrosion characteristics should be roughly the same as that of the DIC strain image so that the correspondence of the two data can be achieved when CNN neural network is used for voxelization.This is the raw data utilized in the machine learning process outlined in Subsection 3.3.3 to train the model.

3.3.2.Featureselection

The material considered in the current work is 2297-T8 Al-Li alloy which has been in the Marine environment for a long time and has a complex deterioration mechanism.However,corrosion is one of the critical factors affecting 2297-T8 al-Li alloy.At the same time,the material environment also has a particular influence,such as temperature, humidity, salinity, and so on.However, for simplicity, only the size, location, corrosion rate, and temperature of the corrosion pit were considered in this study on the mechanical properties of 2297-T8 materials.Table 4 shows the selected features.

3.3.3.DefineMLsystem

The primary goal of this section is to establish an ML framework for mapping the input data set to the output response.The suggested ML framework for estimating the tensile yield stress and tensile elastic modulus of 2297-T8 at different intervals in the Marine Environment is shown schematically in Fig.8.

Voxelization of DIC image.The grid images obtained by DIC were converted from a cartesian coordinate system to two-dimensional space by the voxelization method,.Before voxelization,each voxel point needs to be normalized.So the indices are determined by

Table 4Names and descriptions of selected characteristics.

Fig.8.Schematics of the proposed ML framework for predicting the local strain and force-displacement response of 2297-T8 at different periods in the Marine Environment.

whereI,Jare the index of voxel space.(xmax,xmin),(ymax,ymin),represents the limits ofx-axis,limits ofy-axis and the location DIC mesh nodes,n, in the Cartesian space.

Time-Dependent Input Data Structuring for LSTM-NN To eliminate any bias caused by the differing scales of the parameters, all input parameters are normalized between -1 and 1.At a given point in time,tis computed for each feature selection as an input parameter

where(xpi,t,ypi,t) is the pit location at timet.

whereRpi,tis the pit radius at timet.RmaxandRminrepresents the maximum and min value of the pit radius current sample.

whereDpi,tis the pit depth at timet.DmaxandDminrepresents the maximum and min value of the pit depth current sample.

whereFtis force during tensile deformation at timet.FmaxandFminrepresents the max and min value of the force current sample.

Finally, by building flattened latent space stored timedependent input data, and then input data were transferred to the LSTM-NN model.The intermediate hidden state from the LSTM cell is decoded using a BPNN to predict the tensile yield stress and tensile elastic modulus of 2297-T8 at different periods in the Marine Environment during uniaxial tensile loading.

4.Results and discussion

4.1.Corrosion feature and DIC

As discussed above, high-resolution cameras and DIC data are used to analyze the relationship between corrosion feature and strain during tensile deformation of 2297-T8 Al-Li alloy.Fig.9 shows the initial samples of 2297-T8 Al-Li alloy at different periods in the Marine Environment,the extracted images of corrosion characteristics, and the strain images obtained by DIC.Fig.9(b)shows the location of the corrosion pit,represented by black origin.So,the corrosion feature and the local strain established a mapping relationship.Table 5 shows the evolutions of corrosion features,such as average pit radius and pit depth.DIC pictures show that the strain is higher in areas with corrosion characteristics, like red in Fig.9(c).This indicates the effect and significance of corrosion characteristics on the local strain evolutions and mechanical property deterioration of sample 2297-T8.

Fig.9.The initial samples of 2297-T8 Al-Li alloy at different periods in the Marine Environment, and the extracted images of corrosion characteristics, and the strain images obtained by DIC: (a) Tensile sample; (b) Corrosion feature; (c) Strain images obtained by DIC.

Table 5Average pit radius,pit depth.

4.2.LSTM-NN in predicting the evolution of mechanical property of 2297-T8 Al-Li alloys

Fig.10 presents the loss with respect to the different hidden states and cells for predicting the evolution of mechanical property of 2297-T8 Al-Li alloys.The above-described training procedure was likewise carried out twelve times with Epoch = 500.Once more, a new seed was used for a random sampling of the training data for each trial.In each trial,similar convergence histories were found.Finally,we settled on 3 cells and 256 hidden states in terms of convergence and calculation speed.

From the above test results, the relationship between the mechanical properties of 2297-T8 and exposure time in the Marine environment is very complicated.In this section, the LSTM-NN model was successfully used to predict the mechanical property of the Marine Environment.The response of 2297-T8 under different exposure times in strain evolution and forcedisplacement curves were obtained.

Fig.11-Fig.13 show the Comparison of the LSTM-NN model predicted results with the experimental results of S6 at 2%,6%,and 9% uniaxial tension.It can be seen that the LSTM-NN model can reasonably predict the strain evolution of 2297-T8 during the uniaxial tensile experiment.Fig.11 shows that the more significant strain mainly exists in the vicinity of the corrosion pit,as shown in red, and the prediction model also captures this change.This phenomenon is also seen in 6% and 9% strains.However, it should be noted that strain in some places was not captured because critical features were not extracted due to differences in pigments when CNN was used for feature extraction, such as marked by the red circle in Figs.11-13.

In this paper, different input characteristics were studied to predict the mechanical response of 2297-T8 Al-Li alloy under different exposure times.Fig.14(a) shows the ML prediction and experimental curve of stress-strain of S6.It can be seen from the figure that there is a specific error between the predicted result and the accurate test result, which is because the internal microscopic structure pores of 2297-T8 due to machining are not taken into account when the prediction model is used for calculation.The margin of error is around 5%.Overall, the ML model has good predictive ability in predicting mechanical response.

Fig.10.(a) Hidden states and (b) cells' convergence verification.

Fig.11.Comparison of LSTM-NN model predicted results with the experimental results of S6 at 2% uniaxial tension.

Fig.12.Comparison of LSTM-NN model predicted results with the experimental results of S6 at 6% uniaxial tension.

5.Conclusions

In the present study, a machine learning-based model was proposed to predict the mechanical response of 2297-T8 Al-Li alloy with different exposure times during uniaxial tensile tests.This model is combined with CNN neural network, LSTM neural network,and feedforward neural network to study the influence of corrosion characteristics (pit radius, pit depth, exposure time,temperature, etc.) on mechanical properties of 2297-T8 al-Li alloy.The main conclusions are as follows: 1.The variation law of mechanical properties of 2297-T8 in the Marine atmosphere is revealed.With the increase in outdoor exposure test time, the tensile elastic model of 2297-T8 changes slowly, within 10%, and the tensile yield stress changes significantly, with a maximum attenuation of 23.6%.2.The prediction model can predict the strain evolution and mechanical response simultaneously with an error of less than 5%.3.This study shows that a CNN/LSTM system based on machine learning can be built to capture the corrosion characteristics of Marine exposure experiments.The results indicate that the relationship between corrosion characteristics and mechanical response can be predicted without considering the microstructure evolution of metal materials.

Fig.13.Comparison of LSTM-NN model predicted results with the experimental results of S6 at 9% uniaxial tension.

Fig.14.(a) ML prediction and experiment curve of stress-strain; (b) Train and test data MSE.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported by the Southwest Institute of Technology and Engineering cooperation fund (Grant No.HDHDW5902020104).

- Defence Technology的其它文章

- The interaction between a shaped charge jet and a single moving plate

- Machine learning for predicting the outcome of terminal ballistics events

- Fabrication and characterization of multi-scale coated boron powders with improved combustion performance: A brief review

- Experimental research on the launching system of auxiliary charge with filter cartridge structure

- Dependence of impact regime boundaries on the initial temperatures of projectiles and targets

- Experimental and numerical study of hypervelocity impact damage on composite overwrapped pressure vessels